Abstract

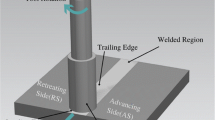

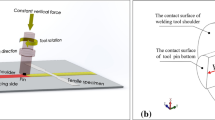

A high strength aerospace aluminum alloy, 24~25 mm thick plate, has been friction stir welded using four different process variants. The process variants used are: stationary shoulder single pass (SSSP), conventional shoulder single pass (CSSP), stationary shoulder dual pass (SSDP), and conventional shoulder dual pass (CSDP). The goal of the reported work was to optimize properties while maintaining nugget temperature below the incipient melting temperature. Defect free welds were produced by all process variants. Properties and characteristics including residual stress, hardness distributions and process control and response parameter relationships are reported.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

P. Upadhyay and A. P. Reynolds, “Effects of Thermal Boundary Conditions in Friction Stir Welded AA7050–T7 Sheets,” Materials Science and Engineering A, 527 (2010), 1537–1543.

A. P. Reynolds, W. Tang, Z. Khandkar, J. A. Khan and K. Lindner, “Relationships between weld parameters, hardness distribution and temperature history in alloy 7050 friction stir welds,” Science and Technology of Welding and Joining, 10 (2005), 190–199.

T Long, W Tang, AP Reynolds, “Process response parameter relationships in aluminium alloy friction stir welds,” Science and Technology of Welding & Joining, 12 (2007), 311–317.

P. L. Threadgill, A. J. Leonard, H. R. Shercliff, P. J. Withers, “Friction stir welding of aluminium alloys,” International Materials Reviews, 54 (2) (2009), 49–93.

H. J. Zhang, H. J. Liu, L. Yu, “Effect of Water Cooling on the Performances of Friction Stir Welding Heat-Affected Zone,” Materials Engineering and Performance, 21 (7) (2012), 1182–1187.

W. Cheng, I. Finnie, “The crack compliance method for residual stress measurement,” Welding in the World, 28 (5–6) (1990), 103–110

H. J. Schindler, W. Cheng, I. Finnie, “Experimental determination of stress intensity factors due to residual stresses,” Experimental Mechanics, 37 (3) (1997), 272–277.

M. B. Prime, “Residual Stress Measurement by Successive Extension of a Slot: The Crack Compliance Method,” Appl. Mech. Rev., 52 (2) (1999), 75–96.

C.T. Canaday, M.A. Moore, W. Tang, and A.P. Reynolds, “Through Thickness Property Variations in a Thick Plate AA7050 Friction Stir Welded Joint,” Materials Science & Engineering A, 559 (2013), 678–682.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 TMS (The Minerals, Metals & Materials Society)

About this chapter

Cite this chapter

Huang, X., Scheuring, J., Reynolds, A.P. (2015). FSW of High Strength 7XXX Aluminum Using Four Process Variants. In: Mishra, R.S., Mahoney, M.W., Sato, Y., Hovanski, Y. (eds) Friction Stir Welding and Processing VIII. Springer, Cham. https://doi.org/10.1007/978-3-319-48173-9_10

Download citation

DOI: https://doi.org/10.1007/978-3-319-48173-9_10

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-48604-8

Online ISBN: 978-3-319-48173-9

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)