Abstract

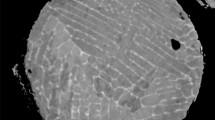

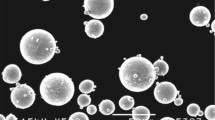

The cold spray of Ti-6Al-4V coatings deposited on Ti-6Al-4V substrates has been investigated. Coatings were produced using nitrogen and helium as propellant gases and subsequently heat treated with various temperature-time conditions. The microstructure was characterized by SEM and optical microscopy while mechanical properties were measured by microhardness and tensile testing. It is shown that coatings sprayed with nitrogen gas were relatively porous in comparison to the nearly completely dense coatings obtained with helium gas. In the as-sprayed condition, coatings displayed high hardness but low tensile strength. Heat treatments at temperatures of 600 °C and higher resulted in a decrease in hardness due to microstructural changes within the particles including recovery, recrystallization, and/or phase transformation. However, an increase in tensile strength was attributed to improved inter-particle bonding due to an observed change from brittle to ductile features on the fracture surface. The highest strength coating produced was a helium-sprayed coating annealed at 600 °C, which featured a tensile strength ~85% of the minimum required bulk value and coating/substrate microstructures similar to the as-received powder/substrate microstructures.

Similar content being viewed by others

References

R.R. Boyer, An Overview on the Use of Titanium in the Aerospace Industry, Mater. Sci. Eng., A, 1996, 213(1–2), p 103-114

R.E. Blose, B.H. Walker, R.M. Walker, and S.H. Froes, New Opportunities to Use Cold Spray Process for Applying Additive Features to Titanium Alloys, Met. Powder Rep., 2006, 61(9), p 30-37

F. Gartner, T. Stoltenhoff, J. Voyer, H. Kreye, S. Riekehr, and M. Kocak, Mechanical Properties of Cold-Sprayed and Thermally Sprayed Copper Coatings, Surf. Coat. Technol., 2006, 200(24), p 6770-6782

V.K. Champagne, The Cold Spray Deposition Process: Fundamentals and Applications, Woodhead Publishing Ltd., Cambridge, 2007

E. Irissou, J.G. Legoux, A.N. Ryabinin, B. Jodoin, and C. Moreau, Review on Cold Spray Process and Technology: Part I—Intellectual Property, J. Therm. Spray Technol., 2008, 17(4), p 495-516

R.G. Maev and V. Leshchynsky, Introduction to Low Pressure Gas Dynamic Spray: Physics & Technology, Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim, 2008

A. Papyrin, V. Kosarev, K.V. Klinkov, and V.M. Fomin, Cold Spray Technology, Elsevier Ltd., Oxford, 2006

T. Schmidt, H. Assadi, F. Gartner, H. Richter, T. Stoltenhoff, H. Kreye, and T. Klassen, From Particle Acceleration to Impact and Bonding in Cold Spraying, J. Therm. Spray Technol., 2009, 18(5–6), p 794-808

G. Bae, Y. **ong, S. Kumar, K. Kang, and C. Lee, General Aspects of Interface Bonding in Kinetic Sprayed Coatings, Acta Mater., 2008, 56(17), p 4858-4868

M. Grujicic, C.L. Zhao, W.S. De-Rosset, and D. Helfritch, Adiabatic Shear Instability Based Mechanism for Particles/Substrate Bonding in the Cold-Gas Dynamic-Spray Process, Mater. Des., 2004, 25(8), p 681-688

T. Schmidt, F. Gartner, H. Assadi, and H. Kreye, Development of a Generalized Parameter Window for Cold Spray Deposition, Acta Mater., 2006, 54(3), p 729-742

H. Assadi, F. Gartner, T. Stoltenhoff, and H. Kreye, Bonding Mechanism in Cold Gas Spraying, Acta Mater., 2003, 51(15), p 4379-4394

E. Calla, D.G. McCartney, and P.H. Shipway, Effect of Deposition Conditions on the Properties and Annealing Behavior of Cold-Sprayed Copper, J. Therm. Spray Technol., 2006, 15(2), p 255-262

A.C. Hall, D.J. Cook, R.A. Neiser, T.J. Roemer, and D.A. Hirschfeld, The Effect of a Simple Annealing Heat Treatment on the Mechanical Properties of Cold-Sprayed Aluminum, J. Therm. Spray Technol., 2006, 15(2), p 233-238

S.H. Zahiri, D. Fraser, and M. Jahedi, Recrystallization of Cold Spray-Fabricated Cp Titanium Structures, J. Therm. Spray Technol., 2009, 18(1), p 16-22

W. Wong, E. Irissou, A. Ryabinin, J.-G. Legoux, and S. Yue, Influence of Helium and Nitrogen Gases on the Properties of Cold Gas Dynamic Sprayed Pure Titanium Coatings, J. Therm. Spray Technol., 2011, 20(1), p 213-226

R. Blose, Spray Forming Titanium Alloys Using the Cold Spray Process, Thermal Spray 2005: Thermal Spray Connects: Explore Its Surfacing Potential!, E. Lugscheider Ed., ASM International, Materials Park, OH, 2005, p 199-207

J. Karthikeyan, C.M. Kay, J. Lindeman, R.S. Lima, and C. Berndt, Cold Spray Processing of Titanium Powder, Thermal Spray: Surface Engineering via Applied Research, C. Berndt Ed., 2000, p 255-262

W.Y. Li, C. Zhang, X. Guo, J. Xu, C.J. Li, H. Liao, C. Coddet, and K.A. Khor, Ti and Ti-6Al-4V Coatings by Cold Spraying and Microstructure Modification by Heat Treatment, Adv. Eng. Mater., 2007, 9(5), p 418-423

T. Marrocco, D.G. McCartney, P.H. Shipway, and A.J. Sturgeon, Production of Titanium Deposits by Cold-Gas Dynamic Spray: Numerical Modeling and Experimental Characterization, J. Therm. Spray Technol., 2006, 15(2), p 263-272

W. Wong, E. Irissou, J.G. Legoux, P. Vo, and S. Yue, Powder Processing and Coating Heat Treatment on Cold Sprayed Ti-6Al-4V Alloy, Mater. Sci. Forum, 2012, 706–709, p 258-263

S. Costil, E. Irissou, Y. Danlos Belfort, J. Legoux, W. Wong, and S. Yue, The Protal Process Applied on Cold Spraying to Improve Interface Adherence and Coating Cohesion—Case of Titanium and Nickel Based Alloys, Thermal Spray 2010: Global Solutions for Future Applications, B. Marple, A. Agarwal, M. Hyland, Y.C. Lau, C.J. Li, R.S. Lima, and G. Montavon, Ed., Springer, 2010, p 836-841

D. Goldbaum, J. Shockley, R. Chromik, A. Rezaeian, S. Yue, J.-G. Legoux, and E. Irissou, The Effect of Deposition Conditions on Adhesion Strength of Ti and Ti6Al4V Cold Spray Splats, J. Therm. Spray Technol., 2012, 21(2), p 288-303

A. Rezaeian, W. Wong, S. Yue, E. Irissou, and J.G. Legoux, Effect of Gun Traverse Speed on Microstructure and Bond Strength of Cold Sprayed Ti6Al4V and Ti Coatings, Materials Science and Technology (MS&T) 2009, ASM International, Materials Park, OH, 2009, p 2268-2278

J. Legoux, E. Irissou, S. Desaulniers, J. Bobyn, B. Harvey, W. Wong, E. Gagnon, and S. Yue, Characterization and Performance Evaluation of a Helium Recovery System Designed for Cold Spraying, Thermal Spray 2010: Global Solutions for Future Applications, B. Marple, A. Agarwal, M. Hyland, Y.C. Lau, C.J. Li, R.S. Lima, and G. Montavon, Ed., Springer, 2010

S.L. Semiatin, F. Montheillet, G. Shen, and J.J. Jonas, Self-Consistent Modeling of the Flow Behavior of Wrought Alpha/Beta Titanium Alloys under Isothermal and Nonisothermal Hot-Working Conditions, Metall. Mater. Trans., 2002, 33A(8), p 2719-2727

K. Farrell, T.S. Byun, J.W. Jones, L.T. Gibson, R.G. Sitterson, N. Hashimoto, J.L. Bailey, and M.J. Gardner, Small Specimen Procedures for Determination of Deformation Maps, Small Specimen Test Techniques: Fourth Volume, M.A. Sokolov, J.D. Landes and G.E. Lucas, Ed., ASTM International, West Conshohocken, PA, 2002

“Standard Test Methods for Tension Testing of Metallic Materials,” ASTM E8/E8M-09, ASTM International, p 1-27

M.K. Decker, R.A. Neiser, D. Gilmore, and H.D. Tran, Microstructure and Properties of Cold Spray Nickel, Thermal Spray 2001: New Surfaces for a New Millenium, C.C. Berndt, K.A. Khor and E.F. Laguscheider, Ed., ASM International, 2001, p 433-439

“Standard Specification for Titanium and Titanium Alloy Forgings,” ASTM B381-03, ASTM International, p 1-7

M.J. Donachie, Titanium: A Technical Guide, 2nd ed., ASM International, Materials Park, OH, 2000

H. Carreon and A. Medina, Nondestructive Characterization of the Level of Plastic Deformation by Thermoelectric Power Measurements in Cold-Rolled Ti-6Al-4V Samples, Nondestruct. Test. Eval., 2007, 22, p 299-311

N. Gey, M. Humbert, and H. Moustahfid, Study of the α-β Phase Transformation of a Ti-6Al-4V Sheet by Means of Texture Change, Scripta Mater., 2000, 42, p 525-530

W.Y. Li, C.J. Li, and H.L. Liao, Effect of Annealing Treatment on the Microstructure and Properties of Cold-Sprayed Cu Coating, J. Therm. Spray Technol., 2006, 15(2), p 206-211

B. Derby and E.R. Wallach, Theoretical Model for Diffusion Bonding, Met. Sci., 1982, 16, p 49-56

B. Derby and E.R. Wallach, Diffusion Bonding: Development of Theoretical Model, Met. Sci., 1984, 18, p 427-431

R.C. Dykhuizen, M.F. Smith, D.L. Gilmore, R.A. Neiser, X. Jiang, and S. Sampath, Impact of High Velocity Cold Spray Particles, J. Therm. Spray Technol., 1999, 8(4), p 559-564

S. Guetta, M.H. Berger, F. Borit, V. Guipont, M. Jeandin, M. Boustie, Y. Ichikawa, K. Sakaguchi, and K. Ogawa, Influence of Particle Velocity on Adhesion of Cold-Sprayed Splats, J. Therm. Spray Technol., 2009, 18(3), p 331-342

E. Klar, Powder Metallurgy, Metals Handbook—Desk Edition, 2nd ed., J.R. Davies, Ed., ASM International, Materials Park, OH, 1998, p 876-891

H.M. Flower, Microstructural Development in Relation to Hot Working of Titanium Alloys, Mater. Sci. Technol., 1990, 6, p 1082-1092

J. Park, M.W. Toaz, D.H. Ro, and E.N. Aqua, Blended Elemental Powder Metallurgy of Titanium Alloys, Titanium Net Shape Technologies, F.H. Froes and D. Eylon, Ed., The Metallurgical Society of AIME, Warrendale, PA, 1984, p 95-105

P.J. Anderson, V.M. Svoyatytsky, F.H. Froes, Y. Mahajan, and D. Eylon, Fracture Behavior of Blended Elemental P/M Titanium Alloys, 1980 International Powder Metallurgy Conference, H.W. Antes, G.D. Smith, and H.H. Hausner, Ed., American Powder Metallurgy Institute, Princeton, NJ, 1981, p 537-549

F.A. Calvo, J.M. Gomez de Salazar, A. Urena, J.G. Carrion, and F. Perosanz, Diffusion Bonding of Ti-6Al-4V Alloy at Low Temperature: Metallurgical Aspects, J. Mater. Sci., 1992, 27, p 391-398

F. Dyment, Self and Solute Diffusion in Titanium and Titanium Alloys, Titanium ‘80: Science and Technology, H. Kimura and O. Izuma, Ed., Metallurgical Society of AIME, Warrendale, PA, 1980, p 519-528

Acknowledgments

The author would like to acknowledge the contributions of B. Harvey and J.-F. Alarie of the National Research Council Canada, A. Rezaiean of McGill University, and J. Larose of Pratt & Whitney Canada. This project was funded by CFI project number 8246, McGill University.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Vo, P., Irissou, E., Legoux, JG. et al. Mechanical and Microstructural Characterization of Cold-Sprayed Ti-6Al-4V After Heat Treatment. J Therm Spray Tech 22, 954–964 (2013). https://doi.org/10.1007/s11666-013-9945-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-013-9945-4