Abstract

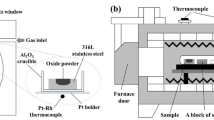

TiC/316L stainless steel composite was prepared by selective laser melting (SLM). The effects of alloying elements X (Cr, Mn, Mo, Ni, Si) in 316L stainless steel on the stability of TiC (001)/γ-Fe (001) interface were calculated by the first principle. The results showed that alloy elements easily replace the Fe atom at the interface, and all of them have the tendency to segregate to the interface. The adhesion work, bond length, interlayer distance, and electronic properties were calculated; it was found that the interface models of Cr4, Mn4, Mo4, Ni1, and Si1 are more conducive to improve the interface bonding strength, and the Cr-, Mn-, and Mo-doped interfaces are more stable than other interfaces. Both X1 and X4 structures represent the do** of an alloy atom but only in different crystallographic sites. Therefore, the introduction of Cr, Mn, Mo, Ni, and Si will promote the heterogeneous nucleation of Fe on TiC and enhance the heterogeneous nucleation potential of TiC and improve the interfacial bonding strength of TiC/316L stainless steel composite.

Graphical abstract

Effects of alloying elements on the interface stability and electronic density of TiC (001)/γ-Fe (001)

Similar content being viewed by others

References

AlMangour B, Grzesiak D, Borkar T, Yang J-M (2018) Densification behavior, microstructural evolution, and mechanical properties of TiC/316L stainless steel nanocomposites fabricated by selectivelaser melting. Mater Des 138:119

Majumdar JD, Kumar A, Li L (2009) Direct laser cladding of SiC dispersed AISI 316L stainless steel. Tribol Int 42:750

Fernandes CM, Senos AMR (2011) Cemented carbide phase diagrams: A review. Int J Refract Met H 29:405

Farahmand P, Kovacevic R (2015) Corrosion and wear behavior of laser cladded Ni–WC coatings. Surf Coat Tech 276:121

Almangour B, Grzesiak D (2016) Selective laser melting of TiC reinforced 316L stainless steel matrix nanocomposites: Influence of starting TiC particle size and volume content. Mater Des 104:141

Zhao S, Shen X, Yang J, Teng W, Wang Y (2018) Densification behavior and mechanical properties of nanocrystalline TiC reinforced 316L stainless steel composite parts fabricated by selective laser melting. Opt Laser Technol 103:239

Fei C, Gu D, Dai D, Yuan P (2015) Selective laser melting of in-situ Al SiC +SiC hybrid reinforced Al matrix composites: Influence of starting SiC particle size. Surf Coat Tech 272:15

Zhao ZY, Li J, Bai PK, Qu HQ, Liang MJ, Liao HH, Wu LY, Huo PC, Liu H, Zhang JX (2019) Microstructure and Mechanical Properties of TiC-Reinforced 316L Stainless Steel Composites Fabricated Using Selective Laser Melting. Metal 2:267

Li J, Zhao Z, Bai P, Qu H, Liang M, Liao H, Wu L, Huo P (2019) Tribological Behavior of TiC Particles Reinforced 316Lss Composite Fabricated Using Selective Laser Melting. Materials 12:950

Zhang L, Zhao Z, Bai P, Du W, Li Y, Yang X, Wang Q (2020) In-situ synthesis of TiC/graphene/Ti6Al4V composite coating by laser cladding. Mater Lett 270:127711

Wu L, Zhao Z, Bai P, Zhao W, Li Y, Liang M, Liao H, Huo P, Li J (2020) Wear resistance of graphene nano-platelets (GNPs) reinforced AlSi10Mg matrix composite prepared by SLM. Appl Surf Sci 503:144156

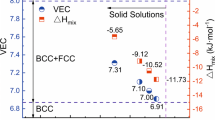

**ong HH, Zhang HH, Zhang HN, Zhou Y (2017) Effects of alloying elements X (X=Zr, V, Cr, Mn, Mo, W, Nb, Y) on ferrite/TiC heterogeneous nucleation interface: First-principles study. J Iron Steel Res Int 24:328

Chen L, Li Y, Peng J, Sun L, Li B, Wang Z, Zhao S (2020) A comparable study of Fe//MCs (M = Ti, V) interfaces by first-principles method: The chemical bonding, work of adhesion and electronic structures. J Phys Chem Solids 138:109292

Dong N, Zhang C, Liu H, Fan G, Fang X, Han P (2015) Effects of different alloying additives X (X=Si, Al, V, Ti, Mo, W, Nb, Y) on the adhesive behavior of Fe/Cr O interfaces: A first-principles study. Comp Mater Sci 109:293

Zhao ZY, Zhao WJ, Bai PK, Wu LY, Huo PC (2019) The interfacial structure of Al/Al C in graphene/Al composites prepared by selective laser melting: First-principles and experimental. Mater Lett 255:126559

Segall MD, Lindan PJD, Probert MJ, Pickard CJ, Hasnip PJ, Clark SJ, Payne MC, Phys J (2002) First-principles simulation: Ideas, illustrations and the CASTEP code. Condens Matter 14:2717

Saib S, Bouarissa N (2006) Electronic properties of GaN at high-pressure from local density and generalized gradient approximations. Comp Mater Sci 37:613

Laasonen K, Pasquarello A, Car R, Lee C, Vanderbilt D (1993) Car-Parrinello molecular dynamics with Vanderbilt ultrasoft pseudopotentials. Phys Rev B 47:10142

Pfrommer BG, Côté M, Louie SG, Cohen ML (1997) Relaxation of Crystals with the Quasi-Newton Method. J Comput Phys 131:233

Wang C, Wang CY (2009) Ni/Ni3Al interface: A density functional theory study. Appl Surf Sci 255:3669

Bai PK, Wang Q, Zhao ZY, Du WB, Liang MJ, Liao HH, Li YX, Zhang LZ, Han B, Li J (2020) Interfacial Stability of TiC/γ-Fe in TiC/316L Stainless Steel Composites Prepared by Selective Laser Melting: First Principles and Experiment. Metal 10:1225

Funding

The authors received funding from the National Natural Science Foundation of China (Grant Nos. 51775521 and U1810112), the China Postdoctoral Science Foundation (2019M661068), the Key Research and Development Project of Shanxi Province (201903D121009), the Natural Science Foundation of Shanxi Province: 201801D221154, the Major Science and Technology Projects of Shanxi Province, China (Nos. 20181101009, 20181102012), the Shanxi Foundation Research Projects for Application (201801D221234), and the Research Project Supported by Shanxi Scholarship Council of China (2019072).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, Q., Zhao, Z., Bai, P. et al. Effects of alloying elements X (Cr, Mn, Mo, Ni, Si) on the interface stability of TiC (001)/γ-Fe (001) in TiC/316L stainless steel composite formed by selective laser melting: first principles and experiments. Adv Compos Hybrid Mater 4, 195–204 (2021). https://doi.org/10.1007/s42114-021-00212-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42114-021-00212-5