Abstract

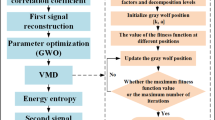

Chatter is a kind of self-excited vibration, which always has a negative impact on production efficiency. In this paper, a novel online chatter detection method for milling processes is proposed. In this method, firstly, the spindle revolution period component is extracted by angular synchronous averaging (ASA) the vibration signals generated in different cutting conditions. Then, the residual part related to chatter is calculated by subtracting the periodic component. Subsequently, the filtered signal is decomposed into a set of intrinsic mode functions (IMFs) using variational mode decomposition (VMD) to obtain chatter information. Finally, the multiscale permutation entropy (MPE) and multiscale power spectral entropy (MPSE) of the selected IMFs are calculated, and Laplacian score (LS) for feature selection is applied to select the optimal sensitive scale features with generalization. Online chatter detection based on selected sensitive scale features by splitting signal up into overlap** frames in milling process. The analysis results show that the proposed method can effectively detect the chatter under stable cutting conditions and variable cutting conditions.

Similar content being viewed by others

References

Quintana G, Ciurana J (2011) Chatter in machining processes: A review. Int J Mach Tools Manuf 51(5):363–376

Altintas Y, Weck M (2004) Chatter stability of metal cutting and grinding. CIRP Ann Manuf Technol 53(2):619–642

Altintaş Y, Budak E (1995) Analytical prediction of stability lobes in milling. CIRP Ann-Manuf Technol 44(1):357–362

Tlusty J, Zaton W, Ismail F (1983) Stability lobes in milling. CIRP Ann- Manuf Technol 32(1):309–313

Bayly PV, Halley JE, Mann BP, Davies MA (2003) Stability of interrupted cutting by temporal finite element analysis. J Manuf Sci Eng 125(2):220–225

Yang K, Wang G, Dong Y, Zhang Q, Sang L (2019) Early chatter identification based on an optimized variational mode decomposition. Mech Syst Signal Process 115:238–254

Lamraoui M, Thomas M, El Badaoui M (2014) Cyclostationarity approach for monitoring chatter and tool wear in high speed milling. Mech Syst Signal Process 44(1-2):177–198

Cao H, Zhou K, Chen X (2015) Chatter identification in end milling process based on EEMD and nonlinear dimensionless indicators. Int J Mach Tools Manuf 92:52–59

Shao Y, Deng X, Yuan Y, Mechefske CK, Chen Z (2014) Characteristic recognition of chatter mark vibration in a rolling mill based on the non-dimensional parameters of the vibration signal. J Mech Sci Technol 28(6):2075–2080

Zhang Z, Li H, Meng G, Tu X, Cheng C (2016) Chatter detection in milling process based on the energy entropy of VMD and WPD. Int J Mach Tools Manuf 108:106–112

Liu C, Zhu L, Ni C (2018) Chatter detection in milling process based on VMD and energy entropy. Mech Syst Signal Process 105:169–182

Huang P, Li J, Sun J, Zhou J (2013) Vibration analysis in milling titanium alloy based on signal processing of cutting force. Int J Adv Manuf Technol 64(5-8):613–621

Soliman E, Ismail F (1997) Chatter detection by monitoring spindle drive current. Int J Adv Manuf Technol 13(1):27–34

Liu Y, Wang X, Lin J, Zhao W (2016) Early chatter detection in gear grinding process using servo feed motor current. Int J Adv Manuf Technol 83(9-12):1801–1810

Aslan D, Altintas Y (2018) On-line chatter detection in milling using drive motor current commands extracted from CNC. Int J Mach Tools Manuf 132:64–80

Nair U, Krishna BM, Namboothiri VNN, Nampoori VPN (2010) Permutation entropy based real-time chatter detection using audio signal in turning process. Int J Adv Manuf Technol 46(1-4):61–68

Cao H, Yue Y, Chen X, Zhang X (2017) Chatter detection in milling process based on synchrosqueezing transform of sound signals. Int J Adv Manuf Technol 89(9-12):2747–2755

Kang J, Feng C, Hu H, Shao Q (2007) Research on chatter prediction and monitor based on DHMM pattern recognition theory. In 2007 IEEE International Conference on Automation and Logistics (pp. 1368-1372). IEEE

Tangjitsitcharoen S (2009) In-process monitoring and detection of chip formation and chatter for CNC turning. J Mater Process Technol 209(10):4682–4688

Choi T, Shin YC (2003) On-line chatter detection using wavelet-based parameter estimation. J Manuf Sci Eng 125(1):21–28

Wang L, Liang M (2009) Chatter detection based on probability distribution of wavelet modulus maxima. Robot Comput-Integr Manuf 25(6):989–998

Cao H, Lei Y, He Z (2013) Chatter identification in end milling process using wavelet packets and Hilbert–Huang transform. Int J Adv Manuf Technol 69:11–19

Li X, Yao ZH, Chen ZC (2010) An Effective EMD-Based Feature Extraction Method for Boring Chatter Recognition. In Applied Mechanics and Materials (Vol. 34, pp. 1058–1063). Trans Tech Publications

Ji Y, Wang X, Liu Z, Yan Z, Jiao L, Wang D, Wang J (2017) EEMD-based online milling chatter detection by fractal dimension and power spectral entropy. Int J Adv Manuf Technol 92(1-4):1185–1200

Dragomiretskiy K, Zosso D (2014) Variational mode decomposition. IEEE Trans Signal Process 62(3):531–544

W Aziz, M Arif. (2005). Multiscale permutation entropy of physiological time series. In 2005 Pakistan Section Multitopic Conference (pp. 1–6). IEEE

Ouyang G, Dang C, Li X (2011) Complexity analysis of EEG data with multiscale permutation entropy. In Advances in Cognitive Neurodynamics (II) (pp. 741–745). Springer, Dordrecht

Abarbanel HDI, Kennel MB (1993) Local false nearest neighbors and dynamical dimensions from observed chaotic data. Phys Rev E 47(5):3057

Finn JT (1993) Use of the average mutual information index in evaluating classification error and consistency. Int J Geogr Inf Sci 7(4):349–366

He X, Cai D, Niyogi P (2006) Laplacian score for feature selection. In Advances in neural information processing systems (pp. 507–514)

Zheng J, Pan H, Yang S, Cheng J (2018) Generalized composite multiscale permutation entropy and Laplacian score based rolling bearing fault diagnosis. Mech Syst Signal Process 99:229–243

Funding

The research is supported by the National Natural Science Foundation of China under Grant nos. 51875224 and 51705174, and Major special projects in Jiangsu Province of China under Grant nos. SBE2017020146.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, K., He, S., Luo, B. et al. Online chatter detection in milling process based on VMD and multiscale entropy. Int J Adv Manuf Technol 105, 5009–5022 (2019). https://doi.org/10.1007/s00170-019-04478-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-04478-4