Abstract

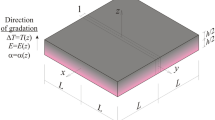

An analytical solution for residual stresses and their energy in an elastically anisotropic two-component plate structure, where the components have an identical type of elastic anisotropy, identical or proportional elastic constants and coinciding principal axes of elastic anisotropy is obtained. The obtained solution has been applied to analyze the anisotropy of the elastic energy of such crystalline structures as the raft structure γ/γ' of single-crystal nickel-base superalloys, multilayer erosion-resistant nanocoatings ZrN/CrN and single-layer coatings of various types. It has been shown that the factor of minimizing the elastic energy of residual stresses has a significant effect on the crystallographic orientation of the interface in multilayer structures and the direction of axis of the growth texture axis of coatings.

Similar content being viewed by others

REFERENCES

A. Tabatabaeian, A. R. Ghasemi, M. M. Shokrieh, et al., “Residual stress in engineering materials: A review,” Adv. Eng. Mater. 24 (3), 2100786 (2022). https://doi.org/10.1002/adem.202100786

X. Wang, H. S. Zurob, G. Xu, et al., “Influence of microstructural length scale on the strength and annealing behavior of pearlite, bainite, and martensite,” Metall. Mater. Trans. A 44, 1454–1461 (2013). https://doi.org/10.1007/s11661-012-1501-1

F. Appel, H. Clemens, and F. Fischer, “Modeling concepts for intermetallic titanium aluminides,” Prog. Mater. Sci. 81, 55–124 (2016). https://doi.org/10.1016/j.pmatsci.2016.01.001

I. L. Svetlov, N. A. Kuzmina, A. V. Neiman, et al., “Effect of the rate of solidification on the microstructure, phase composition, and strength of Nb/Nb5Si3 in-situ composites,” Bull. Russ. Acad. Sci. Phys. 79, 1146–1150 (2015). https://doi.org/10.3103/S1062873815090245

S. A. Muboyadzhyan, D. A. Aleksandrov, and D. S. Gorlov, “Ion-plasma erosion-resistant nanocoatings based on metal carbides and nitrides,” Russ. Metall. 2010, 790–799 (2010). https://doi.org/10.1134/S0036029510090077

A. Epishin, T. Link, U. Bruckner, and P. D. Portella, “Evolution of the γ/γ'-microstructure during high temperature creep of a nickel-base superalloy,” Acta Mater. 48, 4169–4177 (2000). https://doi.org/10.1016/S1359-6454(00)00197-X

A. I. Epishin and D. S. Lisovenko, “Extreme values of the Poisson’s ratio of cubic crystals,” Tech. Phys. 61, 1516–1524 (2016). https://doi.org/10.1134/S1063784216100121

K. Harris, G. L. Erickson, S. L. Sikkenga, et al., “Development of the rhenium containing superalloys CMSX-4 & CM 186 LC for single crystal blade and directionally solidified vane applications in advanced turbine engines,” in Superalloys (TMS, Warrendale, PA, 1992), pp. 297–306. https://doi.org/10.7449/1992/Superalloys_1992_297_306

A. Epishin, T. Link, and U. Brückner, “Microstructural stability of CMSX-4 and CMSX-10 under high temperature creep conditions,” in Materials for Advanced Power Engineering (FZ Jülich, 2006), pp. 507–520.

A. Epishin, B. Fedelich, M. Finn, et al., “Investigation of elastic properties of the single-crystal nickel-base superalloy CMSX-4 in the temperature interval between room temperature and 1300°C,” Crystals 11, 152 (2021). https://doi.org/10.3390/cryst11020152

U. Glatzel, Microstructure and Internal Strains of Undeformed and Creep Deformed Samples of a Nickel-Base Superalloy (Verlag Dr. Köster, Berlin, 1994).

X.-J. Chen, V. V. Struzhkin, Z. Wu, et al., “Hard superconducting nitrides,” PNAS USA 102 (9), 3198–3201 (2005). https://doi.org/10.1073/pnas.0500174102

V. Antonov and I. Iordanova, “First principles study of crystallographic structure and elastic properties of chromium,” AIP Conf. Proc. 1203, 1149–1154 (2010). https://doi.org/10.1063/1.3322328

P. M. Samim, A. Fattah-Alhosseini, H. Elmkhah, and O. Imantalab, “Nanoscale architecture of ZrN/CrN coatings: microstructure, composition, mechanical properties and electrochemical behavior,” J. Mater. Res. Technol. 15, 542–560 (2021). https://doi.org/10.1016/j.jmrt.2021.08.018

D. R. McKenzie, Y. Yin, W. D. McFall, and N. H. Hoang, “The orientation dependence of elastic strain energy in cubic crystals and its application to the preferred orientation in titanium nitride thin films,” J. Phys.: Condens. Matter. 8, 5883–5890 (1996). https://doi.org/10.1088/0953-8984/8/32/008

S.Y. Betsofen, A. A. Ashmarin, L. M. Petrov, et al., “Effect of the ion-plasma process parameters on the texture and properties of TiN and ZrN coatings,” Russ. Metall. 2021, 1238–1244 (2021). https://doi.org/10.1134/S0036029521100037

Low Frequency Properties of Dielectric Crystals. Second and Higher Order Elastic Constants, Ed. by D. F. Nelson (Springer, 1992). https://doi.org/10.1007/b44185

J. O. Kim, J. D. Achenbach, P. B. Mirkarimi, et al., “Elastic constants of single crystal transition metal nitride films measured by line focus acoustic microscopy,” J. Appl. Phys. 72, 1805–1811 (1992). https://doi.org/10.1063/1.351651

S. Sampath and H. Herman, Rapid solidification and microstructure development during plasma spray deposition,” J. Therm. Spray Technol. 5, 445–456 (1996). https://doi.org/10.1007/BF02645275

I. M. Kovensky and V.V. Povetkin, Metallurgy of Coatings (SP Intermet Engineering, Moscow, 1999) [in Russian].

O. Yu. Goncharov, I. A. Ilyin, D. B. Titorov, and D. V. Titorova, “Textures of molybdenum, tantalum and hafnium boride coatings obtained by chemical gas-phase deposition,” Perspektivnye Materialy, No. 4, 69–73 (2008).

C. Kirchlechner, K. J. Martinschitz, R. Daniel, et al., “Residual stresses and thermal fatigue in CrN hard coatings characterized by high-temperature synchrotron X-ray diffraction,” Thin Solid Films 518 (8), 2090–2096 (2010). https://doi.org/10.1016/j.tsf.2009.08.011

S. G. Lekhnitskii, Theory of Elasticity of an Anisotropic Body (Nauka, Moscow, 1977; Mir Publ, Moscow, 1981).

F. A. McClintock and A. S. Argon, Mechanical Behavior of Materials (Addison-Wesley, 1966; Mir, Moscow, 1970).

H. Goldstein, Classical Mechanics (Addison-Wesley, 1951; Gostekhizdat, Moscow, 1957).

Funding

This study was supported by a grant from the Russian Science Foundation (project no. 22-29-01200).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors of this work declare that they have no conflicts of interest.

Additional information

Translated by A. Borimova

Publisher’s Note.

Allerton Press remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

APPENDIX

APPENDIX

Below there are the orientation dependences of the elastic compliances of a cubic crystal \({{s}_{{ij}}} = f\left( {{{S}_{{ij}}},{{\varphi }},\theta ,{{\psi }} = 0} \right)\), where φ, θ and ψ are the Euler angles. In this study, only those orientations are considered for which ψ = 0. The given formulas can be obtained using both the general elastic compliance transformation described in [23] and a special simplified transformation for cubic crystals proposed in [24]. The transformation matrix in Euler angles is presented in [25].

where \(S = {{S}_{{11}}} - {{S}_{{12}}} - {{S}_{{44}}}{\text{/}}2\).

About this article

Cite this article

Lisovenko, D.S., Epishin, A.I. Anisotropy of Residual Stress Energy in Two-Component Plate Crystal Structures. Mech. Solids 58, 2043–2057 (2023). https://doi.org/10.3103/S0025654423601179

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0025654423601179