Abstract

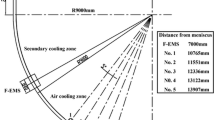

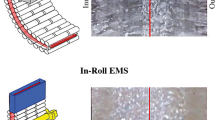

Final electromagnetic stirring (F-EMS) and thermal soft reduction (TSR) are techniques that improve the inner quality of continuous casting billets, but they have rarely been applied simultaneously. The application effects of F-EMS and TSR were compared, and a process integrating F-EMS and TSR was adopted for a billet continuous caster. A heat transfer model was established to calculate the thermal behavior of 82A tire cord steel billet. The locations of F-EMS and TSR were determined, followed by conducting a series of plant trials, involving F-EMS alone, TSR alone, and the integrated process of F-EMS and TSR. The results showed that F-EMS or TSR could effectively improve the inner quality of the billet under their respective suitable working conditions. Moreover, F-EMS was found to be more helpful in terms of improving central segregation, while TSR tended to improve V-segregation, central porosity, and pipe. The integration of F-EMS and TSR allowed the advantages of each technique to be utilized, thereby better improving the inner quality. Among all the working conditions, 82A steel billet showed optimum inner quality when the current of F-EMS was 240 A and the cooling intensity of TSR was 2.2 m3 h−1. These findings demonstrate that the integration of F-EMS and TSR is promising for application on continuous casting billets.

Similar content being viewed by others

References

K. Liu, Q. Sun, J. Zhang, C. Wang, Metall. Res. Technol. 113 (2016) 504.

Y. Chen, M.F. **ao, G.R. Wu, J. Iron Steel Res. Int. 17 (2010) No. 6, 1–5.

X. Zhao, J. Zhang, S. Lei, Y. Wang, Steel Res. Int. 85 (2014) 645–658.

J.P. Zhao, L. Liu, W.W. Wang, W.J. Zhou, H. Lu, Ironmak. Steelmak. 46 (2019) 227–234.

R. Wang, Y.P. Bao, Y.H. Li, H.H. An, Int. J. Miner. Metall. Mater. 23 (2016) 1150–1156.

C. **ao, J.M. Zhang, Y.Z. Luo, X.D. Wei, L. Wu, S.X. Wang, J. Iron Steel Res. Int. 20 (2013) No. 11, 13–20.

J. Li, B. Wang, Y. Ma, J. Cui, Mater. Sci. Eng. A 425 (2006) 201–204.

J. Zeng, W. Chen, S. Zhang, Y. Li, Q. Wang, ISIJ Int. 55 (2015) 2142–2149.

P. Sivesson, G. Hallen, B. Widell, Ironmak. Steelmak. 25 (1998) 239.

C.M. Raihle, P. Sivesson, M. Tukiainen, H. Fredriksson, Ironmak. Steelmak. 21 (1994) 487–495.

P. Sivesson, C.M. Raihle, J. Konttinen, Mater. Sci. Eng. A 173 (1993) 299–304.

J. Zeng, W. Chen, Q. Wang, G. Wang, Trans. Ind. Inst. Met. 69 (2016) 1623–1632.

A. Scholes, Ironmak. Steelmak. 32 (2005) 101–108.

H. An, Y.P. Bao, M. Wang, L.H. Zhao, Metall. Res. Technol. 114 (2017) 405.

H. Sun, L. Li, J. Wang, X. Cheng, F. Zhou, Ironmak. Steelmak. 45 (2018) 708–713.

A. Cristallini, A. Ferretti, R. Moretti, S. Simoni, in: Steelmaking Conf. Proc. 1994, pp. 309–315.

Y. Han, X. Wang, J. Zhang, F. Zeng, J. Chen, M. Guan, Q. Liu, Metals 9 (2019) 543.

Y. Han, W. Yan, J. Zhang, W. Chen, J. Chen, Q. Liu, ISIJ Int. 60 (2020) 106–113.

G. Engstrom, H. Fredriksson, B. Rogberg, Scand. J. Metall. 12 (1983) 3–12.

C.M. Raihle, H. Fredriksson, Metall. Mater. Trans. B 24 (1994) 123–133.

H. Mizukami, M. Komatsu, T. Kitagawa, K. Kawakami, Tetsu-to-Hagane 70 (1984) 194–200.

K.S. Oh, Y.W. Chang, ISIJ Int. 35 (1995) 866–875.

D. Jiang, M. Zhu, Metall. Mater. Trans. B 48 (2017) 444–455.

S. Luo, F.Y. Piao, D.B. Jiang, W.L. Wang, M.Y. Zhu, J. Iron Steel Res. Int. 21 (2014) 51–55.

M.R. Bridge, G.D. Rogers, Metall. Trans. B 15 (1984) 581–589.

S. Asai, N. Nishio, I. Muchi, Trans. Iron Steel Inst. Jpn. 22 (1982) 126–133.

V. Ludlow, A. Normanton, A. Anderson, M. Thiele, J. Ciriza, J. Laraudogoitia, W. Van Der Knoop, Ironmak. Steelmak. 32 (2005) 68–74.

J.J. Moore, N.A. Shah, Int. Met. Rev. 28 (1983) 336–356.

Acknowledgements

The authors acknowledge the financial support provided by the independent subject of State Key Laboratory of Advanced Metallurgy, University of Science and Technology Bei**g, China, grant number 41617003, which enabled the successful completion of the study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Han, Ys., Yan, W., Zhang, Js. et al. Comparison and integration of final electromagnetic stirring and thermal soft reduction on continuous casting billet. J. Iron Steel Res. Int. 28, 160–167 (2021). https://doi.org/10.1007/s42243-020-00412-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-020-00412-1