Abstract

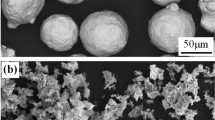

Titanium powder particles accelerated and simultaneously heated by the supersonic gas flow were deposited onto steel substrate by the warm spraying process. The sprayed particles were heavily deformed and bonded to the substrate in solid state. Especially, all the deposited particles showed jetting-out of materials out of the particle-substrate interface triggered by the adiabatic shear instability known to occur under such shock impact conditions. High-magnified images showed that grain refinement occurred in the jetting-out region by dynamic recrystallization. Furthermore, the elemental analysis using the electron energy loss spectrum showed jetting-outs of the substrate as well as the particle. Numerical simulation based on the Johnson-Cook plastic deformation model showed that the jetting-out phenomenon commences about 10 ns after the initial contact of the particle with the substrate and at a position away from the center bottom of particle, where the highest compressive stress is experienced.

Similar content being viewed by others

References

R.C. Dykhuizen, M.F. Smith, D.L. Gilmore, R.A. Neiser, X. Jiang, and S. Sampath, Impact of High Velocity Cold Spray Particles, J. Therm. Spray Technol., 1999, 8(4), p 559-564

M. Grujicic, J.R. Saylor, D.E. Beasley, W.S. DeRosset, and D. Helfritch, Computational Analysis of the Interfacial Bonding Between Feed-Powder Particles and the Substrate in the Cold-Gas Dynamic-Spray Process, Appl. Surf. Sci., 2003, 219(3-4), p 211-227

H. Assadi, F. Gärtner, T. Stoltenhoff, and H. Kreye, Bonding Mechanism in Cold Gas Spraying, Acta Mater., 2003, 51(15), p 4379-4394

T.V. Steenkiste and J.R. Smith, Evaluation of Coatings Produced via Kinetic and Cold Spray Processes, J. Therm. Spray Technol., 2004, 13(2), p 274-282

C. Borchers, F. Gärtner, T. Stoltenhoff, and H. Kreye, Microstructural Bonding Features of Cold Sprayed Face Centered Cubic Metals, J. Appl. Phys., 2003, 93(8), p 4288-4292

T. Schmidt, F. Gärtner, H. Assadi, and H. Kreye, Development of a Generalized Parameter Window for Cold Spray Deposition, Acta Mater., 2006, 54(3), p 729-742

T. Marrocco, D.G. McCartney, P.H. Shipway, and A.J. Sturgeon, Production of Titanium Deposits by Cold-Gas Dynamic Spray: Numerical Modeling and Experimental Characterization, J. Therm. Spray Technol., 2006, 15(2), p 263-272

T. Hussain, D.G. McCartney, P.H. Shipway, and D. Zhang, Bonding Mechanisms in Cold Spraying: The Contributions of Metallurgical and Mechanical Components, J. Therm. Spray Technol., 2009, 18(3), p 364-379

A. Papyrin, V. Kosarev, S. Klinkov, A. Alkhimov, and V. Fomin, Cold Spray Technology, Elsevier, Amsterdam, 2007

V.K. Champagne, The Cold Spray Materials Deposition Process, Woodhead Publishing/CRC Press, Cambridge, 2007

S. Kuroda, J. Kawakita, M. Watanabe, and H. Katanoda, Warm Spraying—A Novel Coating Process Based on the High-Velocity Impact of Solid Particles, Sci. Technol. Adv. Mater., 2008, 9(3), 033002 (17 pp)

J. Kawakita, S. Kuroda, T. Fukushima, H. Katanoda, K. Matsuo, and H. Fukanuma, Dense Titanium Coatings by Modified HVOF Spraying, Surf. Coat. Technol., 2006, 201(3-4), p 1250-1255

K.H. Kim, M. Watanabe, J. Kawakita, S. Kuroda, Effects of Temperature of In-flight Particles on Bonding and Microstructure in Warm Sprayed Titanium Deposits, J. Therm. Spray Technol., 2009, 18(3), p 392-400

S.W. Kieffer, Droplet Chondrules: Jetting on High-Velocity Collision of Small Meteoritic Particles May Have Produced Droplet Chondrules, Science, 1975, 189(4200), p 333-340

K.H. Kim, M. Watanabe, J. Kawakita, and S. Kuroda, Grain Refinement in a Single Titanium Powder Particle Impacted at High Velocity, Scripta Mater., 2008, 59(7), p 768-771

K.H. Kim, M. Watanabe, K. Mitsuishi, K. Iakoubovskii, and S. Kuroda, Impact Bonding and Rebounding Between Kinetically Sprayed Titanium Particle and Steel Substrate Revealed by High Resolution Electron Microscopy, J. Phys. D: Appl. Phys., 2009, 42, 065304 (5 pp)

G.R. Johnson, Material Characterization for Warhead Computations, Prog. Astronaut. Aeronaut., 1993, 155, p 165-197

S. Seo, O. Min, and H. Yang, Constitutive Equation for Ti-6Al-4V at High Temperatures Measured Using the SHPB Technique, Int. J. Impact Eng., 2005, 31, p 735-754

K. Yokoyama, M. Watanabe, S. Kuroda, Y. Gotoh, T. Schmidt, and F. Gärtner, Simulation of Solid Particle Impact Behavior for Spray Processes, Mater. Trans., 2006, 47(7), p 1697-1702

ASM International Handbook, vol. 8, Mechanical Testing and Evaluation, Materials Park, OH, 2000

C. Borchers, T. Schmidt, F. Gärtner, and H. Kreye, High Strain Rate Deformation Microstructures of Stainless Steel 316L by Cold Spraying and Explosive Powder Compaction, Appl. Phys. A, 2008, 90, p 517-526

M. Grujicic, C.L. Zhao, W.S. DeRosset, and D. Helfritch, Adiabatic Shear Instability Based Mechanism for Particles/Substrate Bonding in the Cold-Gas Dynamic-Spray Process, Mater. Des., 2004, 25(8), p 681-688

K.H. Kim, M. Watanabe, and S. Kuroda, Thermal Softening Effect on the Deposition Efficiency and Microstructure of Warm Sprayed Metallic Powder, Scripta Mater., 2009, 60(8), p 710-713

Acknowledgment

The authors would like to acknowledge Dr. K. Mitsuishi and Dr. K. Iakoubovskii of NIMS for the EELS analysis and Ms N. Kawano, Mr M. Komatsu, and Mr N. Kakeya of NIMS for sample preparations. This research was supported by the Nanotechnology Network program and World Premier International Research Center Initiative on Materials Nanoarchitectonics of MEXT, Japan and KAKENHI 19360335.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is an invited paper selected from presentations at the 3rd Asian Thermal Spray Conference (ATSC2008) and has been expanded from the original presentation. ATSC2008 was held at Nanyang Executive Centre, Singapore, November 6-7, 2008, and chaired by K.A. Khor.

Rights and permissions

About this article

Cite this article

Kim, K., Watanabe, M. & Kuroda, S. Jetting-Out Phenomenon Associated with Bonding of Warm-Sprayed Titanium Particles onto Steel Substrate. J Therm Spray Tech 18, 490–499 (2009). https://doi.org/10.1007/s11666-009-9379-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-009-9379-1