Abstract

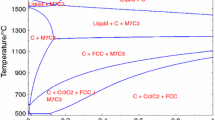

The Direct Reduction of Chromite (DRC) process has the potential to reduce energy consumption and reduce Greenhouse Gas (GHG) emissions for ferrochrome production, as needed to produce stainless steel and other specialty alloys. In the DRC process, Fe and Cr oxides in chromite are reduced at temperatures below their latent heat of fusion which substantially lowers energy requirements, resulting in the production of M7C3-type ferrochrome. In the present work, induration by oxidative sintering, reductant size, and reduction temperature were investigated at the exploratory level to advance our understanding of the DRC process. Induration by oxidative sintering was notably found to slow reaction kinetics and delay metallization, whereas smaller reductant sizes accelerate reaction kinetics. The influence of temperature on reaction kinetics was investigated in several experiments, and an energy barrier identified which may justify a DRC processing temperature of 1320 °C. After an extended time at 1320 °C, the amount of Cr present in the spinel and slag as measured by microprobe analysis are less than 0.43 wt% Cr as Cr2O3, which confirms high degrees of Cr metallization.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Pariser HH, Backeberg NR, Masson OCM, Bedder JCM (2018) Changing nickel and chromium stainless steel markets. Proc 15th Int Ferro-Alloys Congr INFACON 2018 118:1–12. https://doi.org/10.17159/2411-9717/2018/v118n6a1

World Stainless. https://www.worldstainless.org/statistics/stainless-steel-meltshop-production/stainless-steel-meltshop-production-2015-2021. Last accessed 21 Apr 2023

Johnson J, Reck BK, Wang T, Graedel TE (2008) The energy benefit of stainless steel recycling. Energy Policy 36:181–192. https://doi.org/10.1016/j.enpol.2007.08.028

Yu D, Paktunc D (2018) Calcium chloride-assisted segregation reduction of chromite: Influence of reductant type and the mechanism. Fortschr Mineral 8(2):45–63. https://doi.org/10.3390/min8020045

Paktunc D, Thibault Y, Sokhanvaran S, Yu D (2018) Influences of alkali fluxes on direct reduction of chromite for ferrochrome production. J South African Inst Min Metall 118:1305–1314. https://doi.org/10.17159/2411-9717/2018/v118n12a9

Paktunc D (2021) Direct reduction of chromite – conceptual approach and overview. Technical report, CanmetMINING

Hamuyuni J, Johto H, Bunjaku A, Vatanen S, Pajula T, Mäkelä P, Lindgren M (2021) Simulation-based life cycle assessment of ferrochrome smelting technologies to determine environmental impacts. J Clean Prod 295:126503–126513. https://doi.org/10.1016/j.jclepro.2021.126503

Naiker O (2007) The development and advantages of XStrata’s PREMUS process. Proc. 11th Int. Ferro-Alloys Congr. INFACON 2007 112–119. http://refhub.elsevier.com/S2666-7908(21)00346-3/sref28

Gasik M (2013) Handbook of ferroalloys: theory and technology. Butterworth-Heinemann, Oxford

Kleynhans ELJ, Neizel BW, Beukes JP, Van Zyl PG (2016) Utilisation of pre-oxidised ore in the pelletised chromite pre-reduction process. Miner Eng 92:114–124. https://doi.org/10.1016/j.mineng.2016.03.005

Paktunc D (2022) Chromite R&D Initiative – Background, Objectives, Approach and Summary of Accomplishments. Technical report, CanmetMINING

Hockaday SAC, Bisaka K (2010) Some aspects of the production of ferrochrome alloys in pilot dc arc furnaces at mintek. Proc. 12th Int. Ferroalloys Congr. 367–376

Yu D, Paktunc D (2018) Kinetics and mechanisms of the carbothermic reduction of chromite in the presence of nickel. J Therm Anal Calorim 132:143–154. https://doi.org/10.1007/s10973-017-6936-6

Yu D, Paktunc D (2018) Direct production of ferrochrome by segregation reduction of chromite in the presence of calcium chloride. Metals 8(1):69–85. https://doi.org/10.3390/met8010069

Sokhavaran S, Paktunc D (2019) Method of direct reduction of chromite with cryolite additive. U.S. Patent No. 10,358,693

Glastonbury RI, Beukes JP, Van Zyl PG, Sadiki LN, Jordaan A, Campbell QP, Stewart HM, Dawson NF (2015) Comparison of physical properties of oxidative sintered pellets produced with UG2 or metallurgical grade South African chromite: a case study. J South African Inst Min Metall 115:699–706. https://doi.org/10.17159/2411-9717/2015/V115N8A6

Kleynhans ELJ, Beukes JP, Van Zyl PG, Kestens PHI, Langa JM (2012) Unique challenges of clay binders in a pelletised chromite pre-reduction process. Miner Eng 34:55–62. https://doi.org/10.1016/j.mineng.2012.03.021

Riekkola-Vanhanen M (1999) Finnish expert report on best available techniques in ferrochromium production. Technical report Finnish Environment Institute

Beukes JP, Dawson NF, Van Zyl PG (2010) Theoretical and practical aspects of CR(VI) in the south african ferrochrome industry. Proc 12th Int Ferroalloys Congr. 53–62

Bale CW, Chartrand P, Degterov SA, Eriksson G, Hack K, Ben Mahfoud R, Melançon J, Pelton AD, Petersen S (2002) FactSage thermochemical software and databases. Calphad 26:189–228. https://doi.org/10.1016/S0364-5916(02)00035-4

Itaka K, Ogasawara T, Boucetta A, Benioub R, Sumiya M, Hashimoto T, Koinuma H, Furuya Y (2015) Direct carbothermic silica reduction from purified silica to solar-grade silicon. J Phys Conf Ser 596:12015–12015. https://doi.org/10.1088/1742-6596/596/1/012015

Acknowledgments

This project has been funded by CanmetMINING, Natural Resources Canada, under the Critical Minerals Research, Development and Demonstration program. The authors would also like to thank Bhavya Bhatt and Chloe Castell for their assistance in conducting reduction experiments, as well as Derek Smith, and Dominique Duguay for their analyzing samples using XRD and Microprobe, respectively.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Carter, D., Coumans, J.P., Paktunc, D. (2023). Advances in CaCl2-Assisted Direct Reduction of Chromite Processing. In: Proceedings of the 62nd Conference of Metallurgists, COM 2023. COM 2023. Springer, Cham. https://doi.org/10.1007/978-3-031-38141-6_111

Download citation

DOI: https://doi.org/10.1007/978-3-031-38141-6_111

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-38140-9

Online ISBN: 978-3-031-38141-6

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)