Abstract

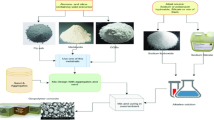

Safety concerns in handling alkali solutions for traditional geopolymers have prompted the development of one-part geopolymer in which solid activators replace activating solution. The characteristics of one-part geopolymer are influenced by the types of material used. Waste materials such as fly ash, blast furnace slag, rice husk ash, red mud, geothermal silica, and albite were employed in one-part geopolymer studies. Solid activators namely sodium hydroxide, sodium silicate, sodium carbonate, sodium oxide, sodium aluminate, calcium hydroxide, potassium carbonate and so on were used to produce dry binders that can initiate geopolymerization when water is added. This chapter clarifies the characteristics of fresh and hardened one-part geopolymer based on materials, water content, additives and thermal treatment involved. The reaction of fabricated one-part geopolymers towards different extreme environments was also explained thoroughly in this chapter.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Bakharev T (2005) Resistance of geopolymer materials to acid attack. Cem Concr Res 35(4):658–670. https://doi.org/10.1016/j.cemconres.2004.06.005

Luukkonen T, Abdollahnejad Z, Yliniemi J, Kinnunen P, Illikainen M (2018) One-part alkali-activated materials: a review. Cem Concr Res 103:21–34. https://doi.org/10.1016/j.cemconres.2017.10.001

Okoye FN, Prakash S, Singh NB (2017) Durability of fly ash based geopolymer concrete in the presence of silica fume. J Clean Prod 149:1062–1067. https://doi.org/10.1016/j.jclepro.2017.02.176

Zhuang XY, Chen L, Komarneni S, Zhou CH, Tong DS, Yang HM, Yu WH, Wang H (2016) Fly ash-based geopolymer: clean production, properties and applications. J Clean Prod 125:253–267. https://doi.org/10.1016/j.jclepro.2016.03.019

Mclellan B, Williams R, Lay J, van Riessen A, Corder G (2011) Costs and carbon emissions for geopolymer pastes in comparison to ordinary Portland cement. J Clean Prod 19:1080–1090. https://doi.org/10.1016/j.jclepro.2011.02.010

Davidovits J (2008) Geopolymer chemistry and applications. Geopolymer Institute, France

Duxson P, Fernández-Jiménez A, Provis J, Lukey G, Palomo A, Van Deventer J (2007) Geopolymer technology: the current state of the art. J Mater Sci 42:2917–2933. https://doi.org/10.1007/s10853-006-0637-z

Hajimohammadi A, Provis J, Van Deventer J (2008) One-part geopolymer mixes from geothermal silica and sodium aluminate. Ind Eng Chem Res 47(23):9396–9405. https://doi.org/10.1021/ie8006825

Yang KH, Song JK, Ashour AF, Lee ET (2008) Properties of cementless mortars activated by sodium silicate. Constr Build Mater 22(9):1981–1989. https://doi.org/10.1016/j.conbuildmat.2007.07.003

Yang KH, Song J (2009) Workability loss and compressive strength development of cementless mortars activated by combination of sodium silicate and sodium hydroxide. J Mater Civ Eng 21(3):119–127. https://doi.org/10.1061/(ASCE)0899-1561(2009)21:3(119)

Yang KH, Song J, Lee JS (2010) Properties of alkali-activated mortar and concrete using lightweight aggregates. Mater Struct Constr 43(3):403–416. https://doi.org/10.1617/s11527-009-9499-6

Hajimohammadi A, Provis J, Van Deventer J (2010) Effect of alumina release rate on the mechanism of geopolymer gel formation. Chem Mater Chem Mater 22(18):5199–5208. https://doi.org/10.1021/cm101151n

Feng D, Provis J, Deventer J, Scherer G (2012) Thermal activation of albite for the synthesis of one‐part mix geopolymers. J Am Ceram Soc 95. https://doi.org/10.1111/j.1551-2916.2011.04925.x

Sturm P, Greiser S, Gluth G, Jaeger C, Brouwers HJH (2015) Degree of reaction and phase content of silica-based one-part geopolymers investigated using chemical and NMR spectroscopic methods. J Mater Sci 50(20):6768–6778. https://doi.org/10.1007/s10853-015-9232-5

Kovtun M, Kearsley E, Shekhovtsova J (2015) Chemical acceleration of a neutral granulated blast-furnace slag activated by sodium carbonate. Cem Conc Res 72:1–9. https://doi.org/10.1016/j.cemconres.2015.02.014

Nematollahi B, Sanjayan J, Shaikh FUA (2015) Synthesis of heat and ambient cured one-part geopolymer mixes with different grades of sodium silicate. Ceram Int 41(4):5696–5704. https://doi.org/10.1016/j.ceramint.2014.12.154

Ke X, Bernal S, Ye N, Provis J, Yang J (2015) One-part geopolymers based on thermally treated red mud/NaOH blends. J Am Ceram Soc 98(1):5–11. https://doi.org/10.1111/jace.13231

Ye N, Yang J, Liang S, Hu Y, Hu J, **ao B, Huang Q (2016) Synthesis and strength optimization of one-part geopolymer based on red mud. Constr Build Mater 111:317–325. https://doi.org/10.1016/j.conbuildmat.2016.02.099

Sturm P, Gluth GJG, Simon S, Brouwers HJH, Kühne HC (2016) The effect of heat treatment on the mechanical and structural properties of one-part geopolymer-zeolite composites. Thermochim Acta 635:41–58. https://doi.org/10.1016/j.tca.2016.04.015

Nematollahi B, Sanjayan J (2016) Ambient temperature cured one-part engineered geopolymer composite: a sustainable alternative to engineered cementitious composite. In: Paper presented at the 9th Rilem International Symposium on Fiber Reinforced Concrete (BEFIB 2016), Vancouver Canada

Choo H, Lim S, Lee W, Lee C (2016) Compressive strength of one-part alkali activated fly ash using red mud as alkali supplier. Constr Build Mater 125:21–28. https://doi.org/10.1016/j.conbuildmat.2016.08.015

Wang K, Du L, Lv X, He Y, Cui X (2017) Preparation of drying powder inorganic polymer cement based on alkali-activated slag technology. Powder Technol 312:204–209. https://doi.org/10.1016/j.powtec.2017.02.036

Hajimohammadi A, van Deventer J (2017) Characterization of one-part geopolymer binders made from fly ash. Waste Biomass Valor 8(1):225–233. https://doi.org/10.1007/s12649-016-9582-5

Hajimohammadi A, Van Deventer J (2017) Solid reactant-based geopolymers from rice hull ash and sodium aluminate. Waste Biomass Valor 8(6):2131–2140. https://doi.org/10.1007/s12649-016-9735-6

Nematollahi B, Sanjayan J, Qiu J, Yang EH (2017) High ductile behavior of a polyethylene fiber-reinforced one-part geopolymer composite: a micromechanics-based investigation. Arch Civ Mech Eng 17(3):555–563. https://doi.org/10.1016/j.acme.2016.12.005

Nematollahi B, Sanjayan J, Qiu J, Yang EH (2017) Micromechanics-based investigation of a sustainable ambient temperature cured one-part strain hardening geopolymer composite. Constr Build Mater 131:552–563. https://doi.org/10.1016/j.conbuildmat.2016.11.117

Ma C, Long G, Shi Y, **e Y (2018) Preparation of cleaner one-part geopolymer by investigating different types of commercial sodium metasilicate in China. J Clean Prod 201:636–647. https://doi.org/10.1016/j.jclepro.2018.08.060

Hajimohammadi A, Ngo T, Kashani A (2018) Sustainable one-part geopolymer foams with glass fines versus sand as aggregates. Constr Build Mater 171:223–231. https://doi.org/10.1016/j.conbuildmat.2018.03.120

Adesanya E, Ohenoja K, Luukkonen T, Kinnunen P, Illikainen M (2018) One-part geopolymer cement from slag and pretreated paper sludge. J Clean Prod 185:168–175. https://doi.org/10.1016/j.jclepro.2018.03.007

Sturm P, Gluth GJG, Jäger C, Brouwers HJH, Kühne HC (2018) Sulfuric acid resistance of one-part alkali-activated mortars. Cem Concr Res 109:54–63. https://doi.org/10.1016/j.cemconres.2018.04.009

Askarian M, Tao Z, Samali B, Adam G, Shuaibu R (2019) Mix composition and characterization of one-part geopolymers with different activators. Constr Build Mater 225:526–537. https://doi.org/10.1016/j.conbuildmat.2019.07.083

Abdollahnejad Z, Luukkonen T, Mastali M, Giosue C, Favoni O, Ruello ML, Kinnunen P, Illikainen M (2019) Microstructural analysis and strength development of one-part alkali-activated slag/ceramic binders under different curing regimes. Waste Biomass Valor 11(6):3081–3096. https://doi.org/10.1007/s12649-019-00626-9

Oderji SY, Chen B, Ahmad MR, Shah SFA (2019) Fresh and hardened properties of one-part fly ash-based geopolymer binders cured at room temperature: effect of slag and alkali activators. J Clean Prod 225:1–10. https://doi.org/10.1016/j.jclepro.2019.03.290

Oderji SY, Chen B, Shakya C, Ahmad MR, Shah SFA (2019) Influence of superplasticizers and retarders on the workability and strength of one-part alkali-activated fly ash/slag binders cured at room temperature. Constr Build Mater 229:116891. https://doi.org/10.1016/j.conbuildmat.2019.116891

Almalkawi AT, Balchandra A, Soroushian P (2019) Potential of using industrial wastes for production of geopolymer binder as green construction materials. Constr Build Mater 220:516–524. https://doi.org/10.1016/j.conbuildmat.2019.06.054

Abdollahnejad Z, Mastali M, Falah M, Shaad KM, Luukkonen T, Illikainen M (2020) Durability of the reinforced one-part alkali-activated slag mortars with different fibers. Waste Biomass Valor 1–15. https://doi.org/10.1007/s12649-020-00958-x

Ma C, Zhao B, Guo S, Long G, **e Y (2019) Properties and characterization of green one-part geopolymer activated by composite activators. J Clean Prod 220:188–199. https://doi.org/10.1016/j.jclepro.2019.02.159

Abdollahnejad Z, Mastali M, Woof B, Illikainen M (2020) High strength fiber reinforced one-part alkali activated slag/fly ash binders with ceramic aggregates: microscopic analysis, mechanical properties, drying shrinkage, and freeze-thaw resistance. Constr Build Mater 241:118129. https://doi.org/10.1016/j.conbuildmat.2020.118129

Shah SFA, Chen B, Oderji SY, Aminul Haque M, Ahmad MR (2020) Comparative study on the effect of fiber type and content on the performance of one-part alkali-activated mortar. Constr Build Mater 243:118221. https://doi.org/10.1016/j.conbuildmat.2020.118221

Zhou S, Ma C, Long G, **e Y (2020) A novel non-Portland cementitious material: mechanical properties, durability and characterization. Constr Build Mater 238:117671. https://doi.org/10.1016/j.conbuildmat.2019.117671

Davidovits J (1994) Global warming impact on the cement and aggregates industries. World Resour Rev 6:263–278

American Society of Testing and Materials (2008) Standard specification for coal fly ash and raw or calcined natural pozzolan for use in concrete (ASTM C618)

Askarian M, Tao Z, Adam G, Samali B (2018) Mechanical properties of ambient cured one-part hybrid OPC-geopolymer concrete. Constr Build Mater 186:330–337. https://doi.org/10.1016/j.conbuildmat.2018.07.160

Escalante JI, Mendoza G, Mancha H, López J, Vargas G (1999) Pozzolanic properties of a geothermal silica waste material. Cem Concr Res 29(4):623–625. https://doi.org/10.1016/S0008-8846(98)00238-5

Gluth GJG, Lehmann C, Rübner K, Kühne H-C (2013) Geopolymerization of a silica residue from waste treatment of chlorosilane production. Mater Struct 46(8):1291–1298. https://doi.org/10.1617/s11527-012-9972-5

Rice Husk Ash (2008) About rice husk ash. Retrieved 21 Feb 2020, from https://www.ricehuskash.com/product.html

Bakar BH, Putra JR, Hamidi A (2011) Malaysian rice husk ash—improving the durability and corrosion resistance of concrete: pre-review. In: Asia Pacific structural engineering conference (APSEC). Concrete Research Letters

Davidovits J (1991) Geopolymers: inorganic polymeric new materials. J Therm Anal Calorim 37:1633–1656. https://doi.org/10.1007/BF01912193

Wang SD, Scrivener KL, Pratt PL (1994) Factors affecting the strength of alkali-activated slag. Cem Concr Res 24(6):1033–1043. https://doi.org/10.1016/0008-8846(94)90026-4

Dong M, Elchalakani M, Karrech A (2020) Development of high strength one-part geopolymer mortar using sodium metasilicate. Constr Build Mater 236:117611. https://doi.org/10.1016/j.conbuildmat.2019.117611

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Ming, L.Y., En, O.W., Yong, H.C., Abdullah, M.M.A.B., Ween, O.S. (2021). Characteristic of One-Part Geopolymer as Building Materials. In: Abdul Kadir, A., Amira Sarani, N., Shahidan, S. (eds) Sustainable Waste Utilization in Bricks, Concrete, and Cementitious Materials. Lecture Notes in Civil Engineering, vol 129. Springer, Singapore. https://doi.org/10.1007/978-981-33-4918-6_6

Download citation

DOI: https://doi.org/10.1007/978-981-33-4918-6_6

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-33-4917-9

Online ISBN: 978-981-33-4918-6

eBook Packages: EngineeringEngineering (R0)