Abstract

Silica is the rubber industry’s most essential and cost-effective reinforcing filler after carbon black. The silica reinforcement mechanism with a non-polar elastomer is complicated by the presence of polar functional groups on the silica surface. This polar nature of silica causes filler-to-filler interaction by forming hydrogen bonds. Therefore, sizeable non-dispersed silica clusters remain in a non-polar rubber matrix. To avoid these strong filler-filler interactions and improve rubber/silica compatibility, the silica surface needs to be modified. This can be done using a coupling agent which has functional groups capable of linking both the rubber and silica. It has been discovered that when silica/silane coupling agents are present, the critical properties like rolling resistance and wet grip in the magic triangle of tire tread balance out better than carbon black formulations, bringing the system closer to the green tire goal. In this review article, the efforts made by both the rubber formulation development and chemistry to fully exploit the potential of silica/silane reinforcement for automotive tires are retrospected. Highlights on how compounding ingredients, process technology, functionalized elastomer, novel silanes, and the variant of silicas can enhance the magic triangle and silica-silane reaction mechanism are provided. In addition, the kinetics of silanization and measurements for the degree of silanization is also highlighted. Future research directions in this area are also touched upon. Hopefully, this review can stimulate future silica/silane scientific and technology developments for both academic and industrial-oriented requirements.

Similar content being viewed by others

Introduction

In the olden days, fillers were used to dilute the overall cost of polymer composites; later, it was discovered that many fillers enhance the toughness and mechanical strength of the composite [1]. Based on the reinforcing efficiency, they are categorized and reported in Table 1 [2]. The volume fraction, shape, and size of the particles, as well as the interactions between the filler and the matrix, all significantly impact the elastomeric material’s physical performance [3]. In the case of elastomers, applying reinforcing fillers concurrently increases the modulus and other essential performance parameters up to its optimum loading, resulting in their success in various industry branches, particularly in the tire industries, where particular material attributes are required [4,5,6]. The significance of a low rolling resistance tire has increased over the decades because of an increased consciousness to aim for an eco-friendly society. Tire rolling resistance is the energy that a vehicle needs to transmit to the tires to maintain movement at a consistent speed over a surface. In other words, it is the effort required to keep a tire rolling [7]. The major contributor to rolling resistance is the process known as hysteresis. Hysteresis is the energy loss that occurs as tire rolls through its footprint [8]. The energy loss has to be compensated by the vehicle’s engine, which results in the additional consumption of fuel. Lower rolling resistance tires can reduce fuel consumption, resulting in the preservation of petroleum resources and even crucial to a decrease in CO2 emission [9]. It is necessary to reduce the energy dissipation of rubbers in the tire components during deformation to minimize the rolling resistance. The rubber’s energy dissipation correlates with the rubber’s loss factor (tan δ). However, there is a certain risk that a reduction of the loss factor of the rubber causes a reduction in the grip performance, which is another significant property of a tire. Wet grip refers to a tire’s ability to maintain a grip on wet surfaces. Wet grip is closely related to factors such as shorter braking distances on wet surfaces, better driving characteristics, and more stable handling in wet conditions [10]. Tires connect vehicles to the road, undergo deterioration, and wear during their lifetime due to mechanical wear and chemical ageing, which affects the durability of tires and reduces mileage. Tire wear behaviour is the fundamental ability to achieve higher mileage. The resistance towards the wear and abrasion is called abrasion resistance [11].

For a tire tread application, three key properties, which are rolling resistance, wet grip performance, and abrasion resistance, form the “magic triangle”, meaning it is complicated to shift all three properties simultaneously to an optimum level (Fig. 1). There are many trade-offs between these three properties [12]. Replacing carbon black with silica expands the wet grip and rolling resistance performance but negatively affects abrasion resistance. In the temperature range of 50–70 °C, rolling resistance correlates directly with tan δ values from the dynamic mechanical analysis (DMA): The lower the tan δ, the lower the rolling resistance. However, reducing the tan δ in this temperature range also reduces the tan δ at lower temperatures.

On the other hand, the wet grip performance of tires corresponds to a higher tan δ at lower temperatures (− 10 to 0 °C). Therefore, the wet-grip and rolling-resistance corners of the magic triangle are hard to pull apart [13]. The abrasion resistance of carbon black materials is always higher than silica because of the hardness difference in the same filler loading. Silica-filled rubber compound hardness is lower than Carbon black filled compound in same filler loading [14]. Addition of silica imparts better rolling resistance and wet grip properties. However, without the addition of silanes, the improvement in abrasion resistance is not possible. As it chemically connects the silica to the polymer, it forms strong linkages between the filler and rubber, preventing the silica from simply chip** under pressure.

In this paper, the mechanism of filler reinforcement is discussed, along with the challenges faced during silica mixing and the solution to them. The effects of different silanes, mixing parameters, silane concentration, silanization catalyst, ionic liquids, and other compounding ingredients are discussed. This review could help academic and industrial researchers understand silica’s chemistry, silica compounding, and mixing of silica-filled rubber compounds.

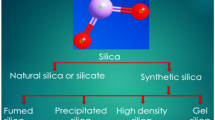

Silica

Silica is the most abundant mineral and the second most abundant element on Earth, with characteristic properties such as hydrophilicity, low toxicity, thermal stability, and an easy synthetic route [15, 16]. The nature of silica can be tailored to meet the needs of a particular application. This includes altering its porosity, crystallinity, particle size, and shape [1].

In the tire industry, hydrated amorphous silicas are typically used. They are synthesized through the precipitation of an acid and a water-soluble sodium silicate. Numerous acids, including mineral acids like sulfuric acid, hydrofluoric acid, and hydrochloric acid, may be employed. The sodium salt is a by-product of the reaction that needs to be removed. In order to obtain excellent mixing of the components, the chemical reaction is carried out in precipitation tanks fitted with stirrers at the temperature range between 50 and 90 °C, and reaction times are typically between 1 and 4 h. The choice of temperature, pH, dosing time, and concentration of each raw material and mixing conditions determine the properties of the resulting silica regarding structure and surface area [17,18,19]. During synthesis, initially, the formation of primary particles happens, followed by aggregates and finally agglomerates [20]. The structure of silica filler along with functional groups presents on its surface is depicted in Fig. 2.

Chemical structure of silica along with functional groups present on it [21]

Carbon black vs. Silica

The surface functional group concentration for typical furnace carbon blacks, such as N220, would be 1–2 COOH groups per nm2 or 2–4 OH groups per nm2 or mixed of these groups, which is substantially lower than silica. The concentration of silanol groups for the majority of precipitated silica types utilized in the tire industry ranges from 4 to 7 per nm2 [22]. The differences between carbon black and silica are not limited only to surface chemistry and surface energy. The overall properties of the vulcanizate are significantly influenced by the morphology of the particles of these two fillers. Carbon black aggregates are more diminutive in size than precipitated silica aggregates because of lower interactions between particles. Moreover, due to the presence of polar groups in the unmodified commercially used industrial grades of the precipitated silica surface, the filler–filler interaction in a silica compound is more potent compared to a carbon black-filled elastomer compound and can be understood by the Payne effect (strain sweep) depicted in Fig. 3. However, problems that arise due to polar groups on the silica surface can be addressed through modification of the silica surface with organosilanes; the process is called silanization [23]. With increasing deformation amplitude, the complex modulus of a filled, crossed-linked elastomer system decreases, known as the Payne effect. The composites’ dam** peak (Loss Tangent) increases with increasing strain, with a higher value of Payne effect (∆G’) possessing a higher dam** peak or hysteresis for the same system. Therefore, the hysteresis resulted from the breakdown of the filler network, and the straining disruption could dissipate energy. Denser rubber networks possess lower dissipation of energy or tan delta [24].

In its rubbery form, the hysteresis of a carbon black reinforced material is still more significant than that of a silica-filled one. This is mainly caused by energy loss during the filler network’s periodic destruction and regeneration. However, as the temperature rises, the hysteresis decreases, just as it would for a polymer without fillers, due to the carbon black filler network being easily thermally destroyed. Contrarily as the temperature rises, the hysteresis of silica-filled rubber also decreases, thereby weakening the filler-filler hydrogen bonding connections and increasing the portion of the filler network that can break and regenerate.

The silica compound provides significantly lower tan delta values than the carbon black vulcanizate in the transition zone (Fig. 4). The Hi-Sil 210 Silica refers to the commercially available precipitated silica having 135 m2/g surface area with a 7 pH value and with a density of 240 g/L. However, the hysteresis for carbon black is still higher in the rubbery state at temperatures above 20 °C, primarily due to the energy lost during repeated filler network destruction and reconstruction. Tan delta decreases rapidly with temperature due to a reduction in filler-filler interaction as well as filler-polymer interaction. On the other hand, it is significant to realize that the hysteresis of the silica-filled rubber increases as temperature increases, eventually revealing a crossover point with carbon black at about 90 °C. The amount of the filler network that can be broken down and reformed during cyclic deformation would increase as the temperature rises due to a weakening of the filler-filler interaction [25]. The effect of both fillers concerning the magic triangle properties in actual tire tread compounds are depicted in Table 2.

Temperature dependence of tan δ for vulcanizates filled with carbon black and silica without a coupling agent [26]

Mechanism of filler reinforcement

Heinzerling et al. [28] began their work on rubber fillers in 1891, and Ditmar et al. [29] published the first actual account of the reinforcing effect of zinc oxide in 1905. In 1951, Schmidt [30] observed significant silica reinforcement effects in styrene-butadiene rubber (SBR) and speculated that the filler’s particle size is of utmost importance for elastomer reinforcement. The filler’s chemical composition appears to be less critical. However, the experiment could not only confirm this theory of reinforcement by particle size, irrespective of chemical composition. It was not established until the late 80’s that a tiny particle diameter is necessary for the reinforcement effect in elastomers [4]. In contrast to the carbon black filler reinforcement mechanism, the silica reinforcement mechanism was unexplored in earlier days. Rubber with silica in it is extremely viscous and challenging to process [31, 32]. Nasir et al. [33] examined the effects of silane coupling agents on silica-filled elastomers in 1988, which attracted the attention of several scientists to focus on silica-silane research. It was determined that even when they are of equivalent sizes, silica’s characteristics are inferior to carbon black. He also disputed most of the explanations for the filler reinforcement theory proposed by Smallwood [34], Guth [35], and others [36]. Nearly every method suggested to characterize rubber reinforcement by fillers was still ambiguous at those times. However, the concept of filling rubber with a shell of filler was first proposed by Harwood et al. [37] Wagner investigated the effect of silica in SBR vulcanizates and came to the conclusion that the amount of adsorbed water, the silica surface area, and the presence of surface silanol all affect the silica-rubber interaction [22]. Followed by that, Medalia et al. [38] studied the filler aggregates and their effect on reinforcement in the elastomer compound. The precipitated silica fillers require a stronger polymer–silica surface bonding and a higher silica surface area to reinforce a hydrocarbon rubber due to the polar nature of the silica surface and the non-polar nature of the hydrocarbon-based rubber matrix. An increase in the amount of coupling agents for Fumed silica compound will improve the modulus. Wolff et al. [23] explored the chemical aspects of rubber reinforcement by fillers. The primary silanization reaction rate concerning the alkoxy group was investigated, and it was found that Methoxy [Toxic] and Ethoxy groups react faster than the Prop-oxy group. A field test is carried out for Silica-TESPT (Bis(triethoxysilylpropyl)tetrasulfide) and carbon black filled tread compound. The primary reaction is the condensation reaction between the alkoxy group of organo-silane and the hydroxyl group of the silica surface, thereby releasing aliphatic alcohol as a by-product. Using Small-angle neutron scattering (SANS), Westermann et al. [39] investigated the matrix chain deformation in a reinforced network. The effect of reinforcement in matrix chains and rubber reinforcement in spherical Polystyrene (PS) domains on a composite model system was investigated.

The results ensure the model for strain improvement in reinforced networks and provide direct microscopic insights into reinforcement mechanisms. A complementary small-angle X-ray scattering (SAXS) study yields all relevant geometrical parameters of the model filler and its complex behaviour under strain. Leblance et al. [40] studied the rubber-filler interactions and rheological properties of filled elastomer composites. This work introduced rubber – mesophase concept to scale the flow singularities (macroscopic flow) from nano to micro range. Also, the relationship between bound rubber and flow properties was discussed concerning percolation level. It was also observed that reinforcing fillers like carbon black or highly dispersible silica impart modification in flow properties because of strong rubber–filler interaction rather than hydrodynamic effect (volume fraction effect). The non-linear rheological behaviour of Silica Filled Solution-Polymerized Styrene Butadiene Rubber was investigated by Sun et al. [41]. The filled rubber’s non-linear viscoelastic behaviour corresponds to that of unfilled S-SBR, which is in contrast with the concept that this characteristic originates from breakdown and reformation of filler network. Due to weakened filler-filler interaction and improved filler dispersion, surface modification of SiO2 results in an enhanced reinforcement factor. The strain amplification factor is unaffected by SiO2’s surface structure.

In the presence of silane coupling agents with various chemical structures, Kaewsakul et al. [42] explained the reinforcement mechanism in silica-filled NR compounds (Fig. 5). This mechanism describes TESPT as a bifunctional silane coupling agent that functions in two different ways in silica-filled NR compounds. By silanization or a hydrophobation process during the mixing step, TESPT interacts with the surface hydroxyl group of silica to lessen its hydrophilic character. In addition, TESPT-modified silica couples with rubber chains during the vulcanization process. In order to improve the compatibility between the hydrophobic NR matrix and the hydrophilic silica filler, TESPT acts as a reactive compatibilizer and coupling agent. A reactive compatibilizer forms a compatibilizer that promotes interfacial adhesion [43, 44] whereas a coupling agent chemically links the filler and polymer matrix. The use of silane coupling agents as reinforcement agents still has several significant drawbacks, such as the production of alcohol as a by-product of the coupling reaction, the high cost of silane coupling agents, and complex processing behaviour [45]. As a result, finding substitutes for expensive silanes as reinforcement agents are crucial for the rubber sector.

The reinforcement mechanism of silica-filled NR composites in the presence of silane with different functionalities [42]. Redrawn with permission from John Wiley and Sons

Surface chemistry and silanization reactions of silica filler

Compared to carbon black, silica filler reinforcement using silane depends on the chemical reaction. It is mandatory to understand the reactivity and surface chemistry of silica filler. In 1975, Dannenberg [1] proposed that the silica surface is simpler and more well-understood than carbon black after researching the surface interaction of the silica system with elastomers. He noted that controlled chemical modification of the silica surface provides an ideal framework for showing the effects of surface chemistry on reinforcement. They recommended two essential methods for altering the surface of silica: esterifying silanol groups and reacting surface silanol groups with various silanes [46]. In the case of chlorosilane, Hydro Chloric Acid (HCl) is produced as a by-product, which in the presence of H2O functions as a strong acid to catalyze the chlorosilane hydrolysis. Alkoxysilane coupling agents are recommended over chloro-silanes to acquire hydrophobic and reactive fillers during the surface modification of silica. The coupling agents that use reactive organo-silanes react with moisture during the initial step of silica filler surface modification using alkoxysilane as a coupling agent (R-Si-OH). Alcohol is the by-product that is produced in this stage [47].

The hydrophobation of the silica/silanization reaction involves a two-step mechanism. Firstly, the primary reaction Involves the hydrolysis of the silane by water and releases ethanol either via direct condensation or via hydrolysis followed by condensation. The secondary reaction involves the condensation of the neighboring silane molecules, which are attached to the silica surface and react with each other in the presence of water upon releasing two molecules of ethanol [48, 49]. Followed by the primary and secondary reaction of hydrophobation, a coupling reaction occurs between the silanized silica and rubber molecules during vulcanization (Fig. 6). The study of reaction kinetics validated the proposed reaction mechanism. Between the rapid primary and slow secondary reactions, the kinetic studies clearly distinguish one from the other [50]. The reaction rate and Arrhenius activation energy of the secondary reaction are much lower than those of the primary reaction. The primary reaction rate (0.122 min− 1) is about 10 to 20 times faster than the secondary reaction (0.008 min− 1). The activation energy is 47 kJ/mol for the primary reaction and 28 kJ/mol for the secondary reaction [51].

Primary and Secondary reaction mechanism of silica with silane Reproduced from Polymers [52]

However, the percentage of reactive silanol groups available for silanization reaction is key to proper hydrophobation and filler reinforcement. Using in-situ infrared spectroscopy, Blume et al. [53] reported on the silica-silane reaction process. They showed that only the isolated and geminal silanol groups were involved in the reaction (Fig. 7). Only 25% of the Si-OH groups are expected to react with silanes because these silanol groups are accessible to incoming silane molecules. The number of silanes grafted on the silica surface is constrained by the fact that two alkoxy molecules of silane coupling agent can only react with two silanol groups. They are separated by more than 0.4 nm on the silica surface, according to molecular modelling with a (3-mercaptopropyl)triethoxysilane (Si 263) silane coupling agent. Out of these three different silanol groups located on the surface of silica filler, only isolated silanols and geminal silanols can be reactive with silica (Fig. 8).

Even when a coupling agent is used, flocculation of silica / reagglomeration of silica particles after mixing and before curing—plays a significant role in the filler reinforcement. Reagglomeration occurs due to the incompatibility of polar silica filler in the non-polar rubber matrix. Using the Rubber Process Analyzer, Luginsland et al. [54] observed the reagglomeration of silica distributed in rubber. They claimed that the following factors affect the reagglomeration process: the silica-silica interaction, which is affected by the silica loading, the silica’s specific surface area, and the degree of silanization; the silica-polymer interaction; and the filler mobility in the rubber, which is affected by the rubber’s viscosity and temperature. Böhm et al. [55] studied the flocculation behaviour of the carbon black in filled rubber compounds. In this work, the carbon black reagglomeration occurred during storage or vulcanization in the absence of shear in the filled rubber compound. Using electrical conductivity and low strain dynamic mechanical properties, the kinetics of the flocculation process is examined. It is noted that the type and concentration of carbon black, number average molecular weight and molecular weight distribution, the history of mixing, and the annealing temperature significantly impact the rate of flocculation. Mihara et al. [56] investigated the flocculation in silica-reinforced rubber compounds using the Payne effect. Due to the polarity differences between the silica and the rubber, attractive flux (forces arise due to polarity difference) will determine silica flocculation. The flocculation process is a physical phenomenon since it depends on temperature, and its activation energy is close to 10 [kJ/mol]. The flocculation rate is correlated with diffusion coefficient and specific bound rubber content.

Sahakaro et al. [57] investigated the flocculation kinetics and filler-rubber interaction in silica-reinforced NR compounds by changing storage modulus during thermal annealing and vulcanization of silica-reinforced NR compounds. The increase in dump temperature [150 °C] of the silica-filled compound and the amount of silane in the system reduced silica flocculation. The higher bound rubber content and smaller Payne effect were observed by the usage of Highly Dispersible (HD) silica in the system compared to conventional silica. In comparison to compounds filled with ordinary silicas, those containing highly dispersible silicas show stronger filler-rubber interaction, but their flocculation processes occur relatively fast. Sato et al. [58] studied the reactivity of Mercapto–Silane, and Sulfide–Silane with Polymer. Mercapto–silanes improve silica dispersion in tire tread compounds compared to sulfide–silanes, providing a better balance of wet grip and rolling resistance. But, it increases Mooney viscosity and reduces scorch time, leading to processing difficulties. Different sulfur functions of silanes interact with a polymer in different ways. Mercapto–silanes react directly to the double bonds of rubber and suppress the flocculation reaction. On the other hand, the mercaptan group will react with the polymer chain and forms a large dense chemical-bound rubber system, which leads to poor processability and reduction of elasticity [58].

Kinetics of silanization of silica and silane coupling agent

Even though silica and silanes were used for a few decades, the actual kinetics was unclear until Norihiro et al. [59] investigated the hydrolysis and condensation mechanisms of a silane coupling agent by the time-dependent behaviour of 13C and 29Si NMR peaks. The rate of hydrolysis and condensation depends on the water content; as water content increases, the intensity of α-CH2 and 29Si peak reduces. Followed by this research work, Goerl et al. [51] investigated the reaction of Silica with TESPT under various parameters along with the kinetics of silanization reaction between silica and silane. Acidic and alkaline systems with moisture accelerate silanization’s primary and secondary reactions. The temperature of the system dramatically influences the primary silanization reaction. As the temperature increases, the concentration of ethanol formation increases which indicates the progression of the primary silanization reaction as depicted in Fig. 9 [51].

Temperature dependency of primary silanization reaction concerning silanization time [51]

Ono et al. [60] used wide line pulsed NMR and high-resolution solid-state NMR combined with TEM to study the structure development in silica–filled rubber composites. The amount of bound rubber content is affected due to the state of aggregation of silica particles as a function of the amount of silanol groups on the particles and particle size. During annealing, the amount of bound rubber increases with increasing annealing temperature. The increase of Bound rubber content with heat treatment is primarily the result of chemical crosslinking of Polyisoprene molecules induced by the acid sites on the silica particles. Suzuki et al. [12] examined the impact of silica particle surface chemistry on the secondary structure and tensile characteristics of silica-filled rubber systems. In this study, the size of the secondary silica structure in SBR is examined concerning the compound’s tensile properties.

Alexey et al. [61] investigated the strong influence of water molecules on the condensation reaction between coupling agents and the reactivity of the coupling agents with silanol groups on the silica surface. The presence of moisture and amines provide a catalytic effect, thereby rate of silanization reaction increases.

Optimization of Silica filled elastomer compound and silanization

In general, increasing silane concentration up to six phr increases the hardness, tear strength, modulus at 100%, abrasion resistance, and rolling resistance properties (Fig. 10) [62]. Mixing is a key to all multi-component materials such as polymer bends [63, 64], polymer composites [65, 66], thermoplastic vulcanizates [67,68,69,70], and rubber composites [3, 71]. Optimized silane concentration or silica content in rubber composite will not result in the desired performance properties if not mixed properly. To utilize the full potential of the silica-silane combination, the significance of the reaction parameter has to be understood. Initially, the preliminary studies of optimization of silanization of silica by 3- aminopropyltriethoxy(APTES) silane in a liquid phase were carried out. The influence of reaction temperature, solution concentration, and reaction time on the structure and morphology of the APTES system on silica was examined. The effects of reaction time, solution concentration, and reaction temperature impacted the morphology and growth kinetics of APTES films deposited from solutions. By making APTES more mobile in the toluene phase and accelerating the reaction rate for silanization at high temperatures, the APTES system’s kinetics is accelerated [72]. However, silanization’s liquid phase test tube optimization does not help in large-scale applications like the tire industry, whereas in-situ silanization occurs inside a solid-state industrial mixer. Later, Kaewsakul et al. [73] optimized the mixing conditions of an internal mixer for silica-reinforced natural rubber tire tread compounds and observed that silica-filled NR compound properties depend on the critical parameter called dump temperature (the temperature at which the mixing is stopped, and the compound is dumped down). Optimized mixing conditions to ensure optimized overall properties for silica - silane - rubber mixing were found to be 10 min with a dump temperature range of 135 to 150 °C. Some premature crosslinking occurs due to the presence of sulfur in the organo-silane system in the first stage of mixing.

Effect of TESPD silane loading on mechanical properties and filler-polymer network of silica filled natural rubber composite [62]. Redrawn with permission from John Wiley and Sons

There are many other parameters or factors of the mixer which can affect the in-situ silanization, thereby affecting the final performance properties of silica-filled elastomer composite. Recently, Neethirajan et al. [74] quantified the significance of mixing parameters on the performance properties of silica-silane functional elastomer composite for tire tread application. It is well established that silanization temperature and time significantly affect silanization reaction, thereby affecting the end compound performance properties. However, the influence of other mixing parameters was not well defined. DOE (Design of experiment) with a preset boundary condition approach was adopted to quantify the mixing parameters on silanization. Mixing temperature and time together have a higher significance of more than 50%, followed by minor factors like Temperature Control Unit (TCU), feed door condition (O/C), fill factor, and ram pressure. A fill factor of more than 70% and less than 50% is not preferred as less fill factor results in shear rate deficiency. In contrast, more fill factor has limited space to generate a new surface so that ethanol can evaporate and facilities a proper silanization during the mixing and condensation of ethanol (Fig. 11).

Effect of compounding ingredients on silica silane functional composite

Luginsland et al. [54] studied the influence of various silanes on the reinforcement of silica-filled rubber composites. The effect of silane modification on the Payne-effect of silica-filled S-SBR/BR elastomer compound using rubber process analyzer (RPA). Also, it was observed that the breakdown of the filler network and loss of occluded rubber was influenced by the silica’s surface area and the silanization degree. Bi-functional silane like TESPT forms an “in-rubber structure” since it has chemical bonding with rubber matrix during curing. The mechanical properties of silane coupling agents with various functions in the reinforcing of silica-filled natural rubber compounds were studied by Kaewsakul et al. [42]. This research looked at the function of five distinct silane coupling agents in natural rubber, including bis-(triethoxysilylpropyl)tetrasulfide (TESPT), bis-(triethoxysilylpropyl) disulfide (TESPD), octyltriethoxysilane (OTES), vinyltrimethoxysilane (VTMS), and bis-(trimethylsilylmethyl tetra sulfide) (TMSMT) (Table 3). Alkoxy silanes significantly reduce the filler–filler interaction and viscosity of silica-filled Natural rubber compounds. Alkoxy silanes with sulfur moiety show improvement in overall compound properties. Silanes with no alkoxy group showed poor mechanical properties, and poor filler dispersion (Table 4). Silane with one alkoxy group has better processability and poor mechanical properties than bifunctional silanes [75]. The superior properties of TESPT silane are due to its disproportion at higher mixing temperatures. TESPT can be disproportionate to a mixture of polysulfides with sulfur chain lengths varying from two to eight atoms, depending on reaction time and temperature. The occurrence of such disproportionation reactions during compounding or subsequent processing appears to have little effect on the effectiveness of TESPT as an adhesion promoter. During vulcanization, TESPT can act as an accelerator or add sulfur to rubber compounds [76]. However, this leads to premature scorching and results in poor processability of rubber compounds, such as premature crosslinking and higher viscosity [51]. Apart from these silanes, NXT (3-octanoylthio-1-propyltriethoxy) and MS (Mercaptopropyl trimethoxy) silanes are also available in the market; These silanes can exhibit better dynamic properties, rolling resistance properties, wet grip, etc. compared to the TESPT silanes.

Kosmalska et al. [77] investigated the adsorption of curatives and silica activity toward elastomers and found that Low molecular weight substances of different polarities solubilized in rubber compounds undergo adsorption on the surface of the active filler. It affects the mechanical properties of vulcanizates. This work investigated the effect of accelerators and modified silica in elastomer compounds. Accelerators cause the deactivation of the filler dispersed in EPDM (Ethylene Propylene Diene Monomer Rubber). Crosslinking system or ZnO-modified silica surface decreases the activity of silica towards elastomer. One of the issues with silica-reinforced rubber compounds is the chemisorption of vulcanizing agents on the silica surface because the polar silanol groups of silica can produce strong adsorption with polar chemicals through hydrogen bonding or van der Waals forces [22, 78]. This could negatively affect the characteristics of several important chemical constituents (particularly accelerators) and result in a decrease in crosslink density and end-use properties [79].

The elastomer is typically mixed with glycols or amines to enhance the curing properties. Diphenyl guanidine (DPG) is frequently utilized for silica-reinforced composites because it works as a catalyst for the silanization reaction between the silica filler and the silica coupling agent synergistic secondary accelerator of sulfur-accelerated sulfur sulfenamide [80,81,82]. The application of DPG increases the silanization reaction rate, namely the hydrolysis of TESPT followed by condensation reaction and the direct condensation reaction of TESPT and silica. DPG might reduce the activation energy of the silanization process from 90.4 kJ/mol to 70.8 kJ/mol [83].

With the study of the impact of different silica, silane coupling agents, and DPG on the compound properties, Kaewsakul et al. [84] optimized the Rubber Formulation for Silica-Reinforced Natural Rubber Compounds and investigated DPG’s dual nature as an activator for silanization and accelerator for curing system. The increase in silane and DPG content favours the physical properties, chemically bound rubber content, reinforcement index, and cure time, along with a negative effect on scorch time. A Higher silica structure results in improved dispersion, smaller aggregate sizes, and, as a result, quicker flocculation. The High Dispersible silica-reinforced-NR vulcanizates have a higher reinforcement index and lower tan delta at 60 degrees C, indicating a lower rolling resistance than standard silica-filled compounds favouring tire application. Although DPG has a dual role in silica-filled rubber compounds, there is a chance for the evolution of aromatic amines like Aniline (toxic) during mixing [85]. There was a demand in search of an alternative to DPG for betterment. Hayichelaeh et al. [52] investigated the impact of amines that could potentially replace DPG on the silanization reaction of the silica-silane system in the model and real-world silica-filled natural rubber compounds. These amines included hexylamine, decylamine, octadecylanime, cyclohexylamine, dicyclohexylamine, and quinuclidine. The primary silanization reaction rate constants of the compound with amine were 3.7 times those of the compound without amine. Linear amines boosted the primary silanization reaction faster than aromatic/cyclic amines. In linear alkyl amine, short alkyl amine showed a higher rate constant of primary silanization reaction than cyclic and long alkyl amines and a lower flocculation constant.

The effects of silica and its various surface treatments on the vulcanization of silica-filled SBR were investigated by Ramier et al. [86]. This study examines the impact of various silica treatments on the vulcanization of rubber packed with silica (SBR). In comparison to the silica-filled compound with DPG, grafting alters the vulcanization kinetics and lowers the cure rate of the substance. A more homogeneous crosslinking may result from the grafting of the filler surface by reducing N-Cyclohexyl-2-Benzothiazole Sulfonamide (CBS) adsorption. Antioxidant functionalized silica’s reinforcing and antioxidation effects in styrene-butadiene rubber were studied by Pan et al. [87]. In this study, precipitated silica and an antioxidant coupling agent were combined to create antioxidant functionalized silica via the reactions of 3-Glycidyloxypropyl) trimethoxy silane (A-187) and N-phenyl-1,4-phenylenediamine (PPDA). Above 3.9% of antioxidant content by weight to silica, functionalized silica dramatically improves the thermal and ageing properties by retaining the mechanical properties of the SBR / Silica compound. The functionalized silica-filled compound has reduced viscosity and optimum cure time than the unmodified silica-filled compound. As toxicity is a concern, even aromatic oils as processing oil are banned; currently, TDAE (Treated Distillate Aromatic Extract) is used as a processing aid by tire industries. C. Hayichelaeh et al. [88] found a better bio-based alternative to TDAE. Epoxidized palm oil and amine-modified epoxidized palm oil tend to increase the filler reinforcement, increase the curing rate, and reduce the Payne effect (Fig. 12). Amine-modified EPO also enhances the silanization reaction as it acts as a silanization catalyst [88]. Weng et al. [89] studied the effect of alkalinity of different ionic liquids as a catalyst for silanization reaction. The silanization reaction enhancement significantly improved silica dispersion and interfacial interaction between silica and rubber in SBR composites. The reactivity of ionic liquids is higher for strong alkalinity and lower for weak alkalinity ionic liquids. The reactivity of Ionic liquids for silanization is as follows: 1-butyl-3-methylimidazolium acetate (CIL) > 1-butyl-3-methylimidazolium hydroxide (OIL) > 1-butyl-3-methylimidazolium tetrafluoroborate (BIL) > 1-butyl-3-methylimidazolium hexafluorophosphate (PIL). The presence of short and linear amines and higher alkalinity ionic liquids significantly enhances the rate of silanization. The polar group of silica adsorbs the curatives added to the compound. To retain the equivalent amount of cross linking and cure rate, additional Phr of curatives must be added while designing formulation. Having sulfur-containing silane enhances a crosslink density as it provides additional sulfur for vulcanization; in contrast to the advantages, it leads to processing difficulties (Scorch effect). The non-sulfur-containing silanes have better processabilities with poor mechanical properties.

Effect of synthetic and bio-based oil on Storage modulus and Payne effect of silica-filled elastomer composite [88]

Conclusions

Silica filler is dominating the rubber industry day by day as the requirement for green tires proceeds. To expand the magic triangle of tyres, silica, along with the coupling agent, is used to address the problem. However, the major problem with silica filler in rubber composite is the complexity of reactive mixing and consistency of end product performance. This review demonstrates how complex silica-silane reinforcement of elastomer composite is established with time and research. This review discusses the fundamental of silica filler reinforcement to describe the difference between carbon black and silica filler reinforcement. The effect of different functional groups like isolated silanol, geminal silanol, vicinal silanol, and siloxane bridge on reactivity towards silanization and filler dispersion in rubber matrix is discussed.

Along with the surface chemistry and its reactivity towards silanization, the kinetics and catalyst-assisted silanization with various compounding ingredients are discussed. In addition, this review has presented several challenges and solutions in develo** silica-silane rubber composites with various chemical methods and process condition optimization. The research towards catalyzed silanization discussed will pave the way for industrial application in the application.

Availability of data and materials

Not applicable.

References

E.M. Dannenberg, The effects of surface chemical Interactions on the Properties of Filler-reinforced rubbers. Rubber Chem. Technol. 48, 410–444 (1975)

J.L. Leblanc, A. Staelraeve, Studying the storage maturation of freshly mixed rubber compounds and its effects on processing properties. J. Appl. Polym. Sci. 53, 1025–1035 (1994)

J. Neethirajan, T.S. Natarajan, S. Wiessner, K. Naskar, A. Das, Tuning the mechanical properties of MgO filled epichlorohydrin elastomer composites through in-situ alteration of filler structure using water as stimulus. Mater. Today Commun. 26, 102116 (2021)

J.-B. Donnet, Black and white fillers and Tire compound. Rubber Chem. Technol. 71, 323–341 (1998)

S. Wolff, Optimization of Silane-Silica OTR Compounds. Part 1: Variations of Mixing Temperature and Time during the Modification of Silica with Bis-(3-Triethoxisilylpropyl)-Tetrasulfide, vol 55 (Rubber Chemistry and Technology, 1982), pp. 967–989

S. Tang et al., Current trends in bio-based elastomer materials. SusMat 2, 2–33 (2022)

J. Barrand, J. Bokar, Reducing Tire rolling resistance to save fuel and lower emissions. SAE Int. J. Passenger Cars - Mechanical Syst. 1, 9–17 (2008)

D.E. Hall, J.C. Moreland, Fundamentals of rolling resistance. Rubber Chem. Technol. 74, 525–539 (2001)

E.M. Cichomski, Silica-Silane Reinforced Passenger car Tire Treads: Effect of Silica Morphology, Silica-Polymer Interface Structure and Rubber Matrix Network on Tire-Performance Indicators (University of Twente, 2015). https://doi.org/10.3990/1.9789036538909

J.T. Chiu, C.R. Shui, Analysis of the wet grip characteristics of tire tread patterns. Tire Sci Technol 46, 2–15 (2018)

S. Bhattacharyya et al., Influence of highly dispersible silica filler on the physical properties, tearing energy, and abrasion resistance of tire tread compound. J. Appl. Polym. Sci. 136, 47560 (2019)

N. Suzuki, F. Yatsuyanagi, M. Ito, H. Kaidou, Effects of surface chemistry of silica particles on secondary structure and tensile properties of silica-filled rubber systems. J. Appl. Polym. Sci. 86, 1622–1629 (2002)

N. Vleugels, W. Pille-Wolf, W.K. Dierkes, J.W.M. Noordermeer, Understanding the influence of oligomeric resins on traction and rolling resistance of silica-reinforced tire treads. Rubber Chem. Technol. 88, 65–79 (2015)

I.M. Ulfah et al., Influence of carbon black and Silica Filler on the rheological and mechanical Properties of natural rubber compound. Procedia Chem 16, 258–264 (2015)

N. Hao, L. Li, F. Tang, Shape matters when engineering mesoporous silica-based nanomedicines. Biomater. Sci. 4, 575–591 (2016)

N. Hao, L. Li, F. Tang, Roles of particle size, shape and surface chemistry of mesoporous silica nanomaterials on biological systems. Int. Mater. Rev. 62, 57–77 (2017)

S. Uhrlandt, A. Blume, Unique production process and silica structure. Rubber World 228, 43–45 (2003)

T.A. Okel, W.H. Waddell, Silica Properties/Rubber Performance Correlation. Carbon Black-Filled Rubber Compounds. Rubber Chem. Technol 67, 217–236 (1994)

J. Karim, A. Ahmad, I. Abdullah, H.M. Dahlan, Effects of pH on mechanical and morphological studies of silica filled polyvinyl chloride-50% epoxidized natural rubber (PVC-ENR50) nanocomposite. J Solgel Sci Technol 62, 7–12 (2012)

D.W. Schaefer et al., Multilevel structure of reinforcing silica and carbon. J. Appl. Crystallogr. 33, 587–591 (2000)

L.T. Zhuravlev, The surface chemistry of amorphous silica. Zhuravlev model. Colloids Surf A Physicochem Eng Asp 173, 1–38 (2000)

M.P. Wagner, Reinforcing Silicas and silicates. Rubber Chem. Technol. 49, 703–774 (1976)

S. Wolff, Chemical aspects of rubber reinforcementby fillers. Rubber Chem. Technol. 69, 325–346 (1996)

R. Chollakup, P. Suwanruji, R. Tantatherdtam, W. Smitthipong, New approach on structure-property relationships of stabilized natural rubbers. J. Polym. Res. 26, 1–11 (2019)

S. Wolff, M.J. Wang, Filler—Elastomer Interactions. Part IV. The Effect of the Surface Energies of Fillers on Elastomer Reinforcement. Rubber Chem. Techno. 65, 329–342 (1992)

M.-J. Wang, Effect of polymer-Filler and Filler-Filler Interactions on dynamic Properties of filled Vulcanizates. Rubber Chem. Technol. 71, 520–589 (1998)

R. Rothon, Fillers for Polymer Applications, vol 489 (Springer, Berlin, 2017)

C. Heinzerling, Schlagwetter und Sicherheitslampen: Entstehung und Erkennung der schlagenden Wetter und Konstruktion der wichtigeren Typen der Sicherheitslampen (1891)

M. Najam et al., Influence of silica materials on synthesis of elastomer nanocomposites: A review. J. Elastomers Plastics 52, 747–771 (2020)

E. Schmidt, Effect of colloidal noncarbon pigments on elastomer properties. Ind. Eng. Chem. 43, 679–683 (1951)

M.P. Wagner, W. MP, Precipitated silicas. A compounding alternative with impending oil shortages (1981)

N.L. Hewitt, Processing Technology of Silica Reinforced SBR (1981)

M. Nasir, B.T. Poh, P.S. Ng, Effect of γ-mercaptopropyltrimethoxysilane coupling agent on t90, tensile strength and tear strength of silica-filled NR, NBR and SBR vulcanizates. Eur. Polym. J. 24, 961–965 (1988)

H.M. Smallwood, Limiting law of the reinforcement of rubber. J. Appl. Phys. 15, 758–766 (1944)

E. Guth, Theory of Filler reinforcement. Rubber Chem. Technol. 18, 596–604 (1945)

S. Chen, A Preliminary Discourse on Tunable Rolling Resistance of Electrorheological Fluid Reinforced Polymer Composites (The University of Akron, 2015)

J.A.C. Harwood, A.R. Payne, R.E. Whittaker, Stress-softening and reinforcement of rubber. Journal of Macromolecular Science, Part B 5, 473–486 (1971)

A.I. Medalia, Filler aggregates and their effect on reinforcement. Rubber Chem. Technol. 47, 411–433 (1974)

S. Westermann et al., Matrix chain deformation in reinforced networks: A SANS approach. Macromolecules 32, 5793–5802 (1999)

J.L. Leblanc, Rubber–filler interactions and rheological properties in filled compounds. Prog. Polym. Sci. 27, 627–687 (2002)

J.I.N. Sun et al., Nonlinear Rheological Behavior of Silica Filled Solution-Polymerized Styrene Butadiene Rubber (2007), pp. 2594–2602. https://doi.org/10.1002/polb

W. Kaewsakul, K. Sahakaro, W.K. Dierkes, J.W.M. Noordermeer, Mechanistic aspects of silane coupling agents with different functionalities on reinforcement of silica-filled natural rubber compounds. Polym. Eng. Sci. 55, 836–842 (2015)

W.Y. Ji et al., Two antagonistic effects of flow/mixing on reactive polymer blending. AICHE J., e17835 (2022). https://doi.org/10.1002/AIC.17835

W.Y. Ji, L.F. Feng, C.L. Zhang, S. Hoppe, G.H. Hu, Development of a reactive Compatibilizer-tracer for studying reactive polymer blends in a twin-screw extruder. Ind. Eng. Chem. Res. 54, 10698–10706 (2015)

V.K. Srivastava, G.C. Basak, M. Maiti, R.V. Jasra, Synthesis and utilization of epoxidized polybutadiene rubber as an alternate compatibilizer in green-tire composites. Int. J. Ind. Chem. 8, 411–424 (2017)

E.E. Reid, Esterification. Ind. Eng. Chem. 46, 1801–1808 (1954)

E.P. Plueddemann, Silane Coupling Agents (Springer, US, 2013)

A. Hunsche, U. Görl, H.G. Koban, T. Lehmann, Investigations on the reaction silica/organosilane and organosilane/polymer. Part 2 : Kinetic aspects of the silica - organosilane reaction (Kautschuk und Gummi, Kunststoffe, 1998)

A. Hunsche, U. Gorl, A. Muller, M. Knaack, T. Gobel, Investigations concerning the reaction silica/organosilane and organosilane/polymer - Part 1: Reaction mechanism and reaction model for silica/organosilane, vol 50 (Kautschuk Gummi Kunststoffe, 1997), pp. 881–889

H. Qiao et al., Preparation and performance of Silica/epoxy group-functionalized biobased Elastomer nanocomposite. Ind. Eng. Chem. Res. 56, 881–889 (2017)

U. Goerl, A. Hunsche, A. Mueller, H.G. Koban, Investigations into the Silica/Silane reaction system. Rubber Chem. Technol. 70, 608–623 (1997)

C. Hayichelaeh et al., Enhancing the silanization reaction of the silica-silane system by different amines in model and practical silica-filled natural rubber compounds. Polymers (Basel) 10, 584 (2018)

A. Blume, M. El-Roz, F. Thibault-Starzyk, Infrared study of the silica/silane reaction. KGK Kautschuk Gummi Kunststoffe 66, 63–70 (2013)

H.D. Luginsland, J. Fröhlich, A. Wehmeier, Influence of different Silanes on the reinforcement of Silica-filled rubber Compounds. Rubber Chem. Technol. 75, 563–579 (2002)

G.G.A. Böhm, M.N. Nguyen, Flocculation of carbon black in filled rubber compounds. I. Flocculation occurring in unvulcanized compounds during annealing at elevated temperatures. J. Appl. Polym. Sci. 55, 1041–1050 (1995)

S. Mihara, R.N. Datta, J.W.M. Noordermeer, Flocculation in silica reinforced rubber compounds. Rubber Chem. Technol. 82, 524–540 (2009)

W. Kaewsakul, K. Sahakaro, W.K. Dierkes, J.W.M. Noordermeer, Flocculation Kinetics and Filler-Rubber Interaction in Silica-Reinforced NR Compounds (186th Technical Meeting of Rubber Division, 2014), pp. 1–20

M. Sato, S. Mihara, N. Amino, W.K. Dierkes, A. Blume, Reactivity study of mercapto–silane and sulfide–silane with polymer. Rubber Chem. Technol. 93, 319–345 (2020)

N. Nishiyama, K. Horie, T. Asakura, Hydrolysis and condensation mechanisms of a silane coupling agent studied by 13C and 29Si NMR. J. Appl. Polym. Sci. 34, 1619–1630 (1987)

S. Ono, Y. Kiuchi, J. Sawanobori, M. Ito, Structure development in silica-filled rubber composites. Polym. Int. 48, 1035–1041 (1999)

A.V. Krasnoslobodtsev, S.N. Smirnov, Effect of water on Silanization of Silica by Trimethoxysilanes. Langmuir 18, 3181–3184 (2002)

P. Sae-Oui, C. Sirisinha, U. Thepsuwan, K. Hatthapanit, Comparison of reinforcing efficiency between Si-69 and Si-264 in a conventional vulcanization system. Polym. Test. 23, 871–879 (2004)

H. Li, G.-H. Hu, The early stage of the morphology development of immiscible polymer blends during melt blending: Compatibilized vs. Uncompatibilized Blends. J Polym Sci B Polym Phys 39, 601–610 (2001)

H. Li, G.H. Hu, A two-zone melting model for polymer blends in a batch mixer. Polym. Eng. Sci. 41, 763–770 (2001)

A.C. Chinellato, S.E. Vidotti, G.H. Hu, L.A. Pessan, Compatibilizing effect of acrylic acid modified polypropylene on the morphology and permeability properties of polypropylene/organoclay nanocomposites. Compos. Sci. Technol. 70, 458–465 (2010)

G.H. Hu, S. Hoppe, L.F. Feng, C. Fonteix, Nano-scale phenomena and applications in polymer processing. Chem. Eng. Sci. 62, 3528–3537 (2007)

S. Li et al., Effects of shear during injection molding on the anisotropic microstructure and properties of EPDM/PP TPV containing rubber nanoparticle agglomerates. Polymer (Guildf) 229, 124008 (2021)

A.R. Parathodika et al., Exploring hybrid vulcanization system in high-molecular weight EPDM rubber composites: A statistical approach. J. Appl. Polym. Sci., e52721 (2022). https://doi.org/10.1002/APP.52721

R.R. Babu, N.K. Singha, K. Naskar, Effects of mixing sequence on peroxide cured polypropylene (PP)/ethylene octene copolymer (EOC) thermoplastic vulcanizates (TPVs). Part. II. Viscoelastic characteristics. J. Polymer Res. 18, 31–39 (2011)

A. Baran Bhattacharya, J. Neethirajan, Kinsuk Naskar, Exploring hybrid vulcanization system in high-molecular weight EPDM rubber composites: A statistical approach Arshad Rahman Parathodika | Aswathy Thuruthil Raju | Mithun Das (2022). https://doi.org/10.1002/app.52721

P. Manoharan, T. Chatterjee, S. Pal, N.C. Das, K. Naskar, Studies on interfacial characteristics of highly dispersible Silica reinforced Epoxidized natural rubber Compounds. Polymer - Plastics Technol. Eng. 57, 1452–1462 (2018)

J.A. Howarter, J.P. Youngblood, Optimization of silica silanization by 3-aminopropyltriethoxysilane. Langmuir 22, 11142–11147 (2006)

W. Kaewsakul, K. Sahakaro, J.W.M. Noordermeer, Optimization of mixing conditions for silica-reinforced natural rubber compounds. Chem. List. 105, 1–36 (2011)

J. Neethirajan et al., Screening of mixing parameters based on their significance on the extent of silanization and energy consumption of silica-filled S-SBR elastomer compounds for fuel-saving tyre application (2022). https://doi.org/10.1002/pen.26061

P. Manoharan, K. Naskar, Exploring a highly dispersible silica–elastomer composite or tire applications. J. Appl. Polym. Sci. 133, 43531 (2016). https://doi.org/10.1002/app.43531

ten Brinke, J. W., Debnath, S. C., Reuvekamp, L. A. E. M. & Noordermeer, J. W. M. Mechanistic aspects of the role of coupling agents in silica-rubber composites. doi:https://doi.org/10.1016/S0266-3538(03)00077-0

A. Kosmalska, M. Zaborski, L. Ślusarski, Adsorption of curatives and activity of silica toward elastomers. Macromol. Symp. 194, 269–275 (2003)

Y. Bomal, P. Cochet, B. Dejean, J. Machurat, Influence of mixing procedures on the properties of a silica reinforced agricultural tire tread. Rubber World-Akron 208, 33 (1993)

S.S. Choi, C. Nah, B.W. Jo, Properties of natural rubber composites reinforced with silica or carbon black: Influence of cure accelerator content and filler dispersion. Polym. Int. 52, 1382–1389 (2003)

H. Issel, L. Steger, A. Bischoff, Application of dithiophosphates in silica reinforced elastomer compounds. Kautschuk und gummi kunststoffe 58, 529 (2005)

C. Penot, Rubber composition for A tire comprising A reinforcing inorganic filler and an (inorganic filler/elastomer) Coupling System, vol 2 (2005)

Penot, C. & Roy, V. Rubber composition for a tire comprising a reinforcing inorganic filler and an (inorganic filler/elastomer) coupling system. Preprint at (2006)

J. Liu, C. Li, C. Sun, S. Zhao, Insights into the Silanization Processes of Silica with and without Acid–Base Additives via TG-FTIR and Kinetic Simulation. Ind. Eng. Chem. Res. 56, 5164–5173 (2017)

W. Kaewsakul, K. Sahakaro, W.K. Dierkes, J.W.M. Noordermeer, Optimization of rubber formulation for silica-reinforced natural rubber compounds. Rubber Chem. Technol. 86, 313–329 (2013)

Q. Hu, H.L. **, X.A. Chen, S. Wang, Thermal and FTIR spectral studies of N,N′-diphenylguanidine. J. Therm. Anal. Calorim. 110, 593–599 (2012)

J. Ramier, L. Chazeau, C. Gauthier, L. Guy, M.N. Bouchereau, Influence of silica and its different surface treatments on the vulcanization process of silica filled SBR. Rubber Chem. Technol. 80, 183–193 (2007)

Q. Pan, B. Wang, Z. Chen, J. Zhao, Reinforcement and antioxidation effects of antioxidant functionalized silica in styrene-butadiene rubber. Mater. Des. 50, 558–565 (2013)

C. Hayichelaeh et al., Silica-reinforced natural rubber tire tread compounds containing bio-based process oils. II: Influence of epoxide and amino functional groups. Rubber Chem. Technol. 93, 195–207 (2020)

P. Weng, Z. Tang, B. Guo, Effects of alkalinity of ionic liquid on catalyzed Silanization in rubber/Silica composites. Ind. Eng. Chem. Res. 58, 18654–18662 (2019)

Funding

Not applicable. This review article was not funded by any funding agencies.

Author information

Authors and Affiliations

Contributions

The authors confirm their contribution to the paper as follows: study conception and design: Jeevanandham N; data collection: Jeevanandham Neethirajan, Guo-Hua HU, and Kinsuk Naskar; analysis and interpretation of results: Jeevanandham Neethirajan, Arshad Rahman Parathodika, and Kinsuk Naskar; draft manuscript preparation: Jeevanandham Neethirajan. All authors reviewed the results and approved the final version of the manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

This review article does not contain any studies with human participants or animals performed by any of the authors.

Consent for publication

Not applicable.

Competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Neethirajan, J., Parathodika, A.R., Hu, GH. et al. Functional rubber composites based on silica-silane reinforcement for green tire application: the state of the art. Functional Composite Mater 3, 7 (2022). https://doi.org/10.1186/s42252-022-00035-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s42252-022-00035-7