Abstract

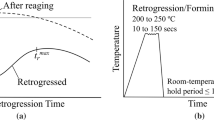

Retrogression forming and reaging is a new scientific approach to producing components of high-strength aluminum alloys through warm forming followed by a single reaging heat treatment to restore T6 strength. Retrogression forming was applied to stamp 1.6-mm-thick AA7075-T6 Alclad sheet at 200 °C to a depth of 45 mm without visible defects or splitting. During stam**, the sheet material was subjected to multiple deformation modes common in automotive stam** processes, producing local major strains in excess of 20%. Time and temperature were controlled during retrogression forming using the concept of accumulated reduced retrogression time to enable recovery of the original T6 sheet strength by a single reaging heat treatment after forming. Tensile specimens extracted from the formed parts were tested to evaluate the effects of retrogression forming on strength. Reaging with a previously recommended reaging heat treatment of 120 °C for 24 h produced strengths approximately 5% greater than those of the original T6 temper. Reaging with a simulated paint-bake cycle of 185 °C for 25 min produced strengths nearly equivalent to those of the original T6 temper. Exceeding the maximum reduced time for retrogression during forming produced a strength loss that could not be recovered.

Similar content being viewed by others

References

T.A. Ivanoff, J.T. Carter, L.G. Hector Jr. and E.M. Taleff, Retrogression and Reaging Applied to Warm Forming of High-Strength Aluminum Alloy AA7075-T6 Sheet, Metall. Mater. Trans. A, 2019, 50(3), p 1545–1561

R.S. Long, E. Boettcher and D. Crawford, Current and Future Uses of Aluminum in the Automotive Industry, J. Mater., 2017, 69(12), p 2635–2639.

N.R. Harrison and S.G. Luckey, Hot Stam** of a B-Pillar Outer from High Strength Aluminum Sheet AA7075, SAE Int. J. Mater. Manuf., 2014, 7(3), p 567–573

J. Mendiguren, E. Saenz de Arganodona and L. Galdos, Hot Stam** of AA7075 Aluminum Sheets, IOP Conf. Ser.: Mater. Sci. Eng., 2016, 159, p 012026.

A. Keci, N. R. Harrison, and S. G. Luckey, Experimental Evaluation of the Quench Rate of AA7075, SAE Tech. Pap. Ser., 2014, no. 2014-01-0984,

H. Wang, Y.B. Luop, P. Friedman, M.H. Chen and L. Gao, Warm Forming Behavior of High Strength Aluminum Alloy AA7075, Trans. Nonferrous Met. Soc. China, 2012, 22(7), p 1–7

K. Zheng, D.J. Politis, L. Wang and J. Lin, A Review on Forming Techniques for Manufacturing Lightweight Complex-Shaped Aluminum Panel Components, Int. J. Light Mater. Manuf., 2018, 1(2), p 55–90

V. Burt, Forming of Aluminum Alloys, ASM Handbook, Volume 2A: Aluminum science and technology, K. Anderson, J. Weritz, and J. G. Kaufman, Eds., ASM International, 2018, p. 336-356

ASM Handbook Committee, Properties of Wrought Aluminum and Aluminum Alloys, ASM Handbook, Volume 2: Properties and Selection: Nonferrous Alloys and Special-Purpose Materials, ASM International, 1990, p. 62-122

K. Anderson, J. Weritz, and J. Gilbert Kaufman, Eds., 7075 and Alclad 7075, ASM Handbook, Volume 2B: Properties and Selection of Aluminum Alloys, ASM International, 2019, p. 432-438

Alcoa Inc., “Alcoa Technical Fact Sheet: Alloy 7075 Plate and Sheet,” Alcoa Inc., Bettendorf, Iowa, Technical Fact Sheet, 2017

T. V. Philip and T. J. McCaffery, Eds., Ultrahigh-Strength Steels, ASM Handbook, Volume Prop. and Selection Irons, Steels, and High-Performance Alloys, ASM International, 1990, pp. 430-448.

H. Kim, L. Cronley, C. Reichert, and P. Zelenak, “Development of the Aluminum Warm Forming Test Cell and Process Solutions,” Int. Auto. Body Cong., Dearborn, MI, Sept 2017

H. Kim, R. Hagnlen, T. Feister and V. Tunga, Comparison of Drawability Between Warm Forming and Cold Forming of Aluminum 6xxx Alloys, IOP Conf. Ser. Mater. Sci. Eng., 2018, 418(012029), p 1–8.

K.E. Rader, J.T. Carter, L.G. Hector Jr. and E.M. Taleff, Plastic Deformation and Ductility of AA7075 and AA6013 at Warm Temperatures Suitable to Retrogression Forming, Metall. Mater. Trans. A, 2021, 52, p 4003–4017

J.A. Osterreicher, G. Kirov, S.S.A. Gerstl, E. Mukeli, F. Grabner and M. Kumar, Stabilization of 7xxx Aluminum Alloys, J. Alloys Compounds, 2018, 740, p 167–173

P.A. Schuster, J.A. Osterreicher, G. Kirov, C. Sommitsch, O. Kessler and E. Mukeli, Characterisation and Comparison of Process Chains for Producing Automotive Structural Parts from 7xxx Aluminium Sheets, Metals, 2019, 9(305), p 1–15.

O.D. Sherby and J. Wadsworth, Superplasticity- Recent Advances and Future Directions, Prog. Mater. Sci., 1989, 33, p 169–221

A.J. Barnes, Superplastic Forming of Aluminum Alloys, Mater. Sci. Forum, 1994, 170–172, p 701–714

T.G. Nieh, J. Wadsworth and O.D. Sherby, Superplasticity in Metals and Ceramics, Cambridge University Press, Cambridge, 1997.

A.J. Barnes, Industrial Applications of Superplastic Forming: Trends and Prospects, Mater. Sci. Forum, 2001, 357, p 3–16

T.E. Langdon, Seventy-Five Years of superplasticity: Historic Developments and New Opportunities, J. Mater. Sci., 2009, 44, p 5998–6010

J. G. Schroth, Advances in Superplasticity and Superplastic Forming, E. M. Taleff, P. A. Friedman, P. E. Krajewski, R. S. Mishra, and J. G. Schroth, Eds., Miner. Metals Mater. Soc., Pittsburgh, PA, 2004, p 9-20.

P.E. Krajewski and A.T. Morales, Tribological Issues during Quick Plastic Forming, J. Mater. Eng. Perf., 2004, 13(6), p 700–709

J. Mendiguren, R. Ortubay, X. Agirretxe, L. Galdos and E.S. de Argandona, Press Hardening of Alternative High Strength Aluminum and Ultra-High Strength Steels, AIP Conf. Proc., 2016, 1769(050006), p 1–6.

AMAG Austria Metall. AG, “AluReport: Safety and Lightweight Construction with AMAG Aluminium”, 2014, www.amag.at.

M. Reinstettel, “The Door Sidecrash Beam in the New BMW i8: Application of a Press Hardened 7xxx Aluminum Alloy Panel,” Proc. Fifth Int. Conf. Acc. Form. Tech., 2015, p. 349-356.

W. ** Condition, Int. J. Adv. Manuf. Tech., 2017, 92, p 3299–3309

M. Kumar and N.G. Ross, Influence of Temper on the Performance of a High-Strength Al-Zn-Mg Alloy Sheet in the Warm Forming Processing Chain, J. Mater. Process. Tech., 2016, 231, p 189–198

M.Y. Lee, S.M. Sohn, C.Y. Kang, D.W. Suh and S.Y. Lee, Effects of Pre-Treatment Condition on Warm Hydroformability of 7075 Aluminum Tubes, J. Mater. Process. Tech., 2004, 155–156, p 1337–1343

W. Huo, L. Huo, Y. Zhang and J. Zhang, Warm Formability and Post-Forming Microstructure/Property of High-Strength AA7075-T6 Al Alloy, Mater. Sci. Eng. A, 2016, 675, p 44–54

J.A. Osterreicher, M.A. Tunes, F. Grabner, A. Arnoldt, T. Kremmer, S. Pogatscher and C.M. Schlogl, Warm-Forming of Pre-Aged Al-Zn-Mg-Cu Alloy Sheet, Mater. Design, 2020, 193(108837), p 1–14

K.E. Rader, J.T. Carter, L.G. Hector Jr. and E.M. Taleff, Retrogression Forming and Reaging of AA7075-T6 Alclad to Produce Stam**s WITH Peak Strength, Light Met., 2020, 2020, p 247–252.

K.E. Rader, J.T. Carter, L.G. Hector Jr. and E.M. Taleff, Review of Retrogression Forming and Reaging of AA7075-T6 Sheet, Light Met., 2021, 2021, p 206–211.

The Aluminum Automotive Manual (European Aluminum Association, Brussels, Belgium, 2002). https://www.european-aluminum.edu/resource-hub/aluminum-automotive-manual/. Accessed 5 Feb. 2020.

J. C. Benedyk: US Patent 5911844, 1999.

J.C. Benedyk and S. Mostovoy, Retrogression Heat Treatment Applied to Aluminum Extrusions for Difficult Forming Applications, Light Met. Age, 1997, 55(1–2), p 29–33

R. M. Kelly: US Patent 20150020927A1, 2015

J.K. Park, Influence of Retrogression and Reaging Treatments on the Strength and Stress Corrosion Resistance of Aluminum Alloy 7705–T6, Mater. Sci. Eng. A, 1988, 103(2), p 223–231

J.K. Park and A.J. Ardell, Effect of Retrogression and Reaging Treatments on the Microstructure of Al-7075-T651, Metall. Trans. A, 1984, 15, p 1531–1543

B. M. Cina and B. Ranish, New Technique for Reducing Susceptibility to Stress-Corrosion of High Strength Aluminum Alloys, Alu. Ind. Prod., 1974, p. 1-29,

K. Rajan, W. Wallace and J.C. Beddoes, Microstructural Study of a High-Strength Stress-Corrosion Resistance 7075 Aluminum Alloy, J. Mater. Sci., 1982, 17, p 2817–2824

N.C. Danh, K. Rajan and W. Wallace, A TEM Study of Microstructural Changes During Retrogression and Reaging in 7075 Aluminum, Metall. Trans. A, 1983, 14(9), p 1843–1850

K.E. Rader, J.T. Carter, L.G. Hector Jr. and E.M. Taleff, Retrogression and Reaging of AA7075 and AA6013 Aluminum Alloys, Met. Metall. Trans. A, 2021, 52(3), p 1006–1018

B. M. Cina, “Reducing the Susceptibility of Alloys, Particularly Aluminum Alloys, to Stress Corrosion Cracking,” US Patent 3856584, Dec 1974

R.N. Lumley, A.J. Morton, R.G. O’Donnell and I.J. Polmear, New Heat Treatments for Age-Hardenable Aluminum Alloys, Heat Treat. Prog., 2005, 5(2), p 23–29

L. Zhuang, R. de Haan, J. Bottema, C.T.W. Lahaye and P. De Smet, Improvement in Bake Hardening Response of Al-Si-Mg Alloys, Mater. Sci. Forum, 2000, 331, p 1309–1314

D.C. Balderach, J.A. Hamilton, E. Leung, M.C. Tejeda, J. Qiao and E.M. Taleff, The Paint-Bake Response of Three Al-Mg-Zn Alloys, Mater. Sci. Eng. A, 2003, 339, p 194–204

J.K. Park and A.J. Ardell, Microstructure of the Commercial 7075 Al Alloy in the T651 and T7 Tempers, Metall. Trans. A, 1983, 14, p 1957–1966

Fuchs Lubricant Co., “Forge Ease AL 278: Synthetic lubricant for use in warm forming,” Fuchs Lubricants Co., Harvey, IL, Technical Fact Sheet, 2015

M.A. Sutton, J.J. Orteu and H. Schreier, Image Correlation for Shape, Moton, and Deformation Measurements, Springer, US, 2009.

GOM, Argus [Software], Available from https://www.gom.com/en/products/3d-testing/argus#1d935204411e47cb9a9da5101175b184

“Standard Test Methods for Tension Testing of Metallic Materials,” ASTM E8/E8M-16a, ASTM International, West Conshohocken, PA, 2017

Correlated Solutions, Inc., Vic-3D [Software], Version 8, Available from https://www.correlatedsolutions.com/vic-3d/

Acknowledgments

The authors thank Hyunok Kim, Tom Feister, Laura Zoller, and Giacomo Melaragno from EWI for providing the facilities used for the forming experiments, their assistance with operating the forming equipment, and providing Argus™ strain data. The authors also thank Todd Meitzner for performing the tensile tests. One author, K. E. Rader, expresses gratitude to General Motors for support during summer research activities. This work was funded by the National Science Foundation under GOALI grant number CMMI-1634495 and by General Motors.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rader, K.E., Carter, J.T., Hector, L.G. et al. Retrogression Forming and Reaging of an AA7075-T6 Alclad Sheet Material. J. of Materi Eng and Perform 31, 5311–5323 (2022). https://doi.org/10.1007/s11665-022-06663-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-06663-1