Abstract

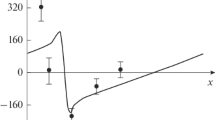

An experimental method is presented that enables stress intensity factors due to residual stress to be determined directly, without prior determination of the residual stress. The method is based on the crack compliance method, where a narrow cut is introduced progressively into the considered component, and the resulting strain change is measured by a strain gage. The required mathematical relations to determine stress intensity factors from strain measurements are established by means of some basic relations of linear elastic fracture mechanics. They are derived explicitly for two exemplary geometrical systems, which allowed for analytical treatment. Experimental data obtained in the case of a steel roller are presented and discussed.

Similar content being viewed by others

References

Cheng, W. andFinnie, I., “Measurement of Residual Hoop Stresses in Cylinders Using the Compliance Method,”ASME J. Eng. Mat. Tech.,108,87–92 (1986).

Cheng, W. and Finnie, I., “An Overview of the Crack Compliance Method for Residual Stress Measurement,” Proc. 4th Int. Conf. Residual Stress, Baltimore, MD, 449–458 (1994).

Fett, T., “Bestimmung von Eigenspannungen mittels bruchmechanischer Beziehungen,”Materialprüfung,29 (4),92–94 (1987).

Kang, K.J., Song, J.H. andEarmme, Y.Y., “A Method for the Measurement of Residual Stress Using a Fracture Mechanics Approach,”J. Strain Analysis,24,23–30 (1989).

Timoshenko, S.P. andGoodier, N.P., Theory of Elasticity, 3rd ed., McGraw-Hill, New York (1970).

Irwin, G.R., “Analysis of Stresses and Strains Near the End of a Crack Traversing a Plate,”J. Appl. Mech.,24,361–363 (1957).

Schindler, H.-J., “Experimentelle Bestimmung von Spannungsintensitätsfaktoren aus Eigenspannungen,” Proc. 27th Vortragsveranstaltung des DVM AK Bruchvorgänge, Deutscher Verband für Materialforschung und prüfung c.V., Köln, 421–430 (1995) (in German).

Buckner, H., “A Novel Principle for Computation of Stress Intensity Factors,”Zeitschrift für angew, Mathematik und Mechanik (ZAMM),50,529 (1970).

Petrosky, H.J. andAchenbach, J.D., “Computation of the Weight Function from a Stress Intensity Factor,”Eng. Fract. Mech.,10,257–266 (1970).

Fett, T. andMunz, D., “Die Methode der Gewichtsfunktionen zur Berechnung von Spannungsintensitätsfaktoren,”Berichtsband der 23, Vortragsveranstaltung des DVM-AK Bruchvorgange, DVM, Berlin, 249–259 (1991) (in German).

Schindler, H.-J., “Weight Functions for Deep Cracks and High Stress Gradients,”Advances in Fracture Resistance and Structural Integrity, ed. V.V. Panasyuk et al., Pergamon, Oxford, 193–205 (1994).

Wu, X.R. andCarlsson, A.J., Weight Functions and Stress Intensity Factor Solutions, Pergamon, Oxford (1991).

Schindler, H.-J. andFinnie, I., “Determination of Residual Stresses and the Resulting Stress Intensity Factors in the Ligament of Pre-cracked Components,”Proc. 9th Int. Conf. Fract., Sydney, Advances in Fracture Research, ed. B.L. Karihaaloo et al., Pergamon, Amsterdam, Vol. 1, 523–530 (1997).

Schindler, H.-J. and Landolt, R., “Experimental Determination of Residual Stress and the Resulting Stress Intensity Factors in Rectangular Plates,” 4th European Conf. Residual Stresses (ECRS4), Cluny, France (1996) (to be published in Journal de Physique, colloques series).

Gregory, R.D., “A Circular Disc Containing a Radial Edge Crack Opened by Constant Internal Pressure,”Mathematical Proceedings of the Cambridge Philosophical Society,81 497–521 (1977).

Gregory, R.D., “The Spinning Circular Disc with a Radial Edge Crack: An Exact Solution,”Int. J. Fract.,41,39–50 (1989).

Schindler, H.-J. andMorf, U., “Schadens- und Sicherheitsanalyse an betriebsgeschädigten Stahlrollen von Brückenlagern,”Report No. 517, Swiss Federal Office for Roads and Bridges, Bern (1995) (in German).

Schindler, H.-J. and Morf, U., “Load Bearing Capacity of Cracked Rollers Containing Residual Stress,s,” Proc. 10th European Fract., ed. K.H. Schwalbe and C. Berger, Vol. 2, EMAS, 767–774 (1994).

Schindler, H.-J., “Determination of Residual Stress Distributions from Measured Stress Intensity Factors,”Int. J. Fract.,74,R23-R30 (1995).

Schindler, H.-J., Cheng, W. and Finnie, I., “Measurement of the Residual Stress Distribution in a Disk or Cylinder Using the Crack Compliance Method,” Proc. 4th Int. Conf. Residual Stress, Baltimore, MD, 1266–1274 (1994).

Cheng, W., Finnie, I. andVardar, O., “Estimation of Axisymmetric Residual Stress in a Long Cylinder,”J. Eng. Mat. Tech.,114,137–140 (1992).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Schindler, H.J., Cheng, W. & Finnie, I. Experimental determination of stress intensity factors due to residual stresses. Experimental Mechanics 37, 272–277 (1997). https://doi.org/10.1007/BF02317418

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF02317418