Abstract

The 2024 anodized aluminum alloy film was sealed by KAl(SO4)2 solution and the effect of sealing on corrosion resistance was investigated by means of potentiodynamic polarization curves, electrochemical impedance spectroscopy, and X-ray photoelectron spectroscopy. The experimental results show that the optimal parameters for KAl(SO4)2 sealing are 35 °C, with the pH value of 8, the concentration of 8 g/L, and the sealing time of 3 min. The corrosion resistance of the KAl(SO4)2 sealed sample can be significantly improved than that of unsealed one, and is obviously superior to that of the conventional hydrothermal sealed sample. Furthermore, X-ray photoelectron spectroscopy demonstrates that more Al(OH)3 will be formed in the process of KAl(SO4)2 sealing, which will shrink the diameter of the microporous and therefore results in the excellent corrosion resistance.

Similar content being viewed by others

References

Song Y F, Ding X F, **ao L R, et al. Effects of Two-stage Aging on the Dimensional Stability of Al-Cu-Mg Alloy[J]. J. Alloys Compd., 2017, 701: 508–514

Khaled K F, Al-Qahtani M M. The Inhibitive Effect of Some Tetrazole Derivatives towards Al Corrosion in Acid Solution: Chemical, Electrochemical and Theoretical Studies[J]. Mater. Chem. Phys., 2009, 113: 150–158

Curioni M, De Miera M S, Skeldon P, et al. Macroscopic and Local Filming Behavior of AA2024 T3 Aluminum Alloy during Anodizing in Sulfuric Acid Electrolyte[J]. J. Electrochem. Soc., 2008, 155: C387–C395

Lee J, Jung U, Kim W, et al. Effects of Residual Water in the Pores of Aluminum Anodic Oxide Layers Prior to Sealing on Corrosion Resistance[J]. Appl. Surf. Sci., 2013, 283: 941–946

Lee W, Ji R, Gösele U, et al. Fast Fabrication of Long-range Ordered Porous Alumina Membranes by Hard Anodization[J]. Nature Mater., 2006, 5: 741–747

Stępniowski W J, Bojar Z. Synthesis of Anodic Aluminum Oxide (AAO) at Relatively High Temperatures[J]. Surf. Coat. Technol., 2011, 206: 265–272

Kim Y C, Park H H, Chun J S, et al. Compositional and Structural Analysis of Aluminum Oxide Films Prepared by Plasma-enhanced Chemical Vapor Deposition[J]. Thin Solid Films, 1994, 237: 57–65

Celebioglu A, Vempati S, Ozgit-Akgun C, et al. Water-soluble Non-polymeric Electrospun Cyclodextrin Nanofiber Template for the Synthesis of Metal Oxide Tubes by Atomic Layer Deposition[J]. RSC Adv., 2014, 4: 61 698–61 705

Kuznetsov B, Serdechnova M, Tedim J, et al. Sealing of Tartaric Sulfuric (TSA) Anodized AA2024 with Nanostructured LDH Layers[J]. RSC Adv., 2016, 6: 13 942–13 952

Wang S, Peng H, Shao Z, et al. Sealing of Anodized Aluminum with Phytic Acid Solution[J]. Surf. Coat. Technol., 2016, 286: 155–164

Bautista A, Gonzalez J A, Lopez V. Influence of Triethanolamine Additions on the Sealing Mechanism of Anodised Aluminium[J]. Surf. Coat. Technol., 2002, 154: 49–54

Yang Y S, Cheng J, Liu S L, et al. Effect of NaAlO2 Sealing on Corrosion Resistance of 2024 Aluminum Alloy Anodized Film[J]. Mater. Corros., 2019, 70: 120–127

Whelan M, Cassidy J, Duffy B. Sol-gel Sealing Characteristics for Corrosion Resistance of Anodised Aluminium[J]. Surf. Coat. Technol., 2013, 235: 86–96

Yang J, Yang Y, Balaskas A, et al. Development of a Chromium-Free Post-Anodizing Treatment Based on 2-Mercaptobenzothiazole for Corrosion Protection of AA2024T3[J]. J. Electrochem. Soc., 2017, 164: C376–C382

Rajguru D, Keshwal B S, Jain S, et al. Alum [KAl (SO4)2·12H2O]: A Green and Efficient Catalyst for Synthesis of Pyrano [4, 3-b] Pyrans in Water Under Conventional and Microwave Conditions[J]. Monatsh Chem., 2013, 144: 1 411–1 416

Liu Z, Xu Z X, Geng H, et al. Study on Fluoride Removal Performance of Activated Alumina Modified by Potassium Aluminum Sulfate[J]. China Water & Wastewater, 2014, 19: 65–71

Zhang C Y. A Sealing Method for Photosensitive Material Plate[P]. CN Patent CN106997157 A, 2017 Aug.1

Wang S, Peng H, Shao Z, et al. Sealing of Anodized Aluminum with Phytic Acid Solution[J]. Surf. Coat. Technol., 2016, 286: 155–164

Moutarlier V, Gigandet M P, Ricq L, et al. Electrochemical Characterisation of Anodic Oxidation Films Formed in Presence of Corrosion Inhibitors[J]. Appl. Surf. Sci., 2001, 183: 1–9

Gonzalez J A, Lopez V, Bautista A, et al. Characterization of Porous Aluminium Oxide Films from Ac Impedance Measurements[J]. J. Appl. Electrochem., 1999, 29: 229–238

López V, Gonzalez J A, Otero E, et al. Atmospheric Corrosion of Bare and Anodised Aluminium in a Wide Range of Environmental Conditions. Part II: Electrochemical responses[J]. Surf. Coat. Technol., 2002, 153: 235–244

Tian L P, Zhao X H, Zhao J M, et al. Electrochemical Behaviors of Anodic Alumina Sealed by Ce-Mo in NaCl Solutions[J]. Trans. Non-ferrous Met. Soc. China, 2006, 16: 1 178–1 183

Hitzig J, Jüttner K, Lorenz W J, et al. AC-impedance Measurements on Porous Aluminium Oxide Films[J]. Corros. Sci., 1984, 24: 945–952

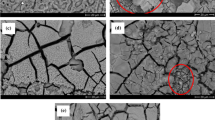

Hu N, Dong X, He X, et al. Effect of Sealing on the Morphology of Anodized Aluminum Oxide[J]. Corros. Sci., 2015, 97: 17–24

Lee J, Kim Y, Jang H, et al. Cr2O3 Sealing of Anodized Aluminum Alloy by Heat Treatment[J]. Surf. Coat. Technol., 2014, 243: 34–38

Kim Y C, Park H H, Chun J S, et al. Compositional and Structural Analysis of Aluminum Oxide Films Prepared by Plasma-enhanced Chemical Vapor Deposition[J]. Thin Solid Films, 1994, 237: 57–65

Celebioglu A, Vempati S, Ozgit-Akgun C, et al. Water-soluble Non-polymeric Electrospun Cyclodextrin Nanofiber Template for The Synthesis of Metal Oxide Tubes by Atomic Layer Deposition[J]. RSC Adv., 2014, 4: 61 698–61 705

He H, Alberti K, Barr TL, et al. ESCA Studies of Aluminophosphate Molecular Sieves[J]. J. Phys. Chem., 1993, 97: 13 703–13 707

Crist B V. Handbooks of Monochromatic XPS Spectra. Volume 2-Commercially Pure Binary Oxides[M]. California: XPS International, LLC, 2005

Hess A, Kemnitz E, Lippitz A, et al. ESCA, XRD, and IR Characterization of Aluminum Oxide, Hydroxyfluoride, and Fluoride Surfaces in Correlation with Their Catalytic Activity in Heterogeneous Halogen Exchange Reactions[J]. J. Catal., 1994, 148: 270–280

Funding

Funded by the National Natural Science Foundation of China (No. 12175107) and the Natural Science Foundation of Nan**g University of Posts and Telecommunications (No.NY220030)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dong, P., Cheng, J. Sealing Effect of KAl(SO4)2 Solution on the Corrosion Resistance of Anodized Aluminum Alloy. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 37, 104–109 (2022). https://doi.org/10.1007/s11595-022-2505-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-022-2505-3