Abstract

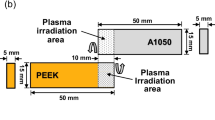

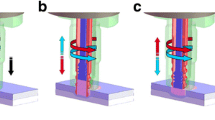

The direct bonding of A5052 aluminum (Al) alloy to the engineering polymer poly(ether ether ketone) (PEEK) using an atmospheric pressure plasma-assisted process was demonstrated. The effect of plasma irradiation on the bonding surface of metal resin on the bonding strength following thermal press fitting method was investigated. Specimens bonded by plasma irradiation on the PEEK surface only showed a high tensile shear stress of 15.5 MPa. With increasing plasma irradiation time, the bond strength of the samples bonded to the PEEK surface by plasma irradiation increased. The increase in the bond strength between metals and polymers following direct bonding is caused by the addition of oxygen functional groups on the polymer. In contrast, specimens in which only the Al was exposed to the plasma showed a decrease in bond strength compared with unirradiated samples. This reduction in bond strength is attributed to the forming magnesium oxide, which forms in the early stages of participation due to plasma irradiation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Multi-material hybrid structures exhibit various useful properties, including both low density and high performance. In particular, metal-polymer hybrids are expected to replace metals in industrial applications because they can reduce weight compared with pure metals and so lower costs, such as by providing improved fuel efficiency in the aerospace and automotive sectors [1,2,3,4,5]. Thermoplastics are also advantageous because they can be joined without the use of adhesives [6, 7] or items such as screws and rivets [8, 9]. To date, these materials have been joined via thermal press fitting using ultrasonic [10,11,12], induction [13], laser [14,15,16,17] or solid friction [18] heat sources. The metals-polymers direct bonding is known to result primarily from hydrogen bonds between oxides formed on metal surfaces and polar functional groups (amino groups, hydroxyl groups, carboxyl groups, etc.) present on polymers. Thus, the addition of functional groups to the surface of polymer using some surface treatment methods is required to obtain high strength, high quality direct metal-polymer bonding. At present, these surface treatment methods include chemical etching using acids and bases [19] and exposure to ultraviolet radiation [20], coronas [44] on metals having a MgO surface layer are frequently poor because of the friability and susceptibility to hydrolysis of the oxide [39]. Typically, MgO formed on Al-Mg alloys such as A5052 via diffusion of Mg will show low cohesive strength and is easily chemically fed to form oxides and thus to generate weakly bonded layers [45]. The present results suggest that the migration of Mg to the surface as a consequence of heating by the plasma with subsequent oxidation by radicals induced the formation of MgO. This, in turn, lowered the bond strength between the A5052 and PEEK.

The effect of exposing the PEEK side of A5052-PEEK specimens to the plasma was also investigated. Figure 9 plots the tensile shear strength of A5052-PEEK joints as a function of the time span over which the PEEK was treated with the plasma, with no treatment applied to the A5052. With increasing irradiation time, the bond strength evidently underwent a moderate increase from 10.2 MPa at 0 min to 15.5 MPa after 5 min and then was almost constant.

In a previous study, the effect of plasma irradiation on the chemical state of PEEK surfaces was assessed using XPS [32]. These prior XPS analyses indicated the O-C=O bond formation due to irradiation of the plasma, as well as C-O and C=O bonds that were originally present in the PEEK. The amount of each of these groups on the PEEK surface was found to increase as the plasma irradiation time was increased. It has been determined that O=C-O groups on the polymer increase the bond strength between metals and polymers following direct bonding [46,47,48]. Hence, these results suggest that oxidation of the PEEK by radicals in the atmospheric pressure RF plasma jet generated oxygen-containing surface functional groups that increased the bond strength.

4 Conclusions

Direct bonding of an Al alloy to PEEK via non-thermal atmospheric pressure plasma-assisted joining technology has been demonstrated. The effect of plasma irradiation on the bond strength following thermal press fitting was investigated. The tensile shear strength of A5052-PEEK joined by thermal press fitting with plasma-assisted joining was established by comparison with specimens made using conventional thermal press fitting and adhesive bonding. The tensile shear stress for samples bonded after irradiation of the plasma of only the PEEK was as high as 15.5 MPa, 50% higher than that of the unirradiated sample. This improved bond strength can be attributed to the addition of oxygen-based functional groups on the surface of PEEK by radicals generated by plasma jet. In contrast, plasma treatment of the A5052 side led to a decrease in bond strength as a consequence of the generation of MgO, which formed on Al-Mg alloys such as A5052 via diffusion of Mg that will show low cohesive strength and is easily chemically fed to form oxides and thus to generate weakly bonded layers. This reduction in bond strength is attributed to the forming magnesium oxide, which forms in the early stages of participation due to plasma irradiation. The effect of exposing the PEEK side of A5052-PEEK specimens to the plasma was also investigated. With increasing irradiation time, the bond strength evidently underwent a moderate increase from 10.2 MPa at 0 min to 15.5 MPa after 5 min and then was almost constant. These results suggest that oxidation of the PEEK by radicals in the atmospheric pressure RF plasma jet generated oxygen-containing surface functional groups that increased the bond strength.

References

Lambiase F, Scipioni SI, Lee CJ et al (2021) A state-of-the-art review on advanced joining processes for metal-composite and metal-polymer hybrid structures. Materials 14. https://doi.org/10.3390/MA14081890

Mondal S (2021) Aluminum or its alloy matrix hybrid nanocomposites. Met Mater Int 27:2188–2204

Li SS, Yue X, Li QY, Peng HL, Dong BX, Liu TS, Yang HY, Fan J, Shu SL, Qiu F, Jiang QC (2023) Development and applications of aluminum alloys for aerospace industry. J Mater Res Technol 27:944–983. https://doi.org/10.1016/j.jmrt.2023.09.274

Han S, Guang X, Li Z, Li Y (2022) Joining processes of CFRP-Al sheets in automobile lightweighting technologies: a review. Polym Compos 43:8622–8633. https://doi.org/10.1002/pc.27088

Chandel R, Sharma N, Bansal SA (2021) A review on recent developments of aluminum-based hybrid composites for automotive applications. Emergent Mater 4:1243–1257. https://doi.org/10.1007/s42247-021-00186-6

Tong L (1998) Failure of adhesive-bonded composite single lap joints with embedded cracks. AIAA J 36:448–456. https://doi.org/10.2514/2.385

Cheuk PT, Tong L (2002) Failure of adhesive bonded composite lap shear joints with embedded precrack. Compos Sci Technol 62:1079–1095. https://doi.org/10.1016/S0266-3538(02)00054-4

Marannano G, Zuccarello B (2015) Numerical experimental analysis of hybrid double lap aluminum-CFRP joints. Compos B Eng 71:28–39. https://doi.org/10.1016/J.COMPOSITESB.2014.11.025

Amancio-Filho ST, Dos Santos JF (2009) Joining of polymers and polymer-metal hybrid structures: recent developments and trends. Polym Eng Sci 49:1461–1476. https://doi.org/10.1002/PEN.21424

Balle F, Wagner G, Eifler D (2007) Ultrasonic spot welding of aluminum sheet/ carbon fiber reinforced polymer - Joints. Materwiss Werksttech 38:934–938. https://doi.org/10.1002/MAWE.200700212

Balle F, Wagner G, Eifler D (2009) Ultrasonic metal welding of aluminium sheets to carbon fibre reinforced thermoplastic composites. Adv Eng Mater 11:35–39. https://doi.org/10.1002/ADEM.200800271

Balle F, Eifler D (2012) Statistical test planning for ultrasonic welding of dissimilar materials using the example of aluminum-carbon fiber reinforced polymers (CFRP) joints. Materwiss Werksttech 43:286–292. https://doi.org/10.1002/MAWE.201200943

Mitschang P, Velthuis R, Didi M (2013) Induction spot welding of metal/CFRPC hybrid joints. Adv Eng Mater 15:804–813. https://doi.org/10.1002/ADEM.201200273

Katayama S, Kawahito Y (2008) Laser direct joining of metal and plastic. Scr Mater 59:1247–1250. https://doi.org/10.1016/J.SCRIPTAMAT.2008.08.026

Lamberti C, Solchenbach T, Plapper P, Possart W (2014) Laser assisted joining of hybrid polyamide-aluminum structures. Phys Procedia 56:845–853. https://doi.org/10.1016/J.PHPRO.2014.08.103

Jung KW, Kawahito Y, Takahashi M, Katayama S (2013) Laser direct joining of carbon fiber reinforced plastic to zinc-coated steel. Mater Des 47:179–188. https://doi.org/10.1016/J.MATDES.2012.12.015

Davies RJ, Kinloch AJ (1989) The surface characterisation and adhesive bonding of aluminium. Adhesion 13:8–22. https://doi.org/10.1007/978-94-010-9082-7_2

Liu FC, Liao J, Nakata K (2014) Joining of metal to plastic using friction lap welding. Mater Des 54:236–244. https://doi.org/10.1016/J.MATDES.2013.08.056

Ha SW, Hauert R, Ernst KH, Wintermantel E (1997) Surface analysis of chemically-etched and plasma-treated polyetheretherketone (PEEK) for biomedical applications. Surf Coat Technol 96:293–299. https://doi.org/10.1016/S0257-8972(97)00179-5

Shi H, Sinke J, Benedictus R (2017) Surface modification of PEEK by UV irradiation for direct co-curing with carbon fibre reinforced epoxy prepregs. Int J Adhes Adhes 73:51–57. https://doi.org/10.1016/J.IJADHADH.2016.07.017

Comyn J, Mascia L, **ao G, Parker BM (1996) Corona-discharge treatment of polyetheretherketone (PEEK) for adhesive bonding. Int J Adhes Adhes 16:301–304. https://doi.org/10.1016/S0143-7496(96)00010-3

Endo T, Reddy L, Nishikawa H et al (2017) Composite engineering - direct bonding of plastic PET films by plasma irradiation. Procedia Eng 171:88–103. https://doi.org/10.1016/J.PROENG.2017.01.315

Uchida G, Kawabata K, Ito T et al (2017) Development of a non-equilibrium 60 MHz plasma jet with a long discharge plume. J Appl Phys 122. https://doi.org/10.1063/1.4993715

Uchida G, Takenaka K, Takeda K et al (2018) Selective production of reactive oxygen and nitrogen species in the plasma-treated water by using a nonthermal high-frequency plasma jet. Jpn J Appl Phys 57. https://doi.org/10.7567/JJAP.57.0102B4

Takenaka K, Machida R, Bono T et al (2022) Development of a non-thermal atmospheric pressure plasma-assisted technology for the direct joining of metals with dissimilar materials. J Manuf Process 75:664–669. https://doi.org/10.1016/j.jmapro.2022.01.041

Martinsen K, Hu SJ, Carlson BE (2015) Joining of dissimilar materials. CIRP annals 64:679–699. https://doi.org/10.1016/J.CIRP.2015.05.006

Zhou Z, Gao X, Zhang Y (2022) Research progress on characterization and regulation of forming quality in laser joining of metal and polymer, and development trends of lightweight automotive applications. Metals 12:1666. https://doi.org/10.3390/MET12101666

Feistauer EE, dos Santos JF, Amancio-Filho ST (2019) A review on direct assembly of through-the-thickness reinforced metal–polymer composite hybrid structures. Polym Eng Sci 59:661–674. https://doi.org/10.1002/PEN.25022

Vasconcelos RL, Oliveira GHM, Amancio-Filho ST, Canto LB (2023) Injection overmolding of polymer-metal hybrid structures: a review. Polym Eng Sci 63:691–722. https://doi.org/10.1002/PEN.26244

Nakamae K, Nishino T, Airu X, Asaoka S (1995) Localization of the curing agent at an epoxy resin/oxidized aluminium interface. Int J Adhes Adhes 15:15–20. https://doi.org/10.1016/0143-7496(95)93638-2

Glazer J (1954) Monolayer studies of some ethoxylin resin adhesives and related compounds. J Polym Sci 13:355–369. https://doi.org/10.1002/pol.1954.120137004

Takenaka K, **da A, Nakamoto S, Toko S, Uchida G, Setsuhara Y (2023) Direct bonding of stainless steel and PEEK using non-thermal atmospheric pressure plasma-assisted joining technology. J Manuf Process 105:276–281. https://doi.org/10.1016/j.jmapro.2023.09.049

Strohmeier BR (1990) An ESCA method for determining the oxide thickness on aluminum alloys. Surface and Interface Analysis 15:51–56. https://doi.org/10.1002/SIA.740150109

Liu M, Zanna S, Ardelean H et al (2009) A preliminary quantitative XPS study of the surface films formed on pure magnesium and on magnesium-aluminium intermetallics by exposure to high-purity water. Materials Science Forum 618–619:255–262. https://doi.org/10.4028/WWW.SCIENTIFIC.NET/MSF.618-619.255

Chen C, Splinter SJ, Do T, McIntyre NS (1997) Measurement of oxide film growth on Mg and Al surfaces over extended periods using XPS. Surf Sci 382:L652–L657. https://doi.org/10.1016/S0039-6028(97)00054-X

Wang X, Lin JP, Min JY, Wang PC, Sun CC (2018) Effect of atmospheric pressure plasma treatment on strength of adhesive-bonded aluminum AA5052. J Adhesion 94:701–722. https://doi.org/10.1080/00218464.2017.1393747

Ritchie IM, Sanders JV, Weickhardt PL (1971) Oxidation of a dilute aluminum magnesium alloy. Oxidation of Metals 3:91–101. https://doi.org/10.1007/BF00604741/METRICS

Goldstein B, Dresner J (1978) Growth of MgO films with high secondary electron emission on Al-Mg alloys. Surf Sci 71:15–26. https://doi.org/10.1016/0039-6028(78)90310-2

Lea C, Ball J (1984) The oxidation of rolled and heat treated Al-Mg alloys. Applications of Surface Science 17:344–362. https://doi.org/10.1016/0378-5963(84)90023-0

Zayan MH, Jamjoom OM, Razik NA (1990) High-temperature oxidation of Al-Mg alloys. Oxid Met 34:323–333. https://doi.org/10.1007/BF00665021

Haginoya I, Fukusako T (1983) Oxidation of molten Al-Mg alloys. T Jpn I Met 24:613–619. https://doi.org/10.2320/matertrans1960.24.613

Guminski RD, Meredith FMP (1961) Lacquer coating of aluminium/magnesium alloys. J Oil Colour Chem Assoc 44:93

Kozma L, Olefjord I (2013) Basic processes of surface preparation and bond formation of adhesively joined aluminium. Mater Sci Tech-lond 3:860–874. https://doi.org/10.1179/MST.1987.3.10.860

Sun TS, Chen JM, Venables JD, Hop** R (1978) Effects of chemical and thermal treatments on the composition of 2024 aluminum adherend surfaces. Applications of Surface Science 1:202–214. https://doi.org/10.1016/0378-5963(78)90015-6

Field DJ, Scamans GM, Butler EP (1987) High temperature oxidation of Al-4. 2 Wt Pct Mg ALLOY. Metall Trans A 18A:463–472. https://doi.org/10.1007/BF02648807

Ochoa-Putman C, Vaidya UK (2011) Mechanisms of interfacial adhesion in metal–polymer composites – effect of chemical treatment. Compos Part A Appl Sci Manuf 42:906–915. https://doi.org/10.1016/J.COMPOSITESA.2011.03.019

Comyn J, Mascia L, **ao G, Parker BM (1996) Plasma-treatment of polyether ether ketone (PEEK) for adhesive bonding. Int J Adhes Adhes 16:97–104. https://doi.org/10.1016/0143-7496(96)89798-3

Laurens P, Sadras B, Decobert F et al (1998) Enhancement of the adhesive bonding properties of PEEK by excimer laser treatment. Int J Adhes Adhes 18:19–27. https://doi.org/10.1016/S0143-7496(97)00063-8

Funding

Open access funding provided by Osaka University.

Author information

Authors and Affiliations

Contributions

Kosuke Takenaka contributed to all parts of this work: Conceptualization, Investigation, and Writing the manuscript. Akiya **da, Sotaro Nakamoto, Ryosuke Koyari and Sususmu Toko contributed to collecting and analyzing the data of surface measurement and the joining experiments. Giichiro Uchida contributed to assistance of conceptualization, analyzing the data of investigation. Yuichi Setsuhara contributed to conceptualization, supervision, and project administration. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Consent for publication

The authors give the publisher the consent to publish the work.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Takenaka, K., **da, A., Nakamoto, S. et al. Improving bonding strength by non-thermal atmospheric pressure plasma-assisted technology for A5052/PEEK direct joining. Int J Adv Manuf Technol 130, 903–913 (2024). https://doi.org/10.1007/s00170-023-12747-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12747-6