Abstract

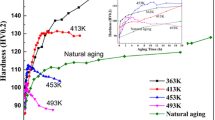

In this study, an Mg–9Al–0.8Zn–0.2Mn–0.3Ca–0.2Y (AZXW9100) alloy having high corrosion and ignition resistance characteristics is recently developed. This study investigates the aging hardening and Mg17Al12 precipitation characteristics of the extruded AZXW9100 alloy by comparing those of a commercial AZ91 counterpart. Both alloys’ microstructures consist of equiaxed recrystallized grains and they have an intense basal texture. Unlike the AZ91 alloy with a few Al–Mn particles, the AZXW9100 alloy contains numerous Al2Y, Al8Mn4Y, and Al2Ca particles. As the aging time increases from 0 to 8 h at 200 °C, the hardness increases from 63.6 to 95.4 Hv and 68.8 to 98.3 Hv for the AZ91 and AZXW9100 alloys, respectively. Although the hardness increments during aging and the peak aging times are almost the same for both alloys, their Mg17Al12 precipitation behavior considerably differs. During aging, the number of Mg17Al12 continuous precipitates formed in the AZXW9100 alloy is less than that in the AZ91 alloy because of the lower amount of Al solute atoms in the former. The nucleation and growth of Mg17Al12 discontinuous precipitates (DPs) are also suppressed in the AZXW9100 alloy because of the combined effect by the reduced Al solutes, finer grains, Ca and Y solutes, and second-phase particles. Consequently, the area fraction of DPs of the peak-aged AZXW9100 alloy is nearly half that of the peak-aged AZ91 alloy. This study demonstrates that adding small amounts of Ca and Y to AZ91 alloy causes drastic variations in the Mg17Al12 precipitation behavior during aging.

Graphical Abstract

Similar content being viewed by others

References

B.L. Mordike, T. Ebert, Mater. Sci. Eng. A 302, 37 (2001)

T. Lee, M. Yamasaki, Y. Kawamura, J. Go, S.H. Park, Met. Mater. Int. 25, 372 (2019)

V.V. Ramalingam, P. Ramasamy, M.D. Kovukkal, G. Myilsamy, Met. Mater. Int. 26, 409 (2020)

M.G. Fontana, Corrosion Engineering, 3rd edn. (McGraw-Hill, Singapore, 1987), p. 42

J.E. Gray, B. Luan, J. Alloys Compd. 336, 88 (2002)

D. Han, J. Zhang, J. Huang, Y. Lian, G. He, J. Magnes, Alloys 8, 329 (2020)

B.S. You, W.W. Park, I.S. Chung, Scr. Mater. 42, 1089 (2000)

M. Esmaily, J.E. Svensson, S. Fajardo, N. Birbilis, G.S. Frankel, S. Virtanen, R. Arrabal, S. Thomas, L.G. Johansson, Prog. Mater. Sci. 89, 92 (2017)

B.S. You, Y.M. Kim, C.D. Yim, H.S. Kim, Magnesium Technology (Wiley, New York, 2014), pp. 325–329

Y. Go, S.M. Jo, S.H. Park, H.S. Kim, B.S. You, Y.M. Kim, J. Alloys Compd. 739, 69 (2018)

S.H. Kim, S.W. Bae, S.W. Lee, B.G. Moon, H.S. Kim, Y.M. Kim, J. Yoon, S.H. Park, Mater. Sci. Eng. A 725, 309 (2018)

Y.J. Kim, Y.M. Kim, S.G. Hong, D.W. Kim, C.S. Lee, S.H. Park, J. Mater. Sci. Technol. 93, 41 (2021)

Y. Uematsu, K. Tokaji, M. Matsumoto, Mater. Sci. Eng. A 517, 138 (2009)

C.H. Caceres, C.J. Davidson, J.R. Griffths, C.L. Newton, Mater. Sci. Eng. A 325, 344 (2002)

W.J. Lai, Y.Y. Li, Y.F. Hsu, S. Trong, W.H. Wang, J. Alloys Compd. 476, 118 (2009)

S.H. Kim, J.U. Lee, Y.J. Kim, J.H. Bae, B.S. You, S.H. Park, J. Mater. Sci. Technol. 34, 265 (2018)

D. Dubey, K. Kadali, H. Kancharla, A. Zindal, J. Jain, K. Mondal, S.S. Singh, Met. Mater. Int. 27, 3282 (2021)

I.C. Jung, Y.K. Kim, T.H. Cho, S.H. Oh, T.E. Kim, S.W. Shon, W.T. Kim, D.H. Kim, Met. Mater. Int. 20, 99 (2014)

J.K. Kim, S.H. Oh, K.C. Kim, W.T. Kim, D.H. Kim, Met. Mater. Int. 23, 308 (2017)

A. Srinivasan, U.T.S. Pillai, B.C. Pai, Mater. Sci. Eng. A 527, 6543 (2010)

B.A. Esgandari, H. Mehrjoo, B. Nami, S.M. Miresmaeili, Mater. Sci. Eng. A 528, 5018 (2011)

H.J. Kim, S.H. Kim, S.W. Lee, B.G. Moon, Y.M. Kim, J.H. Lee, J. Yoon, H. Yu, S.H. Park, Met. Mater. Int. 27, 514 (2021)

J.W. Cha, Y.J. Kim, Y.M. Kim, J.H. Bae, S.H. Park, Met. Mater. Int. 28, 385 (2022)

D.B. Lee, M.A. Abro, B.S. You, Met. Mater. Int. 23, 720 (2017)

D.H. Lee, S.H. Kim, H.J. Kim, B.G. Moon, Y.M. Kim, S.H. Park, Met. Mater. Int. 27, 530 (2021)

S.H. Park, S.H. Kim, H.S. Kim, J. Yoon, B.S. You, J. Alloys Compd. 667, 170 (2016)

G.E. Dieter, in Mechanical Metallurgy, SI Metrix edn. (McGraw-Hill, London, 1988), p. 616

W.H. Sillekensm J.Bohlenm, in Advance in Wrought Magnesium Alloys: Fundamentals of Processing, Properties and Applications, 1st edn., ed by C. Bettles, M. Barnett (Woodhead Publishing, Sawston, 2012), p. 323

J.S. Suh, B. Suh, J.O. Choi, Y.M. Kim, B.S. You, Met. Mater. Int. 27, 2696 (2021)

H.J. Kim, S.C. **, J.G. Jung, S.H. Park, J. Mater. Sci. Technol. 71, 87 (2021)

G.R. Ebrahimi, A.R. Maldar, R. Ebrahimi, A. Davoodi, M. Moshksar, Kov. Mater. 48, 277 (2010)

S.H. Kim, S.W. Lee, B.G. Moon, H.S. Kim, Y.M. Kim, S.H. Park, J. Mater. Res. Technol. 8, 5254 (2019)

D.H. Lee, B.G. Moon, Y.M. Kim, S.H. Park, J. Alloys Compd. 862, 158051 (2021)

S.M. Baek, J.S. Kang, H.J. Shin, C.D. Yim, B.S. You, H.Y. Ha, S.S. Park, Corros. Sci. 118, 227 (2017)

D. Duly, J.P. Simon, Y. Brechet, Acta Matall. Mater. 43, 101 (1995)

K. Zhang, H. Li, X. Liang, Z. Chen, L. Wang, Mater. Charact. 161, 110146 (2020)

J. Wang, X.-R. Zhu, Y.-D. Xu, J.-J. Nie, L.-J. Zhang, Chin. J. Nonferrous Met. 24, 25 (2014)

F. Bu, Q. Yang, X. Qiu, T. Zheng, D. Zhang, X. Niu, Y. Li, X. Liu, J. Meng, Mater. Sci. Eng. A 639, 198 (2015)

Y.X. Wang, J.W. Fu, Y.S. Yang, Trans. Nonferrous Met. Soc. China 22, 1322 (2012)

K.N. Braszczyńska-Malik, J. Alloys Compd. 477, 870 (2009)

B. Kondori, R. Mahmudi, Mater. Sci. Eng. A 527, 2014 (2010)

D. Qui, M.X. Zhang, J.A. Taylor, P.M. Kelly, Acta Mater. 57, 3052 (2009)

L.B. Ren, G.F. Quan, M.Y. Zhou, Y.Y. Guo, Z.Z. Jiang, Q. Tang, Mater. Sci. Eng. A 690, 195 (2017)

S. Lee, S.H. Lee, D.H. Kim, Metall. Mater. Trans. A 29, 1221 (1998)

Acknowledgements

This work was supported by the National Research Foundation of Korea (NRF), and the grant was funded by the Korean government (MSIP, South Korea; No. 2019R1A2C1085272).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kim, H.J., Kim, Y.M., Bae, J.H. et al. Aging Hardening and Precipitation Characteristics of Extruded Mg–9Al–0.8Zn–0.2Mn–0.3Ca–0.2Y Alloy. Met. Mater. Int. 29, 381–389 (2023). https://doi.org/10.1007/s12540-022-01237-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-022-01237-1