Abstract

Control of Infectious diseases such as; bacteria and viruses, has become a globally critical issue, since the appearance of COVID-19 virus in 2020. In addition to the microbial resistance of the currently available therapeutic drugs as well as, its prolonged side effects make its use is of health care concern. Green nanotechnology approach is a promising solution for controlling such infectious diseases and many biomedical purposes. In the present study, green synthesis approach based on microwave-assisted hydrothermal method is an innovative and environmentally friendly method for preparation of bioactive CeO2 and ZnO nanorod structured materials using Olea europaea (O. e.) leaf plant extract as a natural medicinal cap** agent for controlling the shape and size of nano-products. The optical and structural analyses of the obtained nanorod-structures are characterized using; TEM, FTIR, XRD, SBET analyses and particle size analyzer. The green-synthesized ZnO and CeO2 nanorods display an average crystallite size of approximately 15 and 5 nm, respectively. The antimicrobial activity of ZnO and CeO2 nanorods compared with the traditional hydrothermal methods, was examined on six clinical pathogens including; (E. coli Serratia sp., S. aureus, Bacillus subtilis, Streptococcus mutant, and MRSA). The results indicated superior antimicrobial and anti-tumor activities towards hepatocellular carcinoma cell lines (IC50 = 117.24 and 103.50 μg mL−1 for ZnO and CeO2 and LD50 > 3000 mg kg−1). This demonstrates that the green microwave process is a promising approach for the synthesis of effective ZnO and CeO2 nanomaterials applied for many biomedical applications.

Key points

-

Green synthesized ZnO and CeO2 nanorods.

-

High antimicrobial activity against gram-negative and gram-positive bacteria.

-

Non-toxic and antitumor activity against hepatocellular carcinoma cell lines.

Similar content being viewed by others

Introduction

New and emerging infectious diseases such as COVID-19 and many other microbial diseases pose an increasing global health threat and complicate the health situation all over the world. These diseases will lead to the development of a major problem that affects the economy and the productivity of individuals. Diseases often occur when ambient conditions deteriorate and lead to heavy losses. Many microbes have developed resistance to specific antibiotic treatments as a result of the extensive and frequently indiscriminate use of antimicrobial medications, and these strains are particularly noticeable in the hospital setting. Treating these infectious diseases, has led to a significant clinical problem (Tang et al. 2021).

In this work, biological components from Olea europaea leaf extract were used to produce ZnO and CeO2. Olea europaea Belongs to the Oleaceae family and makes up over 98% of the world's harvest. It is one of the most important fruit trees grown in the Mediterranean region. Due to their nutritional value and health advantages, olive leaves are an agricultural byproduct that has gained increasing attention from the scientific and industrial communities. Olea europaea leaves were therefore seen as prospective sources of bioactive substances, particularly phenolic compounds. Oleuropein, Hydroxytyrosol, and other flavonoids like Apigenin-7-glucoside, Luteolin-7-glucoside, and Verbascoside are the most prevalent abundant substances. (Sellami et al. 2021).

In this research, The use of Olea europaea leaf plant extract as a reducing and stabilizing agent during the microwave-assisted synthesis of ZnO and CeO2 nanoparticles is an environmentally friendly method because it is quick, safe, economical, and does not need the use of chemical solvents. The morphological and structural analyses of the green synthesized metal oxide nanomaterials have been studied. Compared with the traditional hydrothermal methods, the antimicrobial, as well as the antitumor activity of the green synthesized nanomaterials, are examined. As this is the first time to make a comparison between green-synthesized ZnO and CeO2 nanorods with the nanoparticles synthesized via traditional hydrothermal methods.

Material and methods

Materials

For the seeding of ZnO, zinc acetate and sodium hydroxide (NaOH) were supplied from lobacheme. For the production of CeO2, cerium nitrate Ce (NO3)3.6H2O was bought from Sigma Aldrich. Merck provided the Dimethylsulfoxide (DMSO) and nutrient agar media that were utilized to determine Zone of Inhibition (ZOI). All compounds were analytical grade and require no further purification.

Microwave digestion device

Microwave digestion Speed Wave XPERT device from Berghof, Germany, was used for synthesis of ZnO and CeO2 nanorod structures. The Magnetron power 1000 W with maximum temp. up to 260 °C and pressure 100 bar. The device was created by the Berghof Fluoroplastic Technology GmbH using eight 100 mL Teflon vessels with the highest quality standards. They are made of premium TFM-PTFE and impressed through dependability and an outstanding lifespan.

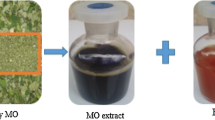

Preparation of Olea europaea leaf plant extract.

Fresh and healthy leaves of Olea europaea (O. e.) were washed multiple times with deionized water to get rid of the dust particles on their surface then they were dried in shade.

A healthy and undamaged leaf was carefully chopped, and stirred with deionized water at 85 °C for 2 h. The extract was filtered through Whatman filter paper after it was allowed to cool. The filtered leaf extract was used for further experiments as, cap** agent, stabilizer and reducing agent for synthesis of the metal oxides nanomaterials, being usable within 2 weeks. The storage done in Argon atmosphere. (Chatterjee et al. 2016; Rosi et al. 2018).

Synthesis of ZnO nanomaterials

ZnO nanorods (NRs) are prepared via environmentally friendly and fast microwave-assisted green hydrothermal method. As in a normal procedure, 12 gm of Zinc acetate hydrated was dissolved in 100 mL of distilled water to form a transparent solution. 15 mL Sodium hydroxide (NaOH) (5Molar) was added to the above solution gradually and under vigorous stirring. After formation of Zn (OH)4 precipitate, it was filtered, cleaned with distilled water, and allowed to dry at room temperature. Then suitable amount from the dried powder was added to 50 mL of (O. e.) extract and/or 50 mL of bi-distilled water. The suspension was put under continuous stirring and sonication for 30 min at room temperature to form a homogeneous suspension. The suspension was then transferred either into four Berghof TFM-PTFE microwave Teflon vessels at 160 °C for 30 min, or for comparison, into 100 mL Teflon-lined stainless-steel autoclave at 160 °C for 48 h, as a traditional hydrothermal synthesis method. After that, the Teflon vessels were allowed to cool down naturally and the resultant nanoproduct was harvested by centrifugation and washed with distilled water, and finally dried at 60 °C in the oven and then milled in a porcelain mill (Abdelmordy 2017).

Synthesis of CeO2 nanomaterials

4 gm of cerium nitrate hexahydrate was dissolved in 100 mL of distilled water to form a transparent solution. Sodium hydroxide (NaOH) was added to the above solution gradually and under vigorous stirring. After formation of Ce (OH)4 precipitate, it was filtered, cleaned with distilled water, and allowed to dry at room temperature.

Then suitable amount of the dried powder was added to 50 mL of (O. e. L.) extract and/or 50 mL of bi-distilled water. The suspension was put under continuous stirring and sonication for 30 min at room temperature to form a homogeneous suspension. The suspension was then transferred either into four Berghof TFM-PTFE microwave Teflon vessels at 200 °C for 30 min, or for comparison, into 100 mL Teflon-lined stainless-steel autoclave at 200 °C for 12 h, as a traditional hydrothermal synthesis method. The Teflon vessels were then allowed to cool naturally, and the last product was obtained by centrifugation, washed with distilled water, and then dried at 60 °C in the oven before being milled in a porcelain mortar (Maqbool 2017).

Characterization

X'pert Philips X-ray diffraction (XRD) Using Cu K radiation, 40 kV, 30 mA, and a scan rate of 50/min, was used to examine the surface characteristics of ZnO and CeO2 nanomaterials. Utilizing Scherer's formula, the crystallite size of the produced materials was calculated from the broadening of the relevant X-ray peaks (Wang et al. 2020). The morphology of the produced nanomaterials was determined by using a transmission electron microscope (TEM), JEM-2000 EX (JEOL, Tokyo, Japan). Brunauer–Emmett–Teller (BET) analysis (Quantachrome Instruments, NOVA series, USA) was used to calculate the specific surface area (m2 g−1) and pore volume of the powders at 77.35 K. A multipoint BET technique was used to calculate the specific surface area (SBET) using adsorption data at relative pressures (P/P0) between 0.05 and 0.25. The Barrett-Joyner-Halenda (BJH) method was utilized to determine the pore size distribution using the adsorption–desorption isotherm. The pore volume and average pore size were calculated using the nitrogen adsorption volume at the relative pressure (P/P0) of 0.976.

The Zeta Sizer Nano (ZS), a high performance two angles particle size, zeta potential, and molecular weight analyzer ideal for measurement of small volume samples at very low or high concentration and the detection of aggregates, was used to calculate the average particle size of synthesised nanomaterials using the Dynamic Light Scattering (DLS) technique. Non-Invasive Backscatter Optics (NIBS) performs significantly better than 90 scattering optics systems (Lopez et al. 2016).

The chemical composition and quality of the synthesized ZnO and CeO2 nanomaterials were evaluated using FTIR 430 spectrometer (Jasco-Japan) equipped with a diffuse reflectance accessory (Harrick, USA) in the range of 400–4000 cm−1.

Anti-bacterial activity assay

The antibacterial activity assay of the green synthesized ZnO and CeO2 nanomaterials compared with that prepared via traditional hydrothermal methods, has been studied against six carefully chosen bacterial strains; two-gram negative bacteria, i.e. E. coli (ATCC 8739) and Serratia marcescens brought from faculty of Pharmacy, Tanta University, Egypt and four-gram positive bacteria, i.e. Staphyllococcus aureus (ATCC 6538), Bacillus subtilis (ATCC 6633), Streptococcus mutant (ATCC 25175), and Methicillin-Resistant Staphylococcus Aureus (MRSA) obtained from faculty of Aquatic and fisheries sciences-Kafr elsheikh university. The experiment is carried out in DMSO solvent using the agar diffusion method (Nabi et al. 2020). The Zone of Inhibition (ZOI) was determined by using Kirby–Bauer disc diffusion susceptibility technique (Ningappa et al. 2008). The experiment was carried out in accordance with the guidelines established by the National Committee for Clinical Laboratory Standards (NCCLS, 1999).The pathogens under investigation were grown in 10 cm test plates on nutrient agar. The test plates were incubated for 48 h at 37 °C. The zone of inhibition (in mm diameter) was observed and recorded after the incubation period. Three different types of assays were carried out to study the antimicorbial activity of the green-synthesized NPs in the concentration range of 50–200 µg mL1. This is in order to determine the most active conc. towards the bacterial strains under investigation. 50 µg mL−1 was chosen as the MIC that gives a remarkable antimicrobial effect.

The experiments were carried out in triplicate, and the results are given as means with standard deviations (SD) for three parallel measurements. Antibiotics amoxicillin and flucloxacillin were used as controls. DMSO was used as negative control.

In-vitro antitumor cytotoxicity assay

The antitumor activity of the microwave-assisted green synthesized ZnO and CeO2 nanorods has been examined on hepatocellular carcinoma cell lines, according to van de Loosdrecht et al. (1994). The cell viability was determined by using MTT assay method. In a typical method, hepatocellular carcinoma cell line was seeded in a plate of 96 wells plate (1 × 105 cells/well) and incubated for 1–5 h at 37 °C in a 5% CO2 incubator to allow cell MTT to be metabolized. After incubation, the media were replaced with new fresh media treated with serial concentrations of ZnO and/or CeO2 nanomaterials (31.25 to 1000 µg mL−1). After incubation, Formazan (MTT metabolic product) was resuspended in 200ul DMSO and was shaken at 150 rpm for 5 min to thoroughly mix the formazan into the solvent. The optical density was measured at 560 nm and background was subtracted at 620 nm. Optical density should be proportional to cell quantity. The IC50 values were determined using nonlinear regression analysis with log (inhibitor) vs. variable slope (four parameters) (Van de Loosdrecht 1994).

In-vivo antitumor toxicity assay

The studied sample was administered orally to clusters of mice, every consisting of six animals, in gradually increasing dosages ranging from 0.1 to 3 g kg−1, in accordance with the procedure outlined by Finny (1964). The identical conditions were used to receive and care for the control animals. For 1 h, animals were continuously checked for abnormal characteristics. After administration, each group's mortality rate was tracked for 24 h (Finny 1964; El-Shafey et al. 2020).

Result

Morphological analysis

The surface morphology of ZnO and CeO2 nanomaterials is investigated by TEM analysis (Fig. 1a). The TEM image of ZnO nanoparticles prepared by traditional hydrothermal methods (Fig. 1a), shows ZnO nanosheets with a high transparency. The dark textures in the TEM image are attributed to overlap** section of nanosheets. This is in consistent with the results of ** agent

The TEM images of CeO2 nanoparticles prepared either by traditional hydrothermal methods (Fig. 1d, e) or by microwave hydrothermal methods show homogeneous nanoparticles with spherical morphology with an average size from 3 to 6 nm. However, by adding O.e leaf plant extract as a cap** agent leads to controlling the shape of the CeO2 nanoproducts and produces rod-like shape morphology (Fig. 1f) with an average diameter (29–37 nm) and length (200–500 nm).

Crystallographic analysis

The crystal structure of the green synthesized ZnO and CeO2 nanorod structured materials via microwave-assisted hydrothermal methods, compared with that synthesized via traditional hydrothermal methods, was estimated by X-ray diffraction and the representative patterns are given in Fig. 2. All the XRD patterns depicted in Fig. 2a, are indexed with highly crystalline wurtzite-structure from ZnO nanomaterials with JCPDS card No. 00-036-145. The diffraction patterns of CeO2 nanomaterials given in Fig. 2b are indexed with crystalline CeO2 nanomaterials with JCPDS card No.00-34-0394. Using Debye-formula Scherrer's Eq. 1 (Wang et al. 2020), the average crystallite sizes of the obtained nanoproducts are calculated, and the results are shown in Table 1.

where D is the crystallite size, θ is the Bragg angle in degree and β is the full width at half maximum (FWHM) of the peak, λ is the X-ray wavelength of Cu which is 1.5406 Å.

BET surface area analysis

Using Brunauer–Emmett–Teller (BET) analysis, the porosity and textural characteristics of the green-synthesized ZnO and CeO2 nanorod structures are examined. The nitrogen adsorption–desorption isotherms and pore size distribution for ZnO and CeO2 nanomaterials prepared by different methods are given in Fig. 3. The BET surface area (SBET) and total pore volume of the samples are estimated using the BJH method and are shown in Table 1.

The N2-adsorption/desorption isotherms of the different ZnO nanomaterials given in (Fig. 3a), depict a type III with H3 hysteresis loop, implying the attendance of macropourous structure. However, the isotherm curves of all CeO2 samples (Fig. 3b) posses type-IV isotherms with H2 hysteresis loop, implying the attendance of mesoporous structure. It can be well recognized from the surface area results in Table 1, that the green microwave assisted hydrothermal methods (MW/ O.e) leads to increase in the surface area and the porosity of the different nanoproducts.

Particle size analyzer

The particle size distribution curves of the green-synthesized ZnO and CeO2 nanorods measured by the dynamic light scattering (DLS) technique is given in Additional file 1: Fig. S1. From which the average particle sizes of green ZnO and CeO2 nanorods are found to be 673 and 890 nm, respectively. On the other hand, the size distribution curve shows that the particle size of both ZnO and CeO2 nanorods is polydispersed and larger than the values measured from TEM images.

FTIR analysis

The FTIR spectra of the green synthesized ZnO and CeO2 nanorod structures are displayed in Additional file 1: Fig. S2. The bands were discovered by FTIR analysis at 667.75, 830.24, 1039.47, 1325.83, 1534.64, 1624.32, 2080.85, 2364.88, and 3393.76 cm−1 in the range of 4000 cm−1 to 400 cm−1. The band 3393 cm−1 was assigned to the O–H stretching vibration (Alrubaie et al. 2019). Stretching vibration at 1624, 1534 and 1039 cm−1 were attributed to C=O, C=C and N–H, respectively. Flavonoids, glycosides, proteins, phenols, and terpenoids with functional groups of alcohols and ketones were found in bioreduction reactions in the bands 3393, 1624, and 1534 cm−1.The bands detected at 667 and 427 cm−1 confirm the formation of nano-sized ZnO (Alrubaie et al. 2019). The formation of CeO2 nanorods indicates by the stretching band of Ce–O which can be seen at 452 cm−1.

Antibacterial activity

The photographs of the antibacterial test for green synthesized ZnO (MW/O.e.) and CeO2 (MW/O.e.) nanorods against the six different pathogenic bacterial strains; two gram negative bacteria (E. coli (ATCC 8739) and Serratia marcescens, and four gram positive pathogens (Staphyllococcus aureus (ATCC 6538), Bacillus subtilis (ATCC 6633), Streptococcus mutant (ATCC 25175), and MRSA, are depicted in Fig. 4 in comparison with that prepared with traditional hydrothermal methods with and without Olea leaf extract.

The antibacterial activity of the green synthesized ZnO and CeO2 nanorods investigated against the different pathogenic under investigation was analyzed regarding the zone of inhibition (ZOI) of the bacterial growth and the results are given in Table 2 and presented in Fig. 5. Amoxicillin and Flucloxacillin antibiotics were used as control. Therefore, a proposed mechanism for the antimicrobial effect of the green synthesized ZnO and CeO2 nanorods, is presented in Scheme 1.

Cytotoxicity and antitumor activity

The antitumor activities of the green-prepared ZnO and CeO2 nanorods via microwave-assisted hydrothermal methods using Olea leaf extract as a cap** agent are tested on hepatocellular carcinoma cell lines. The results are investigated in terms of the cell viability curves (Fig. 6) and identified with IC50 values which were 103.5 and 117.24 µg mL−1 for the green synthesizes ZnO and CeO2 nanorod structures, respectively.

The Inverted microscopy images of the cytotoxic effects of different concentrations from the green synthesized ZnO and CeO2 nanorods on Hepatocellular carcinoma (HeG2) cells, are given in Fig. 7 a and b, respectively.

In-vivo antitumor toxicity

The in-vivo toxicity test (LD50) for the green-produced ZnO and CeO2 nanorod structures was performed on mice groups that received a 0.1–3 g kg−1 oral gradual increasing dose of the investigated nanomaterial. The findings revealed that neither morbidity nor mortality was observed. Whereas, the above doses didnot not cause any acute poisoning symptoms. This reveals that even at high concentrations, the green-synthesized ZnO and CeO2 nanorods are non-toxic (LD50 higher than 3000 mg kg−1). Moreover, the toxicity and cytotoxic activities of the green-synthesized ZnO and CeO2 nanorods via microwave-assisted hydrothermal method using Olea europaea leaf extract have been first reported against Hepatocellular carcinoma (HeG2) cells.