Abstract

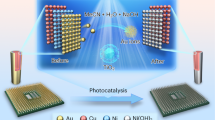

The exploitation of spent battery and electronic waste for the recovery and preparation of metal oxide nanomaterials (MONMs) is vital for technology, economical, sustainable, and environmental research. The recovery of MONMs through recycling waste materials reduces environmental pollutions and saves the primary resources due to industrial consumption. However, the economic benefits of recycling electronic waste for the recovery of these high-value MONMs have still been debated because of the low purity and stability of recovered materials restricting their commercial use. In this chapter, we discuss the motivation and importance of waste recycling for the recovery of nanomaterials, focusing on the possible techniques that can be applied for the efficient synthesis of commercial-grade MONMs (e.g., ferrites, zinc oxides, indium oxides, tin oxides, etc.) with high purity at a minimal cost. Besides, the profit of recovered MONMs in potential applications for wastewater remediation and renewable energy production are addressed.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

Abbreviations

- AFM:

-

Atomic force microscope

- CF:

-

Color filter

- DTA:

-

Differential thermal analysis

- FTIR:

-

Fourier-transform infra-red

- Gg:

-

Gigagram

- GO:

-

Graphene oxide

- ICP:

-

Inductively coupled plasma

- ITO:

-

Indium tin oxide

- LCD:

-

Liquid crystal display

- MONMs:

-

Metal oxide nano materials

- NPs:

-

Nanoparticles

- PVC:

-

Poly vinyl chloride

- RGO:

-

Reduced graphene oxide

- SEM:

-

Scanning electron microscope

- TEM:

-

Transmission electron microscopy

- TFT:

-

Thin film transistor

- TGA:

-

Thermal gravimetric analysis

- VSM:

-

Value stream map**

- XPS:

-

X-ray photoelectron spectroscopy

- XRD:

-

X-ray diffraction

References

Al-Salem SM, Lettieri P, Baeyens J (2009) Recycling and recovery routes of plastic solid waste (PSW): a review. Waste Manag 29(10):2625–2643

Ordoñez J, Gago EJ, Girard A (2016) Processes and technologies for the recycling and recovery of spent lithium-ion batteries. Renew Sustain Energy Rev 60:195–205

Reck BK, Graedel TE (2012) Challenges in metal recycling. Science 337(6095):690–695

Izatt RM, Izatt SR, Bruening RL, Izatt NE, Moyer BA (2014) Challenges to achievement of metal sustainability in our high-tech society. Chem Soc Rev 43(8):2451–2475

Söderholm P, Ekvall T (2019) Metal markets and recycling policies: impacts and challenges. Miner Econ 33(1–2):257–272

Ali GAM, Supriya S, Chong KF, Shaaban ER, Algarni H, Maiyalagan T, Hegde G (2019) Superior supercapacitance behavior of oxygen self-doped carbon nanospheres: a conversion of Allium cepa peel to energy storage system. Biomass Conv Bioref. https://doi.org/10.1007/s13399-019-00520-3

Ali GAM, Habeeb OA, Algarni H, Chong KF (2018) CaO impregnated highly porous honeycomb activated carbon from agriculture waste: symmetrical supercapacitor study. J Mater Sci 54:683–692

Aboelazm EAA, Ali GAM, Algarni H, Yin H, Zhong YL, Chong KF (2018) Magnetic electrodeposition of the hierarchical cobalt oxide nanostructure from spent lithium-ion batteries: its application as a supercapacitor electrode. J Phys Chem C 122(23):12200–12206

Habeeb OA, Ramesh K, Ali GAM, Yunus RM (2017) Low-cost and eco-friendly activated carbon from modified palm kernel shell for hydrogen sulfide removal from wastewater: adsorption and kinetic studies. Desalin Water Treat 84:205–214

Habeeb OA, Ramesh K, Ali GAM, Yunus RM (2017) Experimental design technique on removal of hydrogen sulfide using CaO-eggshells dispersed onto palm kernel shell activated carbon: experiment, optimization, equilibrium and kinetic studies. J Wuhan University Technol-Mater Sci Ed 32(2):305–320

Bensalah H, Bekheet MF, Younssi SA, Ouammou M, Gurlo A (2018) Hydrothermal synthesis of nanocrystalline hydroxyapatite from phosphogypsum waste. J Environ Chem Eng 6(1):1347–1352

Soltani N, Simon U, Bahrami A, Wang X, Selve S, Ep** JD, Pech-Canul MI, Bekheet MF, Gurlo A (2017) Macroporous polymer-derived SiO2/SiOC monoliths freeze-cast from polysiloxane and amorphous silica derived from rice husk. J Eur Ceram Soc 37(15):4809–4820

Witik RA, Teuscher R, Michaud V, Ludwig C, Månson J-AE (2013) Carbon fibre reinforced composite waste: an environmental assessment of recycling, energy recovery and landfilling. Compos A Appl Sci Manuf 49:89–99

Bensalah H, Younssi SA, Ouammou M, Gurlo A, Bekheet MF (2020) Azo dye adsorption on an industrial waste-transformed hydroxyapatite adsorbent: kinetics, isotherms, mechanism and regeneration studies. J Environ Chem Eng 8(3):103807

Abdullayev A, Bekheet MF, Hanaor DA, Gurlo A (2019) Materials and applications for low-cost ceramic membranes. Membranes 9(9):105

Kim TH, Senanayake G, Kang JG, Sohn JS, Rhee KI, Lee SW, Shin SM (2009) Reductive acid leaching of spent zinc–carbon batteries and oxidative precipitation of Mn–Zn ferrite nanoparticles. Hydrometallurgy 96(1–2):154–158

Mylarappa M, Venkata Lakshmi V, Vishnu Mahesh KR, Nagaswarupa HP, Raghavendra N (2019) Recovery of Mn–Zn ferrite from waste batteries and development of rGO/Mn–Zn ferrite nanocomposite for water purification. Mater Today Proc 9:256–265

** G, Yang L, Lu M (2006) Study on preparation of nanocrystalline ferrites using spent alkaline Zn–Mn batteries. Mater Lett 60(29–30):3582–3585

Morais VS, Barrada RV, Moura MN, Almeida JR, Moreira TFM, Gonçalves GR, Ferreira SAD, Lelis MFF, Freitas MBJG (2020) Synthesis of manganese ferrite from spent Zn–MnO2 batteries and its application as a catalyst in heterogeneous photo-Fenton processes. J Environ Chem Eng 8(3):103716

Deng J, Wang X, Duan X, Liu P (2015) Facile preparation of MnO2/graphene nanocomposites with spent battery powder for electrochemical energy storage. ACS Sustain Chem Eng 3(7):1330–1338

Duan X, Deng J, Wang X, Guo J, Liu P (2016) Manufacturing conductive polyaniline/graphite nanocomposites with spent battery powder (SBP) for energy storage: a potential approach for sustainable waste management. J Hazard Mater 312:319–328

Xu J, Thomas HR, Francis RW, Lum KR, Wang J, Liang B (2008) A review of processes and technologies for the recycling of lithium-ion secondary batteries. J Power Sources 177(2):512–527

Ali GAM, Tan LL, Jose R, Yusoff MM, Chong KF (2014) Electrochemical performance studies of MnO2 nanoflowers recovered from spent battery. Mater Res Bull 60:5–9

Ali GAM, Yusoff MM, Shaaban ER, Chong KF (2017) High performance MnO2 nanoflower supercapacitor electrode by electrochemical recycling of spent batteries. Ceram Int 43:8440–8448

Aboelazm EAA, Ali GAM, Chong KF (2018) Cobalt oxide supercapacitor electrode recovered from spent lithium-ion battery. Chem Adv Mater 3:67–74

Ali GAM (2020) Recycled MnO2 nanoflowers and graphene nanosheets for low-cost and high performance asymmetric supercapacitor. J Electron Mater 49:5411–5421

Ali GAM, Yusoff MM, Algarni H, Chong KF (2018) One-step electrosynthesis of MnO2/rGO nanocomposite and its enhanced electrochemical performance. Ceram Int 44:7799–7807

Song M, Cho Y, Yoon D, Nahm S, Oh S, Woo K, Ko J, Cho W (2014) Solvothermal synthesis of ZnMn2O4 as an anode material in lithium ion battery. Electrochim Acta 137:266–272

Smith WN, Arutunian M, Swoffer S (2013) Process for recycling alkaline batteries. U.S. Patent 8,586,218.

Ma Y, Cui Y, Zuo X, Huang S, Hu K, **ao X, Nan J (2014) Reclaiming the spent alkaline zinc manganese dioxide batteries collected from the manufacturers to prepare valuable electrolytic zinc and LiNi0.5Mn1.5O4 materials. Waste Manag 34(10):1793–1799

Ali GAM, Yusoff MM, Feng CK (2015) Electrochemical properties of electrodeposited MnO2 nanoparticles. Adv Mater Res 1113:550–553

Xará S, Almeida MF, Costa C (2015) Life cycle assessment of three different management options for spent alkaline batteries. Waste Manag 43:460–484

Ali GAM, Manaf SAA, Divyashree A, Chong KF, Hegde G (2016) Superior supercapacitive performance in porous nanocarbons. J Energy Chem 25(4):734–739

Hegde G, Abdul Manaf SA, Kumar A, Ali GAM, Chong KF, Ngaini Z, Sharma KV (2015) Biowaste sago bark based catalyst free carbon nanospheres: waste to wealth approach. ACS Sustain Chem Eng 5(9):2247–2253

Ali GAM, Abdul Manaf SA, Kumar A, Chong KF, Hegde G (2014) High performance supercapacitor using catalysis free porous carbon nanoparticles. J Phys D Appl Phys 47(49):495307–495313

Nan J, Han D, Cui M, Yang M, Pan L (2006) Recycling spent zinc manganese dioxide batteries through synthesizing Zn–Mn ferrite magnetic materials. J Hazard Mater 133(1–3):257–261

Gabal MA, Al-Harthy EA, Al Angari YM, Abdel Salam M, Asiri AM (2016) Synthesis, characterization and magnetic properties of MWCNTs decorated with Zn-substituted MnFe2O4 nanoparticles using waste batteries extract. J Magn Magn Mater 407:175–181

Yao L, ** Y, ** G, Feng Y (2016) Synthesis of cobalt ferrite with enhanced magnetostriction properties by the sol−gel−hydrothermal route using spent Li–ion battery. J Alloy Compd 680:73–79

** G-x, Jiao Y-z, Lu M-x (2008) Preparation of CoFe2O4 nanocrystal from spent lithium-ion batteries with coprecipitation method. Electron Compon Mater 27(5):19

Yang L, ** G, Lou T, Wang X, Wang J, He Y (2016) Preparation and magnetic performance of Co0.8Fe2.2O4 by a sol–gel method using cathode materials of spent Li–ion batteries. Ceram Int 42(1):1897–1902

Deep A, Kumar K, Kumar P, Kumar P, Sharma AL, Gupta B, Bharadwaj LM (2011) Recovery of pure ZnO nanoparticles from spent Zn–MnO2 alkaline batteries. Environ Sci Technol 45(24):10551–10556

Deep A, Sharma AL, Mohanta GC, Kumar P, Kim K-H (2016) A facile chemical route for recovery of high quality zinc oxide nanoparticles from spent alkaline batteries. Waste Manag 51:190–195

Mantuano DP, Dorella G, Elias RCA, Mansur MB (2006) Analysis of a hydrometallurgical route to recover base metals from spent rechargeable batteries by liquid–liquid extraction with Cyanex 272. J Power Sources 159(2):1510–1518

Qu J, Feng Y, Zhang Q, Cong Q, Luo C, Yuan X (2015) A new insight of recycling of spent Zn–Mn alkaline batteries: synthesis of ZnxMn1−xO nanoparticles and solar light driven photocatalytic degradation of bisphenol A using them. J Alloy Compd 622:703–707

Bennett JA, Wilson K, Lee AF (2016) Catalytic applications of waste derived materials. J Mater Chem A 4(10):3617–3637

Tang B, Yuan L, Shi T, Yu L, Zhu Y (2009) Preparation of nano-sized magnetic particles from spent pickling liquors by ultrasonic-assisted chemical co-precipitation. J Hazard Mater 163(2–3):1173–1178

Khaloo SS, Torabbeigi M, Jazani RK, Douraghi M, Ghalavand Z (2013) Laboratory waste minimization by recovery of silver as nano-silver colloidal dispersion from waste silver chloride. J Mater Cycles Waste Manage 15(3):342–347

Buzatu T, Popescu G, Birloaga I, Săceanu S (2013) Study concerning the recovery of zinc and manganese from spent batteries by hydrometallurgical processes. Waste Manag 33(3):699–705

Sayilgan E, Kukrer T, Yigit NO, Civelekoglu G, Kitis M (2010) Acidic leaching and precipitation of zinc and manganese from spent battery powders using various reductants. J Hazard Mater 173(1–3):137–143

Provazi K, Campos BA, Espinosa DCR, Tenório JAS (2011) Metal separation from mixed types of batteries using selective precipitation and liquid–liquid extraction techniques. Waste Manag 31(1):59–64

Toro L, Veglio F, Beolchini F, Pagnanelli F, Zanetti M, Furlani G (2006) Process and plant for the treatment of run-down batteries. European Patent Appl EP 1:684

Giacinto V (1967) Process for recovering potassium sulfate from final mother liquors of kaineite. U.S. Patent 3,348,913.

Wen X, Qiao X, Han X, Niu L, Huo L, Bai G (2015) Multifunctional magnetic branched polyethylenimine nanogels with in-situ generated Fe3O4 and their applications as dye adsorbent and catalyst support. J Mater Sci 51(6):3170–3181

Lannoo S, Vilas-Boas A, Sadeghi SM, Jesus J, Soares HMVM (2019) An environmentally friendly closed loop process to recycle raw materials from spent alkaline batteries. J Clean Prod 236:117612

**n B, Jiang W, Aslam H, Zhang K, Liu C, Wang R, Wang Y (2012) Bioleaching of zinc and manganese from spent Zn–Mn batteries and mechanism exploration. Biores Technol 106:147–153

Cui J, Zhang L (2008) Metallurgical recovery of metals from electronic waste: a review. J Hazard Mater 158(2–3):228–256

Oliveira CRd, Bernardes AM, Gerbase AE (2012) Collection and recycling of electronic scrap: a worldwide overview and comparison with the Brazilian situation. Waste Manag 32(8):1592–1610

Zhan L, Xu Z (2008) Application of vacuum metallurgy to separate pure metal from mixed metallic particles of crushed waste printed circuit board scraps. Environ Sci Technol 42(20):7676–7681

Zhan L, Xu Z (2011) Separating and recovering Pb from copper-rich particles of crushed waste printed circuit boards by evaporation and condensation. Environ Sci Technol 45(12):5359–5365

Zhan L, Xu Z (2009) Separating and recycling metals from mixed metallic particles of crushed electronic wastes by vacuum metallurgy. Environ Sci Technol 43(18):7074–7078

**ng M, Zhang F-S (2011) Nano-lead particle synthesis from waste cathode ray-tube funnel glass. J Hazard Mater 194:407–413

Saitoh S, Melber A, Ohbayashi H, Nakai S, Matsuoka M, Hosomi M (2008) Simplified heating time calculation using the schmidt graphical method for PCB-contaminated capacitors undergoing the vacuum thermal recycling process. J Mater Cycles Waste Manage 10(1):71–78

Ohbayashi H, Hosomi M, Kanbe H, Melber A, Bruckamp J (2002) Removal of polychlorinated biphenyls from capacitors and pressure-sensitive paper by vacuum thermal recycling. Waste Manag 22(1):91–98

Saotome Y, Nakazawa Y, Yamada Y (1999) Disassembling and materials recovering process of alkaline manganese dry batteries by vacuum-aided recycling systems technology (VARS Tech.). Vacuum 53(1–2):101-104

Huang K, Li J, Xu Z (2009) A novel process for recovering valuable metals from waste nickel−cadmium batteries. Environ Sci Technol 43(23):8974–8978

Kaya M (2016) Recovery of metals and nonmetals from electronic waste by physical and chemical recycling processes. Waste Manag 57:64–90

Hirajima T, Bissombolo A, Sasaki K, Nakayama K, Hirai H, Tsunekawa M (2005) Floatability of rare earth phosphors from waste fluorescent lamps. Int J Miner Process 77(4):187–198

Mallampati SR, Heo JH, Park MH (2016) Hybrid selective surface hydrophilization and froth flotation separation of hazardous chlorinated plastics from E-waste with novel nanoscale metallic calcium composite. J Hazard Mater 306:13–23

He Y, Zhang T, Wang F, Zhang G, Zhang W, Wang J (2017) Recovery of LiCoO2 and graphite from spent lithium–ion batteries by Fenton reagent-assisted flotation. J Clean Prod 143:319–325

Kachniarz M, Salach J, Szewczyk R, Bieńkowski A (2015) Temperature Influence on the magnetic characteristics of Mn–Zn ferrite materials. In: Advances in intelligent systems and computing, Springer International Publishing, pp 121–127.

Karpova TS, Vasil’ev VG, Vladimirova EV, Nosov AP (2012) Synthesis of ferrite spinel NiFe2O4 by thermal hydrolysis and its magnetic properties. Inorg Mater Appl Res 3(2):107–112

Cao C, **a A, Liu S, Tong L (2013) Synthesis and magnetic properties of hydrothermal magnesium–zinc spinel ferrite powders. J Mater Sci: Mater Electron 24(12):4901–4905

Tudorache F, Petrila I (2014) Effects of partial replacement of iron with tungsten on microstructure, electrical, magnetic and humidity properties of Copper–Zinc ferrite material. J Electron Mater 43(9):3522–3526

Rashad M, Soltan S, Ramadan A, Bekheet M, Rayan D (2015) Investigation of the structural, optical and magnetic properties of CuO/CuFe2O4 nanocomposites synthesized via simple microemulsion method. Ceram Int 41(9):12237–12245

** G, Li Y, Liu Y (2004) Study on preparation of manganese–zinc ferrites using spent Zn–Mn batteries. Mater Lett 58(7–8):1164–1167

Peng C-h, Bai B-s, Chen Y-f (2008) Study on the preparation of Mn–Zn soft magnetic ferrite powders from waste Zn–Mn dry batteries. Waste Manag 28(2):326–332

Lu L, Fang Y, Huang Z, Huang Y, Ren ZJ (2016) Self-sustaining carbon capture and mineralization via electrolytic carbonation of coal fly ash. Chem Eng J 306:330–335

Huang TY, Chiueh PT, Lo SL (2017) Life-cycle environmental and cost impacts of reusing fly ash. Resour Conserv Recycl 123:255–260

Li S, Wang X-m (2016) Fly-ash-based magnetic coagulant for rapid sedimentation of electronegative slimes and ultrafine tailings. Powder Technol 303:20–26

Li S, Wang X-m, Zhang Q-l (2016) Dynamic experiments on flocculation and sedimentation of argillized ultrafine tailings using fly-ash-based magnetic coagulant. Trans Nonferrous Met Soc China 26(7):1975–1984

Lin K-S, Chiang C-L, Hsu P-J, Bat-Erdene K, Tang C-Y, Wu C-M (2018) Magnetic separation and recycling of ferrite nanocatalysts for CO2 decomposition with CH4 recovery from steel industrial flyash. Catal Today 307:260–271

Kim G-Y, Jeon J-H, Kim M-H, Suvorov D, Choi S-Y (2013) Microstructural development of cobalt ferrite ceramics and its influence on magnetic properties. Met Mater Int 19(6):1209–1213

Emamian HR, Honarbakhsh-Raouf A, Ataie A, Mirzaee O (2015) Characterization of mesoporous nanostructured cobalt ferrite foams fabricated by microwave and conventional sintering routes. J Porous Mater 22(3):603–611

Amiri M, Salavati-Niasari M, Akbari A, Razavi R (2017) Sol–gel auto-combustion synthesize and characterization of a novel anticorrosive cobalt ferrite nanoparticles dispersed in silica matrix. J Mater Sci: Mater Electron 28(14):10495–10508

Khan K (2014) Microwave absorption properties of radar absorbing nanosized cobalt ferrites for high frequency applications. J Supercond Novel Magn 27(2):453–461

Zhou J-p, Fu W-l, Qiu K-q, Chen Q-y (2007) Photocatalytic properties of nano tetrapod-like zinc oxide whiskers. J Funct Mater Devices 13(3):195

Guo X, Zhong J, Song Y, Tian Q (2010) Substance flow analysis of zinc in China. Resour Conserv Recycl 54(3):171–177

Zhan L, Li O, Wang Z, **e B (2018) Recycling zinc and preparing high-value-added nanozinc oxide from waste zinc–manganese batteries by high-temperature evaporation-separation and oxygen control oxidation. ACS Sustain Chem Eng 6(9):12104–12109

Zhan L, Li O, Xu Z (2020) Preparing nano-zinc oxide with high-added-value from waste zinc manganese battery by vacuum evaporation and oxygen-control oxidation. J Clean Prod 251:119691

**e Y, Wang S, Tian X, Che L, Wu X, Zhao F (2019) Leaching of indium from end-of-life LCD panels via catalysis by synergistic microbial communities. Sci Total Environ 655:781–786

Lahtela V, Virolainen S, Uwaoma A, Kallioinen M, Kärki T, Sainio T (2019) Novel mechanical pre-treatment methods for effective indium recovery from end-of-life liquid-crystal display panels. J Clean Prod 230:580–591

Bekheet MF, Schwarz MR, Lauterbach S, Kleebe HJ, Kroll P, Riedel R, Gurlo A (2013) Orthorhombic In2O3: a metastable polymorph of indium sesquioxide. Angew Chem Int Ed 52(25):6531–6535

Bekheet MF, Schwarz MR, Lauterbach S, Kleebe H-J, Kroll P, Stewart A, Kolb U, Riedel R, Gurlo A (2013) In situ high pressure high temperature experiments in multi-anvil assemblies with bixbyite-type In2O3 and synthesis of corundum-type and orthorhombic In2O3 polymorphs. High Press Res 33(3):697–711

Bekheet MF, Schwarz MR, Kroll P, Gurlo A (2015) Kinetic control in the synthesis of metastable polymorphs: bixbyite-to-Rh2O3 (II)-to-corundum transition in In2O3. J Solid State Chem 229:278–286

De Boer T, Bekheet M, Gurlo A, Riedel R, Moewes A (2016) Band gap and electronic structure of cubic, rhombohedral, and orthorhombic In2O3 polymorphs: experiment and theory. Phys Rev B 93(15):155205

Boundy T, Boyton M, Taylor P (2017) Attrition scrubbing for recovery of indium from waste liquid crystal display glass via selective comminution. J Clean Prod 154:436–444

Bekheet MF, Miehe G, Fasel C, Gurlo A, Riedel R (2012) Low temperature synthesis of nanocrystalline MnIn2O4 spinel. Dalton Trans 41(12):3374–3376

Schlicker L, Bekheet MF, Gili A, Doran A, Gurlo A, Ploner K, Schachinger T, Penner S (2018) Hydrogen reduction and metal-support interaction in a metastable metal-oxide system: Pd on rhombohedral In2O3. J Solid State Chem 266:93–99

Bekheet MF, Svoboda I, Liu N, Bayarjargal L, Irran E, Dietz C, Stark RW, Riedel R, Gurlo A (2016) Ferroelectric InMnO3: growth of single crystals, structure and high-temperature phase transitions. J Solid State Chem 241:54–63

Bekheet MF, Dubrovinsky L, Gurlo A (2015) Compressibility and structural stability of spinel-type MnIn2O4. J Solid State Chem 230:301–308

Zhuang XN, Ye YY, He WZ, Li GM, Huang JW (2014) Hydrothermal treatment of liquid crystal using a batch reactor. Adv Mater Res 878:563–568

Virolainen S, Ibana D, Paatero E (2011) Recovery of indium from indium tin oxide by solvent extraction. Hydrometallurgy 107:56–61

Pa P-s (2009) Effective tool design of three-rank form as precision removal-process of ITO thin-films. Trans Nonferrous Met Soc China 19:s232–s237

Inoue K, Nishiura M, Kawakita H, Ohto K, Harada H (2008) Recovery of indium from spent panel of liquid crystal display panels. Kagaku Kogaku Ronbunshu 34(2):282–286

Rocchetti L, Amato A, Beolchini F (2016) Recovery of indium from liquid crystal displays. J Clean Prod 116:299–305

Zhang K, Wu Y, Wang W, Li B, Zhang Y, Zuo T (2015) Recycling indium from waste LCDs: a review. Resour Conserv Recycl 104:276–290

Wang S, He Y, Zhang T, Zhang G (2017) Recovery of valuable components from waste LCD panel through a dry physical method. Waste Manag 64:255–262

Savvilotidou V, Hahladakis JN, Gidarakos E (2014) Determination of toxic metals in discarded liquid crystal displays (LCDs). Resour Conserv Recycl 92:108–115

Li J, Gao S, Duan H, Liu L (2009) Recovery of valuable materials from waste liquid crystal display panel. Waste Manag 29(7):2033–2039

Lee C-H, Jeong M-K, Fatih Kilicaslan M, Lee J-H, Hong H-S, Hong S-J (2013) Recovery of indium from used LCD panel by a time efficient and environmentally sound method assisted HEBM. Waste Manag 33(3):730–734

Ruan J, Guo Y, Qiao Q (2012) Recovery of indium from scrap TFT-LCDs by solvent extraction. Procedia Environ Sci 16:545–551

Hsieh S-J, Chen C-C, Say WC (2009) Process for recovery of indium from ITO scraps and metallurgic microstructures. Mater Sci Eng, B 158(1–3):82–87

Ma E, Xu Z (2013) Technological process and optimum design of organic materials vacuum pyrolysis and indium chlorinated separation from waste liquid crystal display panels. J Hazard Mater 263:610–617

Park K-S, Sato W, Grause G, Kameda T, Yoshioka T (2009) Recovery of indium from In2O3 and liquid crystal display powder via a chloride volatilization process using polyvinyl chloride. Thermochim Acta 493(1–2):105–108

Zhang L, Wu B, Chen Y, Xu Z (2017) Energy and valuable resource recovery from waste liquid crystal display panels by an environment-friendly technological process: pyrolysis of liquid crystals and preparation of indium product. J Clean Prod 162:141–152

He Y, Ma E, Xu Z (2014) Recycling indium from waste liquid crystal display panel by vacuum carbon-reduction. J Hazard Mater 268:185–190

Yoshida H, Izhar S, Nishio E, Utsumi Y, Kakimori N, Asghari Feridoun S (2014) Recovery of indium from TFT and CF glasses in LCD panel wastes using sub-critical water. Sol Energy Mater Sol Cells 125:14–19

Higashi A, Saitoh N, Ogi T, Konishi Y (2011) Recovery of indium by biosorption and its application to recycling of waste liquid crystal display panel. J Jpn Inst Met 75(11):620–625

Wang S, He Y, Yang J, Feng Y (2018) Enrichment of indium tin oxide from colour filter glass in waste liquid crystal display panels through flotation. J Clean Prod 189:464–471

Wang S, He Y, Feng Y, Zhang F, Zhang T (2020) Indium tin oxide recycling from waste colour filter glass via thermal decomposition. J Hazard Mater 392:122503

Author information

Authors and Affiliations

Corresponding authors

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 Springer Nature Switzerland AG

About this chapter

Cite this chapter

El-Maghrabi, H.H. et al. (2021). Recovery of Metal Oxide Nanomaterials from Electronic Waste Materials. In: Makhlouf, A.S.H., Ali, G.A.M. (eds) Waste Recycling Technologies for Nanomaterials Manufacturing. Topics in Mining, Metallurgy and Materials Engineering. Springer, Cham. https://doi.org/10.1007/978-3-030-68031-2_8

Download citation

DOI: https://doi.org/10.1007/978-3-030-68031-2_8

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-68030-5

Online ISBN: 978-3-030-68031-2

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)