Abstract

The tailoring effects of MnO2 additive on 0.38Ba(Cu1/3Nb2/3)O3–0.62PbTiO3 ceramic have been investigated for structure, dielectric, ferroelectric and piezoelectric properties. XRD, XPS, SEM and EDS techniques have been used to characterize the compositional controlling of different structures and the chemistry of the resulting phases. The MnO2 addition has been found very effective in improving the piezoelectric, dielectric and ferroelectric properties and modifying the crystal structure and microstructure of the parent compound. The Rietveld refinement reveals that the 0.38Ba(Cu1/3Nb2/3)O3–0.62PbTiO3 ceramic has a rare crystal structure with two coexisting tetragonal phases whose tetragonalities and phase fractions transform with the increasing concentration of MnO2 additive. The tetragonal phase of both the end components is retained in this solid solution composition with modified lattice distortion. A small amount of MnO2 additive in the ceramic, typically 1 wt%, gives maximum enhancement of piezoelectric response. A profound correlation between the structure and physical properties has been established for defect-engineered ceramics.

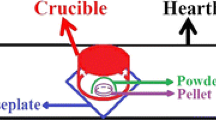

Graphical abstract

-

(a)

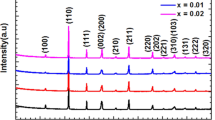

XRD pattern of 0.38Ba(Cu1/3Nb2/3)O3–0.62PbTiO3 ceramic for varying MnO2 additive content. Inset—Zoom view of XRD pattern for illustration of (200) reflection.

-

(b)

Variation of d33 with varying MnO2 additive content for 0.38Ba(Cu1/3Nb2/3)O3–0.62PbTiO3 ceramic.

-

(c)

P–E hysteresis loop of 0.38Ba(Cu1/3Nb2/3)O3–0.62PbTiO3 ceramic for varying MnO2 additive content.

Similar content being viewed by others

Data availability

All required data can be found within the article and its supplementary information file.

Code availability

Not applicable.

References

K. Uchino, Advanced Piezoelectric Materials: Science and Technology (Woodhead Publishing, Oxford, 2017)

L. Zia, G.H. Jaffari, N.A. Khan, J.U. Rahman, S. Lee, S.I. Shah, Identification and comparison of peculiarities in physical properties of multiferroic morphotropic phase boundary sintered BiFeO3-xPbTiO3 nano-ceramics. J. Phys. Chem. Solids 150, 109868 (2021). https://doi.org/10.1016/j.jpcs.2020.109868

R. Pandey, A.K. Singh, Electric field induced cubic to monoclinic phase transition in multiferroic 0.65Bi(Ni1/2Ti1/2)O3–0.35PbTiO3 solid solution. Appl. Phys. Lett. 105, 1–5 (2014). https://doi.org/10.1063/1.4899058

N.K. Verma, A.K. Singh, Discovery of ordered tetragonal and cubic phases in the morphotropic phase boundary region of (1–x)Bi(Mg3/4W1/4)O3-xPbTiO3 piezoceramics. Ceram. Int. 45, 17395–17408 (2019). https://doi.org/10.1016/j.ceramint.2019.05.300

R. Pandey, A. Tiwari, A. Upadhyay, A.K. Singh, Phase coexistence and the structure of the morphotropic phase boundary region in (1–x)Bi(Mg1/2Zr1/2)O3-xPbTiO3 piezoceramics. Acta Mater. 76, 198–206 (2014). https://doi.org/10.1016/j.actamat.2014.05.023

S. Zhang, R. **a, T.R. Shrout, Lead-free piezoelectric ceramics vs. PZT? J. Electroceram. 19, 251–257 (2007). https://doi.org/10.1007/s10832-007-9056-z

H. Jaffe, Piezoelectric ceramics. J. Am. Ceram. Soc. 41, 494–498 (1958). https://doi.org/10.1111/j.1151-2916.1958.tb12903.x

F. Li, D. Lin, Z. Chen, Z. Cheng, J. Wang, C. Li et al., Ultrahigh piezoelectricity in ferroelectric ceramics by design. Nat. Mater. 17, 349–354 (2018). https://doi.org/10.1038/s41563-018-0034-4

M. Ahart, M. Somayazulu, R.E. Cohen, P. Ganesh, P. Dera, H.K. Mao et al., Origin of morphotropic phase boundaries in ferroelectrics. Nature 451, 545–548 (2008). https://doi.org/10.1038/nature06459

F. Li, S. Zhang, T. Yang, Z. Xu, N. Zhang, G. Liu et al., The origin of ultrahigh piezoelectricity in relaxor-ferroelectric solid solution crystals. Nat. Commun. 7, 1–9 (2016). https://doi.org/10.1038/ncomms13807

S. Harada, Y. Takagi, H. Nagata, T. Takenaka, Quenching effects on electrical properties of Cu-doped (Bi1/2Na1/2)TiO3-based solid solution ceramics. J. Mater. Res. 36, 1097–1104 (2021). https://doi.org/10.1557/s43578-020-00048-7

Y. Yan, Z. Li, L. **, H. Du, M. Zhang, D. Zhang et al., Extremely high piezoelectric properties in Pb-based ceramics through integrating phase boundary and defect engineering. ACS Appl. Mater. Interfaces 13, 38517–38525 (2021). https://doi.org/10.1021/acsami.1c10298

D. Lin, S. Zhang, C. Cai, W. Liu, Domain size engineering in 0.5%MnO2-(K0.5Na0.5)NbO3 lead free piezoelectric crystals. J. Appl. Phys. 117, 3–8 (2015). https://doi.org/10.1063/1.4913208

S. Priya, K. Uchino, J. Ryu, C.W. Ahn, S. Nahm, Induction of combinatory characteristics by relaxor modification of Pb(Zr0.5Ti0.5)O3. Appl. Phys. Lett. 83, 5020–5022 (2003). https://doi.org/10.1063/1.1634695

Y. Yan, A. Kumar, M. Correa, K.H. Cho, R.S. Katiyar, S. Priya, Phase transition and temperature stability of piezoelectric properties in Mn-modified Pb(Mg1/3Nb2/3)O3-PbZrO3-PbTiO3 ceramics. Appl. Phys. Lett. 100, 1–5 (2012). https://doi.org/10.1063/1.3703124

Y. Deng, J. Wang, C. Zhang, H. Ma, C. Bai, D. Liu et al., Structural and electric properties of MnO2-doped KNN-LT lead-free piezoelectric ceramics. Crystals 10, 1–8 (2020). https://doi.org/10.3390/cryst10080705

Q. Liu, F.Y. Zhu, L. Zhao, K. Wang, L. Li, J.F. Li et al., Further enhancing piezoelectric properties by adding MnO2 in AgSbO3-modified (Li, K, Na)(Nb, Ta)O3 lead-free piezoceramics. J. Am. Ceram. Soc. 99, 3670–3676 (2016). https://doi.org/10.1111/jace.14412

C.S. Yu, H.L. Hsieh, Piezoelectric properties of Pb(Ni1/3, Sb2/3)O3-PbTiO3-PbZrO3 ceramics modified with MnO2 additive. J. Eur. Ceram. Soc. 25, 2425–2427 (2005). https://doi.org/10.1016/j.jeurceramsoc.2005.03.075

H. Liu, R. Nie, Y. Yue, Q. Zhang, Q. Chen, J. Zhu et al., Effect of MnO2 do** on piezoelectric, dielectric and ferroelectric properties of PNN–PZT ceramics. Ceram. Int. 41, 11359–11364 (2015). https://doi.org/10.1016/j.ceramint.2015.05.094

S.J. Yoon, S.Y. Yoo, J.H. Moon, H.J. Jung, H.J. Kim, Effects of La2O3 and MnO2 on the piezoelectric properties of 0.02Pb(Y2/3W1/3)O3–0.98Pb(Zr0.52Ti0.48)O3. J. Mater. Res. (1996). https://doi.org/10.1557/JMR.1996.0041

X. Wang, P. Liang, X. Chao, Z. Yang, Dielectric properties and impedance spectroscopy of MnCO3-modified (Ba0.85Ca0.15)(Zr0.1Ti0.9)O3 lead-free ceramics. J. Am. Ceram. Soc. 98, 1506–1514 (2015). https://doi.org/10.1111/jace.13481

L.X. He, C.E. Li, Effects of addition of MnO on piezoelectric properties of lead zirconate titanate. J. Mater. Sci. 35, 2477–2480 (2000). https://doi.org/10.1023/A:1004717702149

A. Bradeško, M. Vrabelj, L. Fulanović, Š Svirskas, M. Ivanov, R. Katiliūte et al., Implications of acceptor do** in the polarization and electrocaloric response of 0.9Pb(Mg1/3Nb2/3)O3–0.1PbTiO3 relaxor ferroelectric ceramics. J. Mater. Chem. C 9, 3204–3214 (2021). https://doi.org/10.1039/d0tc05854h

T. Zheng, H. Deng, W. Zhou, X. Zhai, H. Cao, L. Yu et al., Bandgap modulation and magnetic switching in PbTiO3 ferroelectrics by transition elements do**. Ceram. Int. 42, 6033–6038 (2016). https://doi.org/10.1016/j.ceramint.2015.12.157

W. Peng, L. Li, S. Yu, P. Yang, K. Xu, Dielectric properties, microstructure and charge compensation of MnO2-doped BaTiO3-based ceramics in a reducing atmosphere. Ceram. Int. 47, 29191–29196 (2021). https://doi.org/10.1016/j.ceramint.2021.07.083

K. Toshio, S. Toshimasa, T. Takkai, D. Masaki, Effects of manganese addition on piezoelectric properties of Pb(Zr0.5Ti0.5)O3. Jpn. Soc. Appl. Phys. 31, 3058–3060 (1992). https://doi.org/10.1143/JJAP.31.3058

C. Zhou, X. Ke, Y. Yao, S. Yang, Y. Ji, W. Liu et al., Evolution from successive phase transitions to ‘morphotropic phase boundary’ in BaTiO3-based ferroelectrics. Appl. Phys. Lett. 112, 1–6 (2018). https://doi.org/10.1063/1.5028302

S. Priya, A. Ando, Y. Sakabe, Nonlead perovskite materials: Ba(Li1/4Nb3/4)O3 and Ba(Cu1/3Nb2/3)O3. J. Appl. Phys. 94, 1171–1177 (2003). https://doi.org/10.1063/1.1585121

K. Abdelmadjid, F. Gheorghiu, M. Zerdali, M. Kadri, S. Hamzaoui, Preparation, structural and functional properties of PbTiO3-δ ceramics. Ceram. Int. 45, 9043–9047 (2019). https://doi.org/10.1016/j.ceramint.2019.01.240

W. Zhang, N. Kumada, Y. Yonesaki, T. Takei, N. Kinomura, T. Hayashi et al., Ferroelectric perovskite-type barium copper niobate: BaCu1/3Nb2/3O3. J. Solid State Chem. 179, 4052–4055 (2006). https://doi.org/10.1016/j.jssc.2006.08.008

H. Langbein, M. Bremer, I. Krabbes, CuX2O6 and Ba3CuX2O9 (X = Nb, Ta): influence of the preparation conditions on phase formation and phase composition. Solid State Ion. 101–103, 579–584 (1997). https://doi.org/10.1016/s0167-2738(97)00382-2

W.M. Zhu, H.Y. Guo, Z.G. Ye, Structure and properties of multiferroic (1–x)BiFeO3-x PbTiO3 single crystals. J. Mater. Res. 22, 2136–2143 (2007). https://doi.org/10.1557/jmr.2007.0268

A.K. Singh, D. Pandey, Evidence for MB and MC phases in the morphotropic phase boundary region of (1–x)[Pb(Mg1/3Nb2/3)O3]-xPbTiO3: a rietveld study. Phys. Rev. B 67, 064102 (2003). https://doi.org/10.1103/physrevb.67.064102

J. Praveen, P.R. Arjunwadkar, M.A. Nagarbawadi, Structural characterization of lead titanate (PbTiO3) sample using FULLPROF. IOSR J. Appl. Phys. 8, 57–60 (2016). https://doi.org/10.9790/4861-0806055760

T. Li, M. Xu, K. Peng, Y. Sun, M. Wang, H. Dai et al., Evolution of microstructure, defect, optoelectronic and magnetic properties of Cu1-xCaxFeO2 ceramics. J. Phys. Chem. Solids 151, 109910 (2021). https://doi.org/10.1016/j.jpcs.2020.109910

E. Brzozowski, M.S. Castro, Grain growth control in Nb-doped BaTiO3. J. Mater. Process. Technol. 168, 464–470 (2005). https://doi.org/10.1016/j.jmatprotec.2005.02.246

M.J. Brova, B.H. Watson, R.L. Walton, E.R. Kupp, M.A. Fanton, R.J. Meyer et al., Templated grain growth of high coercive field CuO-doped textured PYN-PMN-PT ceramics. J. Am. Ceram. Soc. 103, 6149–6156 (2020). https://doi.org/10.1111/jace.17349

W.A. Goddard, On the wrong assignment of the XPS O1s signal at 531–532 eV attributed to oxygen vacancies in photo- and electro-catalysts for water splitting and other materials applications. Surf. Sci. 284, 1119–1125 (2021). https://doi.org/10.1007/978-3-030-18778-1_51

A. Ono, Preparation of new perovskite-type oxides Ba2.5Nb1.5CuO7.25 and Sr3Ta2CuO9. J. Mater. Sci. Lett. 11, 114–115 (1992). https://doi.org/10.1007/BF00724616

Y. Kamimura, B.Y. Lee, K. Yazawa, H. Funakubo, T. Iijima, H. Uchida, Fabrication and evaluation of Mn-substituted Ba(Cu1/3Nb2/3)O3 ceramics. IOP Conf. Ser. Mater. Sci. Eng. 18, 2–6 (2011). https://doi.org/10.1088/1757-899X/18/9/092038

R.D. Shannon, C.T. Prewitt, Effective ionic radii in oxides and fluorides. Acta Crystallogr. Sect. B 25, 925–946 (1969). https://doi.org/10.1107/s0567740869003220

F.A. Kröger, H.J. Vink, Relations between the concentrations of imperfections in crystalline solids. Solid State Phys. 3, 307–435 (1956). https://doi.org/10.1016/S0081-1947(08)60135-6

R.R. McQuade, P. Mardilovich, N. Kumar, D.P. Cann, Conduction properties of acceptor-doped BaTiO3–Bi(Zn1/2Ti1/2)O3-based ceramics. J. Mater. Sci. 55, 16290–16299 (2020). https://doi.org/10.1007/s10853-020-05175-4

T.M. Kamel, G. de With, Poling of hard ferroelectric PZT ceramics. J. Eur. Ceram. Soc. 28, 1827–1838 (2008). https://doi.org/10.1016/j.jeurceramsoc.2007.11.023

H. Yan, F. Inam, G. Viola, H. Ning, H. Zhang, Q. Jiang et al., The contribution of electrical conductivity, dielectric permittivity and domain switching in ferroelectric hysteresis loops. J. Adv. Dielectr. 01, 107–118 (2011). https://doi.org/10.1142/s2010135x11000148

G.R. Gajula, L.R. Buddiga, M. Dasari, Influence of Gd/Nb on activation energy, relaxation response, impedance, nyquist plots and dielectric studies at high frequency of BaTiO3-Li0.5Fe2.5O4 solid compounds. Results Phys. 18, 103196 (2020). https://doi.org/10.1016/j.rinp.2020.103196

A. Schönhals, F. Kremer, in: Broadband Dielectric Spectroscopy (Springer, Berlin, 2003), pp. 59–98. https://doi.org/10.1007/978-3-642-56120-7_3.

L. Liu, C. Wang, X. Sun, G. Wang, C. Lei, T. Li, Oxygen-vacancy-related relaxations of Sr3CuNb2O9 at high temperatures. J. Alloys Compd. 552, 279–282 (2013). https://doi.org/10.1016/j.jallcom.2012.10.081

Acknowledgments

Authors are thankful to the Central Instrumental Facility, Indian Institute of Technology (Banaras Hindu University) for providing experimental facility such as XPS, HR-XRD, SEM and EDS. AK Singh acknowledges the financial support from Science and Engineering Research Board-Department of Science and Technology.

Author information

Authors and Affiliations

Contributions

KP—Conceptualization, Methodology, Investigation, Writing (Original draft, Visualization); AKS: Supervision, Conceptualization, Resources, Writing (Review & Editing).

Corresponding author

Ethics declarations

Conflict of interest

Authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Prajapati, K., Singh, A.K. Improved ferroelectric and piezoelectric properties and structural correlations in a new ceramic 0.38Ba(Cu1/3Nb2/3)O3–0.62PbTiO3 by MnO2 additive. Journal of Materials Research 38, 2031–2048 (2023). https://doi.org/10.1557/s43578-023-00940-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-023-00940-y