Abstract

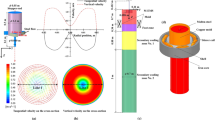

The flow, solidification, and solute transport in continuous-casting bloom molds, under different submerged entry nozzle (SEN) conditions, were numerically investigated. Water experiments and measurements of solute distribution were conducted in order to verify the models of flow and solute transport, respectively. The results showed that the diagonally-installed four-port SEN can reduce the im**ement effect of jet flow to the wall, control the level of fluctuation at a low level, and enhance the removal rate of non-metallic inclusions; the temperature variations and differences between surfaces and corners can also be decreased. Meanwhile, the local solidified shell-thinning phenomenon can be eliminated; the shell thicknesses of the wide and narrow sides at mold outlet are 17.00 mm and 16.39 mm, respectively. The largest negative degrees in the solidified shell at the narrow and wide sides are 0.92 and 0.95, respectively. While the negative degree at the bloom corner is 0.84, the center carbon concentration at the computational outlet increases to 0.7438%.

Similar content being viewed by others

References

R. Chaudhary, G.G. Lee, B.G. Thomas, and S.H. Kim, Metall. Mater. Trans. B 39, 870 (2008).

Q. Yuan, B.G. Thomas, and S.P. Vanka, Metall. Mater. Trans. B 35, 703 (2004).

G.H. Saul, R.D. Morales, and A.G. Hugo, ISIJ Int. 53, 809 (2013).

D.J.B. José, R.D. Morales, S. Garcia-Hernandez, A. Najera-Bastida, and I. Calderon-Ramos, Steel Res. Int. 86, 517 (2015).

I. Calderón-Ramos and R.D. Morales, Mater. Trans. B 46, 1314 (2015).

J. Shen, D. Chen, X. **e, L. Zhang, Z. Dong, and X. Xuan, Ironmak. Steelmak. 40, 263 (2013).

S. Garcia-Hernandez, R.D. Morales, J.D.J. Barreto, and K. Morales-Higa, ISIJ Int. 53, 1794 (2013).

I. Calderón-Ramos, R.D. Morales, and M. Salazar-Campoy, Steel Res. Int. 86, 1610 (2016).

S. Wang, G.A. De Toledo, K. Välimaa, and S. Louhenkilpi, ISIJ Int. 54, 2273 (2014).

D. Wu, S. Cheng, and J. Zhao, J. Iron. Steel Res. Int. 15, 315 (2008).

M. He, N. Wang, M. Chen, and M. Xuan, Steel Res. Int. 88, 1600447 (2017).

S. Yokoya, S. Takagi, M. Iguchi, Y. Asako, R. Westoff, and H. Sigeta, ISIJ Int. 38, 827 (1998).

H. Sun and L. Li, Ironmak. Steelmak. 43, 228 (2016).

H. Sun and J. Zhang, ISIJ Int. 51, 1657 (2011).

Q. Fang, H. Ni, H. Zhang, B. Wang, and Z. Lv, Metals 7, 146 (2017).

H. Sun and J. Zhang, Mater. Trans. B 45, 936 (2014).

C.M. Hrenya, E.J. Bolio, D. Chakrabarti, and J.L. Sinclair, Chem. Eng. Sci. 50, 1923 (1995).

H. Sun and J. Zhang, Mater. Trans. B 45, 1133 (2014).

FLUENT 6.2-Theory Guide (Fluent Inc., Lebanon, 2005).

Acknowledgements

The authors would like to express their gratitude for the financial support provided by the National Natural Science Foundation of China (51471122), (51604200) and (51774217), and the key program of the Natural Science Foundation of Hubei Province of China (2015CFA128).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Fang, Q., Ni, H., Zhang, H. et al. Influence of SEN on Flow, Solidification, and Solute Transport in Bloom Casting Mold. JOM 70, 719–725 (2018). https://doi.org/10.1007/s11837-018-2770-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-018-2770-y