Abstract

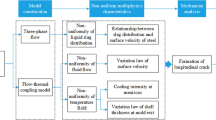

A coupled three-dimensional numerical model combining fluid flow, heat transfer, and solidification has been established to study the effect of two types of nozzle on the internal quality of LZ50 steel in a φ 690 mm sized continuously cast round bloom. The model is validated by measured data of the strand surface temperature for plant tests. According to the simulation and experimental results, it is found that the larger tangential velocity on meniscus and the higher vortex depth in the six-port nozzle is beneficial to melting mold powder and the floating removal of inclusions. When the injection mode is the six-port nozzle, the level fluctuation was an effective control to avoid slag entrapment, and the washing effect with multiple swirling flow reinforces both the heat exchange through the solidification front and the dendrite re-melting or fragmenting, stimulating the formation of an equiaxed crystal at the round bloom center. As the injection mode changes from the five-port nozzle to the six-port nozzle, the superheat degree in the round bloom center at the mold exit decreases by 9.3 K, which is one of the resulting increase in the center equiaxed crystal ratio is about 4.3% and the length of columnar decreases by 20 mm. A weaker im**ement of the outlet flow on the shell has been observed as well, which can be expected to eliminate the popular subsurface white band phenomenon with an even shell thickness in the mold region. This suggests that the six-port nozzle can effectively improve the quality of large round bloom casting.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Cai KK (2008) Continuous casting mold. Metallurgical Industry Press, Bei**g

Sun HB, Li L (2016) Application of swirling flow nozzle and investigation of superheat dissipation casting for bloom continuous casing. Ironmaking Steelmaking 43(3):228–233

Yamane H, Ohtani Y, Fukuda J, Kawase T, Nakashima J, Kiyose A (1997) Steelmaking Conf Proc 80:159–164

Fang Q, Ni HW et al (2017) The effects of a submerged entry nozzle on flow and initial solidification in a continuous casting bloom mold with electromagnetic stirring. Metals Open Access Metall J 7(4):146

Wang P, Li SX, Zhang JQ et al (2019) Swirling flow effect of radial outlet nozzle for bloom and its effect on initial solidification. China Metall 29(09):15–22

Sun HB, Han ZG, Qian HZ et al (2010) Effects of injection modes on the flow pattern and temperature distribution of molten steel in a bloom casting mould. Chin J Eng 32(9):1131–1137

Sun HB, Zhang JQ (2014) Macrosegregation improvement by swirling flow nozzle for bloom continuous castings. Metall Mater Trans B 45(3):936–946

Wang C, Zhang H, Ma Z W et al (2014) Simulation study on optimization of nozzle structure for round mould. J Iron Steel Res 026(003):15–20,26

Cheng XW, Fu QH, Dai FQ et al (2015) Application of swirling flow nozzle technology for bloom continuous castings. Steelmaking 031(005):32–37

Wang P, Zhang JQ et al (2019) Initial transfer behavior and solidification structure evolution in a large continuously cast bloom with a combination of nozzle injection mode and M-EMS. Metals 9(10):1083–1097

Wang P, Zhang JQ et al (2019) Effect of different types of nozzles on swirling flow development and shell growth behavior in a bloom casting mold. In: AISTech2019

Li SX, Zhang XM, Li L et al (2019) Representation and effect of mushy zone coefficient on the coupled flow and solidification simulation during continuous casting. Chin J Eng 41(2):199–208

Aboutalebi MR, Guthrie RIL, Seyedein SH (2007) Mathematical modeling of coupled turbulent flow and solidification in a single belt caster with electromagnetic brake. Appl Math Model 31(8):1671–1689

Lai KYM, Salcudean M, Tanaka S et al (1986) Mathematical modeling of flows in large tundish systems in steelmaking. Metall Trans B 17(3):449–459

Li SX, Lan P, Tang H et al (2018) Study on the electromagnetic field fluid flow and solidification in a bloom continuous casting mold by numerical simulation. Steel Res Int 89(12):1800071

Yuan Q, Vanka SP, Thomas BG et al (2004) Computational and experimental study of turbulent flow in a 0.4-scale water model of a continuous steel caster. Metall Mater Trans 35(5):967–982

Thomas BG (2006) Modeling of continuous casting defects related to mold fluid flow. Iron Steel Technol 3(7):127

Thomas BG, Zhang L (2007) Mathematical modeling of fluid flow in continuous casting. Trans Iron Steel Inst Japan 41(10):1181–1193

Xu ZG, Wang XH, Jiang M et al (2016) Investigation on formation of equiaxed zone in low carbon steel slabs. Metall Res Technol 113(1):106–116

Zhang LF et al (2010) Transient fluid flow phenomena in continuous casting tundishes. Iron Steel Technol 7(7):55

Li YQ, Liu JH, He Y et al (2019) Surface defects analysis and mechanism research of 15CrMoG steel bars and process improvement. Special Steel 40(6):1–6

Sun H, Li L, Wu X et al (2018) Effect of subsurface negative segregation induced by M-EMS on componential homogeneity for bloom continuous casting. Metall Res Technol 115(6):603

Beckermann C, Diepers HJ (1999) Modeling melt convection in phase field simulations of solidification. Comput Phys 154:468–496

Acknowledgements

The authors wish to acknowledge the financial support of the National Natural Science Foundation of China (No. U1860111, and 51874033).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Wang, P. et al. (2021). Effect of Nozzle Injection Mode on Initial Transfer Behavior of Round Bloom. In: TMS 2021 150th Annual Meeting & Exhibition Supplemental Proceedings. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-030-65261-6_53

Download citation

DOI: https://doi.org/10.1007/978-3-030-65261-6_53

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-65260-9

Online ISBN: 978-3-030-65261-6

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)