Abstract

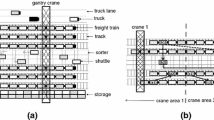

In this chapter, four different automated Rail-Mounted Gantry (RMG) yard crane systems – Single RMG, Twin RMG, Double RMG (DRMG) and Triple RMG (TRMG) – are compared with respect to their characteristics and performance. Furthermore, different approaches for their scheduling are presented: On the one hand, a branch-and-bound procedure for single yard block optimization which incorporates important aspects like crane interference, and on the other hand, an integrated scheduling approach which optimizes the equipment at terminal yard and waterside simultaneously, taking the interrelations with horizontal transport and quay cranes into account. Moreover, a combination of the two approaches is studied. Using a specifically designed simulation model, both the crane systems and the different scheduling approaches are extensively examined with respect to their performance and practical use, e.g. in case of disturbances. Standard priority rules (e.g. First-IN-First-OUT) serve as a benchmark here. It turns out that both approaches are advantageous compared to simple priority rules, and that the crane systems with overtaking possibility are well-adaptable, optimizable, flexible and productive. Moreover, it can be concluded that optimization aspects should already be taken into account in the terminal planning phase, in order to reach optimal productivity levels later on.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

Notes

- 1.

CPLEX is a commercial optimization software package (standard solver). The software is named for the simplex method being implemented in the C programming language.

References

Briskorn D, Drexl A, Hartmann S (2006) Inventory-based dispatching of automated guided vehicles on container terminals. OR Spectr 28(4):611–630

Carlo HJ, Vis IFA, Roodbergen KJ (2014) Storage yard operations in container terminals: literature overview, trends, and research directions. Eur J Oper Res 235(2):412–430

Chen L, Bostel N, Dejax P, Cai J, ** L (2007) A tabu search algorithm for the integrated scheduling problem of container handling systems in a maritime terminal. Eur J Oper Res 181(1):40–58

Chen L, Langevin A, Lu Z (2013) Integrated scheduling of crane handling and truck transportation in a maritime container terminal. Eur J Oper Res 225(1):142–152

Choe R, Park T, Seung MO, Kwang RR (2007) Real-time scheduling for non-crossing stacking cranes in an automated container terminal. In: Orgun MA, Thornton J (eds) AI 2007: advances in artificial intelligence. Lecture notes in computer science, vol 4830. Springer, Berlin, pp 625–631

Dorndorf U, Schneider F (2010) Scheduling automated triple cross-over stacking cranes in a container yard. OR Spectr 32(3):593–615

Ehrgott M (2006) A discussion of scalarization techniques for multiple objective integer programming. Ann Oper Res 147(1):343–360

Fereidoonian F, Mirzazadeh A (2012) A genetic algorithm for the integrated scheduling model of a container-handling system in a maritime terminal. Proc Inst Mech Eng Part M J Eng Marit Environ 226(1):62–77

Gharehgozli AH, Laporte G, Yu Y, de Koster R (2013) Scheduling twin yard cranes in a container block. Transp Sci 49(3):686–705

Goodchild AV, Daganzo CF (2006) Double-cycling strategies for container ships and their effect on ship loading and unloading operations. Transp Sci 40(4):473–483

Grötschel M, Krumke SO, Rambau J, Winter T, Zimmermann U (2001) Combinatorial online optimization in real time. In: Grötschel M, Krumke SO, Rambau J (eds) Online optimization of large scale systems. Springer, Berlin, pp 679–704

Grunow M, Günther H, Lehmann M (2006) Strategies for dispatching AGVs at automated seaport container terminals. OR Spectr 28(4):587–610

Guo X, Huang SY, Hsu WJ, Low YH (2011) Dynamic yard crane dispatching in container terminals with predicted vehicle arrival information. Adv Eng Inform 25(3):472–484

Hartmann S (2004) Generating scenarios for simulation and optimization of container terminal logistics. OR Spectr 26(2):171–192

He J, Huang Y, Yan W, Wang S (2015) Integrated internal truck, yard crane and quay crane scheduling in a container terminal considering energy consumption. Expert Syst Appl 42(5):2464–2487

Johnson D (2007) Alternative RMG applications in container ports. Port Technology International, Oakland, CA. https://www.porttechnology.org/technical-papers/alternative_rmg_applications_in_container_ports

Kemme N (2011) RMG crane scheduling and stacking. In: Böse JW (ed) Handbook of terminal planning. Springer, Berlin, pp 271–301

Kemme N (2012) Effects of storage block layout and automated yard crane systems on the performance of seaport container terminals. OR Spectr 34(3):563–591

Kemme N (2013) Design and operation of automated container storage systems. Springer Physica, Heidelberg

Koch T (2004) Automatik-Portalkrane im CTA-Containerlager. Hebezeuge und Fördermittel 44(11):632–636

Lau HYK, Zhao Y (2008) Integrated scheduling of handling equipment at automated container terminals. Ann Oper Res 159(1):373–394

Lee DH, ** J, Chen J (2011) Integrated bay allocation and yard crane scheduling problem for transshipment containers. Transp Res Rec 2222:63–72

Lorscheid I, Heine BH, Meyer M (2012) Opening the ‘black box’ of simulations: increased transparency and effective communication through the systematic design of experiments. Comput Math Organ Theory 18(1):22–62

Park T, Choe R, Ok SM, Ryu KR (2010) Real-time scheduling for twin RMGs in an automated container yard. OR Spectr 32(3):593–615

Petering MEH, Wu Y, Li W, Goh M, de Souza R (2009) Development and simulation analysis of real-time yard crane control systems for seaport transshipment terminals. OR Spectr 31(4):801–835

Saanen YA (2004) An approach for designing robotized maritime container terminals. PhD Thesis. Technical University of Delft, Delft

Saanen YA, van Valkengoed M (2005) Comparison of three automated stacking alternatives by means of simulation. In: WSC ’05 – proceedings of the 37th conference on winter simulation. IEEE, Piscataway, pp 1567–1576

Skinner B, Yuan S, Huang S, Liu D, Cai B, Dissanayake G, Lau H, Bott A, Pagac D (2013) Optimisation for job scheduling at automated container terminals. Comput Ind Eng 64(1):511–523

Song JH (2007) Tandem operation and double cycling in container terminals. Port Technol 51:73–79

Speer U (2017) Optimierung von automatischen Lagerkransystemen auf Containerterminals. Springer Gabler, Wiesbaden

Speer U, Fischer K (2016) Scheduling of different automated yard crane systems at container terminals. Transp Sci 51(1):305–324

Speer U, John G, Fischer K (2011) Scheduling yard cranes considering crane interference. In: ICCL 2011 – proceedings of the 2nd international conference on computational logistics. Springer, Berlin, pp 321–340

Stahlbock R, Voß S (2008) Operations research at container terminals – a literature update. OR Spectr 30(1):52

Stahlbock R, Voß S (2010) Efficiency considerations for sequencing and scheduling of double-rail-mounted gantry cranes at maritime container terminals. Int J Ship** Transp Logist 2(1):95–123

Steenken D, Voß S, Stahlbock R (2004) Container terminal operations and operations research – a classification and literature review. OR Spectr 26(3):49

Vis IFA, Carlo HJ (2010) Sequencing two cooperating automated stacking cranes in a container terminal. Transp Sci 44(2):169–182

Ya X, Qiushuang C, **ongwen Q (2010) A robust integrated approach to yard space allocation and crane scheduling in container terminals. In: ICSSSM 2010 – proceedings of the 7th international conference on service systems and service management. IEEE, Piscataway, pp 232–237

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Switzerland AG

About this chapter

Cite this chapter

Speer, U., Fischer, K. (2020). Comparison and Optimization of Automated Yard Crane Systems at Container Terminals. In: Böse, J.W. (eds) Handbook of Terminal Planning. Operations Research/Computer Science Interfaces Series. Springer, Cham. https://doi.org/10.1007/978-3-030-39990-0_18

Download citation

DOI: https://doi.org/10.1007/978-3-030-39990-0_18

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-39989-4

Online ISBN: 978-3-030-39990-0

eBook Packages: Business and ManagementBusiness and Management (R0)