Abstract

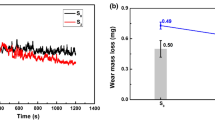

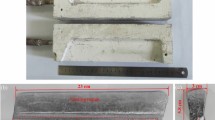

A Zn-38Al-3.5Cu-1.2Mg composite reinforced with nano-SiCp was fabricated via stirring-assisted ultrasonic vibration. To improve the abrasive resistance of the Zn-38Al-3.5Cu-1.2Mg/SiCp composite, several stabilization treatments with distinct solid solutions and aging temperatures were designed. The results indicated that the optimal stabilization treatment for the Zn-38Al-3.5Cu-1.2Mg/SiCp composite comprised solution treatment at 380°C for 6 h and aging at 170°C for 48 h. The stabilization treatment led to the formation of dispersive and homogeneous nano-SiCp. During the friction wear condition, the nano-SiCp limited the microstructure evolution from the hard α(Al,Zn) phase to the soft β(Al,Zn) phase. Moreover, the increased amount of nano-SiCp improved the grain dimension and contributed to the composite abrasive resistance. Furthermore, the stabilization treatment suppressed the crack initiation and propagation in the friction wear process, thereby improving the abrasive resistance of the Zn-38Al-3.5Cu-1.2Mg/SiCp composite.

Similar content being viewed by others

References

Z. Azakli and T. Savaşkan, An examination of friction and sliding wear properties of Zn-40Al-2Cu-2Si alloy in case of oil cut off, Tribol. Int., 41(2008), 1, p. 9.

S. Temel, A.M. Reza, and O.T. Hasan, Tribological properties of Zn-25Al-3Cu-1Si alloy, Tribol. Int., 81(2015), p. 105.

T. Liu, N.C. Si, G.L. Liu, R. Zhang, and C.Y. Qi, Effects of Si addition on microstructure, mechanical and thermal fatigue properties of Zn-38Al-2.5Cu alloys, Trans. Nonferrous Met. Soc. China, 26(2016), No. 7, p. 1775.

S. Liu, Q. Yuan, Y.Q. Gong, G. Xu, and W.W. Qiao, Relationship between microstructure and dry wear behavior of compocast nano-SiC(p)+micro-Gr(p)/Zn-35Al-1.2Mg-0.2Sr composite under different chilling conditions, Kovove Mater., 58(2020), No. 1, p. 1.

S.K. Mishra, S. Biswas, and A. Satapathy, A study on processing, characterization and erosion wear behavior of silicon carbide particle filled ZA-27 metal matrix composites, Mater. Des., 55(2014), p. 958.

B. Biljana, B. Jelena, B. Ilija, and J. Bore, Corrosion influence on surface appearance and microstructure of compo cast ZA27/SiCp composites in sodium chloride solution, Trans. Nonferrous Met. Soc. China, 26(2016), No. 6, p. 1512.

S. Liu, Q. Yuan, Y.Q. Gong, Y.L. Zhou, L.X. Li, and G. Xu, Correlations between microstructure and dry friction wear behavior of Zn-38Al-3.5Cu-1.2 Mg alloy reinforced with SiC nanoparticles, Trans. Indian Inst. Met., 72(2019), No. 10, p. 2557.

H.A. Deore, J. Mishra, A.G. Rao, H.V. Mehtani, and D. Hiwarkar, Effect of filler material and post process ageing treatment on microstructure, mechanical properties and wear behaviour of friction stir processed AA 7075 surface composites, Surf. Coat. Technol., 374(2019), p. 52.

L. Chen, S.W. Yuan, D.M. Kong, G.Q. Zhao, Y.Y. He, and C.S. Zhang, Influence of aging treatment on themicrostructure, mechanical properties and anisotropy of hot extruded Al-Mg-Si plate, Mater. Des., 182(2019), art. No. 107999.

M.B. Seyedeh, J.A. Hamed, and J. Roohollah, Effect of non-isothermal aging on microstructure and mechanical properties of friction surfaced AA5083-15wt%Zn composites, Surf. Coat. Technol., 384(2020), art. No. 125307.

P. Liu, L.L. Hu, Q.H. Zhang, C.P. Yang, Z.S. Yu, J.Q. Zhang, J.M. Hu, and F.H. Cao, Effect of aging treatment on microstructure and corrosion behavior of Al-Zn-Mg aluminum alloy in aqueous solutions with different aggressive ions, J. Mater. Sci. Technol., 64(2019), p. 85.

Y.C. Chiu, K.T. Du, H.Y. Bor, G.H. Liu, and S.L. Lee, The effects of Cu, Zn and Zr on the solution temperature and quenching sensitivity of Al-Zn-Mg-Cu alloys, Mater. Chem. Phys., 247(2020), art. No. 122853.

Z.Q. Zhang, J.H. Yu, and D.Y. He, Effect of contact solid solution process on peak aging of Al-Zn-Mg-Cu alloys, J. Mater. Res. Technol., 9(2020), No. 3, p. 6940.

J.G. Zhao, Z.Y. Liu, S. Bai, D.P. Zeng, L. Luo, and J. Wang, Effects of natural aging on the formation and strengthening effect of G.P. zones in a retrogression and Re-aged Al-Zn-Mg-Cu alloy, J. Alloys Compd., 829(2020), art. No. 154469.

X.W. Li, Q.Z. Cai, B.Y. Zhao, B. Liu, and W.W. Li, Precipitation behaviors and properties of solution-aging Al-Zn-Mg-Cu alloy refined with TiN nanoparticles, J. Alloys Compd., 746(2018), p. 462.

H.B. Zhang, B. Wang, Y.T. Zhang, Y. Li, J.L. He, and Y.F. Zhang, Influence of aging treatment on the microstructure and mechanical properties of CNTs/7075 Al composites, J. Alloys Compd., 814(2020), art. No. 152357.

W.H. Yuan and B.L. An, Effect of heat treatment on microstructure and mechanical property of extruded 7090/SiCp composite, Trans. Nonferrous Met. Soc. China, 22(2012), No. 9, p. 2080.

G.N. Ma, D. Wang, Z.Y. Liu, B.L. **ao, and Z.Y. Ma, An investigation on particle weakening in T6-treated SiC/Al-Zn-Mg-Cu composites, Mater. Charact., 158(2019), art. No. 109966.

W. L. Zhang, X. Ma, and D.Y. Ding, Aging behavior and tensile response of a SiC reinforced eutectoid zinc-aluminium-copper alloy matrix composite, J. Alloys Compd., 727(2017), p. 375.

Q. Yuan, G. Xu, S. Liu, M. Liu, H.J. Hu, and G.Q. Li, Effect of rolling reduction on microstructure and property of ultrafine grained low-carbon steel processed by cryorolling martensite, Metals, 8(2018), No. 7, p. 518.

Q. Yuan, G. Xu, M. Liu, H.J. Hu, and J.Y. Tian, Effects of rolling temperature on the microstructure and mechanical properties in an ultrafine-grained low-carbon steel, Steel Res. Int., 90(2019), art. No. 1800318.

Q. Yuan, G. Xu, J.Y. Tian, and W.C. Liang, The recrystallization behavior in ultrafine-grained structure steel fabricated by cold rolling and annealing, Arab. J. Sci. Eng., 42(2017), No. 11, p. 4771.

Q. Yuan, G. Xu, M. Liu, S. Liu, and H.J. Hu, Evaluation of mechanical properties and microstructures of ultrafine grain low-carbon steel processed by cryorolling and annealing, Trans. Indian Inst. Met., 72(2019), No. 3, p. 741.

Q. Yuan, G. Xu, S. Liu, M. Liu, and H.J. Hu, Effects of strain rate on the microstructure of ultrafine grained medium-carbon steel, Arch. Metall. Mater., 63(2018), No. 4, p. 1805.

X.L. Gan, Q. Yuan, G. Zhao, H.J. Hu, J.Y. Tian, and G. Xu, Investigating the properties of coil tail in Ti-Nb-Mo microalloyed hot-rolled strip, Steel Res. Int., 90(2019), art. No. 1900040.

X.L. Gan, Q. Yuan, G. Zhao, H.W. Ma, W. Liang, Z.L. Xue, W.W. Qiao, and G. Xu, Quantitative analysis of microstructures and strength of Nb-Ti microalloyed steel with different Ti additions, Metall. Mater. Trans. A., 51(2020), p. 2084.

W. Liang, Q. Yuan, G.H. Chen, M. Liu, and W.W. Qiao, Fracture evolution in ferrite/martensite dual phase flange steel, Ironmaking Steelmaking, 48(2021), No. 1, p. 88.

M. Taya and R.J. Arsenault, A comparison between a shear lag type and eshelby type model in predicting the mechanical properties of a short fiber composite, Scripta Metall., 21(1987), No. 3, p. 349.

V.C. Nardone and K.M. Prewo, On the strength of discontinuous silicon carbide reinfirced aluminum composites, Script. Metall., 20(1986), No. 1, p. 43.

R. Zare, H. Sharifi, and M.R. Saeri, Investigating the effect of SiC particles on the physical and thermal properties of Al6061/SiCp composite, J. Alloys Compd., 801(2019), p. 520.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (No. 52004193), the National Training Programs of Innovation and Entrepreneurship for Undergraduates (No. 202110488004), the Guidance Programs of Science and Technology Research for Hubei Provincial Department of Education (No. B2020008); the National Defence Pre-research Foundation of Wuhan Univesity of Science and Technology (No. GF202006), the Postdoctoral Innovative Research Post of Hubei Province, China, and the Post-doctoral Research Funding Program of Jiangsu rovince, China.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare no conflict of interest.

Rights and permissions

About this article

Cite this article

Liu, S., Yuan, Q., Sima, Y. et al. Wear behavior of Zn-38Al-3.5Cu-1.2Mg/SiCp composite under different stabilization treatments. Int J Miner Metall Mater 29, 1270–1279 (2022). https://doi.org/10.1007/s12613-020-2217-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-020-2217-7