Abstract

Suffusion is arguably the most complicated type of internal erosion. Although there are several popular assessment methods, the most realiable assessment is possibly still laboratory testing. However, there is not a standardised test for suffusion yet as different laboratories use different equipment and test configurations. Hence, a reliable comparison of outcomes across laboratories may not be able to achieve yet. This paper presents a new and simple, but very effective, way to test the susceptibility of soil to internal erosion using a novel segregation test. The test employs standard equipment which can be easily found in any geotechnical laboratory. There are some common characteristics of internal erosion and transport segregation, where fine particles are transported through the pore constrictions formed by the soil’s primary fabric. In segregation, particles are transported by gravitational/mechanical force to the bottom of the soil mass. Meanwhile, they are washed out of the soil mass by hydraulic force in internal erosion. Laboratory testing for internal erosion often requires specific equipment and a long duration. Meanwhile, segregation test could be undertaken with standardised sieving tower, which is available in any geotechnical laboratory. The approach was verified with an acrylic setup and some 3D-printed details. Later, the tests of 25 mixtures were undertaken with standard sieving sets. The correlation of laboratory results shows good agreement and prompts the common application of the new approach. The new test may not be able to completely replace the conventional suffusion test yet as it overlooks the critical hydraulic gradients at this stage, but it can be very useful if the research focuses on only the erodible mass and susceptibility to suffusion. In addition, it is a standardisable test with no specific requirements on equipment. The new approach may also be a starting point to study other types of internal erosion.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Suffusion is an insidious hazard occurring under the ground surface. As not all soil particles contribute equally to the stress transfer (Skempton and Brogan 1994), soils may have a bimodal structure. That is, coarse particles form the primary fabric, while fine particles embedded loosely in pores can be mobilised and transported by seepage. When fine particles are washed out of the soil mass, the porosity and hydraulic conductivity of the soil may increase. As a sequence, seepage is enhanced and may facilitate the destruction of the primary fabric.

Although there are plenty of suffusion assessment methods, their accuracy may need to be scrutinised (To and Scheuermann 2021). Field test is way too expensive, and numerical simulation is limited by number of particles. The laboratory test may be still the most reliable method to confirm the internal stability. However, the laboratory approach requires a special setup, including an erosion unit with diffusers, a hydraulic system for water cycle and water head control, and a collecting system for fine particles. These devices are not often available in geotechnical lab and may need to be manufactured. As a sequence, different laboratories may employ different testing configurations and equipment.

In general, suffusion tests could be classified in two categories. The first category of suffusion tests adapts existing laboratory setups, which are usually triaxial tests (**, a slot or hole can be preformed (Wan and Fell 2004; Benahmed and Bonelli 2012).

Up to date, there is no standardised unit for the use in commercial laboratories yet because the lab setup and testing conditions are frequently alternated for specific monitoring (To et al. 2018). It is authorial experience that professional dam engineering practice are based on some traditional assessment methods, which have not been standardised. There is a need of a standardised setup, which may study fewer parameters but can be applied with minimum nuances. Thereby, test results can be verified by an independent third party.

A possible parameter to be removed is the critical hydraulic gradient. In laboratory tests, the hydraulic gradient is usually changed instantaneously. Meanwhile, it varies gradually in real incidents, except pipe cracking/leaking. The exact estimation of the critical hydraulic gradient in a gradual change is an actual challenge (To and Scheuermann 2021). Besides, the impact of this gradient on internal erosion may depend on the deviation of seepage direction (Goldin and Rasskazov 1992), which could vary widely in porous medium at both macro and particle scales (To et al. 2020). When the spotlight on hydraulic force is off, the similarity between internal erosion and segregation attracts attention. Segregation is a phenomenon when fine particles are transported through pore constrictions to form local particle size distributions (PSD) that are distinct from the global PSD. Although the segregation is well known as a common issue for soils transported and dumped by trucks (To et al. 2016), it also can be caused by seepage in internal erosion and clogging, which is a type of internal instability of soil (Goldin and Rasskazov 1992).

This paper presents a new test in the first category of suffusion tests. The new setup is adapted from sieving test and named segregation test, where the particle transportation is driven by gravity and shaking impact instead of seepage force (Fig. 1). The initial verifying setup was transparent to observe the similarity of segregation due to shaking and suffusion due to seepage. Later, 25 mixtures were tested with a steel sieving set. The nets of sieves, except the bottom sieve, were removed to facilitate the free transportation of particles. The laboratory results of the new segregation tests showed that the new test still can estimate the erodible mass with a similar accuracy to the traditional suffusion test but with much less effort. No water management is required, and the testing devices can be found easily in any geotechnical laboratory.

Laboratory setup

The original idea came from an experimental experience in a suffusion test with downward seepage direction (To and Van Thinh 2021). The test investigated the maximum proportion of fine particles, which can fully fill the pores. This way, fine particles clog themselves and cannot be washed out (Indraratna et al. 2011). When the erosion unit (Fig. 2) was accidentally shaken, the soil particles were rearranged and transported. A time-lapse video showed some similarities between transportation due to shaking and internal erosion due to seepage. This discovery led to the idea that it may be feasible to test the susceptibility of soils to suffusion with standard sieving equipment. The new test is named in this paper as segregation test.

There may be one problem with segregation test. The shaking impact may be way too large and destruct the soil primary fabric from the beginning, which does not occur in suffusion. Hence, different amplitudes must be tested to find a good value that does not cause any change in soil primary fabric. As the normal sieves are made from steel, it is difficult to notice the change inside the tower. Hence, a transparent acrylic setup was made to verify the idea.

Transparent segregation setup

The acrylic segregation tower was made from up to 6 layers with a compressing top cap and a bottom pan (Fig. 3). All components were tightened together with bolts and wing nuts. The external and internal diameters of the tower were 200 mm and 194 mm, respectively. These are the closest dimensions of commercially available acrylic tubes to the size of laboratory standard sieves at 200/203 mm (ISO 2016, 2020). The thickness of each layer was 50 mm, which was roughly 10 \(d_{100}\). A net was placed at the top of the bottom pan to keep the sample above shaken-off particles. This helped to simulate the internal erosion process, where particles are washed out of the soil mass. The net was tested against both static and dynamic loads of 340 and 260 N, respectively (Fig 4). This is the proposed cyclic impact from the vibration with 20 kg of soil. It is authorial experience that good quality sieves in general soil laboratories could hold 20 kg of soil without problems. As there are hundreds of wires, each steel wire carries just a few grams. Nevertheless, if the net is anchored with only four wing bolts, each bolt has to carry 5 kg. Hence, small cracks may occur in acrylic, near the bolts. Preformed cracks may help to reduce the damage.

In the first trial, a gap-graded soil was used, and the whole tower was shaken for half an hour with 1 mm amplitude. A total of 1.27 kg of the erodible soil mass was shaken off in the first 15 min. During the last 15 min, only 20 g were collected. A visual observation confirmed the similarity of the particle transportation in a 30-min segregation test and a 48-h suffusion test (Fig. 5). After the test, the soil was removed by layer to estimate the local PSD due to segregation. Although the tower was shaken well, not all fine particles are dropped to the lower layers. They were trapped at pore constrictions. Soil primary fabric moved collectively, and pore constrictions were not significantly widened, given the small amplitude of vibration and large compressing loads. The ‘eroded’ soil mass for the gap-graded soil increased slightly from 15.76% in suffusion test to 17.19% in segregation test. A repeated test with poorly graded soil showed a negligible increase from 1.62 to 1.67%. Note that, due to the heterogeneity, suffusion test results of the same soil with the same hydraulic erosion unit may still vary slightly.

There may be some interesting notes of the transparent setup. Firstly, although the vibration amplitude was small, the coated layer of the acrylic tower was scratched, and particles could not be observed easily after ten tests. A replaceable thin film may be placed inside to protect the tower from scratches. Secondly, as the tower was fully filled, the total soil mass was roughly 19.7 kg. This required a powerful shaker, which might damage the acrylic tower, especially the near-bottom layer with the net. Nevertheless, a normal 300W Octagon shaker carried the test well without any noticeable cracks induced. Thirdly, a small amplitude from 0.5 to 1.5 mm is recommended. The sieve shaker has amplitude varied from 0 to 3 mm with 0.1 mm steps. When the amplitude was 0.4 mm, fine particles did not drop out well. In contrast, when the amplitude was more than 1.6 mm, soil seemed to be tossed up. Therefore, the amplitude of 1 mm was selected in this research as the average for the tested soils. The vibration should be hardly noticed in the recorded FHD videos from a distance of 60 cm. Fourthly, if there was not any constraint at the boundary, contact erosion loss may occur at the gap between soil particles and the acrylic wall. A rubber donut of 5 mm width and 200 mm in diameter can stop contact erosion. Last but not least, when suffosion—an extreme type of suffusion with volume change (Fannin R, Slangen 2014)—occurred, the top cap could not compress the soil well. It even may not touch the soil’s upper surface (Fig. 6). To study the susceptibility of compacted soils to suffusion, a compressed thick sponge may be placed underneath the top cap to ensure that there is always a sufficient surcharge on the sample.

In general, the acrylic setup worked well as a transparent prototype to observe the transportation and confirm the feasibility of the new laboratory approach for suffusion assessment.

Standard sieving setup

To obtain a durable device, a steel segregation tower was made from two standard sieving sets. The nets in the first set were cut to make the middle layers of the tower (Fig. 7). Note that a metal ring is deliberately left/attached to the sieve to avoid contact erosion along the tower wall. Based on the PSD of the tested soil, a sieve with suitable net size will be selected from the second set to be used as the near-bottom layer above the pan.

If the soil is gap-graded with the gap ratio \(G_r\) (equation 1) larger than 2, the largest standard sieve size within the size gap is selected to be the opening size of the net, \(d_{net}\).

where \(d_{begin}\) and \(d_{end}\) are the sizes at the lower and upper boundary of the size gap, respectively (To et al. 2018).

For continuously graded soils, \(d_{net}\) is selected to be the closest standard sieving size (ISO 2016) smaller than

where 0.77 is the ratio between the diameter of transportable granular particles and the pore constriction size (Goldin and Rasskazov 1992).

If there is no close standard size, a smaller standard size can be accepted if it allows particles of \(d_{40}\) passing through (Fig. 8).

This estimation may not be recommended in some special cases of very well graded soils, where \(d_{40}\) can be very small. In general, dry sieving may be effective if the opening size is no less than 0.075 mm, which is the sieve #200 (To et al. 2023). However, cohesive soils with the proportion of fines larger than 12.5% still could be tested as long as \(d_{40}\) is large enough for sieving. When \(d_{40}\) is very small, the soil is unlikely to be suffusive because the hydaulic

Tested soils could be compressed if required (Fig. 9). However, the influence of relative density is not in the scope of this research. Hence, all tested mixtures below were not compressed so that the results could be compared with the traditional erosion test (Fig. 2). The testing procedure for both segregation setups can be summarised as below:

-

Prepare the desired mass of soils or mixtures. The moisture content must be low to avoid any possible cohesion/adhesion.

-

Estimate \(d_{60}\) to find the recommended net size. Stack the tower.

-

Carefully place the soil by layer into the tower to ensure the homogeneity of the soil. (Optional) Compress each layer to the design stress and place a hard sponge on the top before closing the tower to maintain the desired stress.

-

Shake the tower for 30 min.

-

Measure the soil mass dropped into the bottom pan and compare to the total soil mass.

-

(Optional) Remove the soil by layer and undertake the sieving test for each layer.

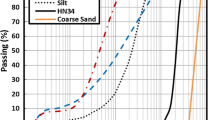

Soil particle size distribution

In order to investigate the work of the new testing setup, mixtures were made from four different soils: fine, gravel mix, filter, and CSR (Fig. 10). CSR is the technical name of a construction sand. Although the PSDs are different, these soils have similar roundness and sphericity (Fig. 11) to avoid the unknown possible effect of different particle shapes in different soils. The characteristics of the particle shape were estimated with charts (Santamarina and Cho 2004). In general, the sphericity and roundness of soil particles were 0.7 ± 0.2 and 0.4 ± 0.1, respectively.

In the first step, PSDs were predicted with a MATLAB code for a given proportion. Then, the proportion was amended with ‘trial and error’ to reach the desired PSD. The number of mixtures was 25 to maintain the maximum difference between PSDs no less than 5%. After that, the soils were mixed thoroughly with a concrete mixer and shovels. Before the test, the PSDs had been verified with standard sieving test because the actual PSD may be different to the proposed one. Very fine fractions were analysed with Mastersizer 3000, a laser diffraction particle size analyser. The resultant PSDs are presented in Fig. 12. For the convenience of readers, main characteristics of mixtures are listed in Table 1. Due to the heterogeneity, the local PSD of each layer may vary within 3% from the estimated PSD.

A preliminary study on the required vibrating time found that the duration of the test might strongly depend on the PSD. Gap-graded soils may take 15 min or less, while continuously graded soils may require a longer time. Besides, the amplitude of vibration can also influence the ‘eroded’ mass. High amplitude might shake more fine particles off as shaking impact may destruct the primary fabric of soils. For all of the below tests, the amplitude was set at 1 mm, and the shaking time was set at 30 min. For most of the tests, fine particles were not shaken off after 25 min.

Results and discussion

Contact erosion calibration

As mentioned above, if there is no boundary constraint, contact erosion may occur between the soil mass and the wall. This phenomenon occurs with both erosion unit (Fig. 2) and segregation tower (Fig. 7). A comparison for three typical PSDs was undertaken to assess the mass loss with and without contact erosion (Table 2). To assess the influence of contact erosion, acrylic segregation tower and normal erosion unit were employed. To eliminate the contact erosion, a filter-paper ring was placed in the erosion unit, and standard sieves were used to build the segregation tower.

When contact erosion occurs, fine particles were transported down along the wall, while they are still trapped in pores in the middle of the acrylic tower (Fig. 13). The mass loss in the contact erosion test was increased significantly to nearly four times in comparison with the traditional suffusion test for gap-graded soil (Table 2). A similar increase was also found in the segregation test with the acrylic tower. Nearly all fine particles have been transported out of the gap-graded soil. For soil ‘19’, the stability was changed to unstable as the eroded mass went over 5%. This may be caused by the larger diameter of the tower. This milder curvature may create larger gaps and allow more fines to pass. Nevertheless, the suffusion loss and segregation loss were close. Hence, this paper will focus on only suffusion.

There was a concern that segregation due to vibration could form layers perpendicular to the particle flow, while segregation due to seepage could form layers parallel to the flow. However, lab results showed that they are both parallel to the flow. The segregation due to vibration may be sharper.

Erodible mass

The laboratory experience showed some advantages of the new test over the conventional approach. An undeniable advantage of the new segregation test is its simplicity. The test does not require any special equipment. Old standard sieving devices are popular in geotechnical laboratories and may be replaced after a few years. In general, a suffusion test for a soil sample of 300 mm height may take 1 or 2 days. Meanwhile, a similar sample in segregation test requires just 30 min to shake. If the soil is wet, a drying process in oven may be required before the test. However, the suffusion test may take an even longer time to dry and prepare for sieving after the test. It is the authors’ experience that the segregation test may be 8–10 times faster than the conventional suffusion test.

Moreover, segregation test may be more accurate in measuring the ‘eroded’ amount. If the water is recycled due to the long suffusion test duration, a proportion of fine particles may be pumped back to the erosion unit. This trouble does not happen in segregation tower. Also, the erosion unit may experience leaks as rubber seals may deteriorate.

In contrast, the suffusion test is still irreplaceable. It can study the effect of many factors, including the applied hydraulic gradient and stability of the pathway in pi**, a later stage of suffusion. If soil primary fabric is compressed and moves collectively, the hydraulic gradient may have a certain relation with shaking amplitude and frequency. However, it is challenging to study pi** in segregation test because the pathways often collapse due to strong shaking impact.

To assess the accuracy of the new test with the standard sieving setup, the mixtures were assessed with segregation test and traditional erosion tests. PSDs were also assessed with four key-size methods (Table 3), which use only PSD as the input (Wan and Fell 2008; Burenkova 1993; Kenny and Lau 1985; To et al. 2018). Other methods may be difficult to be compared as they may require some unknown factors, e.g. relative density or hydraulic gradient (To et al. 2016; To and Scheuermann 2021). The laboratory test result is classified as ‘stable’ if less than 3% of soil mass was shaken off and ‘unstable’ if more than 5% of soil mass dropped out (Goldin and Rasskazov 1992). The transitional result means the susceptibility to suffusion may depend on uncontrollable factors, e.g. the spatial distribution of particles. Transitional soil is generally not recommended for the construction of hydraulic structures.

Although the PSD was widely alternated to have about 28% of unstable soils, which would not satisfy Burenkova’s stable condition (Eq. 4), just only three mixtures were estimated as ‘unstable’ or ‘transitional’ after the laboratory tests.

However, the results showed a good coherence between segregation test and erosion test (Table 3). Although the difference spreads from -1% to +1%, erosion loss is frequently less than segregation loss (Fig. 14). The mode of difference is close to zero with \(\mu \) = 0.1648% and \(\sigma \) = 0.401%. It is understandable that segregation may transport slightly more particles because the vibration impact rearranges and reorients fine particles better than a consistent seepage flow. As a sequence, transportation can better avoid particle jam at the pore constrictions. Note that erosion loss is always larger than 0.15% of soil mass. This may be caused by some initial loss during the water filling process.

There may be a concern about a larger difference of losses if soils are unstable. However, the results seem to be consistent for tests with less than 10% of mass loss. If the loss is bigger, it may be out of interest as the soil is obviously unstable in many assessment methods. Hence, there is no need to test those soils in laboratory to confirm the internal stability.

It is interesting that the method of Wan and Fell (2008) assesses all tested soils as stable and makes three major misalignments, when an ‘unstable’ or ‘transitional’ soil is assessed as ‘stable’. In contrast, the method of Burenkova (Burenkova 1993) makes no major but five minor misalignments, when a ‘stable’ soil is assessed as ‘unstable’ or ‘transitional’. These two methods might be cheated by complicated PSDs as they use just several fixed key sizes (To et al. 2018). Methods of Kenney and Lau (1985) and To (2018) are consistent, except one extra major misalignment with the method of Kenny and Lau (1985). Summary of the comparison is given in Table 4. Note that the lab result of mixture 16 is very close to transitional zone. If this mixture is considered as transitional, method of To et al. (2018) makes just one major misalignment.

Segregation

Although the sieving test after the main segregation test is optional, sieving results provided some good understanding of the transportation. When a gap-graded soil was segregated (Fig. 15a), a large shift of PSD was found in layer 6 as it is the bottom layer. There is not any below layer to provide resistance to the transport. However, the largest shift in PSD shape was found in layer 1 because it had no fine particles dropped from above. Moreover, when suffosion occurred, the top layer might not have any firm constraint applied from above (Fig. 6a). Hence, soil particles can be tossed up to allow more fines to drop into the below pores. Although the segregation seems to be continuing because PSDs of layers 2, 3, 4, and 5 were still close to the original PSD, the transportation was actually stopped at the end of the test as no more fine particles dropped out. All erodible particles were shaken off via formed transportation pathways. Meanwhile, the trapped fine particles fully filled pores in clogged pathways. Hence, layers 3 and 4 had more fine particles than the original mixture.

A similar result was found for erodible continuously graded soils (Fig. 15b). Although the PSD of the bottom layer was close to the original PSD, nearly 1 kg of fine particles were shaken off. Note that continuously graded soils may require a longer testing time. Mixture 17 had nearly 1.2% of soil mass eroded after 30 min. Then, the particle flow was stifled, but it still could reach 1.8 % of soil mass after approximately 2 h.

For stable mixtures, the local PSDs of layers were close (Fig. 15c) with the maximum deviation of less than 5%. This difference may also be caused by soil heterogeneity. The consistent PSDs of layers 2, 3, and 4 might hint that the number of middle layers could be reduced to four layers.

Note that segregation test is a disturbed test as soil has been dried in oven and placed into the segregation tower by layer. A careless preparation may have some initial segregation. However, as the tested soil mass is large, this initial segregation might not significantly influence the segregation. In case the soil is naturally segregated, it is obviously suffusive and can be detected by the test results.

Net size

Although many conventional suffusion testing setups used granular materials to simulate the continuation of soil (Nguyen et al. 2019; To and Scheuermann 2021), this may make constriction size hard to be controlled. Hence, many other suffusion testing setups used a net after the tested soil (**ao and Shwiyhat 2012; Rochim et al. 2017; Kodieh et al. 2021). However, they often used a fixed size and neglected the net size determination.

The current research initially proposed to use \(d_{point}\)—the size at the kinking point on soil PSD (To and Scheuermann 2014) as the net size. However, this approach may not be applicable to some straight-like PSDs. Kenny and Lau (1985) proposed that particles sized d are kept by particles sized 4d, and the maximum amount of erodible fine particles is 20% of the soil mass. Hence, 4\(d_{20}\) may be a good choice as this size does not allow coarse particles to drop through. Nevertheless, some other studies proposed that the fraction of fine may occupy up to 40% of soil mass (Li and Fannin 2008). A numerical study pointed out that the size of transportable particles can go up to a high value, less than \(0.25d_{100}\) (To et al. 2015). However, the transportation of these particles may terminate very quickly after a few pores. Another possible selection was the use of a delimiting point so that fine particles would fully fill the pores (Indraratna et al. 2011). However, this approach requires the porosity of the primary fabric, which must be calculated approximately with a sophisticated computer program. In addition, suffusive soils do not have this condition. Hence, the real delimiting size may be smaller.

This paper does not deny any of the above possible selections. It simply agrees with some experimental studies that the fraction of coarse particles should be presented by \(d_{60}\) (Burenkova 1993; Wan and Fell 2008). Hence, Eq. 2 was proposed with a hypothesis that the maximum effective opening can be up to \(d_{60}\). Nevertheless, laboratory experience showed that smaller sieve sizes may still work, if they allow particles of \(d_{40}\) passing through (To et al. 2023). The only small difference in eroded mass was found in a thin slice at the bottom layer. The middle-size particles in upper layers are trapped by self-filtration effect. Future study may focus more on the selection of the appropriate sieve size.

Stress transfer

A possible drawback of the segregation test is the application of large loads. Sieving meshes are often made of thin wires to maximise the sieving ability. Hence, the mesh may deform under high stress. However, it is evidenced that relative density and compaction could influence the internal stability of soils (Israr and Aziz 2019; To et al. 2020). Therefore, the application of high stress is a considerable need. Nevertheless, this is also the significant problem with all other apparatus for large specimens. A steel plate with large holes can be placed underneath the mesh (Sarmah and Watabe 2023). If the holes are close, the plate may not be strong enough. However, if the holes are discrete, the plate may block a series of mesh holes in a local area. Another good solution may be the use of round gravels or large glass beads in the bottom pan. These large particles may still block some mesh holes, but discretely. If the apparatus is used to test the filter work, a mesh may not be necessary. The tested setup with supporting glass beads could bear 50 kPa static load at ease. This is the stress on soil at a few meters beneath the ground level. If the load is much higher, triaxial setup may be a better choice, given the soil is fine.

As the load is not monitored and maintained automatically, it may be varied due to the volume change due to the test. A DEM simulation showed that vibration could cause some short transportation and possibly a very small volume change in most segregation tests of wide graded soils (Fig. 16), where fine particles are relatively small to the pores formed by coarse particles. When fine particles are transported, the coarse particles have more room to move horizontally. However, the observed change is insignificant for non-suffusive representative volume (Fig. 16). Note that the number of particles in DEM simulation is roughly 100,000. This number is limited by computational resources. High performance computing cluster can simulate millions particles of general shape, but the computation may take weeks or even months (To et al. 2016).

The influence of boundary wall to the stress transfer in segregation test may be less than in conventional tests because the tested soil samples are large. Standard sieves in geotechnical laboratory are normally 200 mm in diameter and could be 300 mm for large sieve (ISO 2020). Meanwhile, most conventional triaxial setups employed specimens of less than 100 mm in diameter. In addition, the o-ring keeps in place a thin layer of soil particles along the wall. Hence, the boundary contact could be considered as soil-soil contact at some level.

Conclusion

The paper has presented a novel approach to test the susceptibility of granular soils to suffusion. The only significant difference in mechanism is claimed to be the mechanical driving force, not the seepage force.

-

The new test is generally 8–10 times faster than the conventional suffusion test, including adequate preparation. Laboratory results showed a good agreement with the conventional erosion test with 100% matched for tested soils. In general, the new test showed a slight increase in the amount of mass loss because vibration generally works better than seepage in driving fine particles out of pores. Hence, it provides some safety in assessment.

-

The biggest advantage of the new test is a consistent and unified setup. The new test employs only standard equipment available in common geotechnical laboratories. The vibration could be accurately controlled with digital controller. Hence, it may have some good potential to be standardised.

-

As the only crucial difference is the driving force, the new approach may also be applied for other types of internal erosion, such as contact erosion or filter design.

-

The test may not completely replace the conventional suffusion test yet as it cannot study some specific factors, e.g. critical hydraulic gradient. However, it may be good if only the internal stability is focused on. More tests may be required to correlate the impact of vibrating magnitude and hydraulic gradient.

Future studies will aim to discover the applicability of the new test to investigate soil behaviour under various loadings.

Data Availability

All associated data and informations have been included in the paper. Any other inquiries can be satisfied on request.

References

Benahmed N, Bonelli S (2012) Internal erosion of cohesive soils: laboratory parametric study, 8-p (SHF)

Burenkova V (1993) Assessment of suffusion in non-cohesive and graded soils. Filters in geotechnical and hydraulic engineering. Balkema, Rotterdam 357–360

Chang D, Zhang L (2011) A stress-controlled erosion apparatus for studying internal erosion in soils. Geotech Test J 34:579–589

Fannin R, Slangen P (2014) On the distinct phenomena of suffusion and suffosion. Géotechnique Letters 4:289–294

Goldin A, Rasskazov L (1992) Earth dam design

Indiketiya S, Jegatheesan P, Rajeev P (2017) Evaluation of defective sewer pipe- induced internal erosion and associated ground deformation using laboratory model test. Can Geotech J 54:1184–1195

Indraratna B, Nguyen VT, Rujikiatkamjorn C (2011) Assessing the potential of internal erosion and suffusion of granular soils. Journal of Geotechnical and Geoenvironmental Engineering 137:550–554

ISO (2016) Specifies the technical requirements and corresponding test methods for test sieves of metal wire cloth. Standard, International Organization for Standardization, Geneva, CH

ISO (2020) Standard specification for woven wire test sieve cloth and test sieves. Standard, ASTM International, West Conshohocken, PA

Israr J, Aziz M (2019) Integrating the role of relative density on assessing internal stability of granular filters using existing geometrical methods. Arab J Geosci 12:646

Ke L, Takahashi A (2014) Triaxial erosion test for evaluation of mechanical consequences of internal erosion. Geotech Test J 37:347–364

Kenny T, Lau D (1985) Internal stability of granular soils. Can Geotech J 21:634–643

Kodieh A, Gelet R, Marot D, Fino A (2021) A study of suffusion kinetics inspired from experimental data: comparison of three different approaches. Acta Geotech 16:347–365

Li M, Fannin RJ (2008) Comparison of two criteria for internal stability of granular soil. Can Geotech J 45:1303–1309

Mehdizadeh A, Disfani M, Evans R, Arulrajah A (2019) Impact of suffusion on the cyclic and post-cyclic behaviour of an internally unstable soil. Géotechnique Letters 9:218–224

Moffat R, Fannin RJ, Garner SJ (2011) Spatial and temporal progression of internal erosion in cohesionless soil. Can Geotech J 48:399–412

Nguyen CD, Benahmed N, Andó E, Sibille L, Philippe P (2019) Experimental investigation of microstructural changes in soils eroded by suffusion using x-ray tomography. Acta Geotech 14:749–765

Rochim A, Marot D, Sibille L, Le Thao V (2017) Effects of hydraulic loading history on suffusion susceptibility of cohesionless soils. Journal of Geotechnical and Geoenvironmental Engineering 143:04017025

Sail Y, Marot D, Sibille L, Alexis A (2011) Suffusion tests on cohesionless gran444 ular matter: experimental study. Eur J Environ Civ Eng 15:799–817

Santamarina JC, Cho G-C (2004) Soil behaviour: The role of particle shape, 604–617 (Thomas Telford Publishing)

Sarmah R, Watabe Y (2023) Suffusion in densely compacted satozuka pumice sand and its impact on static loading undrained shear strength and dilation behaviour. Soils Found 63:101397

Sato M, Kuwano R (2015) Influence of location of subsurface structures on develop458 ment of underground cavities induced by internal erosion. Soils Found 55:829–840

Skempton A, Brogan J (1994) Experiments on pi** in sandy gravels. Geotechnique 44:449–460

To HD, Scheuermann A (2014) Separation of grain size distribution for application of self-filtration criteria in suffusion assessment 121–128

To HD, Torres SAG, Scheuermann A (2015) Primary fabric fraction analysis of granular soils. Acta Geotech 10:375–387

To HD, Galindo-Torres SA, Scheuermann A (2016a) Sequential sphere packing by trilateration equations. Granular Matter 18:1–14

To HD, Scheuermann A, Galindo-Torres SA (2016b) Probability of transportation of loose particles in suffusion assessment by self-filtration criteria. Journal of Geotechnical and Geoenvironmental Engineering 142:04015078

To P, Agius D, Cussen L (2020) Influence of relative density of the granular base soil on filter performance. Acta Geotech 15:3621–3627

To P, Sayayman R, van Donderen-Livock J (2023) Net size selection for suffusion test – a laboratory verification with segregation test 1–8

To P, Scheuermann A (2021) Suffusion assessment methods: A critical review, 103– 118

To P, Scheuermann A, Williams D (2018) Quick assessment on susceptibility to suffusion of continuously graded soils by curvature of particle size distribution. Acta Geotech 13:1241–1248

To P, Van Thinh L (2021) Segregation index - a new soil parameter for internal erosion assessment

Wan CF, Fell R (2004) Laboratory tests on the rate of pi** erosion of soils in embankment dams. Geotech Test J 27:295–303

Wan CF, Fell R (2008) Assessing the potential of internal instability and suffu489 sion in embankment dams and their foundations. Journal of Geotechnical and Geoenvironmental Engineering 134:401–407

**ao M, Shwiyhat N (2012) Experimental investigation of the effects of suffusion on physical and geomechanic characteristics of sandy soils. Geotech Test J 35:890–900

Funding

Open Access funding enabled and organized by CAUL and its Member Institutions.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There is no conflict of interest to the knowledge of the authors. The authors are not employed or paid by any organisation which could have financial benefits or damages from the results of the paper.

Additional information

Responsible Editor: Zeynal Abiddin Erguler.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

To, P., Vang, S., Dempsey, S. et al. Segregation test—a standardisable test for suffusion assessment of granular soils. Arab J Geosci 17, 186 (2024). https://doi.org/10.1007/s12517-024-11988-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-024-11988-3