Abstract

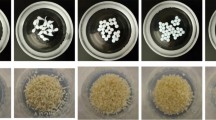

Removal of heavy metal pollution has received considerable research attention due to its severe effects on human health. In the present study, for the first time, a reusable monolithic 3D porous adsorbing filter was fabricated by integrating 3D printing technique with a natural adsorbent (chitosan), which is a low-cost and highly effective solution for heavy metal removal. The –NH2 and –OH functional groups found on the highly porous monoliths were capable of adsorbing metal ions. Further analyses revealed that the adsorption capacity increases with the filter’s surface area, with T = 25 °C and pH 5.5 representing the optimal working conditions. The maximum adsorption capacity of 13.7 mg/g (calculated by using the total mass) was measured for the filter with skewed hexagonal holes. The pseudo-first-order equation and Langmuir isotherm model presented a good fit to the experimental data, thus accurately describing the adsorption kinetics and the adsorption equilibrium. The monolithic chitosan-loaded filter exhibited a superior adsorption kinetics of 2.2 mg/(g min) for Cu(II) removal. Findings yielded by the desorption experiment also demonstrated that EDTA can desorb the metal ions from the monoliths, and its ~ 92% desorption capacity indicates high reusability. All results reported in this work indicate that 3D printing offers an alternative, cost-effective and facile approach for fabricating structured adsorbents with tunable structural and chemical properties for use in metal ion removal.

Similar content being viewed by others

References

Hu Y et al (2013) Assessing heavy metal pollution in the surface soils of a region that had undergone three decades of intense industrialization and urbanization. Environ Sci Pollut Res 20(9):6150–6159

Li Z et al (2014) A review of soil heavy metal pollution from mines in China: pollution and health risk assessment. Sci Total Environ 468–469:843–853

Salomons W, Förstner U, Mader P (2012) Heavy metals: problems and solutions. Springer, Berlin

Franzetti A et al (2014) Biosurfactant use in heavy metal removal from industrial effluents and contaminated sites. In: Kosaric N, Sukan FV (eds) Biosurfactants: production and utilization—processes, technologies, and economics, vol 159. CRC Press, Boca Raton, pp 361–369

Oncel M et al (2013) A comparative study of chemical precipitation and electrocoagulation for treatment of coal acid drainage wastewater. J Environ Chem Eng 1(4):989–995

Ahmed MJK, Ahmaruzzaman M (2016) A review on potential usage of industrial waste materials for binding heavy metal ions from aqueous solutions. J Water Process Eng 10:39–47

Fu F, Wang Q (2011) Removal of heavy metal ions from wastewaters: a review. J Environ Manage 92(3):407–418

Parga JR et al (2013) Removal of aqueous lead and copper ions by using natural hydroxyapatite powder and sulphide precipitation in cyanidation process. Sci Res 4(4):231–237

Reichert J, Binner JGP (1996) An evaluation of hydroxyapatite-based filters for removal of heavy metal ions from aqueous solutions. J Mater Sci 31(5):1231–1241. https://doi.org/10.1007/BF00353102

Agboola O, Mokrani T, Sadiku R (2016) Porous and fractal analysis on the permeability of nanofiltration membranes for the removal of metal ions. J Mater Sci 51(5):2499–2511. https://doi.org/10.1007/s10853-015-9562-3

Karnib M et al (2014) Heavy metals removal using activated carbon, silica and silica activated carbon composite. Energy Procedia 50:113–120

Sankararamakrishnan N, Jaiswal M, Verma N (2014) Composite nanofloral clusters of carbon nanotubes and activated alumina: an efficient sorbent for heavy metal removal. Chem Eng J 235:1–9

Hua M et al (2012) Heavy metal removal from water/wastewater by nanosized metal oxides: a review. J Hazard Mater 211:317–331

Mubarak N et al (2014) Removal of heavy metals from wastewater using carbon nanotubes. Sep Purif Rev 43(4):311–338

Kırbıyık Ç, Pütün AE, Pütün E (2016) Comparative studies on adsorptive removal of heavy metal ions by biosorbent, bio-char and activated carbon obtained from low cost agro residue. Water Sci Technol 73(2):423–436

Ribeiro C et al (2018) A comprehensive evaluation of heavy metals removal from battery industry wastewaters by applying bio-residue, mineral and commercial adsorbent materials. J Mater Sci 53(11):7976–7995. https://doi.org/10.1007/s10853-018-2150-6

Barakat MA (2011) New trends in removing heavy metals from industrial wastewater. Arab J Chem 4(4):361–377

Ayoub A et al (2013) Novel hemicellulose–chitosan biosorbent for water desalination and heavy metal removal. ACS Sustain Chem Eng 1(9):1102–1109

Wang J, Chen C (2014) Chitosan-based biosorbents: modification and application for biosorption of heavy metals and radionuclides. Biores Technol 160:129–141

Chen T et al (2013) Performance analysis of Al2O3/water nanofluid with cationic chitosan dispersant. Adv Mater Sci Eng 2013:1–8

Kim K-J, Park J-W (2017) Stability and reusability of amine-functionalized magnetic-cored dendrimer for heavy metal adsorption. J Mater Sci 52(2):843–857. https://doi.org/10.1007/s10853-016-0380-z

Yang Q (2018) Removal and reuse of Ag nanoparticles by magnetic polyaniline/Fe3O4 nanofibers. J Mater Sci 53(12):8901–8908. https://doi.org/10.1007/s10853-018-2181-z

Reddy DHK, Lee S-M (2013) Application of magnetic chitosan composites for the removal of toxic metal and dyes from aqueous solutions. Adv Coll Interface Sci 201–202:68–93

Lu F, Astruc D (2018) Nanomaterials for removal of toxic elements from water. Coord Chem Rev 356:147–164

Zhang N et al (2011) Fabrication of highly porous biodegradable monoliths strengthened by graphene oxide and their adsorption of metal ions. Carbon 49(3):827–837

Prevot V, Tokudome Y (2017) 3D hierarchical and porous layered double hydroxide structures: an overview of synthesis methods and applications. J Mater Sci 52(19):11229–11250. https://doi.org/10.1007/s10853-017-1067-9

Kuang S-P et al (2013) Preparation of triethylene-tetramine grafted magnetic chitosan for adsorption of Pb(II) ion from aqueous solutions. J Hazard Mater 260:210–219

Dong C et al (2014) Synthesis of magnetic chitosan nanoparticle and its adsorption property for humic acid from aqueous solution. Colloids Surf, A 446:179–189

Duffy E et al (2015) Hierarchical porous graphitic carbon monoliths with detonation nanodiamonds: synthesis, characterisation and adsorptive properties. J Mater Sci 50(19):6245–6259. https://doi.org/10.1007/s10853-015-9195-6

Li Y et al (2016) Removal of Cr(VI) by 3D TiO2-graphene hydrogel via adsorption enriched with photocatalytic reduction. Appl Catal B 199:412–423

Huš S, Kolar M, Krajnc P (2016) Separation of heavy metals from water by functionalized glycidyl methacrylate poly (high internal phase emulsions). J Chromatogr A 1437:168–175

Zhang D et al (2017) Initiator-integrated 3D printing of magnetic object for remote controlling application. IEEE Trans Magn 99:1

Guo Q et al (2013) “Paintable” 3D printed structures via a post-ATRP process with antimicrobial function for biomedical applications. J Mater Chem B 1(48):6644

Couck S et al (2017) CO2, CH4 and N2 separation with a 3DFD-printed ZSM-5 monolith. Chem Eng J 308:719–726

Thakkar H et al (2016) 3D-printed zeolite monoliths for CO2 removal from enclosed environments. ACS Appl Mater Interfaces 8(41):27753–27761

Thakkar H et al (2017) Formulation of aminosilica adsorbents into 3D-printed monoliths and evaluation of their CO2 capture performance. ACS Appl Mater Interfaces 9(8):7489–7498

Kalsoom U, Nesterenko PN, Paull B (2018) Current and future impact of 3D printing on the separation sciences. Trends Anal Chem 105:492–502

Thakkar H et al (2017) 3D-printed metal-organic framework monoliths for gas adsorption processes. ACS Appl Mater Interfaces 9(41):35908–35916

Couck S et al (2018) 3D-printed SAPO-34 monoliths for gas separation. Microporous Mesoporous Mater 255:185–191

Rezaei F et al (2017) MOF-74 and UTSA-16 film growth on monolithic structures and their CO2 adsorption performance. Chem Eng J 313:1346–1353

Parra-Cabrera C et al (2018) 3D printing in chemical engineering and catalytic technology: structured catalysts, mixers and reactors. Chem Soc Rev 47(1):209–230

Zhou X, Liu C-J (2017) Three-dimensional printing for catalytic applications: current status and perspectives. Adv Func Mater 27(30):1701134

Lee HS et al (2012) Reversible swelling of chitosan and quaternary ammonium modified chitosan brush layers: effect of pH and counter anion size and functionality. J Mater Chem 22(37):19605–19616

Funk C et al (2012) Epoxy-functionalized surfaces for microarray applications: surface chemical analysis and fluorescence labeling of surface species. Surf Interface Anal 44(8):890–894

Griffiths PR, De Haseth JA (2007) Fourier transform infrared spectrometry, vol 171. Wiley, Hoboken

Milosavljević NB et al (2011) Removal of Cu2+ ions using hydrogels of chitosan, itaconic and methacrylic acid: FTIR, SEM/EDX, AFM, kinetic and equilibrium study. Colloids Surf A 388(1):59–69

Zhou Y-T et al (2009) Removal of Cu2+ from aqueous solution by chitosan-coated magnetic nanoparticles modified with α-ketoglutaric acid. J Colloid Interface Sci 330(1):29–37

He J, Lu Y, Luo G (2014) Ca(II) imprinted chitosan microspheres: an effective and green adsorbent for the removal of Cu(II), Cd(II) and Pb(II) from aqueous solutions. Chem Eng J 244:202–208

Shen D et al (2009) Adsorption kinetics and isotherm of anionic dyes onto organo-bentonite from single and multisolute systems. J Hazard Mater 172(1):99–107

Azizian S (2004) Kinetic models of sorption: a theoretical analysis. J Colloid Interface Sci 276(1):47–52

Wu F-C, Tseng R-L, Juang R-S (2001) Kinetic modeling of liquid-phase adsorption of reactive dyes and metal ions on chitosan. Water Res 35(3):613–618

Chen C-Y, Yang C-Y, Chen A-H (2011) Biosorption of Cu(II), Zn(II), Ni(II) and Pb(II) ions by cross-linked metal-imprinted chitosans with epichlorohydrin. J Environ Manage 92(3):796–802

Chen A-H et al (2008) Comparative adsorption of Cu(II), Zn(II), and Pb(II) ions in aqueous solution on the crosslinked chitosan with epichlorohydrin. J Hazard Mater 154(1):184–191

Laus R et al (2010) Adsorption and desorption of Cu(II), Cd(II) and Pb(II) ions using chitosan crosslinked with epichlorohydrin-triphosphate as the adsorbent. J Hazard Mater 183(1):233–241

Chang Y-C, Chen D-H (2005) Preparation and adsorption properties of monodisperse chitosan-bound Fe3O4 magnetic nanoparticles for removal of Cu(II) ions. J Colloid Interface Sci 283(2):446–451

Wan M-W et al (2010) Adsorption of copper (II) and lead (II) ions from aqueous solution on chitosan-coated sand. Carbohydr Polym 80(3):891–899

Yuwei C, Jianlong W (2011) Preparation and characterization of magnetic chitosan nanoparticles and its application for Cu(II) removal. Chem Eng J 168(1):286–292

Yan H et al (2012) Preparation of chitosan/poly(acrylic acid) magnetic composite microspheres and applications in the removal of copper(II) ions from aqueous solutions. J Hazard Mater 229–230:371–380

Salehi E et al (2012) Novel chitosan/poly(vinyl) alcohol thin adsorptive membranes modified with amino functionalized multi-walled carbon nanotubes for Cu(II) removal from water: preparation, characterization, adsorption kinetics and thermodynamics. Sep Purif Technol 89:309–319

Bazargan-Lari R et al (2014) Removal of Cu(II) ions from aqueous solutions by low-cost natural hydroxyapatite/chitosan composite: equilibrium, kinetic and thermodynamic studies. J Taiwan Inst Chem Eng 45(4):1642–1648

Zhang Y et al (2014) Porous graphene oxide/carboxymethyl cellulose monoliths, with high metal ion adsorption. Carbohydr Polym 101:392–400

Zeng QR et al (2005) Recycling EDTA solutions used to remediate metal-polluted soils. Environ Pollut 133(2):225–231

Zhang L, Zeng Y, Cheng Z (2016) Removal of heavy metal ions using chitosan and modified chitosan: a review. J Mol Liq 214:175–191

Acknowledgements

The author is grateful for the financial support from the Natural Sciences and Engineering Research Council of Canada (NSERC) and Xerox UAC award and Research Accelerator Grant Program of the University of Western Ontario.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Zhang, D., **ao, J., Guo, Q. et al. 3D-printed highly porous and reusable chitosan monoliths for Cu(II) removal. J Mater Sci 54, 6728–6741 (2019). https://doi.org/10.1007/s10853-019-03332-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-019-03332-y