Abstract

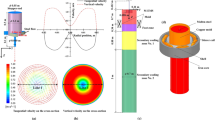

Flow field, heat transfer and inclusion behavior in a 700 mm round bloom mold under the effect of a swirling flow submerged entry nozzle (SEN) were investigated with the aim to enhance the casting process. The results indicate that the im**ing flow phenomenon, which is commonly observed in conventional single-port SEN casting, was completely suppressed by the swirling flow SEN coming from a novel swirling flow generator design in tundish. Steel from the SEN port moved towards the mold wall in 360° direction, leading to a uniform temperature distribution in the mold. Compared to a conventional single-port SEN casting, the steel super-heat was decreased by about 5 K at the mold center, and the temperature was increased by around 3.5 K near the meniscus. In addition, the removal ratio of inclusions to the mold top surface in the swirling flow SEN casting was found to be increased. Specifically, the removal ratio of spherical inclusions with diameters of 1, 10, 50 and 100 μm was increased by 18.2%, 18.5%, 22.6% and 42.7%, respectively. Furthermore, the ratio was raised by 18.2%, 20.8%, 21.5% and 44.1% for non-spherical inclusions, respectively.

Similar content being viewed by others

References

L.Q. Cai, X.D. Wang, M. Yao, J. Iron Steel Res. Int. 29 (2022) 80–87.

A.Y. Deng, E.G. Wang, J.C. He, J. Iron Steel Res. Int. 13 (2006) 13–16.

B. Yang, A.Y. Deng, Y. Li, X.J. Xu, E.G. Wang, J. Iron Steel Res. Int. 26 (2019) 219–229.

D.B. Jiang, L.F. Zhang, Y.D. Wang, J. Iron Steel Res. Int. 29 (2022) 124–131.

Y.D. Wang, L.F. Zhang, W. Yang, Y. Ren, J. Iron Steel Res. Int. 29 (2022) 237–246.

Z.G. Yang, B. Wang, X.F. Zhang, Y.T. Wang, H.B. Dong, Q. Liu, J. Iron Steel Res. Int. 21 (2014) 1095–1103.

B.X. Wang, W. Chen, Y. Chen, Y.P. Feng, Ironmak. Steelmak. 42 (2015) 63–69.

H.Q. Yu, M.Y. Zhu, Acta Metall. Sin. (Engl. Lett.) 22 (2009) 461–467.

M.Y. Zhang, Y.P. Bao, C. Gu, C. Yao, Ironmak. Steelmak. (2022) https://doi.org/10.1080/03019233.2022.2119062.

T. Sun, F. Yue, H.J. Wu, C. Guo, Y. Li, Z.C. Ma, J. Iron Steel Res. Int. 23 (2016) 329–337.

H.Q. Yu, M.Y. Zhu, Ironmak. Steelmak. 39 (2012) 574–584.

X.L. Li, B.K. Li, Z.Q. Liu, R. Niu, X.C. Huang, Steel Res. Int. 90 (2019) 1800133.

S. Yokoya, Y. Asako, S. Hara, J. Szekely, ISIJ Int. 34 (1994) 883–888.

H.B. Sun, J.Q. Zhang, Metall. Mater. Trans. B 45 (2014) 936–946.

H.B. Sun, L.J. Li, Ironmak. Steelmak. 43 (2016) 228–233.

H.B. Sun, L.J. Li, C.B. Liu, Metals 8 (2018) 842.

C.L. Wu, X.M. Liu, Q. Wang, M. He, X.W. Zhu, D.W. Li, L.J. Zhao, H. Lei, Metall. Mater. Trans. B 52 (2021) 3571–3575.

D.W. Li, Z.J. Su, K. Marukawa, J.C. He, J. Iron Steel Res. Int. 21 (2014) 159–165.

Q.H. **e, M. Nabeel, M. Ersson, P.Y. Ni, Steel Res. Int. 93 (2022) 2100410.

P.Y. Ni, L.T.I. Jonsson, M. Ersson, P.G. Jönsson, Steel Res. Int. 88 (2017) 1600155.

P.Y. Ni, L.T.I. Jonsson, M. Ersson, P.G. Jönsson, ISIJ Int. 57 (2017) 2175–2184.

P.Y. Ni, D.X. Wang, L.T.I. Jonsson, M. Ersson, T.A. Zhang, P.G. Jönsson, Metall. Mater. Trans. B 48 (2017) 2695–2706.

P.Y. Ni, M. Ersson, L.T.I. Jonsson, P.G. Jönsson, Metall. Mater. Trans. B 49 (2018) 723–736.

Q.H. **e, P.Y. Ni, M. Ersson, P.G. Jönsson, Y. Li, Metall. Mater. Trans. B 53 (2022) 3197–3214.

Q. Fang, H.W. Ni, H. Zhang, B. Wang, Z. Lv, Metals 7 (2017) 146.

B.R. Baliga, S.V. Patankar, Numerical Heat Transfer 3 (1980) 393–409.

Ansys Inc, ANSYS Fluent 17.0 Theory Guide, Ansys Inc., Canonsburg, USA, 2016.

Ansys Inc, ANSYS Fluent 17.0 User’s Guide, Ansys Inc., Canonsburg, USA, 2016.

T.H. Shih, W.W. Liou, A. Shabbir, Z. Yang, J. Zhu, Comput. Fluids 24 (1995) 227–238.

M.M. Gibson, B.E. Launder, J. Fluid Mech. 86 (1978) 491–511.

F.S. Lien, M.A. Leschziner, Int. J. Numer. Meth. Fluids 19 (1994) 527–548.

P.G. Saffman, J. Fluid Mech. 22 (1965) 385–400.

S.A. Morsi, A.J. Alexander, J. Fluid Mech. 55 (1972) 193–208.

A. Haider, O. Levenspiel, Powder Technol. 58 (1989) 63–70.

A.D. Gosman, E. Ioannides, J. Energy 7 (1983) 482–490.

X. Huang, B.G. Thomas, Can. Metall. Quart. 37 (1998) 197–212.

Y. Yang, P.G. Jönsson, M. Ersson, Z. Su, J. He, K. Nakajima, Steel Res. Int. 86 (2015) 1312–1327.

S. Yokoya, S. Takagi, M. Iguchi, K. Marukawa, W. Yasugaira, S. Hara, ISIJ Int. 40 (2000) 584–588.

M.H. Sha, T.M. Wang, J. Li, T.J. Li, J.Z. **, Int. J. Cast Met. Res. 24 (2011) 197–202.

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant No. 51704062) and the Fundamental Research Funds for the Central Universities (Grant No. N2025019).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

**e, Qh., Ni, Py., Tanaka, T. et al. Flow field, heat transfer and inclusion behavior in a round bloom mold under effect of a swirling flow submerged entry nozzle. J. Iron Steel Res. Int. 30, 1211–1221 (2023). https://doi.org/10.1007/s42243-023-00975-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-023-00975-9