Abstract

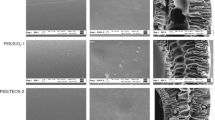

In this study, polyethersulfone (PES)-based nanocomposite membranes with the incorporation of inorganic filler of α-alumina were prepared via thermal phase inversion method. The fabricated flat sheet-mixed matrix membranes were characterized using X-ray diffraction, thermal gravimetric analysis, differential scanning calorimetry, scanning electron microscopy, and atomic force microscope analysis, and the permeation tests were performed for hydrogen, nitrogen and carbon dioxide. Also prepared α-alumina particles were identified by X-ray diffraction and the surface area, total pore volume and average pore diameter of particles were measured with a high-speed gas-sorption analyzer. The distribution and dispersion of α-alumina particles suspended in the polymer matrix were uniform and the surface roughness of the nanocomposite membranes was obviously lower than that of the pure membranes. The thermal analysis indicated that the glass transition temperature of the mixed matrix membranes was around 221.23 °C and the initial degradation temperature was up to 433 °C in air. The nanocomposite membranes increased the permeability of hydrogen, nitrogen and carbon dioxide gases and the hydrogen over nitrogen selectivity, simultaneously and shifted above the Robeson’s upper bound line-2008. The results showed that the nanocomposite membrane containing 8 wt % of α-alumina led to a considerable and simultaneous increase in the permeability of hydrogen (up to 8 times at pressure of 4 bar) and the selectivity of hydrogen over nitrogen (up to 2.4 times at pressure of 4 bar) in comparison to the neat polyethersulfone membranes. The pressure dependence of the gas permeability of the membranes was also investigated and based on selectivity versus permeability charts, the appropriate morphology of the nanocomposite membrane was suggested. Overall, the capability of α-alumina as an inorganic filler for hydrogen separation application has been shown.

Similar content being viewed by others

References

Yu J, Li L, Liu N, Lee R (2013) An approach to prepare defect-free PES/MFI-type zeolite mixed matrix membranes for CO2/N2 separation. J Mater Sci 48:3782–3788

Liang CY, Uchytil P, Petrychkovych R, Lai YC, Friess K, Sipek M, Reddya MM, Suen SY (2012) A comparison on gas separation between PES (polyethersulfone)/MMT (Na-montmorillonite) and PES/TiO2 mixed matrix membranes. Sep Purif Technol 92:57–63

Yeo ZY, Chew TL, Zhu PW, Mohamed AR, Chai SP (2012) Conventional processes and membrane technology for carbon dioxide removal from natural gas: a review. J Nat Gas Chem 21:282–298

Madaeni SS, Farhadian A, Vatanpour V (2012) Effects of phase inversion and composition of casting solution on morphology and gas permeance of polyethersulfone/polyimide blend membranes. Adv Polym Tech 31:298–309

Ge L, Zhu Z, Rudolph V (2011) Enhanced gas permeability by fabricating functionalized multi-walled carbon nanotubes and polyethersulfone nanocomposite membrane. Sep Purif Technol 78:76–82

Chung TS, Jiang LY, Li Y, Kulprathipanja S (2007) Mixed matrix membranes (MMMs) comprising organic polymers with dispersed inorganic fillers for gas separation. Prog Polym Sci 32:483–507

Khanbabaei G, Vasheghani-Farahani E, Rahmatpour A (2012) Pure and mixed gas CH4 and n-C4H10 permeation in PDMS-fumed silica nanocomposite membranes. Chem Eng J 191:369–377

Clarizia G, Algieri C, Drioli E (2004) Filler-polymer combination: a route to modify gas transport properties of a polymeric membrane. Polymer 45:5671–5681

Robeson LM (2008) The upper bound revisited. J Membr Sci 320:390–400

Aroon MA, Ismail AF, Matsuura T, Montazer-Rahmati MM (2010) Performance studies of mixed matrix membranes for gas separation: a review. Sep Purif Technol 75:229–242

Cakal U, Yilmaz L, Kalipcilar H (2012) Effect of feed gas composition on the separation of CO2/CH4 mixtures by PES-SAPO 34-HMA mixed matrix membranes. J Membr Sci 417–418:45–51

Lin R, Ge L, Hou L, Strounina E, Rudolph V, Zhu Z (2014) Mixed matrix membranes with strengthened MOFs/polymer interfacial interaction and improved membrane performance. ACS Appl Mater Interfaces 6:5609–5618

Liu J, Wu S, Zou M, Zheng X, Cai Z (2012) Surface modification of silica and its compounding with polydimethylsiloxane matrix: interaction of modified silica filler with PDMS. Iran Polym J 21:583–589

Saeed Kh, Khan I (2014) Preparation and properties of single-walled carbon nanotubes/poly (butylene terephthalate) nanocomposites. Iran Polym J 23:53–58

Ma XH, Xu ZL, Wu F, Xu HT (2012) PFSA-TiO2 (or Al2O3)-PVA/PVA/PAN difunctional hollow fiber composite membranes prepared by dip-coating method. Iran Polym J 21:31–41

Li Y, Chung TS, Cao C, Kulprathipanja S (2005) The effects of polymer chain rigidification, zeolite pore size and pore blockage on polyethersulfone (PES)-zeolite A mixed matrix membranes. J Membr Sci 260:45–55

Li Y, Chung TS, Kulprathipanja S (2007) Novel Ag+-zeolite/polymer mixed matrix membranes with a high CO2/CH4 selectivity. AIChE J 53:610–616

Karatay E, Kalıpçılar H, Yılmaz L (2010) Preparation and performance assessment of binary and ternary PES-SAPO 34-HMA based gas separation membranes. J Membr Sci 364:75–81

Tutuk DK, Ahmad FI, Ahmad M (2010) Application of activated carbon mixed matrix membrane for oxygen purification. Int J Sci Eng 1:21–24

Ismail AF, Rahim NH, Mustafa A, Matsuura T, Ng BC, Abdullah S, Hashemifard SA (2011) Gas separation performance of polyethersulfone/multi-walled carbon nanotubes mixed matrix membranes. Sep Purif Technol 80:20–31

Sadeghi M, Khanbabaei G, Saeedi Dehaghani AH, Sadeghi M, Aravand MA, Akbarzade M, Khatti S (2008) Gas permeation properties of ethylene vinyl acetate–silica nanocomposite membranes. J Membr Sci 322:423–428

Li JF, Xu ZL, Yang H, Yu LY, Liu M (2009) Effect of TiO2 nanoparticles on the surface morphology and performance of microporous PES membrane. Appl Surf Sci 255:4725–4732

Wu T, **e T, Yang G (2009) Preparation and characterization of poly(ε-caprolactone)/Na+-MMT nanocomposites. Appl Clay Sci 45:105–110

Chowdhury G, Kruczek B, Matsuura T (2001) Polyphenylene oxide and modified polyphenylene oxide membranes: gas, vapour and liquid separation. Kluwer Academic Publishers, Dordrecht

Khulbe KC, Matsuura T, Lamarche G, Lamarche AM (2000) X-Ray diffraction analysis of dense PPO membranes. J Membr Sci 170:81–89

Sing KSW, Everett DH, Haul RAW, Moscou L, Pierotti RA, Rouquerol J, Siemieniewska T (1985) Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity. Pure Appl Chem 57:603–619

Cong H, Radosz M, Towler BF, Shen Y (2007) Polymer-inorganic nanocomposite membranes for gas separation. Sep Purif Technol 55:281–291

Ismail AF, Rahim RA, Rahman WAWA (2008) Characterization of polyethersulfone/Matrimid®5218 miscible blend mixed matrix membranes for O2/N2 gas separation. Sep Purif Technol 63:200–206

Luo M, Wen Q, Liu J, Liu H, Jia Z (2011) Fabrication of SPES/nano-TiO2 composite ultrafiltration membrane and its anti-fouling mechanism. Chin J Chem Eng 19:45–51

Wang MJ (1998) Effect of polymer-filler and filler–filler interactions on dynamic properties of filled vulcanizates. Rubber Chem Technol 71:520–589

Ahn J, Chung WJ, Pinnau I, Guiver MD (2008) Polysulfone/silica nanoparticle mixed-matrix membranes for gas separation. J Membr Sci 314:123–133

Li Y, Guan HM, Chung TS, Kulprathipanja S (2006) Effects of novel silane modification of zeolite surface on polymer chain rigidification and partial pore blockage in polyethersulfone (PES)–zeolite A mixed matrix membranes. J Membr Sci 275:17–28

Li Y, Chung TS (2010) Molecular-level mixed matrix membranes comprising Pebax® and POSS for hydrogen purification via preferential CO2 removal. Int J Hydrog Energy 35:10560–10568

Rubal M, Wilkins CW Jr, Cassidy PE, Lansford C, Yamada Y (2008) Fluorinated polyimide nanocomposites for CO2/CH4 separation. Polym Adv Technol 19:1033–1039

Ismail AF, Kusworo TD, Mustafa A (2008) Enhanced gas permeation performance of polyethersulfone mixed matrix hollow fiber membranes using novel Dynasylan Ameo silane agent. J Membr Sci 319:306–312

Khulbe KC, Kruczek B, Chowdhury G, Gagné S, Matsuura T, Verma SP (1996) Characterization of membranes prepared from PPO by Raman scattering and atomic force microscopy. J Membr Sci 111:57–70

David OC, Gorri D, Urtiaga A, Ortiz I (2011) Mixed gas separation study for the hydrogen recovery from H2/CO/N2/CO2 post combustion mixtures using a Matrimid membrane. J Membr Sci 378:359–368

Li Y, Chung TS, Huang Z, Kulprathipanja S (2006) Dual-layer polyethersulfone (PES)/BTDA-TDI/MDI co-polyimide (P84) hollow fiber membranes with a submicron PES-zeolite beta mixed matrix dense-selective layer for gas separation. J Membr Sci 277:28–37

Ramanathan T, Fisher FT, Ruoff RS, Brinson LC (2005) Amino-functionalized carbon nanotubes for binding to polymers and biological systems. Chem Mater 17:1290–1295

Merkel TC, Freeman BD, Spontak RJ, He Z, Pinnau I, Meakin P, Hill AJ (2002) Ultrapermeable, reverse-selective nanocomposite membranes. Science 296:519–522

Moore TT, Koros WJ (2005) Non-ideal effects in organic-inorganic materials for gas separation membranes. J Mol Struct 739:87–98

Merkel TC, Bondar VI, Nagai K, Freeman BD, Pinnau I (2000) Gas sorption, diffusion and permeation in poly(dimethylsiloxane). J Polym Sci B Polym Phys 38:415–434

Yampolskii Y, Pinnau I, Freeman BD (2006) Materials science of membranes for gas and vapor separation. Wiley, New York

Matteucci S, Yampolskii Y, Freeman BD, Pinnau I (2006) Transport of gases and vapors in glassy and rubbery polymers. Materials science of membranes for gas and vapor separation. Wiley, New York, pp 1–47

Ge L, Zhou W, Rudolph V, Zhu Z (2013) Mixed matrix membranes incorporated with size-reduced Cu-BTC for improved gas separation. J Mater Chem A 1:6350–6358

Acknowledgments

Appreciation is expressed to Research Institute of Petroleum Industry (RIPI) of IRAN for the financial support with the grant number of 83481047. The authors would like to thank Mrs. R. Akbari Anari for her technical helps.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Farrokhnia, M., Rashidzadeh, M., Safekordi, A. et al. Fabrication and evaluation of nanocomposite membranes of polyethersulfone/α-alumina for hydrogen separation. Iran Polym J 24, 171–183 (2015). https://doi.org/10.1007/s13726-015-0308-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-015-0308-5