Search

Search Results

-

Research on Impact–Abrasion–Corrosion Behavior of Three Typical Wear-Resistant Steels under High Impact Energy

The impact–abrasion–corrosion behavior of three typical wear-resistant steels including low-alloy wear-resistant steel, martensitic stainless steel...

-

Optimization of Nano and Micro Filler Concentration in Epoxy Matrix for Better Mechanical and Anticorrosion Properties

Coatings as a protection for mechanical equipment and components is one of the major targets for the scientific research. Coatings are widely applied...

-

Cationic UV-cured epoxy coating with inhibitor-loaded nanoparticles: photoinitiated cationic polymerization, mechanical properties and corrosion protection of steel

This work aims to explore how the cationic UV-curing technology can be applied for corrosion protection of metals. For this purpose, the cationic...

-

Slippery surface for enhancing surface robustness and chemical stability

Aluminum (Al) is often used for aircraft, shipbuilding, automobile and other related fields because of its low density, high strength, and low cost....

-

Laser Powder Bed Fusion Printing of CoCrFeMnNi High Entropy Alloy: Processing, Microstructure, and Mechanical Properties

Equiatomic CoCrFeMnNi high entropy alloy (HEA) powder was processed by laser powder bed fusion (LPBF) additive manufacturing (AM). The properties of...

-

Assessment of technologies to produce corrosion resistant coatings on nuclear waste disposal canisters

A strategy for reducing the cost of nuclear waste canisters for deep geological disposal is to fabricate the core with a relatively cheap carbon...

-

Use of a Ni-TiO2 nanocomposite film to enhance agricultural cutting knife surfaces by electrodeposition technology

Crop harvester machines have played a significant role in increasing crop yield by harvesting at the optimal time and reducing crop losses; however,...

-

Influence of the Counter-Body Material on Micro-Abrasion-Corrosion

This study aims to investigate how the ball material used in micro-abrasion-corrosion testing affects AISI 304 stainless steel. Three different...

-

Wear Mechanisms/Models

The surfaces are continuously damaged by wear. Friction always leads to wear. According to statistics, wear, fatigue, and corrosion are the three...

-

Graphite and Carbide Friction and Wear

In tribological applications like bearings and cutting tools, graphite and carbide are used as components.

-

Some Thoughts on Modeling Abrasion-Corrosion: Wear by Hard Particles in Corrosive Environments

Wear by hard particles can involve abrasion or erosion and is one of the most severe forms of wear. When a corrosive environment is present, the...

-

Surface Protection from Wear Through Coating

Four general categories can be used to classify surface engineering treatments: surface coatings (including metallic plating, and thin and thick...

-

Silicone-Based Coatings for High-Temperature Applications

This chapter explores the use of silicone-based coatings for high-temperature applications. These coatings have unique properties that make them...

-

Wear in Metals

Two significant advancements were achieved in the second half of the twentieth century that are intended to increase the resistance of engineering...

-

SiC and MWCNT Blending Actions on Functional Performance of Hybrid AA2024 Alloy Nanocomposite Via Two Step Stir Cast Route

The hybrid aluminium alloy matrix composites are adopted in high-strength-to-weight ratio applications with technical benefits, including high...

-

Comprehensive Overview of Nano, Micro, and Macro Tribometers in Practice

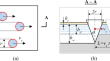

Tribological studies, crucial in understanding the complex interactions between surfaces in relative motion, necessitate the use of diverse...

-

Corrosive Wear Mechanism of Supersonic Atmospheric Plasma Spray Coating of Hydraulic Supports in Industrial Environment

The Cr 3 C 2 -NiCr coating was fabricated using supersonic atmospheric plasma spraying technology (SAPS), and its corrosive wear resistance in a...

-

Protective Coatings for High-Temperature Thermoelectric Materials

Thermoelectric materials (TEM) are one of the renewable energy sources which convert heat directly into electricity without the emission of any...

-

Silicon-Based Technologies for High-Temperature Coatings and Their Corrosion Behaviours

Polymers based on silicon make excellent materials for coating applications in industrial sectors, manufacturing, energy sector, transportation,...

-

Role of Carbide-Based Thermal-Sprayed Coatings to Prevent Failure for Boiler Steels: A Review

Modern boilers operating at high temperatures and pressures face a constant battle against wear, corrosion, and oxidation. These harsh conditions can...