Abstract

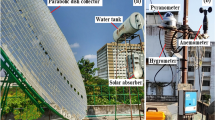

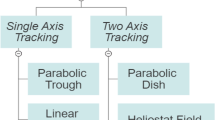

Solar energy has received substantial attention as a source of clean and sustainable power. Among various techniques, solar parabolic dish collectors (PDCs) show significant promise in effectively harnessing solar energy. However, maximizing their thermal efficiency requires overcoming challenges like heat loss and solar intermittency. This review article critically analyzes recent advancements in PDC technology, particularly those focused on improving thermal performance. Specifically, we have explored advancements in receiver geometries, integration of thermal energy storage, and the utilization of nanofluids as heat transfer fluids (HTFs). Our review method involves examining the effectiveness of various receiver geometries, from traditional designs to creative new configurations, within PDC systems. Furthermore, the paper investigates the potential of employing nanofluids as HTFs in different receiver geometries to enhance the overall thermal performance. As a novel contribution, we propose the synergistic integration of optimized receiver geometries, nanofluids, and phase change materials for thermal energy storage within PDCs. This innovative approach has the potential to revolutionize PDC technology by minimizing heat loss, improving heat transfer, and mitigating the impact of solar intermittency. Finally, the review identifies challenges associated with PDC technology and explores how integration with these advanced strategies can contribute to more efficient and sustainable energy conversion.

Similar content being viewed by others

Data availability

Data sharing is not applicable to this article as no new data were created or analyzed in this study.

Abbreviations

- A :

-

Area, m2

- A dish :

-

Aperture area of the parabolic dish collector, m2

- A rec. :

-

Area of receiver, m2

- A s :

-

Surface area of receiver, m2

- a :

-

Semiminor axis, m

- b :

-

Major axis, m

- C :

-

Geometric concentration ratio

- C p :

-

Specific heat, kJ/kg.K

- C irr :

-

Irradiation concentration ratio

- D dish :

-

Diameter of dish, m

- D o :

-

Diameter of the inner hole of the dish aperture, m

- D rec. :

-

Diameter of receiver, m

- D h :

-

Hydraulic diameter, m

- d :

-

Diameter, m

- E s :

-

Solar energy flux, W

- E u :

-

Usable exergy output, W

- \(\overrightarrow{F}\) :

-

Force, N

- F :

-

Shape factor, geometric factor

- F R :

-

Heat removal factor

- f :

-

Focal length of parabolic dish collector, m

- LPG:

-

Liquid petroleum gas

- g :

-

Acceleration due to gravity, m/s2

- Gr:

-

Grashof number

- h :

-

Heat transfer coefficient, W/m2.K

- H :

-

Height of parabolic dish collector, m

- I S :

-

Direct normal irradiance, W/m2

- k :

-

Thermal conductivity, W/m.K

- K B :

-

Boltzmann constant, J/K

- L :

-

Length of cylindrical receiver, m

- m :

-

Mass flow rate, kg/s

- Nu:

-

Nusselt number

- Nueq. :

-

Equivalent Nusselt number

- N RC :

-

Radiation conduction number

- P :

-

Pressure, N/m2

- Pr:

-

Prandtl number

- ∆P :

-

Pressure drop, kPa

- Q s :

-

Incident energy from sun, W

- Q r :

-

Energy available at receiver, W

- Q u :

-

Useful heat gain, W

- Q loss :

-

Heat loss, W

- Ra:

-

Rayleigh number

- Re:

-

Reynolds number

- ∆S :

-

Entropy increase, J/K

- T :

-

Temperature, K

- T R :

-

Temperature ratio

- u :

-

Velocity, m/s

- U L :

-

Overall heat loss coefficient, W/m2.K

- x :

-

Thickness, m

- μ :

-

Dynamic viscosity, N.s/m2

- μ′ :

-

Dynamic viscosity of drop, N.s/m2

- π :

-

Constant Pi

- η :

-

Efficiency, %

- δ :

-

Solar declination angle, °

- ϕ rim :

-

Rim angle of parabolic dish collector, °

- ϕ :

-

Nanoparticle concentration

- ϕ m :

-

Maximum concentration at which flow can occur

- θ :

-

Half acceptance angle, °

- ρ :

-

Density, kg/m3

- ρ c :

-

Reflectivity of collector

- ε v :

-

Intrinsic viscosity of the suspension, m2/kg

- ε :

-

Emissivity

- ε eff :

-

Effective emissivity

- ε s :

-

Actual emissivity of the cavity inner surfaces

- σ :

-

Stefan–Boltzmann constant, W/m2.K4

- β :

-

Ratio of the nanolayer thickness to the particle radius

- ξ :

-

Receiver inclination angle, °

- α :

-

Fan-shaped unfilled angle, °

- α eff :

-

Effective absorptivity

- α s :

-

Absorptivity of radiative surface

- α c :

-

Absorptivity of collector

- τ :

-

Transmissivity

- (τα):

-

Effective transmittance–absorptance product

- amb:

-

Ambient

- ap:

-

Cavity aperture

- av:

-

Average

- bf:

-

Basefluid

- com:

-

Combined

- conv:

-

Convection

- cond:

-

Conduction

- dr:

-

Drift

- eq.:

-

Equivalent

- ex:

-

Exergy

- ex, Surface:

-

Exterior cavity surface

- f :

-

Fluid

- forced:

-

Forced convection

- o :

-

Outlet

- i :

-

Inlet

- ins:

-

Insulation

- mf:

-

Mean fluid

- nat :

-

Natural

- nf:

-

Nanofluid

- np :

-

Nanoparticle

- opt, conc:

-

Optical, concentrator

- opt, rec:

-

Optical, receiver

- out:

-

Exterior of an insulated receiver

- rad:

-

Radiative

- rad, em:

-

Radiation losses due to emission

- rad, ref:

-

Radiation losses due to reflection

- rec:

-

Receiver

- S :

-

Surface

- th:

-

Thermal

- ∞ :

-

Ambient air

References

Mazur A (2011) Does increasing energy or electricity consumption improve quality of life in industrial nations? Energy Policy 39:2568–2572. https://doi.org/10.1016/j.enpol.2011.02.024

Rostami M, Pirvaram A, Talebzadeh N, O’Brien PG (2021) Numerical evaluation of one-dimensional transparent photonic crystal heat mirror coatings for parabolic dish concentrator receivers. Renew Energy 171:1202–1212. https://doi.org/10.1016/j.renene.2021.03.007

Mourad A, Aissa A, Said Z et al (2022) Recent advances on the applications of phase change materials for solar collectors, practical limitations, and challenges: a critical review. J Energy Storage 49:104186. https://doi.org/10.1016/j.est.2022.104186

Kalogirou SA (2014) Solar Energy engineering: processes and systems. Academic Press, Oxford, UK

Garg HP (1987) Advances in solar energy technology, 1st edn. Springer, Dordrecht, Holland

Keith L, Wes S (2021) Concentrating solar power technology principles, developments, and applications. Woodhead Publishing Limited, Kidlington

Bopche SB, Kumar R, Singh I (2021) Development of a novel two-stage parabolic dish collector-receiver system for efficiency improvement. Energy Sources Part A Recovery Utilization Environ Eff 43:2692–2723. https://doi.org/10.1080/15567036.2020.1861134

Allouhi H, Allouhi A, Buker MS et al (2022) Recent advances, challenges, and prospects in solar dish collectors: designs, applications, and optimization frameworks. Sol Energy Mater Sol Cells 241:111743. https://doi.org/10.1016/j.solmat.2022.111743

Zayed ME, Zhao J, Elsheikh AH et al (2021) A comprehensive review on Dish/Stirling concentrated solar power systems: design, optical and geometrical analyses, thermal performance assessment, and applications. J Clean Prod 283:124664. https://doi.org/10.1016/j.jclepro.2020.124664

Malik MZ, Shaikh PH, Zhang S et al (2022) A review on design parameters and specifications of parabolic solar dish Stirling systems and their applications. Energy Rep 8:4128–4154. https://doi.org/10.1016/j.egyr.2022.03.031

Li H, Huang W, Huang F et al (2013) Optical analysis and optimization of parabolic dish solar concentrator with a cavity receiver. Sol Energy 92:288–297. https://doi.org/10.1016/j.solener.2013.03.011

**ao L, Guo FW, Wu SY, Chen ZL (2020) A comprehensive simulation on optical and thermal performance of a cylindrical cavity receiver in a parabolic dish collector system. Renew Energy 145:878–892. https://doi.org/10.1016/j.renene.2019.06.068

Hassan A, Quanfang C, Abbas S et al (2021) An experimental investigation on thermal and optical analysis of cylindrical and conical cavity copper tube receivers design for solar dish concentrator. Renew Energy 179:1849–1864. https://doi.org/10.1016/j.renene.2021.07.145

Daabo AM, Mahmoud S, Al-Dadah RK (2016) The effect of receiver geometry on the optical performance of a small-scale solar cavity receiver for parabolic dish applications. Energy 114:513–525. https://doi.org/10.1016/j.energy.2016.08.025

Yan J, Peng YD, Wang H (2020) Assessing the impact of non-ideal optical factors on optimized solar dish collector system with mirror rearrangement. Int J Energy Res 44:8799–8822. https://doi.org/10.1002/er.5575

Bellos E, Bousi E, Tzivanidis C, Pavlovic S (2019) Optical and thermal analysis of different cavity receiver designs for solar dish concentrators. Energy Convers Manag X 2:100013. https://doi.org/10.1016/j.ecmx.2019.100013

Pavlovic S, Daabo AM, Bellos E et al (2017) Experimental and numerical investigation on the optical and thermal performance of solar parabolic dish and corrugated spiral cavity receiver. J Clean Prod 150:75–92. https://doi.org/10.1016/j.jclepro.2017.02.201

Pavlović SR, Bellos E, Stefanović VP et al (2016) Design, simulation, and optimization of a solar dish collector with spiral-coil thermal absorber. Therm Sci 20:1387–1397. https://doi.org/10.2298/TSCI160213104P

Pavlovic SR, Stefanovic VP (2015) Ray tracing study of optical characteristics of the solar image in the receiver for a thermal solar parabolic dish collector. J Solar Energy 2015:1–10. https://doi.org/10.1155/2015/326536

Loni R, Pavlovic S, Bellos E et al (2018) Thermal and exergy performance of a nanofluid-based solar dish collector with spiral cavity receiver. Appl Therm Eng 135:206–217. https://doi.org/10.1016/j.applthermaleng.2018.02.070

Stefanovic VP, Pavlovic SR, Bellos E, Tzivanidis C (2018) A detailed parametric analysis of a solar dish collector. Sustain Energy Technol Assess 25:99–110. https://doi.org/10.1016/j.seta.2017.12.005

Chang H, Duan C, Wen K et al (2015) Modeling study on the thermal performance of a modified cavity receiver with glass window and secondary reflector. Energy Convers Manage 106:1362–1369. https://doi.org/10.1016/j.enconman.2015.10.043

Abid M, Khan MS, Hussain Ratlamwala TA (2019) Thermodynamic performance evaluation of a solar parabolic dish assisted multigeneration system. J Solar Energy Eng Trans ASME 141:1–10. https://doi.org/10.1115/1.4044022

Bopche S, Rana K, Kumar V (2020) Performance improvement of a modified cavity receiver for parabolic dish concentrator at medium and high heat concentration. Sol Energy 209:57–78. https://doi.org/10.1016/j.solener.2020.08.089

Madadi V, Tavakoli T, Rahimi A (2015) Estimation of heat loss from a cylindrical cavity receiver based on simultaneous energy and exergy analyses. J Non-Equilib Thermodyn 40:49–61. https://doi.org/10.1515/jnet-2014-0029

Aslfattahi N, Loni R, Bellos E et al (2021) Efficiency enhancement of a solar dish collector operating with a novel soybean oil-based-MXene nanofluid and different cavity receivers. J Clean Prod 317:128430. https://doi.org/10.1016/j.jclepro.2021.128430

Sendhil Kumar N, Reddy KS (2007) Numerical investigation of natural convection heat loss in modified cavity receiver for fuzzy focal solar dish concentrator. Sol Energy 81:846–855. https://doi.org/10.1016/j.solener.2006.11.008

Azzouzi D, Boumeddane B, Abene A (2017) Experimental and analytical thermal analysis of cylindrical cavity receiver for solar dish. Renew Energy 106:111–121. https://doi.org/10.1016/j.renene.2016.12.102

Bekele EA, Ancha VR, Binchebo TL (2022) Analysis of solar irradiance variation on heat flux and temperature distribution for a dish concentrator receiver. ASME Open J Eng 1:1–9. https://doi.org/10.1115/1.4053963

Hafez AZ, Soliman A, El-Metwally KA, Ismail IM (2016) Solar parabolic dish Stirling engine system design, simulation, and thermal analysis. Energy Convers Manage 126:60–75. https://doi.org/10.1016/j.enconman.2016.07.067

Sup BA, Zainudin MF, ZanariahShamsirAli T et al (2015) Effect of rim angle to the flux distribution diameter in solar parabolic dish collector. Energy Procedia 68:45–52. https://doi.org/10.1016/j.egypro.2015.03.231

Soltani S, Bonyadi M, Madadi Avargani V (2019) A novel optical-thermal modeling of a parabolic dish collector with a helically baffled cylindrical cavity receiver. Energy 168:88–98. https://doi.org/10.1016/j.energy.2018.11.097

Zayed ME, Zhao J, Li W et al (2020) Performance prediction and techno-economic analysis of solar dish/stirling system for electricity generation. Appl Therm Eng 164:114427. https://doi.org/10.1016/j.applthermaleng.2019.114427

Thirunavukkarasu V, Nair VU, Tiwari K, Cheralathan M (2022) Experimental investigation on thermal performance of cavity receiver integrated with short-term thermal energy storage for a solar parabolic dish concentrator. J Therm Anal Calorim 147:741–752. https://doi.org/10.1007/s10973-020-10387-6

Khan MMA, Ibrahim NI, Mahbubul IM et al (2018) Evaluation of solar collector designs with integrated latent heat thermal energy storage: a review. Sol Energy 166:334–350. https://doi.org/10.1016/j.solener.2018.03.014

Bianco N, Fragnito A, Iasiello M, Maria Mauro G (2024) Multiscale analysis of a seasonal latent thermal energy storage with solar collectors for a single-family building. Therm Sci Eng Progress 50:102538. https://doi.org/10.1016/j.tsep.2024.102538

Gholikhani M, Roshani H, Dessouky S, Papagiannakis AT (2020) A critical review of roadway energy harvesting technologies. Appl Energy 261:114388. https://doi.org/10.1016/j.apenergy.2019.114388

Khlebtsov NG, Trachuk LA, Mel’nikov AG (2005) The effect of the size, shape, and structure of metal nanoparticles on the dependence of their optical properties on the refractive index of a disperse medium. Optics Spectrosc (English translation of Optika i Spektroskopiya) 98:77–83. https://doi.org/10.1134/1.1858043

Chen M, He Y, Zhu J, Kim DR (2016) Enhancement of photo-thermal conversion using gold nanofluids with different particle sizes. Energy Convers Manage 112:21–30. https://doi.org/10.1016/j.enconman.2016.01.009

Choi SUS, Eastman JA (1995) Enhancing thermal conductivity of fluids with nanoparticles

Hamzat AK, Omisanya MI, Sahin AZ et al (2022) Application of nanofluid in solar energy harvesting devices: a comprehensive review. Energy Convers Manage 266:115790. https://doi.org/10.1016/j.enconman.2022.115790

Al-Aasam AB, Ibrahim A, Sopian K et al (2023) Nanofluid-based photovoltaic thermal solar collector with nanoparticle-enhanced phase change material (Nano-PCM) and twisted absorber tubes. Case Stud Therm Eng 49:103299. https://doi.org/10.1016/j.csite.2023.103299

Abdel-Aziz EA, Mansour TM, Dawood MMK et al (2023) Exergoeconomic and enviroeconomic evaluations of conventional solar still using PCM and electric heater powered by solar energy: an experimental study. Environ Sci Pollut Res 30:66135–66156. https://doi.org/10.1007/s11356-023-26761-4

Rajendran DR, Ganapathy Sundaram E, Jawahar P et al (2020) Review on influencing parameters in the performance of concentrated solar power collector based on materials, heat transfer fluids and design. J Therm Anal Calorim 140:33–51. https://doi.org/10.1007/s10973-019-08759-8

Bellos E, Tzivanidis C (2019) A review of concentrating solar thermal collectors with and without nanofluids. J Therm Anal Calorim 135:763–786. https://doi.org/10.1007/s10973-018-7183-1

Verma SK, Tiwari AK, Tripathi M (2018) An evaluative observation on impact of optical properties of nanofluids in performance of photo-thermal concentrating systems. Sol Energy 176:709–724. https://doi.org/10.1016/j.solener.2018.10.084

Maurya A, Kumar A, Sharma D (2022) A comprehensive review on performance assessment of solar cavity receiver with parabolic dish collector. Energy Sources Part A Recovery Utilization Environ Eff 44:4808–4845. https://doi.org/10.1080/15567036.2022.2080890

Kumar KH, Daabo AM, Karmakar MK, Hirani H (2022) Solar parabolic dish collector for concentrated solar thermal systems: a review and recommendations. Environ Sci Pollut Res 29:32335–32367. https://doi.org/10.1007/s11356-022-18586-4

Kasaeian A, Kouravand A, Vaziri Rad MA et al (2021) Cavity receivers in solar dish collectors: a geometric overview. Renew Energy 169:53–79. https://doi.org/10.1016/j.renene.2020.12.106

Coventry J, Andraka C (2017) Dish systems for CSP. Sol Energy. https://doi.org/10.1016/j.solener.2017.02.056

Azzouzi D, Boumeddane B, Abene A, Said N (2015) Experimental and parametric study of a solar paraboloid designed to receive a Stirling engine. Mech Ind. https://doi.org/10.1051/meca/2014082

Subramaniam SB, Senthil R (2021) Heat transfer enhancement of concentrated solar absorber using hollow cylindrical fins filled with phase change material. Int J Hydrogen Energy 46:22344–22355. https://doi.org/10.1016/j.ijhydene.2021.04.061

Kalbande VP, Fating G, Mohan M et al (2022) Experimental and theoretical study for suitability of hybrid nano enhanced phase change material for thermal energy storage applications. J Energy Storage 51:104431. https://doi.org/10.1016/j.est.2022.104431

Hafez AZ, Soliman A, El-Metwally KA, Ismail IM (2017) Design analysis factors and specifications of solar dish technologies for different systems and applications. Renew Sustain Energy Rev 67:1019–1036. https://doi.org/10.1016/j.rser.2016.09.077

Santhi Rekha SM, Sukchai S (2018) Design of phase change material based domestic solar cooking system for both indoor and outdoor cooking applications. J Solar Energy Eng Trans ASME 140:1–8. https://doi.org/10.1115/1.4039605

Pavlovic S, Loni R, Bellos E et al (2018) Comparative study of spiral and conical cavity receivers for a solar dish collector. Energy Convers Manage 178:111–122. https://doi.org/10.1016/j.enconman.2018.10.030

Prakash M (2014) Numerical study of natural convection heat loss from cylindrical solar cavity receivers. ISRN Renew Energy 2014:1–7. https://doi.org/10.1155/2014/104686

Vishnu SK, Senthil R (2023) Experimental performance evaluation of a solar parabolic dish collector using spiral flow path receiver. Appl Therm Eng. https://doi.org/10.1016/j.applthermaleng.2023.120979

Vishnu SK, Senthil R (2023) Experimental performance and economic analysis of finned solar receiver for parabolic dish solar collector. Heliyon 9:e21236. https://doi.org/10.1016/j.heliyon.2023.e21236

Sahu SK, K AS, Natarajan SK (2021) Impact of double trumpet-shaped secondary reflector on flat receiver of a solar parabolic dish collector system. Energy Sources Part A Recovery Utilization Environ Eff 00:1–19. https://doi.org/10.1080/15567036.2021.1918803

Swanepoel JK, le Roux WG, Lexmond AS, Meyer JP (2021) Helically coiled solar cavity receiver for micro-scale direct steam generation. Appl Therm Eng 185:116427. https://doi.org/10.1016/j.applthermaleng.2020.116427

Sharma S, Saha SK, Kedare SB, Singh S (2020) Experimental and numerical study of thermal performance of helical coil receiver with Fresnel lens. Appl Therm Eng 165:114608. https://doi.org/10.1016/j.applthermaleng.2019.114608

Murugavel KK, Vivekanandan M, Kumaran ET et al (2020) Comparative study on convection loss of different shape solar dish collector cavity receivers at different positions using CFD. Mater Today Proc 37:3091–3095. https://doi.org/10.1016/j.matpr.2020.09.018

Awasthi K, Khan MK (2019) Performance evaluation of coiled tube receiver cavity for a concentrating collector. Renew Energy 138:666–674. https://doi.org/10.1016/j.renene.2019.02.015

Bopche S, Lamba S (2020) Experimental evaluation study of collection efficiency of cavity receivers. World J Eng 17:161–173. https://doi.org/10.1108/WJE-05-2019-0156

Sendhil Kumar N, Reddy KS (2008) Comparison of receivers for solar dish collector system. Energy Convers Manage 49:812–819. https://doi.org/10.1016/j.enconman.2007.07.026

Loni R, Askari Asli-Ardeh E, Ghobadian B et al (2018) Numerical comparison of a solar dish concentrator with different cavity receivers and working fluids. J Clean Prod 198:1013–1030. https://doi.org/10.1016/j.jclepro.2018.07.075

Pavlovic S, Bellos E, Le Roux WG et al (2017) Experimental investigation and parametric analysis of a solar thermal dish collector with spiral absorber. Appl Therm Eng 121:126–135. https://doi.org/10.1016/j.applthermaleng.2017.04.068

Pratik NA, Ali MH, Lubaba N et al (2024) Numerical investigation to optimize the modified cavity receiver for enhancement of thermal performance of solar parabolic dish collector system. Energy 290:130133. https://doi.org/10.1016/j.energy.2023.130133

Daabo AM, Bellos E, Pavlovic S et al (2020) Characterization of a micro thermal cavity receiver–experimental and analytical investigation. Therm Sci Eng Progress 18:100554. https://doi.org/10.1016/j.tsep.2020.100554

Li X, Dai YJ, Wang RZ (2015) Performance investigation on solar thermal conversion of a conical cavity receiver employing a beam-down solar tower concentrator. Sol Energy 114:134–151. https://doi.org/10.1016/j.solener.2015.01.033

Mandal P, Rajan A, Reddy KS (2024) Optical and thermal investigation of hyperbolic cavity receiver with secondary reflector for solar parabolic dish collector. Therm Sci Eng Progress 47:102350. https://doi.org/10.1016/j.tsep.2023.102350

Rajan A, Reddy KS (2024) Integrated optical-thermal model and deep learning technique to estimate the performance of a conical cavity receiver coupled solar parabolic dish collector. Energy Convers Manage 301:118052. https://doi.org/10.1016/j.enconman.2023.118052

Jeter SM (1986) The distribution of concentrated solar radiation in paraboloidal collectors. J Solar Energy Eng Trans ASME 108:219–225. https://doi.org/10.1115/1.3268096

Taumoefolau T, Paitoonsurikarn S, Hughes G, Lovegrove K (2004) Experimental investigation of natural convection heat loss from a model solar concentrator cavity receiver. J Solar Energy Eng Trans ASME 126:801–807. https://doi.org/10.1115/1.1687403

Loni R, Najafi G, Asli-Ardeh EA et al (2019) Performance investigation of solar ORC using different nanofluids. Appl Sci (Switzerland). https://doi.org/10.3390/app9153048

Karimi R, Gheinani TT, Madadi Avargani V (2018) A detailed mathematical model for thermal performance analysis of a cylindrical cavity receiver in a solar parabolic dish collector system. Renew Energy 125:768–782. https://doi.org/10.1016/j.renene.2018.03.015

Bopche SB, Kumar S (2019) Experimental investigations on thermal performance characteristics of a solar cavity receiver. Int J Energy Environ Eng 10:463–481. https://doi.org/10.1007/s40095-019-00321-4

Yuan Y, Wu G, Yang Q et al (2021) Experimental and analytical optical-thermal performance of evacuated cylindrical tube receiver for solar dish collector. Energy 234:121301. https://doi.org/10.1016/j.energy.2021.121301

Esfanjani P, Mahmoudi A, Valipour MS, Rashidi S (2023) An experimental study on a cylindrical-conical cavity receiver for the parabolic dish collector. Environ Sci Pollut Res 30:6517–6529. https://doi.org/10.1007/s11356-022-22569-w

Loni R, Askari Asli-Ardeh E, Ghobadian B et al (2019) Effects of size and volume fraction of alumina nanoparticles on the performance of a solar organic Rankine cycle. Energy Convers Manage 182:398–411. https://doi.org/10.1016/j.enconman.2018.12.079

Diver RB (1987) Reoeiver/reactor concepts for thermochemical transport of solar energy. J Solar Energy Eng Trans ASME 109:199–204. https://doi.org/10.1115/1.3268206

Abdullatif Alshuhail L, Shaik F, Syam Sundar L (2023) Thermal efficiency enhancement of mono and hybrid nanofluids in solar thermal applications–a review. Alex Eng J 68:365–404. https://doi.org/10.1016/j.aej.2023.01.043

Khodadadi H, Aghakhani S, Majd H et al (2018) A comprehensive review on rheological behavior of mono and hybrid nanofluids: effective parameters and predictive correlations. Int J Heat Mass Transf 127:997–1012. https://doi.org/10.1016/j.ijheatmasstransfer.2018.07.103

Babu JAR, Kumar KK, Rao SS (2017) State-of-art review on hybrid nanofluids State-of-art review on hybrid nano fluids. Renew Sustain Energy Rev 77:551–565

Said Z, Saidur R, Sabiha MA et al (2016) Energy and exergy efficiency of a flat plate solar collector using pH treated Al2O3 nanofluid. J Clean Prod 112:3915–3926. https://doi.org/10.1016/j.jclepro.2015.07.115

AbdEl-Rady Abu-Zeid M, Elhenawy Y, Bassyouni M et al (2024) Performance enhancement of flat-plate and parabolic trough solar collector using nanofluid for water heating application. Results Eng 21:101673. https://doi.org/10.1016/j.rineng.2023.101673

Michael JJ, Iniyan S (2015) Performance of copper oxide/water nanofluid in a flat plate solar water heater under natural and forced circulations. Energy Convers Manage 95:160–169. https://doi.org/10.1016/j.enconman.2015.02.017

Ajeena AM, Farkas I, Víg P (2024) Energy and exergy assessment of a flat plate solar thermal collector by examine silicon carbide nanofluid: an experimental study for sustainable energy. Appl Therm Eng 236:121844. https://doi.org/10.1016/j.applthermaleng.2023.121844

Selvam L, Aruna M, Hossain I, Karthigairajan M, Prabagaran S, Mohanavel V, Seikh AH, Abul Kalam Md (2024) Impact of hybrid nanofluid on thermal behavior of flat-plate solar collector: performance study. J Therm Anal Calorim 149(10):5047–5057. https://doi.org/10.1007/s10973-024-12994-z

Tong Y, Wang R, Wang S et al (2023) Comparison and evaluation of energetic and exergetic performance of an evacuated tube solar collector using various nanofluid. Process Saf Environ Prot 174:585–594. https://doi.org/10.1016/j.psep.2023.04.025

Firoozzadeh M, Shafiee M (2023) Thermodynamic analysis on using titanium oxide/oil nanofluid integrated with porous medium in an evacuated tube solar water heater. J Therm Anal Calorim 148:8309–8322. https://doi.org/10.1007/s10973-023-11961-4

Sathish T, Kathirvel S, Dwivedi YD et al (2024) Performance enhancement by tungsten trioxide and silicon dioxide mixed nanofluids in solar collector of evacuated tube type. Case Stud Thermal Eng 55:104098. https://doi.org/10.1016/j.csite.2024.104098

Moosavian SF, Ha**ezhad A, Fattahi R, Shahee A (2023) Evaluating the effect of using nanofluids on the parabolic trough collector’s performance. Energy Sci Eng 11:3512–3535. https://doi.org/10.1002/ese3.1537

Safari Chukami B, Heyhat MM (2024) Numerical investigation on the effect of Al2O3-water nanofluid on direct steam generation in parabolic trough collectors. Appl Therm Eng 241:122300. https://doi.org/10.1016/j.applthermaleng.2023.122300

Cui F, Liu F, Tong Y, Wang S, Guo W, Han T, Qiu X (2022) Energy and exergy assessment of evacuated tube solar collector using water, Fe3O4 nanofluid and Fe3O4/MWCNT hybrid nanofluid. Process Saf Environ Prot 163:236–243. https://doi.org/10.1016/j.psep.2022.05.023

Bellos E, Tzivanidis C (2018) Thermal analysis of parabolic trough collector operating with mono and hybrid nanofluids. Sustain Energy Technol Assess 26:105–115. https://doi.org/10.1016/j.seta.2017.10.005

Ekiciler R, Arslan K, Turgut O, Kurşun B (2020) Effect of hybrid nanofluid on heat transfer performance of parabolic trough solar collector receiver. J Therm Anal Calorim. https://doi.org/10.1007/s10973-020-09717-5

Okonkwo EC, Wole-Osho I, Kavaz D et al (2020) Thermodynamic evaluation and optimization of a flat plate collector operating with alumina and iron mono and hybrid nanofluids. Sustain Energy Technol Assess 37:100636. https://doi.org/10.1016/j.seta.2020.100636

Chaji H, Ajabshirchi Y, Esmaeilzadeh E et al (2013) Experimental study on thermal efficiency of flat plate solar collector using tio2/water nanofluid. Mod Appl Sci 7:60–69. https://doi.org/10.5539/mas.v7n10p60

Faizal M, Saidur R, Mekhilef S et al (2015) Energy, economic, and environmental analysis of a flat-plate solar collector operated with SiO2nanofluid. Clean Technol Environ Policy 17:1457–1473. https://doi.org/10.1007/s10098-014-0870-0

Tong Y, Chi X, Kang W, Cho H (2020) Comparative investigation of efficiency sensitivity in a flat plate solar collector according to nanofluids. Appl Thermal Eng. https://doi.org/10.1016/j.applthermaleng.2020.115346

Nuhash MM, Alam MI, Zihad A et al (2023) Enhancing energy harvesting performance of a flat plate solar collector through integrated carbon-based and metal-based nanofluids. Results Eng 19:101276. https://doi.org/10.1016/j.rineng.2023.101276

Ajeena AM, Farkas I, Víg P (2023) Performance enhancement of flat plate solar collector using ZrO2-SiC/DW hybrid nanofluid: a comprehensive experimental study. Energy Convers Manag X 20:100458. https://doi.org/10.1016/j.ecmx.2023.100458

Eidan AA, Alsahlani A, Alshukri MJ, Alsabery AI (2023) Experimental investigation of a solar evacuated tube collector embedded with a heat pipe using different nanofluids and controlled mechanical exciting pulsations. Int J Thermofluids 20:100415. https://doi.org/10.1016/j.ijft.2023.100415

Amraee AA, Yazdi ME, Lavasani AM (2024) Numerical simulation of nanofluid in central tube of solar collector by two-phase mixture approach. Environ Prog Sustain Energy 43:1–11. https://doi.org/10.1002/ep.14247

Khan MS, Abid M, Ali HM et al (2018) Comparative performance assessment of solar dish assisted s-CO2 brayton cycle using nanofluids. Appl Therm Eng. https://doi.org/10.1016/j.applthermaleng.2018.11.021

Ouyang P, Xu YP, Qi LY et al (2021) Comprehensive evaluation of flat plate and parabolic dish solar collectors’ performance using different operating fluids and MWCNT nanofluid in different climatic conditions. Energy Rep 7:2436–2451. https://doi.org/10.1016/j.egyr.2021.04.046

Loni R, Askari Asli-Areh E, Ghobadian B et al (2020) Research and review study of solar dish concentrators with different nanofluids and different shapes of cavity receiver: experimental tests. Renew Energy 145:783–804. https://doi.org/10.1016/j.renene.2019.06.056

Loni R, Asli-Ardeh EA, Ghobadian B, Kasaeian A (2018) Experimental study of carbon nano tube/oil nanofluid in dish concentrator using a cylindrical cavity receiver: outdoor tests. Energy Convers Manage 165:593–601. https://doi.org/10.1016/j.enconman.2018.03.079

Loni R, Asli-ardeh EA, Ghobadian B et al (2018) Thermal performance comparison between Al2O3/oil and SiO2/oil nano fl uids in cylindrical cavity receiver based on experimental study. Renew Energy 129:652–665. https://doi.org/10.1016/j.renene.2018.06.029

Loni R, Asli-Ardeh EA, Ghobadian B et al (2018) GMDH modeling and experimental investigation of thermal performance enhancement of hemispherical cavity receiver using MWCNT/oil nanofluid. Sol Energy 171:790–803. https://doi.org/10.1016/j.solener.2018.07.003

Loni R, Askari Asli-ardeh E, Ghobadian B et al (2017) Thermodynamic analysis of a solar dish receiver using different nanofluids. Energy 133:749–760. https://doi.org/10.1016/j.energy.2017.05.016

Alnaqi AA, Alsarraf J, Al-Rashed AAAA (2021) Numerical investigation of hydrothermal efficiency of a parabolic dish solar collector filled with oil based hybrid nanofluid. J Taiwan Inst Chem Eng 124:238–257. https://doi.org/10.1016/j.jtice.2021.04.011

Alsabery AI, Abosinnee AS, Al-Hadraawy SK et al (2023) Convection heat transfer in enclosures with inner bodies: a review on single and two-phase nanofluid models. Renew Sustain Energy Rev 183:113424. https://doi.org/10.1016/j.rser.2023.113424

Kakaç S, Pramuanjaroenkij A (2016) Single-phase and two-phase treatments of convective heat transfer enhancement with nanofluids-a state-of-the-art review. Int J Therm Sci 100:75–97. https://doi.org/10.1016/j.ijthermalsci.2015.09.021

Eshgarf H, Nadooshan AA, Raisi A (2023) A review of multi-phase and single-phase models in the numerical simulation of nanofluid flow in heat exchangers. Eng Anal Boundary Elem 146:910–927. https://doi.org/10.1016/j.enganabound.2022.10.013

Habeeb AS, Karamallah AA, Aljabair S (2022) Review of computational multi-phase approaches of nano-fluids filled systems. Thermal Sci Eng Progress 28:101175. https://doi.org/10.1016/j.tsep.2021.101175

Brinkman HC (1952) The viscosity of concentrated suspensions and solutions. J Chem Phys 20:571. https://doi.org/10.1063/1.1700493

Meyer JP, Adio SA, Sharifpur M, Nwosu PN (2016) The viscosity of nanofluids: a review of the theoretical, empirical, and numerical models. Heat Transf Eng 37:387–421. https://doi.org/10.1080/01457632.2015.1057447

Taylor GI (1932) The viscosity of a fluid containing small drops of another fluid. Proc R Soc 138:41–48

Jeffery GB (1922) The motion of ellipsoidal particles immersed in a viscous fluid. Proc R Soc A Math Phys Eng Sci 102:161–179

Thomas CU, Muthukumar M (1991) Three-body hydrodynamic effects on viscosity of suspensions of spheres. J Chem Phys 94:5180–5189. https://doi.org/10.1063/1.460555

Hatschek E (1913) The general theory of viscosity of two-phase systems. Trans Faraday Soc 9:80–92. https://doi.org/10.1039/tf9130900080

Chen H, Ding Y, Tan C (2007) Rheological behaviour of nanofluids. New J Phys. https://doi.org/10.1088/1367-2630/9/10/367

James Clerk Maxwell (1873) A Treatise on Electricity and Magnetism. Cambridge University Press, Cambridge

Hamilton RL (1962) Thermal conductivity of heterogeneous two-component systems. Ind Eng Chem Fundam 1:187–191. https://doi.org/10.1021/i160003a005

Bruggeman DAG (1937) Berechnung verschiedener physikalischer Konstanten von heterogenen Substanzen. III. Die elastischen Konstanten der quasiisotropen Mischkörper aus isotropen Substanzen. Ann Phys 421:160–178. https://doi.org/10.1002/andp.19374210205

Das PK (2017) A review based on the effect and mechanism of thermal conductivity of normal nanofluids and hybrid nanofluids. J Mol Liq 240:420–446. https://doi.org/10.1016/j.molliq.2017.05.071

Yu W, Choi SUS (2004) The role of interfacial layers in the enhanced thermal conductivity of nanofluids: a renovated Hamilton-Crosser model. J Nanopart Res 6:355–361. https://doi.org/10.1007/s11051-004-2601-7

Xuan Y, Li Q, Hu W (2003) Aggregation structure and thermal conductivity of nanofluids. AIChE J 49:1038–1043. https://doi.org/10.1002/aic.690490420

Maïga SEB, Nguyen CT, Galanis N, Roy G (2004) Heat transfer behaviours of nanofluids in a uniformly heated tube. Superlattices Microstruct 35:543–557. https://doi.org/10.1016/j.spmi.2003.09.012

Namburu PK, Das DK, Tanguturi KM, Vajjha RS (2009) Numerical study of turbulent flow and heat transfer characteristics of nanofluids considering variable properties. Int J Therm Sci 48:290–302. https://doi.org/10.1016/j.ijthermalsci.2008.01.001

Bayat J, Nikseresht AH (2012) Thermal performance and pressure drop analysis of nanofluids in turbulent forced convective flows. Int J Therm Sci 60:236–243. https://doi.org/10.1016/j.ijthermalsci.2012.04.012

Mokmeli A, Saffar-Avval M (2010) Prediction of nanofluid convective heat transfer using the dispersion model. Int J Therm Sci 49:471–478. https://doi.org/10.1016/j.ijthermalsci.2009.09.005

Özerinç S, Yazcoglu AG, Kakaç S (2012) Numerical analysis of laminar forced convection with temperature-dependent thermal conductivity of nanofluids and thermal dispersion. Int J Therm Sci 62:138–148. https://doi.org/10.1016/j.ijthermalsci.2011.10.007

Sheikholeslami M, Jafaryar M, Said Z et al (2021) Modification for helical turbulator to augment heat transfer behavior of nanomaterial via numerical approach. Appl Therm Eng 182:115935. https://doi.org/10.1016/j.applthermaleng.2020.115935

Sheikholeslami M, Farshad SA (2021) Investigation of solar collector system with turbulator considering hybrid nanoparticles. Renew Energy 171:1128–1158. https://doi.org/10.1016/j.renene.2021.02.137

Mirzaei M, Saffar-Avval M, Naderan H (2014) Heat transfer investigation of laminar develo** flow of nanofluids in a microchannel based on Eulerian-Lagrangian approach. Can J Chem Eng 92:1139–1149. https://doi.org/10.1002/cjce.21962

He Y, Men Y, Zhao Y et al (2009) Numerical investigation into the convective heat transfer of TiO2 nanofluids flowing through a straight tube under the laminar flow conditions. Appl Therm Eng 29:1965–1972. https://doi.org/10.1016/J.APPLTHERMALENG.2008.09.020

Bianco V, Chiacchio F, Manca O, Nardini S (2009) Numerical investigation of nanofluids forced convection in circular tubes. Appl Therm Eng 29:3632–3642. https://doi.org/10.1016/J.APPLTHERMALENG.2009.06.019

Aminfar H, Motallebzadeh R (2012) Investigation of the velocity field and nanoparticle concentration distribution of nanofluid using lagrangian-eulerian approach. J Dispers Sci Technol 33:155–163. https://doi.org/10.1080/01932691.2010.528336

Aminfar H, Motallebzadeh R (2011) Numerical investigation of the effects of nanoparticle diameter on velocity field and nanoparticle distribution of nanofluid using lagrangian-eulerian approach. J Dispers Sci Technol 32:1311–1317. https://doi.org/10.1080/01932691.2010.505815

Mojarrad MS, Keshavarz A, Shokouhi A (2013) Nanofluids thermal behavior analysis using a new dispersion model along with single-phase. Heat and Mass Transfer/Waerme- und Stoffuebertragung 49:1333–1343. https://doi.org/10.1007/s00231-013-1182-3

Singh PK, Harikrishna PV, Sundararajan T, Das SK (2012) Experimental and numerical investigation into the hydrodynamics of nanofluids in microchannels. Exp Thermal Fluid Sci 42:174–186. https://doi.org/10.1016/J.EXPTHERMFLUSCI.2012.05.004

Bahiraei M (2015) Effect of particle migration on flow and heat transfer characteristics of magnetic nanoparticle suspensions. J Mol Liq 209:531–538. https://doi.org/10.1016/J.MOLLIQ.2015.06.030

El Bécaye MS, Palm SJ, Nguyen CT et al (2005) Heat transfer enhancement by using nanofluids in forced convection flows. Int J Heat Fluid Flow 26:530–546. https://doi.org/10.1016/J.IJHEATFLUIDFLOW.2005.02.004

Göktepe S, Atalik K, Ertürk H (2014) Comparison of single and two-phase models for nanofluid convection at the entrance of a uniformly heated tube. Int J Therm Sci 80:83–92. https://doi.org/10.1016/j.ijthermalsci.2014.01.014

Kakaç S, Pramuanjaroenkij A (2016) Analysis of convective heat transfer enhancement by nanofluids: single-phase and two-phase treatments. J Eng Phys Thermophys 89:758–793. https://doi.org/10.1007/s10891-016-1437-1

Hirt CW, Nichols BD (1981) Volume of fluid (VOF) method for the dynamics of free boundaries. J Comput Phys 39:201–225. https://doi.org/10.1016/0021-9991(81)90145-5

Kalteh M, Abbassi A, Saffar-Avval M, Harting J (2011) Eulerian-Eulerian two-phase numerical simulation of nanofluid laminar forced convection in a microchannel. Int J Heat Fluid Flow 32:107–116. https://doi.org/10.1016/J.IJHEATFLUIDFLOW.2010.08.001

Moraveji MK, Ardehali RM (2013) CFD modeling (comparing single and two-phase approaches) on thermal performance of Al2o3/water nanofluid in mini-channel heat sink. Int Commun Heat Mass Transfer 44:157–164. https://doi.org/10.1016/j.icheatmasstransfer.2013.02.012

Naphon P, Nakharintr L (2015) Turbulent two phase approach model for the nanofluids heat transfer analysis flowing through the minichannel heat sinks. Int J Heat Mass Transf 82:388–395. https://doi.org/10.1016/J.IJHEATMASSTRANSFER.2014.11.024

Bég OA, Rashidi MM, Akbari M, Hosseini A (2014) Comparative numerical study of single-phase and two-phase models for bio-nanofluid transport phenomena. J Mech Med Biol 14:1–31. https://doi.org/10.1142/S0219519414500110

Haghshenas Fard M, Esfahany MN, Talaie MR (2010) Numerical study of convective heat transfer of nanofluids in a circular tube two-phase model versus single-phase model. Int Commun Heat Mass Transf 37:91–97. https://doi.org/10.1016/j.icheatmasstransfer.2009.08.003

Rashidi MM, Hosseini A, Pop I et al (2014) Comparative numerical study of single and two-phase models of nanofluid heat transfer in wavy channel. Appl Math Mech (English Edition) 35:831–848. https://doi.org/10.1007/s10483-014-1839-9

Behzadmehr A, Saffar-Avval M, Galanis N (2007) Prediction of turbulent forced convection of a nanofluid in a tube with uniform heat flux using a two phase approach. Int J Heat Fluid Flow 28:211–219. https://doi.org/10.1016/J.IJHEATFLUIDFLOW.2006.04.006

Hejazian M, Moraveji MK, Beheshti A (2014) Comparative numerical investigation on TiO2/water nanofluid turbulent flow by implementation of single phase and two phase approaches. Numer Heat Transf Part A Appl 66:330–348. https://doi.org/10.1080/10407782.2013.873271

Beheshti A, Moraveji MK, Hejazian M (2015) Comparative numerical study of nanofluid heat transfer through an annular channel. Numer Heat Transf Part A Appl 67:100–117. https://doi.org/10.1080/10407782.2014.894359

Lotfi R, Saboohi Y, Rashidi AM (2010) Numerical study of forced convective heat transfer of nanofluids: comparison of different approaches. Int Commun Heat Mass Transfer 37:74–78. https://doi.org/10.1016/J.ICHEATMASSTRANSFER.2009.07.013

Kurowski L, Chmiel-Kurowska K, Thulliea J (2009) Numerical simulation of heat transfer in nanofluids. Comput Aided Chem Eng 26:967–972. https://doi.org/10.1016/S1570-7946(09)70161-0

Allahyari S, Behzadmehr A, Hosseini Sarvari SM (2011) Conjugate heat transfer of laminar mixed convection of a nanofluid through a horizontal tube with circumferentially non-uniform heating. Int J Therm Sci 50:1963–1972. https://doi.org/10.1016/J.IJTHERMALSCI.2011.03.025

Drew DA, Lahey RT (1979) Application of general constitutive principles to the derivation of multidimensional two-phase flow equations. Int J Multiph Flow 5:243–264. https://doi.org/10.1016/0301-9322(79)90024-7

Bouillard JX, Lyczkowski RW, Gidaspow D (1989) Porosity distributions in a fluidized bed with an immersed obstacle. AIChE J 35:908–922. https://doi.org/10.1002/aic.690350604

Rw E (1952) Evaporation form drops. Chem Eng Prog 48:141–146

Kalteh M, Abbassi A, Saffar-Avval M et al (2012) Experimental and numerical investigation of nanofluid forced convection inside a wide microchannel heat sink. Appl Therm Eng 36:260–268. https://doi.org/10.1016/J.APPLTHERMALENG.2011.10.023

Peng W, Minli B, Jizu L et al (2014) Numerical investigation on the turbulent flow characteristic of nanofluids in a horizontal circular tube. Numer Heat Transf Part A Appl 66:646–668. https://doi.org/10.1080/10407782.2014.894389

Ibrahim M, Berrouk AS, Algehyne EA et al (2021) Numerical evaluation of exergy efficiency of innovative turbulators in solar collector filled with hybrid nanofluid. J Therm Anal Calorim. https://doi.org/10.1007/s10973-021-10759-6

**ong Q, Tayebi T, Izadi M et al (2021) Numerical analysis of porous flat plate solar collector under thermal radiation and hybrid nanoparticles using two-phase model. Sustain Energy Technol Assess 47:101404. https://doi.org/10.1016/j.seta.2021.101404

Kaloudis E, Papanicolaou E, Belessiotis V (2016) Numerical simulations of a parabolic trough solar collector with nanofluid using a two-phase model. Renew Energy 97:218–229. https://doi.org/10.1016/j.renene.2016.05.046

Azodinia M, Mudabbir M, Karimipour A (2023) Numerical investigation of two-phase Al2O3 nanofluid in a microchannel equipped with bump through slip flow. Eng Anal Boundary Elem 155:1028–1034. https://doi.org/10.1016/j.enganabound.2023.07.019

Klazly M, Mahabaleshwar US, Bognár G (2022) Comparison of single-phase Newtonian and non-Newtonian nanofluid and two-phase models for convective heat transfer of nanofluid flow in backward-facing step. J Mol Liq 361:119607. https://doi.org/10.1016/j.molliq.2022.119607

Akbari OA, Pourfattah F, Mojaddarasil M et al (2023) Assessing heat transfer and nanofluid laminar flow in the curved micro-mixers by adopting two-phase model. Alex Eng J 73:189–203. https://doi.org/10.1016/j.aej.2023.04.061

Abdollahzadeh Y, Mehrpooya M, Mousavian SMA, Moqtaderi H (2023) Modeling and simulation of nanofluid in low Reynolds numbers using two-phase Lattice Boltzmann method based on mixture model. Chem Eng Res Des 192:402–411. https://doi.org/10.1016/j.cherd.2023.02.023

**ong T, Zheng L, Shah KW (2020) Nano-enhanced phase change materials (NePCMs): a review of numerical simulations. Appl Therm Eng 178:115492. https://doi.org/10.1016/j.applthermaleng.2020.115492

Ibrahim D, Rosen MA (2011) Thermal energy storage, systems and applications. Wiley, New Jersey

Nandanwar YN, Kalbande VP, Mohan M et al (2022) An approach toward higher electrical conversion efficiency of solar photovoltaic module using phase change materials. Energy Storage. https://doi.org/10.1002/est2.379

Kalidasan B, Pandey AK, Saidur R et al (2023) Nano additive enhanced salt hydrate phase change materials for thermal energy storage. Int Mater Rev 68:140–183. https://doi.org/10.1080/09506608.2022.2053774

Pielichowska K, Pielichowski K (2014) Phase change materials for thermal energy storage. Prog Mater Sci 65:67–123. https://doi.org/10.1016/j.pmatsci.2014.03.005

Berroug F, Lakhal EK, El Omari M et al (2011) Thermal performance of a greenhouse with a phase change material north wall. Energy Build 43:3027–3035. https://doi.org/10.1016/j.enbuild.2011.07.020

Nandanwar YN, Walke PV, Kalbande VP, Mohan M (2023) Performance improvement of vapour compression refrigeration system using phase change material and thermoelectric generator. Int J Thermofluids 18:100352. https://doi.org/10.1016/j.ijft.2023.100352

Cabeza LF, Castell A, Barreneche C et al (2011) Materials used as PCM in thermal energy storage in buildings: a review. Renew Sustain Energy Rev 15:1675–1695. https://doi.org/10.1016/j.rser.2010.11.018

Krishna J, Kishore PS, Solomon AB (2017) Heat pipe with nano enhanced-PCM for electronic cooling application. Exp Thermal Fluid Sci 81:84–92. https://doi.org/10.1016/j.expthermflusci.2016.10.014

Guimarães TC, da Gomes OFM, Oliveira de Araújo OM et al (2023) PCM-impregnated textile-reinforced cementitious composite for thermal energy storage. Textiles 3:98–114. https://doi.org/10.3390/textiles3010008

Tete PR, Gupta MM, Joshi SS (2021) Developments in battery thermal management systems for electric vehicles: a technical review. J Energy Storage 35:102255. https://doi.org/10.1016/j.est.2021.102255

Yadav V, Kumar Y, Agrawal H, Yadav A (2017) Thermal performance evaluation of solar cooker with latent and sensible heat storage unit for evening cooking. Aust J Mech Eng 15:93–102. https://doi.org/10.1080/14484846.2015.1093260

Bashir MA, Giovannelli A (2019) Design optimization of the phase change material integrated solar receiver: a numerical parametric study. Appl Therm Eng 160:114008. https://doi.org/10.1016/j.applthermaleng.2019.114008

Senthil R (2020) Effect of charging of phase change material in vertical and horizontal rectangular enclosures in a concentrated solar receiver. Case Stud Thermal Eng 21:100653. https://doi.org/10.1016/j.csite.2020.100653

Senthil R, Cherlathan M (2017) Effect of the phase change material in a solar receiver on thermal performance of parabolic dish collector. Therm Sci 21:2803–2812

Senthil R, Cheralathan M (2019) Enhancement of the thermal energy storage capacity of a parabolic dish concentrated solar receiver using phase change materials. J Energy Storage 25:100841. https://doi.org/10.1016/j.est.2019.100841

Senthil R (2021) Enhancement of productivity of parabolic dish solar cooker using integrated phase change material. Mater Today Proc 34:386–388. https://doi.org/10.1016/j.matpr.2020.02.197

Vishnu SK, Senthil R (2023) Experimental study of the thermal performance of heat storage–integrated solar receiver for parabolic dish collectors. Environ Sci Pollut Res 30:76044–76059. https://doi.org/10.1007/s11356-023-27608-8

Kalogirou SA, Karellas S, Braimakis K et al (2016) Exergy analysis of solar thermal collectors and processes. Prog Energy Combust Sci 56:106–137. https://doi.org/10.1016/j.pecs.2016.05.002

Wu SY, **ao L, Cao Y, Li YR (2010) Convection heat loss from cavity receiver in parabolic dish solar thermal power system: a review. Sol Energy 84:1342–1355. https://doi.org/10.1016/j.solener.2010.04.008

Incropera F, Dewitt D (2011) Introduction to heat transfer. Wiley, Hoboken, NJ

Reddy KS, Sendhil Kumar N (2008) Combined laminar natural convection and surface radiation heat transfer in a modified cavity receiver of solar parabolic dish. Int J Therm Sci 47:1647–1657. https://doi.org/10.1016/j.ijthermalsci.2007.12.001

Zou C, Zhang Y, Falcoz Q et al (2017) Design and optimization of a high-temperature cavity receiver for a solar energy cascade utilization system. Renew Energy 103:478–489. https://doi.org/10.1016/j.renene.2016.11.044

Kumar A, Sharma M, Thakur P et al (2020) A review on exergy analysis of solar parabolic collectors. Sol Energy 197:411–432. https://doi.org/10.1016/j.solener.2020.01.025

Bellos E, Tzivanidis C, Antonopoulos KA, Daniil I (2016) The use of gas working fluids in parabolic trough collectors–an energetic and exergetic analysis. Appl Therm Eng 109:1–14. https://doi.org/10.1016/j.applthermaleng.2016.08.043

Jeter SM (1981) Maximum conversion efficiency for the utilization of direct solar radiation. Sol Energy 26(3):231–236. https://doi.org/10.1016/0038-092X(81)90207-3

Petela R (1964) Exergy of heat radiation. J Heat Transf 86:187–192. https://doi.org/10.1115/1.3687092

Bellos E, Tzivanidis C, Antonopoulos KA, Gkinis G (2016) Thermal enhancement of solar parabolic trough collectors by using nanofluids and converging-diverging absorber tube. Renew Energy 94:213–222. https://doi.org/10.1016/j.renene.2016.03.062

Askari-Asli Ardeh E, Loni R, Najafi G et al (2019) Exergy and economic assessments of solar organic Rankine cycle system with linear V-Shape cavity. Energy Convers Manage 199:111997. https://doi.org/10.1016/j.enconman.2019.111997

Badescu V (2015) Maximum reversible work extraction from a blackbody radiation reservoir. A way to closing the old controversy. Europhys Lett 109(4):40008. https://doi.org/10.1209/0295-5075/109/40008

Badescu V (2014) Is Carnot efficiency the upper bound for work extraction from thermal reservoirs? Europhys Lett 106:1–7. https://doi.org/10.1209/0295-5075/106/18006

Yan J, Cheng ZR, Peng YD (2018) Effects of geometrical parameters of a dish concentrator on the optical performance of a cavity receiver in a solar dish-Stirling system. Int J Energy Res 42:2152–2168. https://doi.org/10.1002/er.3998

Stine WB, Diver RB (1994) A compendium of solar dish/Stirling technology. Albuquerque, NM, United States

Mohammed IL (2013) Design and development of a parabolic dish solar thermal cooker. Int J Eng Res Appl (IJERA) 3:1179–1186

Reinalter W, Ulmer S, Heller P et al (2008) Detailed performance analysis of a 10kW dish/stirling system. J Solar Energy Eng Trans ASME 130:0110131–0110136. https://doi.org/10.1115/1.2807191

Venkatachalam T, Cheralathan M (2019) Effect of aspect ratio on thermal performance of cavity receiver for solar parabolic dish concentrator: an experimental study. Renew Energy 139:573–581. https://doi.org/10.1016/j.renene.2019.02.102

Singh SK, Sarkar J (2018) Energy, exergy and economic assessments of shell and tube condenser using hybrid nanofluid as coolant. Int Commun Heat Mass Transf 98:41–48. https://doi.org/10.1016/j.icheatmasstransfer.2018.08.005

Kumar V, Chandrashekara M, Yadav A (2023) Experimental investigation of solar-powered food steamer based on parabolic dish concentrator for domestic applications. Heat Transf 52:2796–2837. https://doi.org/10.1002/htj.22805

Sahu SK, Natarajan SK (2020) Design and development of a low-cost solar parabolic dish concentrator system with manual dual-axis tracking. Int J Energy Res. https://doi.org/10.1002/er.6164

Pourmoghadam P, Mehrpooya M (2021) Dynamic modeling and analysis of transient behavior of an integrated parabolic solar dish collector and thermochemical energy storage power plant. J Energy Storage 42:103121. https://doi.org/10.1016/j.est.2021.103121

Said Z, Iqbal M, Mehmood A et al (2023) Nanofluids-based solar collectors as sustainable energy technology towards net-zero goal: recent advances, environmental impact, challenges, and perspectives. Chem Eng Process Process Intensif 191:109477. https://doi.org/10.1016/j.cep.2023.109477

Kadri Y, Hadj Abdallah H (2016) Performance evaluation of a stand-alone solar dish Stirling system for power generation suitable for off-grid rural electrification. Energy Convers Manage 129:140–156. https://doi.org/10.1016/j.enconman.2016.10.024

Bekele A, Dereje S, Pandey V, Badruddin IA (2024) Experimental investigation of parabolic dish solar collector using nanofluids for steam cooking. Arab J Sci Eng 49:2581–2597. https://doi.org/10.1007/s13369-023-08278-7

Esfanjani P, Mahmoudi A, Rashidi S, Valipour MS (2024) Experimental investigation of a novel design of cavity receiver for a parabolic dish collector humidification-dehumidification desalination system. Energy Convers Manage 299:117845. https://doi.org/10.1016/j.enconman.2023.117845

Arab Asadi MTAA, Rashidi S, Mirhosseini M (2024) Sustainable and clean water distillation by parabolic dish collector and different heat absorber and thermal storage materials: an experimental study. Sustain Energy Technol Assess 62:103620. https://doi.org/10.1016/j.seta.2024.103620

Funding

This research received no specific grant from any funding agency in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Contributions

Yogesh N. Nandanwar contributed to writing—original draft and methodology. Pramod V. Walke performed writing—review and editing, and supervision.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical approval

Authors declare that the manuscript is not under consideration in more than one journal simultaneously. Also, the submitted work is original and not published elsewhere in any form or language. All the necessary permissions secured for material that is copyrighted.

Informed consent

Corresponding author declares that prior to the study, written informed consent was obtained from co-authors before inclusion.

Additional information

Technical Editor: Ahmad Arabkoohsar.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Nandanwar, Y.N., Walke, P.V. A comprehensive review on integration of receiver geometries, nanofluids, and efficient thermal energy storage for solar parabolic dish collectors. J Braz. Soc. Mech. Sci. Eng. 46, 480 (2024). https://doi.org/10.1007/s40430-024-05034-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-024-05034-2