Abstract

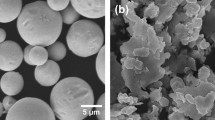

This study investigates the influence of adding Sb on the microstructure and adhesive strength of the Sn3.5Ag solder. Both solidus and liquidus temperatures increase as Sb additions increase. Adding 1.5wt.%Sb leads to the narrowest range (6.6°C) between the solidus and liquidus temperature of the solder. Adding Sb decomposes the as-soldered ringlike microstructure of Sn3.5Ag and causes solid-solution hardening. The as-soldered hardness increases with increasing Sb addition. For long-term storage, adding Sb reduces the size of the rodlike Ag3Sn compounds. The hardness also increases with increasing Sb addition. Adding Sb depresses the growth rate of interfacial intermetallic compounds (IMCs) layers, but the difference between 1% and 2% Sb is not distinct. For mechanical concern, adding Sb improves both adhesive strength and thermal resistance of Sn3.5Ag, where 1.5% Sb has the best result. However, adding Sb causes a variation in adhesive strength during thermal storage. The more Sb is added, the higher the variation reveals, and the shorter the storage time requires. This strength variation helps the solder joints to resist thermal storage.

Similar content being viewed by others

References

National Center of Manufacturing Sciences, Lead-Free Solder Project—Final Report (Ann Arbor, MI: National Center of Manufacturing Sciences, 1997).

A.Z. Miric and A. Grusd, Solder. Surf. Mount Technol. 10, 19 (1998).

Y. Miyazawa and T. Ariga, 1st Int. Symp. on Environmentally Conscious Design and Inverse Manufacturing (Los Alamitos, CA: IEEE Computer Society, 1999), pp. 616–619.

W. Yang and R.W. Messler, Jr., J. Electron. Mater. 23, 765 (1994).

D.R. Flanders, E.G. Jacobs, and R.F. Pinizzotto, J. Electron. Mater. 26, 883 (1997).

L. Zakraysek, Welding J., Res. Suppl., 1972.11, 536s (1972).

M. McCormack and S. **, J. Electron. Mater. 23, 715 (1994).

K. Habu, N. Takeda, H. Watanabe, H. Ooki, J. Abe, T. Saito, Y. Taniguchi, and K. Takayama, 1st Int. Symp. on Environmentally Conscious Design and Inverse Manufacturing (Los Alamitos, CA: IEEE Computer Society, 1999), pp. 606–609.

C.M. Miller, I.E. Anderson, and J.F. Smith, J. Electron. Mater. 23, 595 (1994).

S. ** and M. T. McCormack, U.S. patent 5,762,866 (9 June 1998).

G. Petzow and G. Effenberg, eds., Ternary Alloys, Vol. 2 (New York: VCH, 1988), pp. 549–550.

N.R. Bonda and I.C. Noyan, IEEE Trans. Comp., Packaging Manufacturing Technol.—Part A 19, 208 (1990).

H.-T. Lee and M.-H. Chen, Mater. Sci. Eng. A 333, 24 (2002).

American Society for Metals, Metals Handbook, 8th ed., Vol. 8 (Metals Park, OH: American Society for Metals, 1976), pp. 428–430.

D.B. Masson and B.K. Kirkpatrick, J. Electron. Mater. 15, 349 (1986).

C.-S. Oh, J.-H. Shim, B.-J. Lee, and D.-N. Lee, J. Alloys Compounds 238, 155 (1996).

R.K. Mahidhara, S.M.L. Sastry, K.L. Jerina, I. Turlik, and K.L. Murty, J. Mater. Sci. Lett. 13, 1387 (1994).

D.R. Olsen and K.G. Spanjer, U.S. patent 4,170,472 (9 October 1979).

D.R. Olsen and K.G. Spanjer, Solid State Technol. 1981, 9, 121 (1981).

S.G. Gonya, J.K. Lake, R.C. Long, and R.N. Wild, U.S. patent 5,393,489 (28 February 1995).

S. Kusabiraki and M. Sumita, U.S. patent 6,229,248 (8 May 2001).

L. Zakraysek, Welding J., Res. Suppl. 1972, 11, 536 (1972).

E.K. Ohriner, Welding J., Res. Suppl. 1987, 7, 191 (1987).

A.Z. Miric and A. Grusd, Soldering Surf. Mount Technol. 10, 19 (1998).

I. Artaki, A.M. Jackson, and P.T. Vianco, J. Electron. Mater. 23, 757 (1994).

P.T. Vianco, K.L. Erickson, and P.L. Hopkins, J. Electron. Mater. 23, 721 (1994).

H.-T. Lee, M.-H. Chen, H.-M. Jao, and T.-L. Liao, Mater. Sci. Eng. A 358, 134 (2003).

M.E. Loomans, S. Vaynman, G. Ghosh, and M.E. Fine, J. Electron. Mater. 23, 741 (1994).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lee, HT., Chen, MH., Jao, HM. et al. Effect of adding Sb on microstructure and adhesive strength of Sn-Ag solder joints. J. Electron. Mater. 33, 1048–1054 (2004). https://doi.org/10.1007/s11664-004-0034-9

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s11664-004-0034-9