Highlights

-

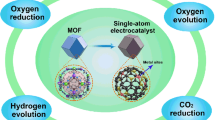

Synthesis protocols, design engineering, theoretical calculations, and energy applications for metal–organic frameworks (MOFs)-derived electrocatalysts are systematically analyzed.

-

Synthesizing methods of MOF-derived catalysts and their oxygen reduction reaction, oxygen evolution reaction, and hydrogen evolution reaction electrocatalysis are discussed.

-

The current status, ongoing challenges, and potential future outlooks of MOFs-derived electrocatalysts are highlighted.

Abstract

The core reactions for fuel cells, rechargeable metal–air batteries, and hydrogen fuel production are the oxygen reduction reaction (ORR), oxygen evolution reaction (OER), and hydrogen evolution reaction (HER), which are heavily dependent on the efficiency of electrocatalysts. Enormous attempts have previously been devoted in non-noble electrocatalysts born out of metal–organic frameworks (MOFs) for ORR, OER, and HER applications, due to the following advantageous reasons: (i) The significant porosity eases the electrolyte diffusion; (ii) the supreme catalyst–electrolyte contact area enhances the diffusion efficiency; and (iii) the electronic conductivity can be extensively increased owing to the unique construction block subunits for MOFs-derived electrocatalysis. Herein, the recent progress of MOFs-derived electrocatalysts including synthesis protocols, design engineering, DFT calculations roles, and energy applications is discussed and reviewed. It can be concluded that the elevated ORR, OER, and HER performances are attributed to an advantageously well-designed high-porosity structure, significant surface area, and plentiful active centers. Furthermore, the perspectives of MOF-derived electrocatalysts for the ORR, OER, and HER are presented.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Currently, global warming and air pollution have become two critical worldwide tasks in the twenty-first-century civilization caused by fossil fuel during production and use, which can be resolved only by using alternative environmentally friendly energy sources. Over the last decades, increasing endeavors have been devoted to energy alternative sources in particular wind energy [1, 2], hydroelectric power [3,4,5,6,7,8], hydrogen energy [9,10,11], solar energy [12], and nuclear energy [13], which have already been served as complementary sources of energy to the traditional fossil fuels. One of the most promising is eco-friendly hydrogen energy and its applications for hydrogen fuel production, and hydrogen fuel cells [81,82,83,84]. Furthermore, elucidative synthesis, design engineering, and energy applications of materials derived from MOFs will be presented in the subsequent sections.

Through ORR catalysts, three major categories will be investigated: (i) nonmetal heteroatom-doped porous carbon catalysts derived from MOFs materials; (ii) monometallic-MOF derivative-nanocarbon electrocatalysts, and (iii) bimetallic/multimetallic-MOFs-based electrocatalysts. Nitrogen-doped carbon was noticed to be the extremely generally explored nanomaterials for the ORR in contrast to heteroatoms. Through this section, synthesis protocols for nitrogen-doped carbon will be covered, while the other categories will also be covered through the review. General synthesis protocols for previous studies can be assigned into three kinds: (i) the pyrolysis of MOFs containing nitrogen such as zeolitic imidazolate frameworks ZIFs, which is nominated as in situ nitrogen do**; (ii) the amendment approach for carbonization processing after synthesis through utilizing gas guest molecule such as ammonia, which is nominated as ex situ nitrogen do**; (iii) using second solid material as a nitrogen source mixed with MOFs, which can produce an in situ nitrogen-doped carbon with bulky surface area and controlled pore size distribution. Several organic materials, for example, melamine, furfuryl alcohol (FA), and glucose, are utilized to accomplish function [85,86,3.2 MOF–Heteroatom Source Mixture Carbonization Method Concerning preparing highly active electrocatalysts, the MOF–heteroatom source carbonization technique is extensively utilized. Via inserting another heteroatom resource to MOFs as precursors, the do** with exterior heteroatom could be prepared rationally and exhibit a second solution for the atom types limitations in the catalysts. The external heteroatom do** sources consist of nonmetal sources (for instance as N, P, S, and C) [93,94] and/or metals source (Fe, Co, Cu, etc.) [27, 3.3 MOF-Based Composite Carbonization Method It is widely recognized that carbon electrocatalysts arising out of MOF precursors at elevated temperatures commonly undergo many difficulties. For instance, the skeleton distortion at temperatures over 700 °C and the porosity reduction occurs for MOFs [98]. Remarkably, the composite obtained from MOF-based precursors, such as MOF/carbon nanotubes, and MOF/graphene, become capable of overwhelming the hindrances to obtaining highly efficient catalysts. For instance, carbon coating on MOFs surfaces or merging the MOF with an appropriate templating agent could competently prohibit the MOF skeleton material from breakdown, which indicates that the porous carbon composite catalysts derived from MOF can preserve highly specific surface area (SSA) and durable porousness, which leads an improved conductivity and graphitization degree of the produced materials. Therefore, this method greatly enhances the catalytic efficiency of the catalysts.

4 Theoretical Exploration for Related Electrocatalytic Reaction Mechanism

As shown in Fig. 1e, the OER process is simply a reverse version of the ORR process (Table 1). By the reduction for O2 to H2O or OH, the ORR pathway could occur; meanwhile, by the H2O oxidation to O2 occurs through the OER pathway. Through numerous effects such as the electrode surface structure, materials with several facets, different reaction mechanisms could happen [99]. The most admitted OER overall reaction pathways include four discrete electron transfer stages, which are listed in Table 1, where * is the catalyst active site. The DFT computations outcomes expose that the HER process probably includes the Volmer–Heyrovsky or Volmer–Tafel route on a range of transition-metal surfaces, whereby the Volmer step is a fast reaction whereas the Heyrovsky or Tafel reaction is assigned to the rate-determining step [100, 101].

One of the central issues in electrochemistry is to design highly active, selective, and stable electrocatalysts at a reduced price through the intimate knowledge of the active sites and reaction mechanism. The principal goal for having a deep understanding is to determine the catalytic activity which can be used to tailor the catalysts atom by atom. Meanwhile, it is particularly challenging to acquire all of the details we need from the experimental techniques. Despite the experimental results that could not give the ideal catalyst expectation, the density functional theory (DFT) exhibits the ability to afford vital mechanistic understandings and predict the promising heterogeneous catalysts. In the electrocatalysis field, DFT is principally revolving around the adsorption energy, binding energy, reaction energy, and reaction barrier. Diverse DFT functionals such as LDA, GGA, meta-GGAs, B3LYP, and other hybrid functions are commonly implemented for calculating different systems since DFT calculations are functional dependent [102, 103]. Nevertheless, through the implementation of DFT calculations in electrocatalysis, there are still three difficulties: (1) the precision of the calculations, (2) the efficacy of the computations, and (3) the intricacy of the environment. The dependability of the DFT results can be determined through the computational accuracy; those numerous advanced methods were settled to have the DFT outcomes more precise; and nevertheless, several features are inadequate owing to the DFT limitations [104, 105]. Conquering these difficulties will let DFT offer more rational designed electrocatalysts. Recently, Shinde et al. [106] did a theoretical study to afford additional perceptions into the root of the Mn/Fe-HIB-MOF intrinsic bifunctional catalytic performance by studying the M-HIB-MOFs OER/ORR electrocatalytic performances and electronic structures (Fig. 4). Theoretically, the overpotential is caused by the potential-determining step, which has the greatest endothermic free energy change in consecutive OER and ORR elementary reaction steps under the standard reaction potential which for OER/ORR in alkaline media is U = 0.402 V, as shown in Fig. 4d, e for the green free energy diagrams. Hence, the overpotential donates further potential to the standard reaction potential to increase the catalytic reaction with all energetically advantageous downhill reactions, as exhibited in the diagrams for the blue free energy. The determined M-HIB-MOFs overpotentials versus descriptors exposed that the smallest overpotentials with 0.37 and 0.43 V are for Mn/Fe-HIB-MOF, which surpass those of RuO2 + Pt/C (0.42 and 0.45 V), Mn-HIB-MOF (0.53 and 0.64 V), and Fe-HIB-MOF (0.63 and 0.59 V) for OER and ORR, respectively (Fig. 4b, c). It can be concluded that the square planar dual-linked M(II) hexaiminobenzene-MOFs show the ability to be an efficient bifunctional catalyst relating to the overpotential. Consequently, the Mn(II) and Fe(II) dual-linked HIB-MOFs reveal remarkable activity as bifunctional catalytic in an alkaline medium in comparison with Mn-HIB-MOF and Fe-HIB-MOF with electronic characteristics owing to the abundant carbon active sites and improved participation of carbons to the frontier bands. In conclusion, the remarkable efficiency of the bifunctional catalyst and the long-life durability of Mn/Fe-HIB-MOF have been successfully expected and affirmed by the computational analysis.

Mechanistic study of bifunctionality for OER and ORR. a Initial structure and structures after the adsorption of hydroxyl OH*, oxyl O*, and hydroperoxyl OOH* intermediates on Mn/Fe-HIB-MOF. (Inset: active sites with elements and Arabic numbers.) Volcano profiles for b OER and c ORR for Mn-HIB-MOF, Fe-HIB-MOF, and Mn/Fe-HIB-MOF catalysts. Free energy diagrams on Mn/Fe-HIB-MOF in an alkaline environment: d OER pathways and e ORR pathways [106], Copyright © 2019, The Royal Society of Chemistry

5 Energy Applications of MOF-Derived Electrocatalysts

The fundamental purpose of a well-designed electrocatalyst is to enhance catalytic efficiency as far as feasibility for particular implementations. Due to the functional fragments, morphologies with fine shapes, and advantageous structures, numerous constituents derived from MOFs have been demonstrated as electrocatalysts in the direction of diverse energy conversion methods, in particular the ORR, OER, and HER [102, 107,108,109,110,111,112,113,114,115,116]. Remarkably, the MOF-derived materials with unique structures display valuable bifunctional catalytic performance which starts up a novel path for the wide implementation for energy applications, for instance, rechargeable metal–air batteries and water electrolysis. Despite numerous reports that have offered MOF-derived materials for electrocatalysis, a little extraordinary development was done very lately; consequently, an updated progression survey in this area could deliver additional extensive knowledge for the design strategies, DFT calculations, and synthesis protocols for better MOF-derived electrocatalysts.

5.1 MOF-Derived Materials for ORR

5.1.1 MOF-Derived Nonmetal Heteroatom-Doped Porous Carbon Electrocatalysts

MOFs crystals contain a large number of carbon-based organic linkers that boost in easing the fabrication of nanocarbon materials. Recently, researchers are dedicating more efforts to develo** ORR catalysis based on nonmetal-doped carbon-based materials. Up to now, metal-free electrocatalysts are considered as an exceptional material class with highly functionalized porous heteroatom-doped nanocarbon, categorized as a promising applicant for fuel cells resulting from the exceptional chemical/physical features. Also, they exhibit highly electrocatalytic efficiency, low price, and exceptional stability [93, 94], along with nanocarbon hybrids (nanocarbon/CNTs, nanocarbon/graphene) [120], were investigated as exceptional fuel cells electrocatalysts.

5.1.1.1 N-Doped Carbon Electrocatalysts

Obviously, the existence of N-atoms inside the lattice of carbon is able to extensively raise the surface polarity and movement of electron donor inside the frameworks of carbon, producing developed ORR electrocatalytic performance [117, 118, 121, 122]. Nitrogen-doped carbon could be noticed to be the extremely generally explored nanomaterials for the ORR in contrast with heteroatoms. Thanks to the electronegativity variance between C as X = 2.55 and N as X = 3.06 that polarizes the frameworks of carbon effectively and eases the oxygen adsorption. Furthermore, nitrogen-rich sources are more eco-friendly relative to other heteroatoms. Besides, nitrogen do** modifies the charge distribution and as a consequence enhances the ORR performance. At the catalyst/electrolyte interface, the catalyst–O2 adsorption could change from Pauling model (end-on adsorption) to Yeager model (side-on adsorption), resulting in weakening O–O bond, which leads to excess conducive to the approach of the ORR [93, 94]. Sulfur atoms are positively charged which is thought to be efficient ORR catalytic sites. Besides, do** with phosphorous can improve the carbon atoms charge delocalization and produce carbon networks including raised edge sites. Current studies have proved that co-do** with heteroatoms for graphitic carbon could positively enhance the ORR performance, which leads to a synergistic effect caused by the charge and spin density differences. This is desirable for oxygen adsorption, electron transfer along with improving the ORR activity [124].

At the same time, ORR electrocatalysts with multi-dopants nanocarbon in particular N-, B-, P-, and S-co-doped carbon can be acquired via changing the organic linkers of MOFs constituent or by rational post-processing processes [125,126,127]. Dai et al. [127] have reported nitrogen, phosphorous, and sulfur as triple-doped metal-free porous carbon materials. As a template, MOF-5 was used; dicyandiamide (DCDA), dimethyl sulfoxide (DMSO), and triaryl phosphine (TPP) were used as N, S, and P precursors, respectively. In a systematic approach, the influence of the pyrolysis temperature on ORR performance was explored. MOF-5 was pyrolyzed at 700, 900, and 1000 °C. By the way of comparison, the free do**, nitrogen do**, NS, or NP co-doped porous carbon was also employed under the same conditions. In particular, XPS spectra showed that the processing at 900 ℃ of MOF-5/organics leads to an integration of N (4.1%), P (0.27%), and S (0.75%) in the carbon lattice. Likewise, CVs and LSVs have been accomplished to explore the best ORR performances. The optimum temperature appeared to be 900 °C nominated as C-MOF-5-900 which displayed the best ORR onset potential among the studied materials, demonstrating that C-MOF-5-900 had an outstanding electrocatalytic performance. Furthermore, NPS-C-MOF-5 cathodic current density was considerably greater than the signal of the Pt/C electrocatalyst. Particularly, for NPS-C-MOF-5, the peak potential was more positive compared with the other carbon materials, whereas it was insignificantly negative regarding Pt/C electrocatalyst (− 0.13 V). Consequently, these outcomes indicate that NPS-C-MOF-5 was an extraordinary ORR electrocatalyst. But still, more understanding is needed to probe the vital function of the doped carbon on ORR activity which is considerable in designing and optimizing the metal-free doped carbon electrocatalysis. Additionally, Yan et al. [128] obtained nitrogen-doped hollow carbon polyhedrons (NHCP) by directly pyrolyzing ZIF-8 and followed by immersing in NaCl (Fig. 5d). The CVs in Fig. 5e display that both NHCP 1000 and NC catalysts have a clear oxygen reduction peak in O2-saturated 0.1 M KOH, compared to N2-saturated 0.1 M KOH. Additionally, the cathodic peak of NHCP-1000 (0.79 V) is better than that of NC (0.70 V), signifying a remarkable catalyzing capability for the ORR process of NHCP-1000. Consequently, as indicated in Fig. 5f, NHCP-1000 exhibits outstanding catalytic efficiency with an increased potential (Eonset = 0.98 V) and half-wave potential (E1/2 = 0.86 V), analogous to 20% Pt/C (Eonset = 1.03 V, E1/2 = 0.88 V).

5.1.1.3 MOF-Derived Nanocarbon Composite Electrocatalysts

Earlier studies widely explained that the presence of graphene oxide sheets during MOFs formation could successfully form nanocarbon between the graphene oxide layers with a large specific surface area in addition to the superior electronic conductivity [129]. Also, MOFs can rise on carbon nanotubes, accompanied by pyrolysis that could give high catalytic activity toward ORR as have been reported by Zhu et al. [120]. Figure 6a displays the schematic synthesis where ZIF-8 nanocrystals were formed hydrothermally and ORR catalysts based on MOF/CNT composites were employed. MOF/CNT exposed outstanding tolerance to methanol and excellent MOF/CNT electrocatalyst shows a half-wave potential of 24 mV, lesser than Pt/C electrocatalysts. Furthermore, it exhibited a low Tafel slope of 49 mV dec−1 in comparison with other electrocatalysts. Owing to the high surface area and nitrogen-functionalized carbon and the exceptional affinity among the thin N-carbon layer and the CNT skeleton, the high ORR electrocatalytic activity was obtained. This composite eases considerably the charge movement, electrical conductivity, and steadiness on the ORR in addition to gas diffusion over the hierarchical porous framework.

a Schematic representations for develo** high-surface-area N-doped carbon from MOF/CNT composites, b low-magnification TEM image of C-CZ-4-1000, CNT, C-ZIF-1000, c C-CZ-4-1000 (0.72 mg catalyst cm2) and 40 wt% Pt/C electrocatalysts (80 µgPt cm2) at 1600 rpm in O2-saturated 0.1 M KOH at 5 mV s−1, and d Tafel plots of C-CZ-4-1000 and Pt/C [120], Copyright© 2021, Elsevier. e ORR LSV curves in the O2-saturated 0.1 M KOH at 1600 rpm with a scan rate of 5 mV s−1 and f OER LSV curves at 1600 rpm at a scan rate of 5 mV s−1 in O2-saturated 0.1 M KOH [135], Copyright© 2019, Elsevier. g LSV curves of C-HZ8-950, C-HZ8@g-C3N4-950, C-FeHZ8-950, C-FeHZ8@g-C3N4-950, and 20 wt% Pt/C in h O2-saturated 0.1 M KOH and 0.1 M HClO4 (rotation rate: 1600 rpm) [79], Copyright© 2019, The Royal Society of Chemistry. k TEM images of the MOF(Fe/Co) sample and l ORR activities of the samples: (a) MOF(Fe/Co) + SP and (b) SP [143], Copyright © 2014, Elsevier

5.1.2 Monometallic-MOF Derivative-Nanocarbon Electrocatalysts

Metal/metal oxides merging as dopants in porous carbon can enhance the catalytic performance [130, 131]. Moreover, theoretical studies exposed the incorporating metal dopants could remarkably enhance the electron movement from carbon to O2 molecules and decrease the O2 free energy of adsorption molecules, therefore producing additional ORR active sites. Nevertheless, one of the limiting factors that reduce the implementation of oxides as catalysts in fuel cells is the intrinsic poor conductivity. To overcome this obstacle, covering metal or metal oxide particles with the highly conductive nanocarbon layer (from MOFs pyrolysis) has been studied as an efficient strategy. Lately, transition metal/metal oxide–nanocarbon composite catalysts derived from MOF were broadly investigated, especially Co/Co-oxide and Fe/Fe-oxide nanocarbon. In addition, the obtained highly porous carbon matrix obtained from MOFs can stabilize the ORR performance for M/MO and exhibit fast electron transfer paths and diffusion channels to enhance ORR efficiency.

5.1.2.1 MOF-Derived Cobalt/Cobalt Derivative-Nanocarbon Electrocatalysts

Up till now, Co/Co3O4 with supported carbon is among the most widely investigated catalysts for ORR in fuel cells [132,133,134]. Yin and coworkers [135] reported the fabrication of bifunctional electrocatalysis (ORR/OER) by the thermal treatment of a combination of cobalt-based MOF with carbon black (CB). Different ratios between MOF(Co) and CB (1:1, 3:1, and 5:1, respectively) were utilized, and the mixtures were annealed for 2 h in N2 at 500 °C. As exposed in Fig. 6e, f, the obtained LSV curves show the enhancement for onset potentials and E1/2 for the three specimens with added CB than those of MOF(Co)-500. Furthermore, MOF(Co)/C(3:1)-500 with E1/2 and onset potential are 0.80 and 0.92 V, respectively, and were the highest between them, which were closely resembled of Pt/C catalyst (0.98 and 0.84 V, respectively). Additionally, MOF(Co)/C (3:1)-500 showed current density at 0.76 V (4.10 mA cm−2) and the limiting current density (5.12 mA cm−2), similar to those of Pt/C catalyst (4.35 and 5.31 mA cm−2, respectively), and significantly more than those of the other samples, signifying the outstanding ORR performance of MOF(Co)/C(3:1)-500 to that of other as-sensitized catalysts. The adjusted Co–CoO–Co3O4/NC displayed outstanding bifunctional performance, robustness, and showed enhanced performance than Pt/C catalyst (for ORR).

5.1.2.2 MOF-Derived Iron/Iron Derivative-Nanocarbon Electrocatalysts

Other transition-metal MOFs, such as Fe-MOFs, were additionally stated as constitutions in the production of Fe-Nx-C and N-doped Fe/Fe3C@C/RGO electrocatalysts to activate ORR [27, 95, 96, 136]. Deng et al. [137] described a hollow N, Fe-doped carbon nanopolyhedron catalyst, obtained through thermal treatment for hollow ZIF-8 with C15H24FeO6 and g-C3N4. The higher ORR activities are arranged in the order C-HZ8-950 > C-HZ8@g-C3N4-950 > C-FeHZ8-950 > CFeHZ8@g-C3N4-950 in 0.1 M potassium hydroxide and 0.1 M perchloric acid. The supreme ORR efficiency of C-FeHZ8@g-C3N4-950 in the alkaline and acidic media was additionally approved by the LSV curves as displayed in Fig. 6g, h. With the optimized FeHZ8@g-C3N4-950 electrocatalyst, the half-wave potential was larger than commercial Pt/C (30 mV) in an alkaline electrolyte, and only 60 mV lesser than that of Pt/C in an acidic electrolyte (0.78 vs. 0.84 V), similar to the performance of up-to-date Fe–N–C. Furthermore, C-FeHZ8@g-C3N4-950 displayed outstanding robustness in both acidic and alkaline electrolytes, confirmed via elongated chronoamperometric measurement with 0.78 V in the former and 0.845 V in the latter of the half-wave potential. The current density of Pt/C reduced by 11%, while C-FeHZ8@g-C3N4-950 missed 4% of its original ORR efficiency (for 5.55 h) and still reserves 91.6% of its initial ORR efficiency for 24 h. Furthermore, CFeHZ8@g-C3N4-950 reserved more than 93% of its original current density, while the Pt/C displayed a current loss of 35% for 5.55 h. After completing the test for 24 h, C-FeHZ8@gC3N4-950 reserved 75% of its original ORR activity. Benefiting from the high density of Fe(II)–N4–H2O active sites, the large surface area, and the hollow porous structure, the catalyst displayed excellent ORR performance and superior robustness in the acidic and alkaline electrolytes.

5.1.2.3 Other MOF-Derived Monometal-Nanocarbon Electrocatalysts

There are numerous classes of metal-based MOFs as Cu-MOFs, Zr-MOFs, Ni-MOFs, and Cd-MOFs that were broadly explored as template precursors to obtain porous metal-nanocarbon electrocatalysts for fuel cells [138,139,140]. Kim et al. [139] presented a simple process for the efficient filling of Cu- and Ni-HKUST-1. The obtained MOF@mC samples displayed supreme ORR activities compared with the pristine MOFs. Besides, Cu-MOF@mC also displayed noticeable ORR performance, outstanding methanol tolerance, and long-term stability in comparison with the non-Pt-based catalysts for the ORR. Additionally, Cu-MOF@mC exhibited raised jK values than Ni-MOF@mC at all potentials, strongly demonstrating the noticeable ORR performance of the Cu center. Through this study, it was inducted that large surface area MOFs with well-organized pore constructions and chemical tunability can be hired as an ORR platform for electrocatalysts to obtain conducting 3D networks.

5.1.3 Bimetallic-MOFs-Based Electrocatalysts

Two or more kinds of inorganic centers from metal ions or clusters can be incorporated in bimetallic-MOFs, coordinating with different organic ligands, or linkers containing different metals. To obtain a controlled composition, different metals can play an important role [141, 142]. Moreover, the M1 and M2 coupling is vital for supporting the electrocatalytic performance. By substituting metal or presenting heterogeneity, it would be feasible to adapt the metal sites. Up to 2, 4, 6, 8, and 10 different metal ions types were combined inside one MOF to prepare heterometallic MOF with retaining the original topology, which could open a new avenue in electrocatalysis [54].

5.1.3.1 Fe/M (M = Co or Cu) Bimetallic-MOFs Electrocatalysts

MOFs consisting of two different metals ions like Fe and Co were reported by Yin et al. [143], and Fe and Cu were also applied as bifunctional electrocatalysis by Wang et al. [17]. The MOF(Fe/Co) catalyst was obtained hydrothermally and showed a fine crystalline structure containing plenty of micropores with a large specific surface area and significant thermal stability. As can be seen, Fig. 6k demonstrates TEM images of MOF(Fe/Co) with a size range of 50–150 nm. The current density at − 2 mA cm2 was then indicated for the corresponding onset potential in the ORR process. Figure 6l indicates poor ORR performance and an onset potential of − 0.22 V for SP, whereas it became − .13 V for MOF(Fe/Co) + SP. Likewise, SP exhibited a current density of 0.07 mA cm2 at − 0.3 V; however, the current density of MOF(Fe/Co) became 17 times higher than that of SP at the same potential. The reduction process of Fe(III) to Fe(II) was indicated through ORR LSV at − 0.38 V, which proved that MOF(Fe/Co) possessed outstanding ORR/OER dual-function catalytic performance. Results also evidenced that various transition metals, for instance, Fe and Co, are auspicious to the OER and ORR. Furthermore, other factors such as exceptional surface area and microporous morphology of MOF(Fe/Co) exhibited beneficial influences on oxygen diffusion and catalytic site implementation in reaction procedures. Thanks to these considerations, an exceptional dual-function catalytic performance for both OER and ORR of the MOF(Fe/Co) could be obtained.

5.1.3.2 Ni/M Bimetallic-MOFs Catalysts

Ni/M incorporating in porous carbon was considered a successful method for enhancing the activity for non-noble ORR catalysts. Recently, ZIF-67 was used as a precursor for polyhedral morphology with a porous structure containing Ni/Co, as stated by Chen et al. [7c shows the SEM image of ZIF-67 particles, exhibiting dodecahedral morphology. Furthermore, Fig. 7d, e indicates the SEM images of Ni/Co/NC. Ni/Co/NC particles preserved the dodecahedral construction of ZIF-67 particles with hollow morphology. Also, when Ni/Co/NC was doped with P element by evaporating technique, it preserved the dodecahedral geometry and the hollow morphology. Figure 7f–k indicates the formation of P/Ni/Co/NC. Also, P/Ni/Co/NC EDS maps were performed for P, Co, Ni, C, O, and N elements. All particles have well-dispersed elements. Figure 7f–k shows the LSV measurements, where the ORR onset potential of Co/NC was 0.847 V corresponding to a current density of 0.1 mA cm−2. It was concluded that phosphorous and nickel can enhance the ORR onset potential of Co/NC might be released from the rise of the active sites in the electrocatalyst via do** with phosphorous and nickel elements. Finally, it is feasible for P/Ni/Co/NC to be utilized in actual fuel cells owing to its outstanding ORR activity.

a Schematic illustration of the synthesis of Ni/Co/NC electrocatalyst. SEM images of b ZIF-67, c Ni/ZIF-8, d Ni/Co/NC, e P/Ni/Co/NC, f–k EDS maps of P/Ni/Co/NC and l linear sweep voltammetry of Co/NC. Ni/Co/NC, P/Ni/Co/NC in O2-saturated 0.1 mol L−1 KOH at a scan rate of 10 mV s−1 with an RDE rotation rate of 1600 rpm [7p shows the LSV plot of the CuCo@ NC electrocatalyst with an enhanced ORR efficiency. CuCo@ NC gave an increased onset potential of 0.96 V and outstanding E1/2 of 0.884 V, relative to 1.038 and 0.842 V of 30% Pt/C catalysts, respectively.

5.2 MOF-Derived Materials for OER

Hitherto, OER electrocatalysis is controlled by the presence of transitional metals oxides and hydroxides. Consequently, MOFs open a promising approach through changing into metal oxides efficiently. Lately, OER MOF-derived materials have gained great attention from various research groups [146,147,148]. This attention thanks to numerous factors, such as (i) there are increased probabilities to obtain new OER active sites through metal–ligand coordination; (ii) different cations replacement in MOFs boosts catalyst activity; and (iii) MOF-derived materials support the design for forming composites with a high surface area. In the present section, we will essentially concentrate on diverse methods that boost the OER performance for the MOF-derived catalysts.

5.2.1 Metal-Free OER Electrocatalyst

Transition metals that emerged in porous materials were comprehensively investigated as OER catalysts; nevertheless, they are still restricted by metal particle accumulation and leaking after long-term cycles. Relative to loaded electrocatalysts, electrocatalysts of metal-free carbon do not expose the challenges of particle agglomeration and leaching and consequently can display improved stability throughout long-term usage. Furthermore, it was confirmed that carbon materials doped with one or numerous types of heteroatoms (e.g., nitrogen, phosphorus, sulfur, and boron) are advantageous for their catalytic activity. Qian et al. [77] by pyrolyzing a MOF precursor Zn-MOF (MC-BIF-1S) under H2-containing gas, prepared extremely porous boron–nitrogen dual-doped carbon materials. The existence of N and B in the carbon materials (BNPC) and the high porosity were able to efficiently enhance the OER catalytic activity (Fig. 8). As indicated, the uppermost OER electrocatalytic current across all the carbon-based electrocatalysts in that study and BNPC-1100 had the second-lowest slope in the Tafel plots. Thanks to the porosity (859 m2 g−1) and boron–nitrogen dual-doped chemical composition, BNPC-1100 exhibited outstanding OER catalytic performance. It is common knowledge that the adsorption of OH− and H2O is vital to begin the OER pathway; furthermore, nitrogen dopants with positively charged carbon atoms around it along with the boron dopants deliver adequate centers to enhance the electron transfer among electrocatalyst and reactants.

a Synthetic scheme of BNPCs, LSV. b, d Tafel plots of pyrolyzed non-B-doped MOFs, BNC, BNPCs, 20% Pt/C, and RuO2 in 0.1 M KOH and c, e 6 M KOH [77], Copyright© 2017, Elsevier. f LSVs for the OER by Co-MOF/AB, commercial RuO2, CoO (after TGA), and AB in a 1 M KOH electrolyte at the sweep rate of 5 mV s−1 and g the corresponding Tafel plot [153], Copyright © 2019, The Royal Society of Chemistry

5.2.2 MOF-Derived Metal-Involved Electrocatalysts

The hierarchy surface morphology, larger specific surface area, tunable chemical structure, and the existence of the maximum number of active centers make MOFs an appropriate substitute for noble metal-based OER electrocatalysts [

Based on this understanding, in addition to the status of up-to-date studies on MOF-derived electrocatalysis, the following points can be taken into account to design good and promising MOF-derived ORR, OER, and HER catalysts:

-

(1)

Via intrinsic MOFs and MOF-derived materials, different MOFs including ZIFs and MILs need to be extensively extended to accomplish the necessitates of modern catalysts structures. Additional protocols and synthesis methods for MOF-based materials should be explored to adapt the constitutions, morphologies, and structures to obtain more optimized materials. Additional properties could be explored for indicating the reaction mechanisms and maximizing the synthesis knowledge to reduce the expenses, beneficial to improve the activity and stability of the materials.

-

(2)

Theoretically, computational calculations and structural designing should be implemented to know the requirements of particular reactions and decreasing repetition for trial-and-error endeavors. Up till now, although well-established DFT approaches have been established and applied for numerous structures, the DFT direct endorsement in MOF-derived electrocatalysis is still rare and further investigation is demanded. At the same time, thanks to the multi-function performance of MOF materials, it is expected that such area will remain to enlarge and cross with researches, other than those constrained to up-to-date like ORR, OER, and HER electrochemical reactions.

-

(3)

Multi‐do** is an encouraging approach to designing high-efficiency MOF-derived electrocatalysts. More consideration is needed to adapt the dopants configuration. Do** with diverse dopants can produce numerous synergetic effects for ORR, OER, and HER electrocatalysis.

-

(4)

Under the ORR/OER/HER reaction conditions, the chemical and thermodynamic stability shall be considered for MOF-derived electrocatalysts. Therefore, a high level of graphitization in the carbon matrix is preferred to maintain the high conductivity and stability of the catalysts.

-

(5)

In terms of advanced characterization techniques and theoretical calculations, systematized researches will offer a novel perspective to detect the intrinsic catalytic active sites and numerous new possibilities for the rational design and performance revolutions for ORR/OER/HER electrocatalysts.

-

(6)

Though significant progress has been attained recently, MOF‐derived electrocatalysis is still far away from utilization in industrial‐scale energy applications toward fuel cells and water electrolyzes. We believe that the continuous development of nanotechnology and electrochemical science, characterizations, and theoretical calculations will conduct the multi‐scale design and synthesis of MOF‐derived materials with optimal activity and robustness.

References

O. Inderwildi, C. Zhang, X. Wang, M. Kraft, The impact of intelligent cyber-physical systems on the decarbonization of energy. Energy Environ. Sci. 13(3), 744–771 (2020). https://doi.org/10.1039/c9ee01919g

Z. Qian, Y. Pei, H. Zareipour, N. Chen, A review and discussion of decomposition-based hybrid models for wind energy forecasting applications. Appl. Energy 235, 939–953 (2019). https://doi.org/10.1016/j.apenergy.2018.10.080

D. Farinotti, V. Round, M. Huss, L. Compagno, H. Zekollari, Large hydropower and water-storage potential in future glacier-free basins. Nature 575(7782), 341–344 (2019). https://doi.org/10.1038/s41586-019-1740-z

S.G. Yalew, M.T. van Vliet, D.E. Gernaat, F. Ludwig, A. Miara et al., Impacts of climate change on energy systems in global and regional scenarios. Nat. Energy 5(10), 794–802 (2020). https://doi.org/10.1038/s41560-020-0664-z

J. Chang, Q. Huang, Y. Gao, Z. Zheng, Pathways of develo** high-energy-density flexible lithium batteries. Adv. Mater. (2021). https://doi.org/10.1002/adma.202004419

A. Radwan, Y. Liu, Y. Qi, W. **, V. Nguyen et al., Cycling stability of carbon coated Na5V12O32 ultralong nanowires as a cathode material for sodium-ion batteries. Mater. Res. Bull. 97, 24–29 (2018). https://doi.org/10.1016/j.materresbull.2017.08.047

Y.-T. Liu, S. Liu, G.-R. Li, X.-P. Gao, Strategy of enhancing the volumetric energy density for lithium–sulfur batteries. Adv. Mater. 33(8), 2003955 (2021). https://doi.org/10.1002/adma.202003955

A.R. Radwan, Y. Liu, V. Nguyen, W. Chen, Sodium vanadate nanoflowers/rGO composite as a high-rate cathode material for sodium-ion batteries. J. Mater. Sci. Mater. Electron. 29(8), 7032–7039 (2018). https://doi.org/10.1007/s10854-018-8690-3

G. Qian, J. Chen, T. Yu, L. Luo, S. Yin, N-doped graphene-decorated NiCo alloy coupled with mesoporous NiCoMoO nano-sheet heterojunction for enhanced water electrolysis activity at high current density. Nano-Micro Lett. 13(1), 77 (2021). https://doi.org/10.1007/s40820-021-00607-5

M. Hirscher, T. Autrey, S.-I. Orimo, Hydrogen energy. ChemPhysChem 20(10), 1157–1157 (2019). https://doi.org/10.1002/cphc.201900429

H. **, X. Wang, C. Tang, A. Vasileff, L. Li et al., Stable and highly efficient hydrogen evolution from seawater enabled by an unsaturated nickel surface nitride. Adv. Mater. 33(13), 2007508 (2021). https://doi.org/10.1002/adma.202007508

T. Kirchartz, U. Rau, What makes a good solar cell? Adv. Energy Mater. 8(28), 1703385 (2018). https://doi.org/10.1002/aenm.201703385

A.Q. Gilbert, M.D. Bazilian, Can distributed nuclear power address energy resilience and energy poverty? Joule 4(9), 1839–1843 (2020). https://doi.org/10.1016/j.joule.2020.08.005

S.L. Zhang, B.Y. Guan, X.F. Lu, S. **, Y. Du et al., Metal atom-doped Co3O4 hierarchical nanoplates for electrocatalytic oxygen evolution. Adv. Mater. 32(31), 2002235 (2020). https://doi.org/10.1002/adma.202002235

W. Cheng, X.F. Lu, D. Luan, X.W. Lou, NiMn-based bimetal–organic framework nanosheets supported on multi-channel carbon fibers for efficient oxygen electrocatalysis. Angew. Chem. Int. Ed. 59(41), 18234–18239 (2020). https://doi.org/10.1002/anie.202008129

S.Y. Lim, S. Martin, G. Gao, Y. Dou, S.B. Simonsen et al., Self-standing nanofiber electrodes with Pt–Co derived from electrospun zeolitic imidazolate framework for high temperature PEM fuel cells. Adv. Funct. Mater. (2020). https://doi.org/10.1002/adfm.202006771

Z. Wang, H. **, T. Meng, K. Liao, W. Meng et al., Fe, Cu-coordinated ZIF-derived carbon framework for efficient oxygen reduction reaction and Zinc–air batteries. Adv. Funct. Mater. 28(39), 1802596 (2018). https://doi.org/10.1002/adfm.201802596

I.S. Amiinu, Z. Pu, X. Liu, K.A. Owusu, H.G.R. Monestel et al., Multifunctional Mo–N/C@ MoS2 electrocatalysts for HER, OER, ORR, and Zn–air batteries. Adv. Funct. Mater. 27(44), 1702300 (2017). https://doi.org/10.1002/adfm.201702300

H. Zhou, D. He, A.I. Saana, J. Yang, Z. Wang et al., Mesoporous-silica induced doped carbon nanotube growth from metal–organic frameworks. Nanoscale 10(13), 6147–6154 (2018). https://doi.org/10.1039/C8NR00137E

I.S. Amiinu, X. Liu, Z. Pu, W. Li, Q. Li et al., From 3D ZIF nanocrystals to Co–Nx/C nanorod array electrocatalysts for ORR, OER, and Zn–Air batteries. Adv. Funct. Mater. 28(5), 1704638 (2018). https://doi.org/10.1002/adfm.201704638

X.F. Lu, Y. Chen, S. Wang, S. Gao, X.W. Lou, Interfacing manganese oxide and cobalt in porous graphitic carbon polyhedrons boosts oxygen electrocatalysis for Zn–Air batteries. Adv. Mater. 31(39), 1902339 (2019). https://doi.org/10.1002/adma.201902339

Q. Sun, N. Wang, Q. Xu, J. Yu, Nanopore-supported metal nanocatalysts for efficient hydrogen generation from liquid-phase chemical hydrogen storage materials. Adv. Mater. 32(44), e2001818 (2020). https://doi.org/10.1002/adma.202001818

H. Yuan, J. Nai, H. Tian, Z. Ju, W. Zhang et al., An ultrastable lithium metal anode enabled by designed metal fluoride spansules. Sci. Adv. 6(10), 3112 (2020). https://doi.org/10.1126/sciadv.aaz3112

H. Yuan, J. Nai, Y. Fang, G. Lu, X. Tao et al., Double-shelled C@MoS2 structures preloaded with sulfur: an additive reservoir for stable lithium metal anodes. Angew. Chem. Int. Ed. 59(37), 15839–15843 (2020). https://doi.org/10.1002/ange.202001989

X. Zhu, C. Hu, R. Amal, L. Dai, X. Lu, Heteroatom-doped carbon catalysts for zinc–air batteries: progress, mechanism, and opportunities. Energy Environ. Sci. 13(12), 4536–4563 (2020). https://doi.org/10.1039/D0EE02800B

C.Y. Su, H. Cheng, W. Li, Z.Q. Liu, N. Li et al., Atomic modulation of FeCo–nitrogen–carbon bifunctional oxygen electrodes for rechargeable and flexible all-solid-state zinc–air battery. Adv. Energy Mater. 7(13), 1602420 (2017). https://doi.org/10.1002/aenm.201602420

Y. Qiao, P. Yuan, Y. Hu, J. Zhang, S. Mu et al., Sulfuration of an Fe–N–C catalyst containing FexC/Fe species to enhance the catalysis of oxygen reduction in acidic media and for use in flexible Zn–air batteries. Adv. Mater. 30(46), 1804504 (2018). https://doi.org/10.1002/adma.201804504

Z. Lu, B. Wang, Y. Hu, W. Liu, Y. Zhao et al., An isolated zinc–cobalt atomic pair for highly active and durable oxygen reduction. Angew. Chem. Int. Ed. 58, 2622–2626 (2019). https://doi.org/10.1002/anie.201810175

T. Wang, Z. Kou, S. Mu, J. Liu, D. He et al., 2D dual-metal zeolitic-imidazolate-framework-(ZIF)-derived bifunctional air electrodes with ultrahigh electrochemical properties for rechargeable zinc–air batteries. Adv. Funct. Mater. 28(5), 1705048 (2018). https://doi.org/10.1002/adfm.201705048

L. Yan, Y. Xu, P. Chen, S. Zhang, H. Jiang et al., A freestanding 3D Heterostructure film stitched by MOF-derived carbon nanotube microsphere superstructure and reduced graphene oxide sheets: a Superior multifunctional electrode for overall water splitting and Zn–air batteries. Adv. Mater. 32(48), 2003313 (2020). https://doi.org/10.1002/adma.202003313

J. Zhang, Y. Sun, J. Zhu, Z. Kou, P. Hu et al., Defect and pyridinic nitrogen engineering of carbon-based metal-free nanomaterial toward oxygen reduction. Nano Energy 52, 307–314 (2018). https://doi.org/10.1016/j.nanoen.2018.08.003

H. Wang, F.X. Yin, N. Liu, R.H. Kou, X.B. He et al., Engineering Fe–Fe3C@ Fe–N–C active sites and hybrid structures from dual metal–organic frameworks for oxygen reduction reaction in H2–O2 fuel cell and Li–O2 battery. Adv. Funct. Mater. 29(23), 1901531 (2019). https://doi.org/10.1002/adfm.201901531

S.L. Zhang, B.Y. Guan, X.W. Lou, Co–Fe alloy/N-doped carbon hollow spheres derived from dual metal–organic frameworks for enhanced electrocatalytic oxygen reduction. Small 15(13), 1805324 (2019). https://doi.org/10.1002/smll.201805324

B.Y. Guan, Y. Lu, Y. Wang, M. Wu, X.W. Lou, Porous iron–cobalt alloy/nitrogen-doped carbon cages synthesized via pyrolysis of complex metal–organic framework hybrids for oxygen reduction. Adv. Funct. Mater. 28(10), 1706738 (2018). https://doi.org/10.1002/adfm.201706738

H. Liu, J. Guan, S. Yang, Y. Yu, R. Shao et al., Metal–organic-framework-derived Co2P nanoparticle/multi-doped porous carbon as a trifunctional electrocatalyst. Adv. Mater. 32(36), 2003649 (2020). https://doi.org/10.1002/adma.202003649

A.I. Douka, Y. Xu, H. Yang, S. Zaman, Y. Yan et al., A zeolitic-imidazole frameworks-derived interconnected macroporous carbon matrix for efficient oxygen electrocatalysis in rechargeable zinc–air batteries. Adv. Mater. 32(28), 2002170 (2020). https://doi.org/10.1002/adma.202002170

Y. Wang, L. Yan, K. Dastafkan, C. Zhao, X. Zhao et al., Lattice matching growth of conductive hierarchical porous MOF/LDH heteronanotube arrays for highly efficient water oxidation. Adv. Mater. (2021). https://doi.org/10.1002/adma.202006351

T. Liu, P. Li, N. Yao, T. Kong, G. Cheng et al., Self-sacrificial template-directed vapor-phase growth of MOF assemblies and surface vulcanization for efficient water splitting. Adv. Mater. 31(21), 1806672 (2019). https://doi.org/10.1002/adma.201806672

C.C. Hou, L. Zou, Y. Wang, Q. Xu, MOF-mediated fabrication of a porous 3D superstructure of carbon nanosheets decorated with ultrafine cobalt phosphide nanoparticles for efficient electrocatalysis and zinc–air batteries. Angew. Chem. Int. Ed. 132(48), 21544–21550 (2020). https://doi.org/10.1002/ange.202011347

M. Zhang, Q. Dai, H. Zheng, M. Chen, L. Dai, Novel MOF-derived Co@ N-C bifunctional catalysts for highly efficient Zn–air batteries and water splitting. Adv. Mater. 30(10), 1705431 (2018). https://doi.org/10.1002/adma.201705431

H. **a, J. Zhang, Z. Yang, S. Guo, S. Guo et al., 2D MOF Nanoflake-assembled spherical microstructures for enhanced supercapacitor and electrocatalysis performances. Nano-Micro Lett. 9(4), 43 (2017). https://doi.org/10.1007/s40820-017-0144-6

Y. Arafat, M.R. Azhar, Y. Zhong, X. Xu, M.O. Tadé et al., A Porous Nano-micro-composite as a high-performance bi-functional air electrode with remarkable stability for rechargeable zinc–air batteries. Nano-Micro Lett. 12(1), 130 (2020). https://doi.org/10.1007/s40820-020-00468-4

Q. Niu, B. Chen, J. Guo, J. Nie, X. Guo et al., Flexible, porous, and metal–heteroatom-doped carbon nanofibers as efficient ORR electrocatalysts for Zn–air battery. Nano-Micro Lett. 11(1), 8 (2019). https://doi.org/10.1007/s40820-019-0238-4

K. Chen, S. Kim, M. Je, H. Choi, Z. Shi et al., Ultrasonic plasma engineering toward facile synthesis of single-atom M-N4/N-doped carbon (M = Fe, Co) as superior oxygen electrocatalyst in rechargeable zinc–air batteries. Nano-Micro Lett. 13(1), 60 (2021). https://doi.org/10.1007/s40820-020-00581-4

Z. Zhao, C. Chen, Z. Liu, J. Huang, M. Wu et al., Pt-based nanocrystal for electrocatalytic oxygen reduction. Adv. Mater. 31(31), 1808115 (2019). https://doi.org/10.1002/adma.201808115

X. Zhao, Y. Hamamura, Y. Yoshida, T. Kaneko, T. Gunji et al., Plasma-devised Pt/C model electrodes for understanding doubly beneficial roles of nanoneedle-carbon morphology and strong Pt-carbon interface in oxygen reduction reaction. ACS Appl. Energy Mater. 3(6), 5542–5551 (2020). https://doi.org/10.1021/acsaem.0c00528

P. Mardle, X. Ji, J. Wu, S. Guan, H. Dong et al., Thin film electrodes from Pt nanorods supported on aligned N-CNTs for proton exchange membrane fuel cells. Appl. Catal. B-Environ. 260, 118031 (2020). https://doi.org/10.1016/j.apcatb.2019.118031

A.M. Jauhar, Z. Ma, M. **ao, G. Jiang, S. Sy et al., Space-confined catalyst design toward ultrafine Pt nanoparticles with enhanced oxygen reduction activity and durability. J. Power Sources 473, 228607 (2020). https://doi.org/10.1016/j.jpowsour.2020.228607

S. Anantharaj, S. Kundu, S. Noda, “The Fe Effect”: A review unveiling the critical roles of Fe in enhancing OER activity of Ni and Co based catalysts. Nano Energy 80, 105514 (2021). https://doi.org/10.1016/j.nanoen.2020.105514

L. Wang, Q. Zhou, Z. Pu, Q. Zhang, X. Mu et al., Surface reconstruction engineering of cobalt phosphides by Ru inducement to form hollow Ru-RuPx-CoxP pre-electrocatalysts with accelerated oxygen evolution reaction. Nano Energy 53, 270–276 (2018). https://doi.org/10.1016/j.nanoen.2018.08.061

P. Wang, Z. Pu, Y. Li, L. Wu, Z. Tu et al., Iron-doped nickel phosphide nanosheet arrays: an efficient bifunctional electrocatalyst for water splitting. ACS Appl. Mater. Interfaces 9(31), 26001–26007 (2017). https://doi.org/10.1021/acsami.7b06305

M. Wang, C. Zhang, T. Meng, Z. Pu, H. ** et al., Iron oxide and phosphide encapsulated within N, P-doped microporous carbon nanofibers as advanced tri-functional electrocatalyst toward oxygen reduction/evolution and hydrogen evolution reactions and zinc-air batteries. J. Power Sources 413, 367–375 (2019). https://doi.org/10.1016/j.jpowsour.2018.12.056

X.F. Lu, L. Yu, X.W. Lou, Highly crystalline Ni-doped FeP/carbon hollow nanorods as all-pH efficient and durable hydrogen evolving electrocatalysts. Sci. Adv. 5(2), eaav6009 (2019). https://doi.org/10.1126/sciadv.aav6009

H.-F. Wang, L. Chen, H. Pang, S. Kaskel, Q. Xu, MOF-derived electrocatalysts for oxygen reduction, oxygen evolution and hydrogen evolution reactions. Chem. Soc. Rev. 49(5), 1414–1448 (2020). https://doi.org/10.1126/sciadv.aav6009

Z. Liang, T. Qiu, S. Gao, R. Zhong, R. Zou, Multi-scale design of metal–organic framework-derived materials for energy electrocatalysis. Adv. Energy Mater. (2021). https://doi.org/10.1002/aenm.202003410

C.C. Hou, Q. Xu, Metal–organic frameworks for energy. Adv. Energy Mater. 9(23), 1801307 (2019). https://doi.org/10.1002/aenm.201801307

H. Dou, M. Xu, B. Wang, Z. Zhang, G. Wen et al., Microporous framework membranes for precise molecule/ion separations. Chem. Soc. Rev. 50(2), 986–1029 (2021). https://doi.org/10.1039/d0cs00552e

R.-B. Lin, S. **ang, H. **ng, W. Zhou, B. Chen, Exploration of porous metal–organic frameworks for gas separation and purification. Coord. Chem. Rev. 378, 87–103 (2019). https://doi.org/10.1016/j.ccr.2017.09.027

Q. Qian, P.A. Asinger, M.J. Lee, G. Han, K. Mizrahi Rodriguez et al., MOF-based membranes for gas separations. Chem. Rev. 120(16), 8161–8266 (2020). https://doi.org/10.1021/acs.chemrev.0c00119

Q. Liang, H. **, Z. Wang, Y. **ong, S. Yuan et al., Metal-organic frameworks derived reverse-encapsulation Co-NC@Mo2C complex for efficient overall water splitting. Nano Energy 57, 746–752 (2019). https://doi.org/10.1016/j.nanoen.2018.12.060

J. Chen, H. Li, C. Fan, Q. Meng, Y. Tang et al., Dual single-atomic Ni-N4 and Fe-N4 sites constructing janus hollow graphene for selective oxygen electrocatalysis. Adv. Mater. 32(30), 2003134 (2020). https://doi.org/10.1002/adma.202003134

L.J. Small, S.E. Henkelis, D.X. Rademacher, M.E. Schindelholz, J.L. Krumhansl et al., Near-zero power MOF-based sensors for NO2 detection. Funct. Mater. Adv. (2020). https://doi.org/10.1002/adfm.202006598

C. Chen, D. **ong, M. Gu, C. Lu, F.-Y. Yi et al., MOF-derived bimetallic CoFe-PBA composites as highly selective and sensitive electrochemical sensors for hydrogen peroxide and nonenzymatic glucose in human serum. ACS Appl. Mater. Interfaces 12(31), 35365–35374 (2020). https://doi.org/10.1021/acsami.0c09689

X.S. **ng, Z.H. Fu, N.N. Zhang, X.Q. Yu, M.S. Wang et al., High proton conduction in an excellent water-stable gadolinium metal-organic framework. Chem. Commun. 55(9), 1241–1244 (2019). https://doi.org/10.1039/c8cc08700h

Y. Ye, L. Gong, S. **ang, Z. Zhang, B. Chen, Metal–organic frameworks as a versatile platform for proton conductors. Adv. Mater. 32(21), 1907090 (2020). https://doi.org/10.1002/adma.201907090

Y. Feng, H. Wang, S. Zhang, Y. Zhao, J. Gao et al., Antibodies@ MOFs: an in vitro protective coating for preparation and storage of biopharmaceuticals. Adv. Mater. 31(2), 1805148 (2019). https://doi.org/10.1002/adma.201805148

I.A. Lázaro, R.S. Forgan, Application of zirconium MOFs in drug delivery and biomedicine. Coord. Chem. Rev. 380, 230–259 (2019). https://doi.org/10.1016/j.ccr.2018.09.009

H.-C. Zhou, J.R. Long, O.M. Yaghi, Introduction to metal–organic frameworks. Chem. Rev. 112(2), 673–674 (2012). https://doi.org/10.1021/cr300014x

S. Kitagawa, Metal–organic frameworks (MOFs). Chem. Soc. Rev. 43(16), 5415–5418 (2014). https://doi.org/10.1039/C4CS90059F

C.A. Downes, S.C. Marinescu, Electrocatalytic metal-organic frameworks for energy applications. Chemsuschem 10(22), 1701420 (2017). https://doi.org/10.1002/cssc.201701420

S. Yuan, L. Feng, K. Wang, J. Pang, M. Bosch, Stable metal–organic frameworks: design, synthesis, and applications. Adv. Mater. 30(37), 1704303 (2018). https://doi.org/10.1002/adma.201704303

X. Long, P. Yin, T. Lei, K. Wang, Z. Zhan, Methanol electro-oxidation on Cu@Pt/C core-shell catalyst derived from Cu-MOF. Appl. Catal. B-Environ. 260, 118187 (2020). https://doi.org/10.1016/j.apcatb.2019.118187

H. Zhang, Z. Ma, J. Duan, H. Liu, G. Liu, Active sites implanted carbon cages in core–shell architecture: highly active and durable electrocatalyst for hydrogen evolution reaction. ACS Nano 10(1), 684–694 (2016). https://doi.org/10.1021/acsnano.5b05728

V. Briega-Martos, E. Herrero, J.M. Feliu, Hydrogen peroxide and oxygen reduction studies on Pt stepped surfaces: surface charge effects and mechanistic consequences. Electrochim. Acta 334, 135452 (2020). https://doi.org/10.1016/j.electacta.2019.135452

M.J. Farias, A.L. Silva, A.A. Tanaka, E. Herrero, J.M. Feliu, Surface defects as ingredients that can improve or inhibit the pathways for CO oxidation at low overpotentials using Pt (111)-type catalysts. J. Phys. Chem. C 124(49), 26583–26595 (2020). https://doi.org/10.1021/acs.jpcc.0c07104

X. Wan, X. Liu, Y. Li, R. Yu, L. Zheng, Fe–N–C electrocatalyst with dense active sites and efficient mass transport for high-performance proton exchange membrane fuel cells. Nat. Catal. 2(3), 259–268 (2019). https://doi.org/10.1038/s41929-019-0237-3

Y. Qian, Z. Hu, X. Ge, S. Yang, Y. Peng, A metal-free ORR/OER bifunctional electrocatalyst derived from metal-organic frameworks for rechargeable Zn-Air batteries. Carbon 111, 641–650 (2017). https://doi.org/10.1016/j.carbon.2016.10.046

X. Wei, Y. Li, H. Peng, D. Gao, Y. Ou, A novel functional material of Co3O4/Fe2O3 nanocubes derived from a MOF precursor for high-performance electrochemical energy storage and conversion application. Chem. Eng. J. 355, 336–340 (2019). https://doi.org/10.1016/j.cej.2018.08.009

Y. Deng, B. Chi, X. Tian, Z. Cui, E. Liu et al., g-C3N4 promoted MOF derived hollow carbon nanopolyhedra doped with high density/fraction of single Fe atoms as an ultra-high performance non-precious catalyst towards acidic ORR and PEM fuel cells. J. Mater. Chem. A 7(9), 5020–5030 (2019). https://doi.org/10.1039/C8TA11785C

M. Kuang, W. Huang, C. Hegde, W. Fang, X. Tan et al., Interface engineering in transition metal carbides for electrocatalytic hydrogen generation and nitrogen fixation. Mater. Horiz. 7(1), 32–53 (2020). https://doi.org/10.1039/C9MH01094G

A. Mahmood, W. Guo, H. Tabassum, R. Zou, Metal-organic framework-based nanomaterials for electrocatalysis. Adv. Energy Mater. 6(17), 1600423 (2016). https://doi.org/10.1002/aenm.201600423

B.Y. Guan, X.Y. Yu, H.B. Wu, X.W. Lou, Complex nanostructures from materials based on metal–organic frameworks for electrochemical energy storage and conversion. Adv. Mater. 29(47), 1703614 (2017). https://doi.org/10.1002/adma.201703614

C. Wang, J. Kim, J. Tang, M. Kim, H. Lim et al., New strategies for novel MOF-derived carbon materials based on nanoarchitectures. Chem 6(1), 19–40 (2020). https://doi.org/10.1016/j.chempr.2019.09.005

X.F. Lu, Y. Fang, D. Luan, X.W.D. Lou, Metal–organic frameworks derived functional materials for electrochemical energy storage and conversion: a mini review. Nano Lett. 21(4), 1555–1565 (2021). https://doi.org/10.1021/acs.nanolett.0c04898

S. Pandiaraj, H.B. Aiyappa, R. Banerjee, S. Kurungot, Post modification of MOF derived carbon via g-C3N4 entrapment for an efficient metal-free oxygen reduction reaction. Chem. Commun. 50(25), 3363–3366 (2014). https://doi.org/10.1039/c3cc47620k

B. Liu, H. Shioyama, T. Akita, Q. Xu, Metal-organic framework as a template for porous carbon synthesis. J. Am. Chem. Soc. 130(16), 5390–5391 (2008). https://doi.org/10.1021/ja7106146

P. Zhang, F. Sun, Z. **ang, Z. Shen, J. Yun et al., ZIF-derived in situ nitrogen-doped porous carbons as efficient metal-free electrocatalysts for oxygen reduction reaction. Energy Environ. Sci. 7(1), 442–450 (2014). https://doi.org/10.1039/c3ee42799d

X.F. Lu, B.Y. **a, S.Q. Zang, X.W. Lou, Metal–organic frameworks based electrocatalysts for the oxygen reduction reaction. Angew. Chem. Int. Ed. 59(12), 4634–4650 (2020). https://doi.org/10.1002/anie.201910309

A. Radwan, H. **, B. Liu, Z. Chen, Q. Wu et al., 3D-ZIF scaffold derived carbon encapsulated iron nitride as a synergistic catalyst for ORR and zinc-air battery cathodes. Carbon 171, 368–375 (2021). https://doi.org/10.1016/j.carbon.2020.09.024

Z. Lyu, G.J.H. Lim, R. Guo, Z. Kou, T. Wang et al., 3D-printed MOF-derived hierarchically porous frameworks for practical high-energy density Li-O2 batteries. Adv. Funct. Mater. 29(1), 1806658 (2019). https://doi.org/10.1002/adfm.201806658

K. Rui, G. Zhao, Y. Chen, Y. Lin, Q. Zhou et al., Hybrid 2D dual-metal-organic frameworks for enhanced water oxidation catalysis. Adv. Funct. Mater. 28(26), 1801554 (2018). https://doi.org/10.1002/adfm.201801554

K. Gong, F. Du, Z. **a, M. Durstock, L. Dai, Nitrogen-doped carbon nanotube arrays with high electrocatalytic activity for oxygen reduction. Science 323(5915), 760–764 (2009). https://doi.org/10.1126/science.1168049

C.H. Choi, S.H. Park, S.I. Woo, Binary and ternary do** of nitrogen, boron, and phosphorus into carbon for enhancing electrochemical oxygen reduction activity. ACS Nano 6(8), 7084–7091 (2012). https://doi.org/10.1021/nn3021234

Z. Yang, Z. Yao, G. Li, G. Fang, H. Nie et al., Sulfur-doped graphene as an efficient metal-free cathode catalyst for oxygen reduction. ACS Nano 6(1), 205–211 (2012). https://doi.org/10.1021/nn203393d

Z.H. Huang, N.H. **e, M. Zhang, B.Q. Xu, Nonpyrolyzed Fe-N coordination-based iron triazolate framework: an efficient and stable electrocatalyst for oxygen reduction reaction. Chemsuschem 12(1), 200–207 (2019). https://doi.org/10.1002/cssc.201801886

A. Bavykina, N. Kolobov, I.S. Khan, J.A. Bau, A. Ramirez et al., Metal–organic frameworks in heterogeneous catalysis: recent progress, new trends, and future perspectives. Chem. Rev. 120(16), 8468–8535 (2020). https://doi.org/10.1021/acs.chemrev.9b00685

R. Wang, X.Y. Dong, J. Du, J.Y. Zhao, S.Q. Zang, MOF-derived bifunctional Cu3P nanoparticles coated by a N, P-codoped carbon shell for hydrogen evolution and oxygen reduction. Adv. Mater. 30(6), 1703711 (2018). https://doi.org/10.1002/adma.201703711

L. Yang, X. Zeng, W. Wang, D. Cao, Recent progress in MOF-derived, heteroatom-doped porous carbons as highly efficient electrocatalysts for oxygen reduction reaction in fuel cells. Adv. Funct. Mater. 28(7), 1704537 (2018). https://doi.org/10.1002/adfm.201704537

C.R. Raj, A. Samanta, S.H. Noh, S. Mondal, T. Okajima et al., Emerging new generation electrocatalysts for the oxygen reduction reaction. J. Mater. Chem. A 4(29), 11156–11178 (2016). https://doi.org/10.1039/C6TA03300H

W. Zhou, J. Zhou, Y. Zhou, J. Lu, K. Zhou et al., N-doped carbon-wrapped cobalt nanoparticles on N-doped graphene nanosheets for high-efficiency hydrogen production. Chem. Mater. 27(6), 2026–2032 (2015). https://doi.org/10.1021/acs.chemmater.5b00331

Q. Fu, J. Han, X. Wang, P. Xu, T. Yao et al., 2D transition metal dichalcogenides: Design, modulation, and challenges in electrocatalysis. Adv. Mater. 33(6), 1907818 (2021). https://doi.org/10.1002/adma.201907818

Y. Li, Z. Wang, J. Hu, S. Li, Y. Du et al., Metal–organic frameworks derived interconnected bimetallic metaphosphate nanoarrays for efficient electrocatalytic oxygen evolution. Adv. Funct. Mater. 30(25), 1910498 (2020). https://doi.org/10.1002/adfm.201910498

H. Huang, Y. Zhao, Y. Bai, F. Li, Y. Zhang et al., Conductive metal–organic frameworks with extra metallic sites as an efficient electrocatalyst for the hydrogen evolution reaction. Adv. Sci. 7(9), 2000012 (2020). https://doi.org/10.1002/advs.202000012

Z.W. Chen, L.X. Chen, Z. Wen, Q. Jiang, Understanding electro-catalysis by using density functional theory. Phys. Chem. Chem. Phys. 21(43), 23782–23802 (2019). https://doi.org/10.1039/c9cp04430b

S. Hammes-Schiffer, A conundrum for density functional theory. Science 355(6320), 28–29 (2017). https://doi.org/10.1126/science.aal3442

S.S. Shinde, C.H. Lee, J.-Y. Jung, N.K. Wagh, S.-H. Kim et al., Unveiling dual-linkage 3D hexaiminobenzene metal–organic frameworks towards long-lasting advanced reversible Zn–air batteries. Energy Environ. Sci. 12(2), 727–738 (2019). https://doi.org/10.1039/C8EE02679C

W. Cheng, X. Zhao, H. Su, F. Tang, W. Che et al., Lattice-strained metal–organic-framework arrays for bifunctional oxygen electrocatalysis. Nat. Energy 4(2), 115–122 (2019). https://doi.org/10.1038/s41560-018-0308-8

Y. Zhu, Z. Zhang, Z. Lei, Y. Tan, W. Wu et al., Defect-enriched hollow porous Co–N-doped carbon for oxygen reduction reaction and Zn-Air batteries. Carbon 167, 188–195 (2020). https://doi.org/10.1016/j.carbon.2020.06.006

Y. Lin, H. Wan, D. Wu, G. Chen, N. Zhang et al., Metal–organic framework hexagonal nanoplates: bottom-up synthesis, topotactic transformation, and efficient oxygen evolution reaction. J. Am. Chem. Soc. 142(16), 7317–7321 (2020). https://doi.org/10.1021/jacs.0c01916

W. Li, S. Xue, S. Watzele, S. Hou, J. Fichtner et al., Advanced bifunctional oxygen reduction and evolution electrocatalyst derived from surface-mounted metal-organic frameworks. Angew. Chem. Int. Ed. 59(14), 5837–5843 (2020). https://doi.org/10.1002/anie.201916507

B. Yan, D. Liu, X. Feng, M. Shao, Y. Zhang, Ru species supported on MOF-derived N-doped TiO2/C hybrids as efficient electrocatalytic/photocatalytic hydrogen evolution reaction catalysts. Adv. Funct. Mater. 30(31), 2003007 (2020). https://doi.org/10.1002/adfm.202003007

H. Huang, S. Zhou, C. Yu, H. Huang, J. Zhao et al., Rapid and energy-efficient microwave pyrolysis for high-yield production of highly-active bifunctional electrocatalysts for water splitting. Energy Environ. Sci. 13(2), 545–553 (2020). https://doi.org/10.1039/C9EE03273H

W. Zhang, Y. Wang, H. Zheng, R. Li, Y. Tang et al., Embedding ultrafine metal oxide nanoparticles in monolayered metal–organic framework nanosheets enables efficient electrocatalytic oxygen evolution. ACS Nano 14(2), 1971–1981 (2020). https://doi.org/10.1021/acsnano.9b08458

L. Huang, G. Gao, H. Zhang, J. Chen, Y. Fang et al., Self-dissociation-assembly of ultrathin metal-organic framework nanosheet arrays for efficient oxygen evolution. Nano Energy 68, 104296 (2020). https://doi.org/10.1016/j.nanoen.2019.104296

W. Cheng, X.F. Lu, D. Luan, X.W. Lou, NiMn-based bimetal–organic framework nanosheets supported on multi-channel carbon fibers for efficient oxygen electrocatalysis. Angew. Chem. Int. Ed. 59(41), 18234–18239 (2020). https://doi.org/10.1002/anie.202008129

G. Yilmaz, K.M. Yam, C. Zhang, H.J. Fan, G.W. Ho, In situ transformation of MOFs into layered double hydroxide embedded metal sulfides for improved electrocatalytic and supercapacitive performance. Adv. Mater. 29(26), 1606814 (2017). https://doi.org/10.1002/adma.201606814

D.Y. Chung, K.J. Lee, S.-H. Yu, M. Kim, S.Y. Lee et al., Alveoli-inspired facile transport structure of N-doped porous carbon for electrochemical energy applications. Adv. Energy Mater. 5(3), 1401309 (2015). https://doi.org/10.1002/aenm.201401309

Y. Hou, T. Huang, Z. Wen, S. Mao, S. Cui et al., Metal−Organic framework-derived nitrogen-doped core-shell-structured porous Fe/Fe3C@C nanoboxes supported on graphene sheets for efficient oxygen reduction reactions. Adv. Energy Mater. 4(11), 1400337 (2014). https://doi.org/10.1002/aenm.201400337

S.S.A. Shah, T. Najam, M.K. Aslam, M. Ashfaq, M.M. Rahman et al., Recent advances on oxygen reduction electrocatalysis: correlating the characteristic properties of metal organic frameworks and the derived nanomaterials. Appl. Catal. B-Environ. 268, 118570 (2020). https://doi.org/10.1016/j.apcatb.2019.118570

L. Ge, Y. Yang, L. Wang, W. Zhou, R. De Marco et al., High activity electrocatalysts from metal–organic framework-carbon nanotube templates for the oxygen reduction reaction. Carbon 82, 417–424 (2015). https://doi.org/10.1016/j.carbon.2014.10.085

C. Xu, Z. Lin, D. Zhao, Y. Sun, Y. Zhong et al., Facile in situ fabrication of Co nanoparticles embedded in 3D N-enriched mesoporous carbon foam electrocatalyst with enhanced activity and stability toward oxygen reduction reaction. J. Mater. Sci. 54(7), 5412–5423 (2019). https://doi.org/10.1007/s10853-018-03255-0

L. Yang, G. Xu, J. Ban, L. Zhang, G. Xu et al., Metal-organic framework-derived metal-free highly graphitized nitrogen-doped porous carbon with a hierarchical porous structure as an efficient and stable electrocatalyst for oxygen reduction reaction. J. Colloid Interface Sci. 535, 415–424 (2019). https://doi.org/10.1016/j.jcis.2018.10.007

X. Zhao, H. Zhao, T. Zhang, X. Yan, Y. Yuan et al., One-step synthesis of nitrogen-doped microporous carbon materials as metal-free electrocatalysts for oxygen reduction reaction. J. Mater. Chem. A 2(30), 11666–11671 (2014). https://doi.org/10.1039/c4ta00846d

F. Zheng, Y. Yang, Q. Chen, High lithium anodic performance of highly nitrogen-doped porous carbon prepared from a metal-organic framework. Nat. Commun. 5(1), 1–10 (2014). https://doi.org/10.1038/ncomms6261

L. Chai, L. Zhang, X. Wang, L. Xu, C. Han et al., Bottom-up synthesis of MOF-derived hollow N-doped carbon materials for enhanced ORR performance. Carbon 146, 248–256 (2019). https://doi.org/10.1016/j.carbon.2019.02.006

J. Li, Y. Chen, Y. Tang, S. Li, H. Dong et al., Metal–organic framework templated nitrogen and sulfur co-doped porous carbons as highly efficient metal-free electrocatalysts for oxygen reduction reactions. J. Mater. Chem. A 2(18), 6316–6319 (2014). https://doi.org/10.1039/C3TA15335E

J.-S. Li, S.-L. Li, Y.-J. Tang, K. Li, L. Zhou et al., Heteroatoms ternary-doped porous carbons derived from MOFs as metal-free electrocatalysts for oxygen reduction reaction. Sci. Rep. 4, 5130 (2014). https://doi.org/10.1038/srep05130

J. Yan, X. Zheng, C. Wei, Z. Sun, K. Zeng et al., Nitrogen-doped hollow carbon polyhedron derived from salt-encapsulated ZIF-8 for efficient oxygen reduction reaction. Carbon 171, 320–328 (2021). https://doi.org/10.1016/j.carbon.2020.09.005

J. Wei, Y. Hu, Y. Liang, B. Kong, J. Zhang et al., Nitrogen-doped nanoporous carbon/graphene nano-sandwiches: synthesis and application for efficient oxygen reduction. Adv. Funct. Mater. 25(36), 5768–5777 (2015). https://doi.org/10.1002/adfm.201502311

Q. Ren, H. Wang, X.F. Lu, Y.X. Tong, G.R. Li, Recent progress on MOF-derived heteroatom-doped carbon-based electrocatalysts for oxygen reduction reaction. Adv. Sci. 5(3), 1700515 (2018). https://doi.org/10.1002/advs.201700515

L. Du, L. **ng, G. Zhang, S. Sun, Metal-organic framework derived carbon materials for electrocatalytic oxygen reactions: recent progress and future perspectives. Carbon 156, 77–92 (2020). https://doi.org/10.1016/j.carbon.2019.09.029

F. Guo, H. Yang, L. Liu, Y. Han, A.M. Al-Enizi et al., Hollow capsules of doped carbon incorporating metal@ metal sulfide and metal@ metal oxide core–shell nanoparticles derived from metal-organic framework composites for efficient oxygen electrocatalysis. J. Mater. Chem. A 7, 3624–3631 (2019). https://doi.org/10.1039/C8TA11213D

X. Wen, X. Yang, M. Li, L. Bai, J. Guan, Co/CoOx nanoparticles inlaid onto nitrogen-doped carbon-graphene as a trifunctional electrocatalyst. Electrochim. Acta 296, 830–841 (2019). https://doi.org/10.1016/j.electacta.2018.11.129

J. Zhu, W. Tu, Z. Bai, H. Pan, P. Ji et al., Zeolitic-imidazolate-framework-derived Co@Co3O4 embedded into iron, nitrogen, sulfur Co-doped reduced graphene oxide as efficient electrocatalysts for overall water splitting and zinc-air batteries. Electrochim. Acta 323, 134821 (2019). https://doi.org/10.1016/j.electacta.2019.134821

X. Yi, X. He, F. Yin, B. Chen, G. Li et al., Co-CoO-Co3O4/N-doped carbon derived from metal-organic framework: The addition of carbon black for boosting oxygen electrocatalysis and Zn-Air battery. Electrochim. Acta 295, 966–977 (2019). https://doi.org/10.1016/j.electacta.2018.11.142

H. **, Z. Kou, W. Cai, H. Zhou, P. Ji et al., P-Fe bond oxygen reduction catalysts toward high-efficiency metal–air batteries and fuel cells. J. Mater. Chem. A 8(18), 9121–9127 (2020). https://doi.org/10.1039/D0TA02334E

Y. Deng, B. Chi, X. Tian, Z. Cui, E. Liu et al., gC3N4 promoted MOF derived hollow carbon nanopolyhedra doped with high density/fraction of single Fe atoms as an ultra-high performance non-precious catalyst towards acidic ORR and PEM fuel cells. J. Mater. Chem. A 7(9), 5020–5030 (2019). https://doi.org/10.1039/C8TA11785C

Q. Lin, X. Bu, A. Kong, C. Mao, X. Zhao et al., New heterometallic zirconium metalloporphyrin frameworks and their heteroatom-activated high-surface-area carbon derivatives. J. Am. Chem. Soc. 137(6), 2235–2238 (2015). https://doi.org/10.1021/jacs.5b00076

H.S. Kim, M.S. Kang, W.C. Yoo, Boost-up electrochemical performance of MOFs via confined synthesis within nanoporous carbon matrices for supercapacitor and oxygen reduction reaction applications. J. Mater. Chem. A 7(10), 5561–5574 (2019). https://doi.org/10.1039/C8TA12200H

Y. Li, W.-J. Zhang, J. Li, H. Ma, H. Du et al., Fe-MOF derived efficient ORR/OER bifunctional electrocatalyst for rechargeable Zinc-Air battery. ACS Appl. Mater. Interfaces 12(40), 44710–44719 (2020). https://doi.org/10.1021/acsami.0c11945

C. Castillo-Blas, N. Lopez-Salas, M.C. Gutierrez, I. Puente-Orench, E. Gutierrez-Puebla et al., Encoding metal-cation arrangements in metal-organic frameworks for programming the composition of electrocatalytically active multimetal oxides. J. Am. Chem. Soc. 141(4), 1766–1774 (2019). https://doi.org/10.1021/jacs.8b12860

X. Duan, S. Ren, N. Pan, M. Zhang, H. Zheng, MOF-derived Fe, Co@ N-C bifunctional oxygen electrocatalysts for Zn–air batteries. J. Mater. Chem. A 8(18), 9355–9363 (2020). https://doi.org/10.1039/D0TA02825H

H. Wang, F. Yin, G. Li, B. Chen, Z. Wang, Preparation, characterization and bifunctional catalytic properties of MOF (Fe/Co) catalyst for oxygen reduction/evolution reactions in alkaline electrolyte. Int. J. Hydrog. Energy 39(28), 16179–16186 (2014). https://doi.org/10.1016/j.ijhydene.2013.12.120

L. Li, W. **e, J. Chen, J. Yang, ZIF-67 derived P/Ni/Co/NC nanoparticles as highly efficient electrocatalyst for oxygen reduction reaction (ORR). J. Solid State Chem. 264, 1–5 (2018). https://doi.org/10.1016/j.jssc.2018.04.035

M. Kuang, Q. Wang, P. Han, G. Zheng, Cu, Co-embedded N-enriched mesoporous carbon for efficient oxygen reduction and hydrogen evolution reactions. Adv. Energy Mater. 7(17), 1700193 (2017). https://doi.org/10.1002/aenm.201700193

X.-F. Lu, L.-F. Gu, J.-W. Wang, J.-X. Wu, P.-Q. Liao et al., Bimetal-organic framework derived CoFe2O4/C Porous hybrid nanorod arrays as high-performance electrocatalysts for oxygen evolution reaction. Adv. Mater. 29(3), 1604437 (2017). https://doi.org/10.1002/adma.201604437

H.B. Wu, X.W.D. Lou, Metal-organic frameworks and their derived materials for electrochemical energy storage and conversion: promises and challenges. Sci Adv (2017). https://doi.org/10.1126/sciadv.aap9252

Y. Yan, T. He, B. Zhao, K. Qi, H. Liu et al., Metal/covalent–organic frameworks-based electrocatalysts for water splitting. J. Mater. Chem. A 6(33), 15905–15926 (2018). https://doi.org/10.1039/C8TA05985C

W. Chen, Y. Zhang, G. Chen, R. Huang, Y. Zhou et al., Mesoporous cobalt–iron–organic frameworks: a plasma-enhanced oxygen evolution electrocatalyst. J. Mater. Chem. A 7(7), 3090–3100 (2019). https://doi.org/10.1039/C8TA10952D

Y.V. Kaneti, J. Tang, R.R. Salunkhe, X. Jiang, A. Yu et al., Nanoarchitectured design of porous materials and nanocomposites from metal-organic frameworks. Adv. Mater. 29(12), 1604898 (2017). https://doi.org/10.1002/adma.201604898

H. Wang, F. Yin, B. Chen, G. Li, Synthesis of an ε-MnO2/metal–organic-framework composite and its electrocatalysis towards oxygen reduction reaction in an alkaline electrolyte. J. Mater. Chem. A 3(31), 16168–16176 (2015). https://doi.org/10.1039/C5TA02244D

E.M. Miner, T. Fukushima, D. Sheberla, L. Sun, Y. Surendranath et al., Electrochemical oxygen reduction catalysed by Ni3(hexaiminotriphenylene)2. Nat. Commun. 7(1), 1–7 (2016). https://doi.org/10.1038/ncomms10942

R.K. Tripathy, A.K. Samantara, J. Behera, A cobalt metal–organic framework (Co-MOF): a bi-functional electro active material for the oxygen evolution and reduction reaction. Dalton Trans. 48(28), 10557–10564 (2019). https://doi.org/10.1039/C9DT01730E

X. Wang, L. Yu, B.Y. Guan, S. Song, X.W. Lou, Metal–organic framework hybrid-assisted formation of Co3O4/Co-Fe oxide double-shelled nanoboxes for enhanced oxygen evolution. Adv. Mater. 30(29), 1801211 (2018). https://doi.org/10.1002/adma.201801211

J. Zhou, Y. Dou, A. Zhou, L. Shu, Y. Chen et al., Layered metal–organic framework-derived metal oxide/carbon nanosheet arrays for catalyzing the oxygen evolution reaction. ACS Energy Lett. 3(7), 1655–1661 (2018). https://doi.org/10.1021/acsenergylett.8b00809

J. Yang, F. Zhang, X. Wang, D. He, G. Wu et al., Porous molybdenum phosphide nano-octahedrons derived from confined phosphorization in UIO-66 for efficient hydrogen evolution. Angew. Chem. Int. Ed. 55(41), 12854–12858 (2016). https://doi.org/10.1002/anie.201604315

X. Liang, D. Zhang, Z. Wu, D. Wang, The Fe-promoted MoP catalyst with high activity for water splitting. Appl. Catal. A 524, 134–138 (2016). https://doi.org/10.1016/j.apcata.2016.06.029

L.-A. Stern, L. Feng, F. Song, X. Hu, Ni2P as a Janus catalyst for water splitting: the oxygen evolution activity of Ni2P nanoparticles. Energy Environ. Sci. 8(8), 2347–2351 (2015). https://doi.org/10.1039/C5EE01155H

E. Hu, Y. Feng, J. Nai, D. Zhao, Y. Hu et al., Construction of hierarchical Ni–Co–P hollow nanobricks with oriented nanosheets for efficient overall water splitting. Energy Environ. Sci. 11(4), 872–880 (2018). https://doi.org/10.1039/C8EE00076J

T. Liu, P. Li, N. Yao, G. Cheng, S. Chen et al., CoP-doped MOF-based electrocatalyst for pH-universal hydrogen evolution reaction. Angew. Chem. Int. Ed. 58(14), 4679–4684 (2019). https://doi.org/10.1002/ange.201901409

Z. Wang, H. **, T. Meng, K. Liao, W. Meng et al., Fe, Cu-coordinated ZIF-derived carbon framework for efficient oxygen reduction reaction and zinc-air batteries. Adv. Funct. Mater. 28(39), 1802596 (2018). https://doi.org/10.1002/adfm.201802596

S. Ren, X. Duan, F. Ge, M. Zhang, H. Zheng, Trimetal-based N-doped carbon nanotubes arrays on Ni foams as self-supported electrodes for hydrogen/oxygen evolution reactions and water splitting. J. Power Sources 480, 228866 (2020). https://doi.org/10.1016/j.jpowsour.2020.228866

L. Liao, S. Wang, J. **ao, X. Bian, Y. Zhang et al., A nanoporous molybdenum carbide nanowire as an electrocatalyst for hydrogen evolution reaction. Energy Environ. Sci. 7(1), 387–392 (2014). https://doi.org/10.1039/C3EE42441C

Y. Du, M. Zhang, Z. Wang, Y. Liu, Y. Liu et al., A self-templating method for metal–organic frameworks to construct multi-shelled bimetallic phosphide hollow microspheres as highly efficient electrocatalysts for hydrogen evolution reaction. J. Mater. Chem. A 7(14), 8602–8608 (2019). https://doi.org/10.1039/C9TA00557A

H.B. Wu, B.Y. **a, L. Yu, X.Y. Yu, X.W. Lou, Porous molybdenum carbide nano-octahedrons synthesized via confined carburization in metal-organic frameworks for efficient hydrogen production. Nat. Commun. 6(1), 6512 (2015). https://doi.org/10.1038/ncomms7512

T. Wang, Q. Zhou, X. Wang, J. Zheng, X. Li, MOF-derived surface modified Ni nanoparticles as an efficient catalyst for the hydrogen evolution reaction. J. Mater. Chem. A 3(32), 16435–16439 (2015). https://doi.org/10.1039/C5TA04001A

Y. Jiao, Y. Zheng, M. Jaroniec, S.Z. Qiao, Design of electrocatalysts for oxygen-and hydrogen-involving energy conversion reactions. Chem. Soc. Rev. 44(8), 2060–2086 (2015). https://doi.org/10.1039/C4CS00470A

B.Y. **a, Y. Yan, N. Li, H.B. Wu, X.W.D. Lou et al., A metal–organic framework-derived bifunctional oxygen electrocatalyst. Nat. Energy 1(1), 1–8 (2016). https://doi.org/10.1038/nenergy.2015.6

L. Zhang, X. Wang, R. Wang, M. Hong, Structural evolution from metal–organic framework to hybrids of nitrogen-doped porous carbon and carbon nanotubes for enhanced oxygen reduction activity. Chem. Mater. 27(22), 7610–7618 (2015). https://doi.org/10.1021/acs.chemmater.5b02708

L. Ye, G. Chai, Z. Wen, Zn-MOF-74 derived N-doped mesoporous carbon as pH-universal electrocatalyst for oxygen reduction reaction. Adv. Funct. Mater. 27(14), 1606190 (2017). https://doi.org/10.1002/adfm.201606190

Q. Lai, Y. Zhao, Y. Liang, J. He, J. Chen, In situ confinement pyrolysis transformation of ZIF-8 to nitrogen-enriched meso-microporous carbon frameworks for oxygen reduction. Adv. Funct. Mater. 26(45), 8334–8344 (2016). https://doi.org/10.1002/adfm.201603607

P.-C. Shi, J.-D. Yi, T.-T. Liu, L. Li, L.-J. Zhang et al., Hierarchically porous nitrogen-doped carbon nanotubes derived from core–shell ZnO@ zeolitic imidazolate framework nanorods for highly efficient oxygen reduction reactions. J. Mater. Chem. A 5(24), 12322–12329 (2017). https://doi.org/10.1039/C7TA02999C

L. Zhang, Z. Su, F. Jiang, L. Yang, J. Qian et al., Highly graphitized nitrogen-doped porous carbon nanopolyhedra derived from ZIF-8 nanocrystals as efficient electrocatalysts for oxygen reduction reactions. Nanoscale 6(12), 6590–6602 (2014). https://doi.org/10.1039/C4NR00348A

H. Park, S. Oh, S. Lee, S. Choi, M. Oh, Cobalt-and nitrogen-codoped porous carbon catalyst made from core–shell type hybrid metal–organic framework (ZIF-L@ ZIF-67) and its efficient oxygen reduction reaction (ORR) activity. Appl. Catal. B-Environ. 246, 322–329 (2019). https://doi.org/10.1016/j.apcatb.2019.01.083

L. Zheng, Y. Dong, B. Chi, Z. Cui, Y. Deng et al., UIO-66-NH2-derived mesoporous carbon catalyst Co-doped with Fe/N/S as highly efficient cathode catalyst for PEMFCs. Small 15(4), 1803520 (2019). https://doi.org/10.1002/smll.201803520

S. Li, Z. Jiang, X. **ao, W. Chen, X. Tian et al., MOF-derived Co nanoparticles embedded in N, S-codoped carbon layer/MWCNTs for efficient oxygen reduction in alkaline media. Ionics 25(2), 785–796 (2019). https://doi.org/10.1007/s11581-018-2775-0

L. Fan, X. Du, Y. Zhang, M. Li, M. Wen et al., N, P-Doped carbon with encapsulated Co nanoparticles as efficient electrocatalysts for oxygen reduction reactions. Dalton Trans. 48(7), 2352–2358 (2019). https://doi.org/10.1039/C8DT04650F

Z. Meng, S. Cai, R. Wang, H. Tang, S. Song et al., Bimetallic− organic framework-derived hierarchically porous Co-Zn-NC as efficient catalyst for acidic oxygen reduction reaction. Appl. Catal. B 244, 120–127 (2019). https://doi.org/10.1016/j.apcatb.2018.11.037

M. Lu, Y. Li, P. He, J. Cong, D. Chen et al., Bimetallic metal-organic framework nanosheets as efficient electrocatalysts for oxygen evolution reaction. J. Solid State Chem. 272, 32–37 (2019). https://doi.org/10.1016/j.jssc.2019.01.023

M. Ding, J. Chen, M. Jiang, X. Zhang, G. Wang, Ultrathin trimetallic metal–organic framework nanosheets for highly efficient oxygen evolution reaction. J. Mater. Chem. A 7(23), 14163–14168 (2019). https://doi.org/10.1039/c9ta00708cr

Acknowledgements

This work was supported by the National Natural Science Foundation of China (22075223, 51701146).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions