Abstract

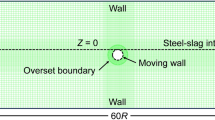

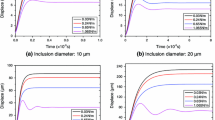

The separation of inclusions at the steel–slag interface is one of the crucial steps in the removal of inclusions. Thus, it is important to study the motion behavior of inclusions at the steel–slag interface to improve the cleanliness of molten steel. In this paper, irregular inclusion clusters with various morphology were fabricated by three-dimensional printing technology. The molten steel and slag were, respectively, simulated with water and silicone oil, according to the similarity principle, and the physical simulation model of inclusions movement at the steel–slag interface was established. The calculation program for calculating the force and moment of inclusion clusters was developed by ourselves based on the user-defined function in FLUENT, and the three-dimensional dynamic numerical simulation of inclusion clusters was carried out by combining dynamic mesh and overset mesh technology. The motion behavior and movement phenomenon of inclusion clusters at the interface is analyzed. The results show that the inclusion cluster produces the liquid film, flips and slips when separating at the interface. The factors influencing the separation of inclusion clusters at the interface are clarified, which indicates that the fractal dimension and the diameter together govern the motion behavior of the inclusion cluster at the interface.

Similar content being viewed by others

References

B.A. Webler and P.C. Pistorius: Metall. Mater. Trans. B, 2020, vol. 51B, pp. 2437–52.

Y. Ren, Y. Wang, S. Li, L. Zhang, X. Zuo, S.N. Lekakh, and K. Peaslee: Metall. Mater. Trans. B, 2014, vol. 45B, pp. 1291–1303.

L. Zhang and B.G. Thomas: XXIV National Steelmaking Symposium, The Morelia Institute of Technology, Morelia, 2003, p. 138.

M. Söder: Growth and Removal of Inclusions During Ladle Stirring, PhD thesis (in Sweden), KTH, 2001.

P. Väyrynen, S. Wang, S. Louhenkilpi, and L. Holappa: in Proceedings of the Materials Science and Technology, Pittsburgh, 2009, pp. 25–29.

U. Zerbst, M. Madia, C. Klinger, D. Bettge, and Y. Murakami: Eng. Fail. Anal., 2019, vol. 98, pp. 228–39.

Y. Payandeh and M. Soltanieh: J. Iron Steel Res. Int., 2007, vol. 14, pp. 39–46.

J. Campbell: The Mechanisms of Metallurgical Failure: On the Origin of Fracture, Butterworth-Heinemann, Birmingham, 2020.

A.L.V. da Costa e Silva: J. Mater. Res. Technol., 2018, vol. 7, pp. 283–99.

S.H. Lee, C. Tse, K.W. Yi, P. Misra, V. Chevrier, C. Orrling, S. Sridhar, and A.W. Cramb: J. Non-Cryst. Solids, 2001, vol. 282, pp. 41–48.

W. Yang, H. Duan, L. Zhang, and Y. Ren: JOM, 2013, vol. 65, pp. 1173–80.

M. Suzuki, R. Yamaguchi, K. Murakami, and M. Nakada: ISIJ Int., 2001, vol. 41, pp. 247–56.

M. Cournil, F. Gruy, P. Gardin, and H. Saint-Raymond: Status Solidi A, 2002, vol. 189, pp. 159–68.

J. Wang, L. Zhang, Y. Zhang, Q. Ren, and H. Duan: Metall. Mater. Trans. B, 2021, vol. 52B, pp. 2831–36.

Q. Tian, G. Wang, D. Shang, H. Lei, X. Yuan, Q. Wang, and J. Li: Metall. Mater. Trans. B, 2018, vol. 49B, pp. 3137–50.

C. Xuan, A.V. Karasev, and P.G. Jönsson: ISIJ Int., 2016, vol. 56, pp. 1204–09.

B.H. Reis, W.V. Bielefeldt, and A.C.F. Vilela: J. Mater. Res. Technol., 2014, vol. 3, pp. 179–85.

D. You, C. Bernhard, A. Mayerhofer, and S.K. Michelic: ISIJ Int., 2021, vol. 61, pp. 2991–97.

B.H. Reis, W.V. Bielefeldt, and A.C.F. Vilela: ISIJ Int., 2014, vol. 54, pp. 1584–91.

K. Nakajima and K. Okamura: in Proceedings of 4th International Conference on Molten Slags and Fluxes, ISIJ, Tokyo, 1992, p. 505.

J. Strandh, K. Nakajima, R. Eriksson, and P. Jönsson: ISIJ Int., 2005, vol. 45, pp. 1597–1606.

J. Strandh, K. Nakajima, R. Eriksson, and P. Jönsson: ISIJ Int., 2005, vol. 45, pp. 1838–47.

M. Valdez, G.S. Shannon, and S. Sridhar: ISIJ Int., 2006, vol. 46, pp. 450–57.

A.B. Fox, M.E. Valdez, J. Gisby, R.C. Atwood, P.D. Lee, and S. Sridhar: ISIJ Int., 2004, vol. 44, pp. 836–45.

C. Liu, S. Yang, J. Li, L. Zhu, and X. Li: Metall. Mater. Trans. B, 2016, vol. 47B, pp. 1882–92.

S. Yang, J. Li, C. Liu, L. Sun, and H. Yang: Metall. Mater. Trans. B, 2014, vol. 45B, pp. 2453–63.

S. Yang, W. Liu, and J. Li: JOM, 2015, vol. 67, pp. 2993–3001.

W. Liu, J. Liu, H. Zhao, S. Yang, and J. Li: Metall. Mater. Trans. B, 2021, vol. 52B, pp. 2430–40.

ANSYS 21.0 help: ANSYS Inc., Pittsburgh, 2020.

L. Gmachowski: Colloids Surf. Physicochem. Eng. Asp., 2000, vol. 170, pp. 209–16.

H. Yang: Study on the movement behavior of inclusions through the steel slag interface, PhD thesis (in Bei**g), USTB, 2014.

S. Neumann, A. Asad, and R. Schwarze: Adv. Eng. Mater., 2020, vol. 22, p. 1900658.

Y. Yin, J. Zhang, S. Lei, and Z. Wang: High Temp. Mater. Process., 2018, vol. 37, pp. 375–86.

R.J. Good and L.A. Girifalco: J. Phys. Chem., 1960, vol. 64, pp. 561–65.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (No. 51704052) and the Venture & Innovation Support Program for Chongqing Overseas Returnees (cx2019026). In addition, we would also like to thank the assistance of the Financial Support from the Tangshan Science and Technology Bureau for the Fundamental Innovation Team of High-Quality Clean Steel in Tangshan (21130209D) and Hebei Financial Support Project for the Introduced Overseas Student (C20210309).

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhu, Y., Cui, H., Li, T. et al. Study on the Motion Behavior of Inclusion Clusters at the Steel–Slag Interface. Metall Mater Trans B 54, 101–114 (2023). https://doi.org/10.1007/s11663-022-02673-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-022-02673-5