Abstract

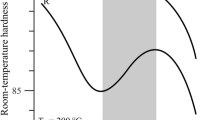

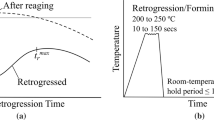

Retrogression forming and reaging (RFRA) is a new warm-forming process designed to produce automotive structural components from high-strength aluminum alloys. A scientific approach is described to determine appropriate RFRA conditions for AA7075-T6 and is applied to laboratory-scale forming experiments. The concept of reduced time is used with the activation energy of retrogression measured for AA7075-T6 to predict appropriate times and temperatures for retrogression forming. Conditions recommended for AA7075-T6 are retrogression at 200 °C for 3 to 12 min while forming at strain rates of up to 10–1 s−1. The recommended reaging heat treatment to fully restore strength to the T6 condition after retrogression forming is 120 °C for 24 h. These RFRA conditions were successfully applied in laboratory-scale experiments to form AA7075-T6 Alclad sheet and produce a final strength equivalent to the T6 condition. Data from tensile tests provide flow stresses and tensile ductilities across the range of conditions appropriate for RFRA.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Long RS, Boettcher E, Crawford D (2017) Current and future uses of aluminum in the automotive industry. J. Mater. 69(12):2635–2639

Harrison NR, Luckey SG (2014) Hot stam** of a B-pillar outer from high strength aluminum sheet AA7075. SAE Tech. Pap. Ser. no:2014-01-0981

Mendiguren J, Saenz de Arganodona E, Galdos L (2016) Hot stam** of AA7075 aluminum sheets. IOP Conf. Ser.: Mater. Sci. Eng. 159 no:012026

Keci A, Harrison NR, Luckey SG (2014) Experimental evaluation of the quench rate of AA7075. SAE Tech. Pap. Ser. no:2014-01-0981

Wang H, Luop YB, Friedman P, Chen MH, Gao L (2010) Warm forming behavior of high strength aluminum alloy AA7075. Trans. Nonferrous Met. Soc. China 22(7):1–7

Zheng K, Politis DJ, Wang L, Lin J (2018) A review on forming techniques for manufacturing lightweight complex-shaped aluminum panel components. Int. J. Lightweight Mater. Manuf. 1(2):55–80

ASM Handbook Committee (1990) Properties of wrought aluminum and aluminum alloys. ASM Handbook, Vol. 2: Properties and Selection: Nonferrous Alloys and Special-Purpose Materials. 62–122

Philip TV, McCaffrey TJ (eds) (1990) Ultrahigh-strength steels. ASM Handbook, Volume 1: Properties and Selection: Irons, Steels, and High-Performance Alloys. 430–448

Schroth JG (2004) General Motors’ quick plastic forming process. Presented at Advances in Superplasticity and Suplerplastic Forming, 14–18 March 2004

Krajewski PE, Morales AT (2004) Tribological issues during quick plastic forming. J. Mater. Eng. Perf. 13(6):700–709

Taleff EM, Nevland PJ, Krajewski PE (2001) Tensile ductility of several commercial aluminum alloys at elevated temperatures. Met. Mater. Trans. A 32A: 1119–1130

Mendiguren J, Ortubay R, Agirretxe X, Galdos L, de Argandona ES (2016) Press hardening of alternative high strength aluminum and ultra-high strength steels. AIP Conf. Proc. 1769(050006):1–6

Ivanoff TA, Carter JT, Hector LG, Taleff EM (2019) Retrogression and reaging applied to warm forming of high-strength aluminum alloy AA7075-T6 sheet. Met. Mater. Trans. A 50A(3):1545–1561

Rader KE, Ivanoff TA, Shin H, Carter JT, Hector LG, Taleff EM (2018) Determining a retrogression heat treatment to apply during warm forming of a high strength aluminum AA7075 sheet material. Light Metals 2018. The Minerals, Metals & Materials Society, Pittsburgh; Springer, New York, p 241–246

Rader KE, Schick M, Carter JT, Hector LG, Taleff EM (2019) Conditions for retrogression forming AA7075-T6 sheet. Light Metals 2019. The Minerals, Metals & Materials Society, Pittsburgh; Springer, New York, p 187–191

Rader KE, Carter JT, Hector LG, Taleff EM (2020) Retrogression forming and reaging of AA7075-T6 Alclad to produce stam**s with peak strength. Light Metals 2020. The Minerals, Metals & Materials Society, Pittsburgh; Springer, New York, p 247–252

Kim H, Cronley L, Reichert C, Zelenak P (2017) Development of the aluminum warm forming test cell and process solutions. Paper presented at the International Automotive Body Congress, Dearborn, Michigan, 20–21 September 2017

Cina BM (1973) U.S. Patent 3856584

Cina B, Ranish B (1974) New technique for reducing susceptibility to stress-corrosion of high strength aluminum alloys, Al. Ind. Prod.:1–29

Danh NC, Rajan K, Wallace W (1983) A TEM study of microstructural changes during retrogression and reaging in 7075 aluminum. Met. Trans. A 14A(9):1843–1850

Park JK, Ardell AJ (1984) Effect of retrogression and reaging treatments on the microstructure of Al-7075-T651. Met. Trans. A 15A:1531–1543

Starink MJ (2004) Analysis of aluminum based alloys by calorimetry: Quantitative analysis of reactions and reaction kinetics. Int. Mater. Rev. 49(3–4):191–226

Barczy P, Tranta F (1975) Precipitation processes in an Al-Mg2Si(Mn) alloy. Scand. J. Metall. 4(6):284–288

Balderach DC, Hamilton JA, Leung E, Tejeda MC, Qiao J, Taleff EM (2003) The paint-bake response of three Al-Mg-Zn alloys. Mater. Sci. Eng. A 339:194–204

Lumley RN, Morton AJ, O’Donnell RG, Polmear IJ (2005) New heat treatments for age-hardenable aluminum alloys. Heat Treat. Prog. 5(2):23–29

Zhuang L, de Haan R, Bottema J, Lahaye CTW, de Smet P (2000) Improvement in bake hardening response of Al-Si-Mg alloys. Mater. Sci. Forum 331-337:1309-1314

ASTM E18–20: ASTM International, West Conshohocken, PA, 2020

Langdon TG (1982) The mechanical properties of superplastic materials. Met. Trans. A 13A: 689–701

Acknowledgements

This work was supported by the National Science Foundation under GOALI grant number CMMI-1634495. The authors thank Brett Mobbs, Matthew Shick, Hyunwook Shin, and Tucker Roemer for their assistance in acquiring hardness and tensile data. The authors thank Hyunok Kim, Tom Feister, Laura Thomas, and Giacomo Melaragno of EWI for their technical support during the forming trials.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Rader, K.E., Carter, J.T., Hector, L.G., Taleff, E.M. (2021). Review of Retrogression Forming and Reaging for AA7075-T6 Sheet. In: Perander, L. (eds) Light Metals 2021. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-030-65396-5_30

Download citation

DOI: https://doi.org/10.1007/978-3-030-65396-5_30

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-65395-8

Online ISBN: 978-3-030-65396-5

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)