Abstract

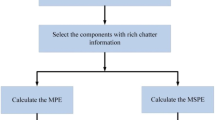

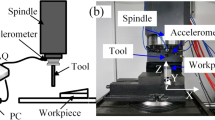

In metal cutting processing, especially in the processing of low-rigidity workpieces, chatter is a crucial factor affecting many aspects such as surface quality, processing efficiency, and tool life. In this paper, a novel online chatter detection method for milling processes is proposed. In this method, firstly, periodic signal and noise parts are filtered by a comb filter and empirical mode decomposition (EMD), respectively. Then, signal reconstruction is performed on the intrinsic mode functions (IMFs) based on the Pearson correlation coefficient. GWO is applied to reconstruct the signal to obtain optimized parameters. Subsequently, the reconstructed signal is decomposed by VMD with the optimal parameters. To obtain rich chatter information frequency bands, the energy entropy characteristics of each order IMF are calculated, and the two-order IMFs with larger energy entropy are selected for reconstruction. Finally, the multi-scale permutation entropy (MPE) and multi-scale fuzzy entropy (MFE) of the reconstructed signal are calculated. According to the value range of entropy in each processing state, the optimal scale feature is selected. The analysis results show that the proposed method can effectively detect the milling processing state based on the optimal scale.

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Dai Y, Li H, **ng X, Hao B (2018) Prediction of chatter stability for milling process using precise integration method. J Precision Engineering 52:152–157

Altintaş Y, Budak E (1995) Analytical prediction of stability lobes in milling. J CIRP Annals. 44:357–362

Wu Y, You Y, Liu A, Deng B, Liu W (2019) An implicit exponentially fitted method for chatter stability prediction of milling processes. J Int J AdvManuf Technol 106:2189–2204

Caliskan H, Kilic ZM, Altintas Y (2018) On-line energy-based milling chatter detection. J Manuf Sci Eng 140:111012

Wang Y, Zhang M, Tang X, Peng F, Yan R (2021) A kMap optimized VMD-SVM model for milling chatter detection with an industrial robot. J Intell Manuf 33(5):1483–1502

Zhu L, Liu C, Ju C, Guo M (2020) Vibration recognition for peripheral milling thin-walled workpieces using sample entropy and energy entropy. J Int J Adv Manuf Technol 108:3251–3266

Liu C, Zhu L, Ni C (2018) Chatter detection in milling process based on VMD and energy entropy. J Mech Syst Signal Process 105:169–182

Cao H, Yue Y, Chen X, Zhang X (2017) Chatter detection in milling process based on synchrosqueezing transform of sound signals. Int J Adv Manuf Technol 89:2747–2755

Liu Y, Wang X, Lin J, Zhao W (2016) Early chatter detection in gear grinding process using servo feed motor current. Int J Adv Manuf Technol 83:1801–1810

Aslan D, Altintas Y (2018) On-line chatter detection in milling using drive motor current commands extracted from CNC. Int J Mach Tools Manuf 132:64–80

Fu Y, Zhang Y, Zhou H, Li D, Liu H, Qiao H, Wang X (2016) Timely online chatter detection in end milling process. J Mech Syst Signal Process 75:668–688

Gao J, Song Q, Liu Z (2018) Chatter detection and stability region acquisition in thin-walled workpiece milling based on CMWT. J Int J Adv Manuf Technol 98(1):699–713

Tlusty J (1983) A critical review of sensors for unmanned machining. JCIRP Annals - Manuf Technol 32:563–572

Liu C, Gao X, Chi D, He Y, Liang M, Wang H (2021) On-line chatter detection in milling using fast kurtogram and frequency band power. J Eur J Mech-A/Solids 90:104341

Ye J, Feng P, Xu C, Ma Y, Huang S (2018) A novel approach for chatter online monitoring using coefficient of variation in machining process. J Int J Adv Manuf Technol 96:287–297

Rumusanu F, Constantin GR, Marinescu IC, Marinescu V, Epureanu A (2013) Development of a stability intelligent control system for turning. J Int J Adv Manuf Technol 64:643–657

Tangjitsitcharoen S (2009) In-process monitoring and detection of chip formation and chatter for CNC turning. J Mater Process Technol 209:4682–4688

Liu C, Zhu L, Ni C (2017) The chatter identification in end milling based on combining EMD and WPD. J Int J Adv Manuf Technol 91:3339–3348

Ji Y, Wang X, Liu Z, Yan Z, Jiao L, Wang D, Wang J (2017) EEMD-based online milling chatter detection by fractal dimension and power spectral entropy. J Int J Adv Manuf Technol 92:1185–1200

Zhu L, Liu C, Ju C, Guo M (2020) Vibration recognition for peripheral milling thin-walled workpieces using sample entropy and energy entropy. J Int J Adv Manuf Technol 108:3521–3266

Cao H, Lei Y, He Z (2013) Chatter identification in end milling process using wavelet packets and Hilbert-Huang transform. Int J Mach Tools Manuf 69:11–19

Zhang Q, Tu X, Li F, Hu Y (2019) An effective chatter detection method in milling process using morphological empirical wavelet transform. IEEE Trans Instrum Measure 69:5546–5555

Li K, He S, Luo B, Li B, Liu H, Mao X (2019) Online chatter detection in milling process based on VMD and multiscale entropy. J Int J Adv Manuf Technol 105:5009–5022

Li X, Wan S, Huang X, Hong J (2020) Milling chatter detection based on VMD and difference of power spectral entropy. J Int J Adv Manuf Technol 111:2051–2063

Yang K, Wang G, Dong Y, Zhang Q, Sang L (2019) Early chatter identification based on an optimized variational mode decomposition. J Mech Syst Signal Process 115:238–254

Zhang Z, Liu C, Liu X, Zhang J (2018) Analysis of milling vibration state based on the energy entropy of WPD. J Mech Eng 54:57–62

Wang R, Song Q, Liu Z, Ma H, Gupta MK, Liu Z (2021) A novel unsupervised machine learning-based method for chatter detection in the milling of thin-walled parts. J Sensors 21:5779

Liu X, Wang Z, Li M, Yue C, Liang SY, Wang L (2021) Feature extraction of milling chatter based on optimized variational mode decomposition and multi-scale permutation entropy. J Int J Adv Manuf Technol 114:2849–2862

Zhou H, Li D, Zhang Y, Liu H, Fu Y (2016) Timely online chatter detection in end milling process. Mech Syst Signal Process 75:668–688

Dragomiretskiy K, Zosso D (2014) Variational mode decomposition. IEEE Trans Signal Process 62:531–544

Sm A, Smm B, Al A (2014) Grey wolf optimizer. J Adv Eng Software 69:46–61

Ouyang G, Dang C, Li X (2011) Complexity analysis of EEG data with multiscale permutation entropy[M]//advances in cognitive neurodynamics (II). Springer, Dordrecht, pp 741–745

Chen D, Zhang X, Zhao H, Ding H (2021) Development of a novel online chatter monitoring system for flexible milling process. J Mech Syst Signal Process 159:107799

Yao Z, Mei D, Chen Z (2010) On-line chatter detection and identification based on wavelet and support vector machine. J Mater Process Tech 210:713–719

Funding

This work was supported by the Startup Research Fund of Liaoning Petrochemical University(2021XJJL-005).

Author information

Authors and Affiliations

Contributions

Bo Liu and Changfu Liu conceived the idea. Daohai Wang and Yang Zhou performed all the experiments. Bo Liu drafted the manuscript, and Bo Liu, Changfu Liu, Daohai Wang, and Yang Zhou interpreted, discussed, and edited the manuscript. Bo Liu finalized the manuscript, including preparing the detailed response letter. Changfu Liu supervised the work.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

This manuscript is approved by all authors for publication. I would like to declare on behalf of my co-authors that the work described was raw research that has not been published previously, and not under consideration for publication elsewhere, in whole or in part.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, B., Liu, C., Zhou, Y. et al. A chatter detection method in milling based on gray wolf optimization VMD and multi-entropy features. Int J Adv Manuf Technol 125, 831–854 (2023). https://doi.org/10.1007/s00170-022-10672-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-10672-8