Abstract

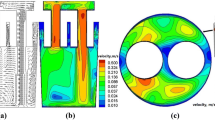

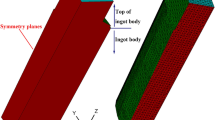

A model of computational fluid dynamics (CFD) coupled with phase-field and flow-solid interaction (FSI) was built to simulate a solid inclusion’s floating in steel and interacting with the steel-slag interface. The numerical model was validated by a water model experiment. The effects of inclusion size, density and contact angle with the interface on the dynamic process and static position were investigated. The simulation results indicate that floating small size inclusions satisfy Stokes flow while a large size inclusion is with turbulent flow. When approaching the interface, the inclusion will decelerate in advance due to steel film drainage and there will be an acceleration of inclusion once the film ruptures. The static position of inclusion settling at the interface is related to the size, density and contact angle of inclusion, and among all these properties, the contact angle of the steel-slag interface with the inclusion is the dominant factor.

Similar content being viewed by others

References

1 B.H. Reis, W.V. Bielefeldt, and A.C.F. Vilela: J. Mater. Res. Technol., 2014, vol. 3, pp. 179–85.

C. Xuan, E.S. Persson, R. Sevastopolev, and M. Nzotta: Metall. Mater. Trans. B, 2019, vol. 50, pp. 1957–73.

K. Nakajima and K. Okamura: in Proceedings of the 4th International Conference on Molten Slags and Fluxes, 1992, pp. 505–10.

4 J. Strandh, K. Nakajima, R. Eriksson, and P. Jönsson: ISIJ Int., 2005, vol. 45, pp. 1597–606.

5 J. Strandh, K. Nakajima, R. Eriksson, and P. Jönsson: ISIJ Int., 2005, vol. 45, pp. 1838–47.

6 M. Valdez, G.S. Shannon, and S. Sridhar: ISIJ Int., 2006, vol. 46, pp. 450–7.

7 G. Shannon, L. White, and S. Sridhar: Mater. Sci. Eng. A, 2008, vol. 495, pp. 310–5.

8 G.N. Shannon and S. Sridhar: Scand. J. Metall., 2005, vol. 34, pp. 353–62.

9 S. Yang, W. Liu, and J. Li: Jom, 2015, vol. 67, pp. 2993–3001.

S. Yang, J. Li, C. Liu, L. Sun, and H. Yang: Metall. Mater. Trans. B, 2014, vol. 45, pp. 2453–63.

C. Liu, S. Yang, J. Li, L. Zhu, and X. Li: Metall. Mater. Trans. B, 2016, vol. 47, pp. 1882–92.

12 W. Liu, S. Yang, J. Li, F. Wang, and H. Yang: J. Iron Steel Res. Int., 2019, vol. 26, pp. 1147–53.

L. Zhang, J. Aoki, and B.G. Thomas: Metall. Mater. Trans. B, 2006, vol. 37, pp. 361–79.

Y. Miki, Y. Shimada, B.G. Thomas, and A. Denissov: Iron Steelmak. (I SM), 1997, 24, vol. 24.

Y. Miki and B.G. Thomas: Metall. Mater. Trans. B, 1999, vol. 30, pp. 639–54.

B.G. Thomas and L. Zhang: ISIJ Int., 2001.

L. Zhang, J. Aoki, and B.G. Thomas: Metall. Mater. Trans. B Process Metall. Mater. Process. Sci., https://doi.org/10.1007/s11663-006-0021-z.

H. Duan, Y. Ren, and L. Zhang: Metall. Mater. Trans. B Process Metall. Mater. Process. Sci., https://doi.org/10.1007/s11663-018-1462-x.

L. Zhang, S. Taniguchi, and K. Cai: Metall. Mater. Trans. B, 2000, vol. 31, pp. 253–66.

20 C. Xuan, E.S. Persson, J. Jensen, R. Sevastopolev, and M. Nzotta: J. Alloys Compd., 2020, vol. 812, p. 152149.

21 J.W. Cahn and J.E. Hilliard: J. Chem. Phys., 1958, vol. 28, pp. 258–67.

22 W. Liu, S. Yang, J. Li, and H. Yang: JOM, 2018, vol. 70, pp. 2877–85.

S. Kimura, Y. Nabeshima, K. Nakajima, and S. Mizoguchi: Metall. Mater. Trans. B, 2000, vol. 31, pp. 1013–21.

P. Yan, B.A. Webler, P.C. Pistorius, and R.J. Fruehan: Metall. Mater. Trans. B, 2015, vol. 46, pp. 2414–8.

25 P.A. Kralchevsky, V.N. Paunov, N.D. Denkov, I.B. Ivanov, and K. Nagayama: J. Colloid Interface Sci., 1993, vol. 155, pp. 420–37.

B. Coletti, S. Vantilt, B. Blanpain, and S. Sridhar: Metall. Mater. Trans. B, 2003, vol. 34, pp. 533–8.

27 W. Mu, N. Dogan, and K.S. Coley: Jom, 2018, vol. 70, pp. 1199–209.

28 W. Liu, S. Yang, and J. Li: Metall. Mater. Trans. B, 2020, vol. 51, pp. 422–5.

Acknowledgments

The authors would like to express their thanks for the support by the China Postdoctoral Science Foundation (Grant No. 2020M680010), the National Nature Science Foundation of China (Grant Nos. 51734003, 51822401 and 52074030), and the Fundamental Research Funds for the Central Universities (Grant No. FRF-TP-20-008A1).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted November 4, 2020; accepted April 23, 2021.

Rights and permissions

About this article

Cite this article

Liu, W., Liu, J., Zhao, H. et al. CFD Modeling of Solid Inclusion Motion and Separation from Liquid Steel to Molten Slag. Metall Mater Trans B 52, 2430–2440 (2021). https://doi.org/10.1007/s11663-021-02203-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-021-02203-9