Abstract

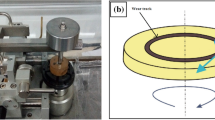

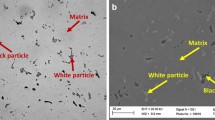

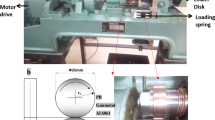

The friction and wear characteristics of aluminum bronze QAl10-4-4 bearing materials are investigated through pin–disk simulation testing under the dry sliding state at the operating conditions with rotating speed, load and temperature using the high-speed and high-temperature friction and wear testing machine (MG-2000). The quality of the pin, the friction coefficient and surface topography of the samples are monitored during the tests. The study results show that the average friction coefficient presents a similar N shape curve with the increase in rotating speed and temperature and a hook shape curve with the increase in load. The wear extent increases linearly with the increase in rotating speed, increases firstly and then decreases with the increase in load and presents a similar N shape trend with the increase in temperature. The main wear mechanisms of QAl10-4-4 bearing materials under high-temperature dry sliding conditions are discussed; the rotating speed mainly influences the friction and wear characteristics of the material by sliding heat. The loads mainly affect the friction and wear characteristics of the material through the actual contact area, and wear debris. The influence of temperature on the friction and wear characteristics of the material mainly depended on the surface layer properties.

Similar content being viewed by others

References

Taga Y, Isogai A, Nakajima K (1977) The role of alloying elements in the friction and wear of copper alloys. Wear 44(2):377–391. https://doi.org/10.1016/0043-1648(77)90152-1

Vander Heide E, Stam ED, Giraud H, Lovato et al (2006) Wear of aluminium bronze in sliding contact with lubricated stainless steel sheet material. Wear 261(1):68–73. https://doi.org/10.1016/j.wear.2005.09.023

Thapliyal S, Dwivedi DK (2017) On cavitation erosion behavior of friction stir processed surface of cast nickel aluminium bronze. Wear 376:1030–1042. https://doi.org/10.1016/j.wear.2017.01.030

Gronostajski J, Chmura W, Gronostajski Z (2002) Bearing materials obtained by recycling of aluminium and aluminium bronze chips. J Mater Proc Technol 125:483–490. https://doi.org/10.1016/S0924-0136(02)00326-6

Chmura W, Gronostajski Z (2006) Bearing composites made from aluminium and aluminium bronze chips. J Mater Proc Technol 178(1–3):188–193. https://doi.org/10.1016/j.jmatprotec.2006.03.156

Kimura T, Shimizu K, Terada K (2007) Sliding wear characteristic evaluation of copper alloy for bearing. Wear 263(1–6):586–591. https://doi.org/10.1016/j.wear.2007.02.012

Quinlan, John R ( 1976) Aluminum bronze bearing. U.S. Patent No. 3,995,917.

Li Y, Ngai TL (1996) Grain refinement and microstructural effects on mechanical and tribological behaviours of Ti and B modified aluminium bronze. J Mater Sci 31(20):5333–5338. https://doi.org/10.1007/BF01159301

Li Y, Ngai TL, **a W (1996) Mechanical, friction and wear behaviors of a novel high-strength wear-resisting aluminum bronze. Wear 197(1–2):130–136. https://doi.org/10.1016/0043-1648(95)06890-2

Prasad BK (2004) Sliding wear behaviour of bronzes under varying material composition, microstructure and test conditions. Wear 257(1–2):110–123. https://doi.org/10.1016/j.wear.2003.10.021

Türk A, Kurnaz C, Şevik H (2007) Comparison of the wear properties of modified ZA-8 alloys and conventional bearing bronze. Mater Des 28(6):1889–1897. https://doi.org/10.1016/j.matdes.2006.04.010

Alemdağ Y, Savaşkan T (2009) Mechanical and tribological properties of Al–40Zn–Cu alloys. Tribol Int 42(1):176–182. https://doi.org/10.1016/j.triboint.2008.04.008

Alam S, Sasaki S, Shimura H (2001) Friction and wear characteristics of aluminum bronze coatings on steel substrates sprayed by a low pressure plasma technique. Wear 248(1–2):75–81. https://doi.org/10.1016/S0043-1648(00)00520-2

Guo X, Zhang G, Li W et al (2009) Investigation of the microstructure and tribological behavior of cold-sprayed tin-bronze-based composite coatings. App Surf Sci 255(6):3822–3828. https://doi.org/10.1016/j.apsusc.2008.10.041

Miguel JM, Vizcaino S, Lorenzana C et al (2011) Tribological behavior of bronze composite coatings obtained by plasma thermal spraying. Tribol Lett 42(3):263–273. https://doi.org/10.1007/s11249-011-9769-7

Rahaman ML, Zhang LC, Ruan HH (2013) Understanding the friction and wear mechanisms of bulk metallic glass under contact sliding. Wear 304(1–2):43–48. https://doi.org/10.1016/j.wear.2013.04.022

Alemani M, Gialanella S, Straffelini G et al (2017) Dry sliding of a low steel friction material against cast iron at different loads: characterization of the friction layer and wear debris. Wear 376:1450–1459. https://doi.org/10.1016/j.wear.2017.01.040

Li X, Gao Y, Wei S, Yang Q (2017) Tribological behaviors of B4C-hBN ceramic composites used as pins or discs coupled with B4C ceramic under dry sliding condition. Ceram Int 43(1):1578–1583. https://doi.org/10.1016/j.ceramint.2016.10.136

Kennedy FE, Lu Y, Baker I (2015) Contact temperatures and their influence on wear during pin-on-disk tribotesting. Tribol Int 82:534–542. https://doi.org/10.1016/j.triboint.2013.10.022

Khadem M, Penkov OV, Yang HK et al (2017) Tribology of multilayer coatings for wear reduction: a review. Friction 5(3):248–262. https://doi.org/10.1007/s40544-017-0181-7

Hutchings I, Shipway P (2017) Tribology: friction and wear of engineering materials. Elsevier, London

Ajayi OO, Lorenzo-Martin C, Erck RA et al (2011) Scuffing mechanism of near-surface material during lubricated severe sliding contact. Wear 271(9–10):1750–1753. https://doi.org/10.1016/j.wear.2010.12.086

Jha P, Gautam RK, Tyagi R (2017) Friction and wear behavior of Cu–4 wt.% Ni–TiC composites under dry sliding conditions. Friction 5(4):437–446. https://doi.org/10.1007/s40544-017-0157-7

Archard J (1953) Contact and rubbing of flat surfaces. J Appl Phys 24(8):981–988. https://doi.org/10.1063/1.1721448

Reid JV, Schey JA (1987) The effect of surface hardness on friction. Wear 118(1):113–125. https://doi.org/10.1016/0043-1648(87)90008-1

Sullivan JL, Wong LF (1985) Wear of aluminium bronze on steel under conditions of boundary lubrication. Tribol Int 18(5):275–281. https://doi.org/10.1016/0301-679X(85)90106-9

Acknowledgements

The work was financially supported by Scientific and Technological Innovation Programs of Higher Education Institutions in Shanxi (No. 2019L0978) and the Key Research and Development Program of Shanxi Province of China (International Cooperation, 201803D421028, 201903D421051).

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Izabel Fernanda Machado, Dr.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, H., Li, R., Yang, F. et al. Friction and wear characteristics of aluminum bronze (QAl10-4-4) bearing materials under high-temperature dry sliding conditions. J Braz. Soc. Mech. Sci. Eng. 42, 354 (2020). https://doi.org/10.1007/s40430-020-02437-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-020-02437-9