Abstract

Background

Develo** economically viable pathways to produce renewable energy has become an important research theme in recent years. Lignocellulosic biomass is a promising feedstock that can be converted into second-generation biofuels and bioproducts. Global warming has adversely affected climate change causing many environmental changes that have impacted earth surface temperature and rainfall patterns. Recent research has shown that environmental growth conditions altered the composition of drought-stressed switchgrass and directly influenced the extent of biomass conversion to fuels by completely inhibiting yeast growth during fermentation. Our goal in this project was to find a way to overcome the microbial inhibition and characterize specific compounds that led to this inhibition. Additionally, we also determined if these microbial inhibitors were plant-generated compounds, by-products of the pretreatment process, or a combination of both.

Results

Switchgrass harvested in drought (2012) and non-drought (2010) years were pretreated using Ammonia Fiber Expansion (AFEX). Untreated and AFEX processed samples were then extracted using solvents (i.e., water, ethanol, and ethyl acetate) to selectively remove potential inhibitory compounds and determine whether pretreatment affects the inhibition. High solids loading enzymatic hydrolysis was performed on all samples, followed by fermentation using engineered Saccharomyces cerevisiae. Fermentation rate, cell growth, sugar consumption, and ethanol production were used to evaluate fermentation performance. We found that water extraction of drought-year switchgrass before AFEX pretreatment reduced the inhibition of yeast fermentation. The extracts were analyzed using liquid chromatography–mass spectrometry (LC–MS) to detect compounds enriched in the extracted fractions. Saponins, a class of plant-generated triterpene or steroidal glycosides, were found to be significantly more abundant in the water extracts from drought-year (inhibitory) switchgrass. The inhibitory nature of the saponins in switchgrass hydrolysate was validated by spiking commercially available saponin standard (protodioscin) in non-inhibitory switchgrass hydrolysate harvested in normal year.

Conclusions

Adding a water extraction step prior to AFEX-pretreatment of drought-stressed switchgrass effectively overcame inhibition of yeast growth during bioethanol production. Saponins appear to be generated by the plant as a response to drought as they were significantly more abundant in the drought-stressed switchgrass water extracts and may contribute toward yeast inhibition in drought-stressed switchgrass hydrolysates.

Similar content being viewed by others

Background

There is an ever-increasing demand for non-conventional energy resources with the fast depletion of natural petroleum reservoirs. The global scientific community has been on a mission to discover alternate ways to harness energy from different sources, including lignocellulosic biomass [1,2,3,4]. Switchgrass, a perennial prairie grass native to the United States, has been identified as a potential bioenergy feedstock [5, 6]. When grown on non-arable land, using switchgrass for bioenergy production mitigates the food vs. fuel debate usually observed with food-based feedstocks, such as corn and sugarcane [3, 4]. However, several challenges exist toward achieving a viable lignocellulosic biofuel industry, one of which is variability in feedstock composition. Due to rapid global warming, changing weather conditions have led to the frequent occurrence of abiotic stresses, such as drought, wildfire, water salinity, and biotic stresses, such as pathogen infections or herbivore attack. These stresses reduce the amount of available biomass and alter the feedstock composition [6,7,8].

Many biotic and abiotic stresses trigger the generation of plant defense compounds that ensure higher plant growth and survival. Beans, olives, wild geophytes, and grasses have been found to generate compounds, such as flavonoids, alkaloids, terpenes, phenols, anthocyanins, tannins, and quinones in response to drought [9,10,11,12]. Osmolytes in the form of amino acids including proline, glycine, and betaine are also commonly observed in plants surviving a drought [13, 14]. Specifically, switchgrass varieties that endured drought conditions possessed higher fructose, trehalose, abscisic acid, and spermine [6, 15, 16]. In our prior work, we showed that the effect of switchgrass harvested during U.S. Midwestern drought of 2012 carried through the biofuel production process to affect fermentation [58, 59], saponins may be potentially responsible for the yeast inhibition in fermentation hydrolysates obtained from drought-stressed switchgrass.

Water had the tendency to remove higher molecular weight saponins and, ethanol and ethyl acetate extracted more of the lower molecular weight saponins. This could possibly be caused due to the higher water solubility of more extensively glycosylated forms. The saponins with molecular weights 1176 and 1212 Da share the same core aglycone called diosgenin but differ in their sugar moieties [16, 28]. The presence of a relatively higher amount of saponins in water extracts obtained from untreated switchgrass corroborates with the fermentation profiles of water extracted untreated switchgrass (Fig. 4B). Saponins appear to withstand AFEX pretreatment (Fig. 8) and likely contribute toward microbial inhibition in unextracted drought-year switchgrass. Microplate fermentation experiments with various concentrations of protodioscin, a commercially available saponin, in control-year non-inhibitory hydrolysate demonstrated the ability of saponins to inhibit yeast growth (Fig. 10). LC–MS/MS analysis will be conducted on the compounds identified in water extracts in further experiments using more targeted MS-based approaches.

Conclusions

This study overcame the challenge of microbial inhibition experienced by drought-stressed switchgrass to produce lignocellulosic ethanol by S. cerevisiae. Including an additional water extraction step before AFEX-pretreatment for drought-stressed switchgrass produced a comparable quantity of ethanol relative to the paired control-year samples and better than the unextracted control-year samples. Non-targeted LC–MS qualitative characterization of compounds showed that saponins, a class of naturally generated triterpene or steroidal glycosides, are more abundant in drought-stressed switchgrass and could potentially be responsible for the inhibition displayed by an engineered S. cerevisiae strain in drought-stress switchgrass hydrolysates.

In future work, the switchgrass extracts will be further concentrated and fractionated using solid-phase extraction. The fractions will be used in add-back fermentation experiments coupled with LC–MS/MS to test the extent of inhibition of S. cerevisiae and identify the critical fermentation inhibitor(s) with targeted MS2 approaches.

Methods

Feedstock production and composition analysis

Shawnee switchgrass, an upland cultivar, was produced at the Arlington Agricultural Research Station (ARL, 43° 17′ 45″ N, 89° 22′ 48″ W, 315 masl) in Arlington, Wisconsin. Switchgrass was grown on the plot ARL-346 but was harvested in different years (2010 and 2012). The Plano-silt-loam soil type (fine-silty, mixed, superactive, mesic Type Argiudoll); a deep (> 1 m), well-drained mollisol developed over glacial till and formed under tallgrass prairie dominated this region [16, 60]. Ambient growth conditions were described by 6.9 °C of mean annual temperature and 869 mm of average precipitation [61]. The methods for cultivation and nutrient supply are the same as previously reported [17, 62]. Switchgrass was harvested and chopped into a trailer. A representative sample was collected, milled through a 5 mm screen, and stored in plastic bags at ambient conditions until used. Switchgrass harvested in 2010 contained 34.24% glucan, 21.54% xylan, 14.90% total extractives and 17.87% Klason lignin (acid-insoluble lignin). Switchgrass harvested in the drought year (2012) composed 29.36% glucan, 18.91% xylan, 22.14% total extractives and 14.31% Klason lignin. Total biomass composition for the two switchgrass types used in this paper was the same as previously reported by Ong et al. [17] (Additional file 1: Table S1).

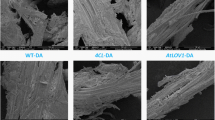

AFEX-pretreatment

Ammonia fiber expansion pretreatment is a completely dry process that uses anhydrous ammonia to disrupt the cell wall to enable enzymes to access the carbohydrates. Custom-made 200 mL stainless-steel tubular reactors rated to 2000 psi were used to pretreat 25 g of switchgrass on dry biomass basis that was lightly packed in the reactor. Unextracted or solvent-extracted switchgrass from drought year (2012) and control year (2010) was adjusted to 60% moisture loading per gram dry biomass prior to pretreatment. The reactor was preheated to 95 °C and loaded with 2 g of anhydrous ammonia per gram of dry biomass using Harvard Apparatus’ HA33 syringe pump. The temperature was ramped to 120 ± 5 °C, at which point, the reaction time was initiated. At the end of 30 min, heating was stopped, and ammonia was vented rapidly inside a well-ventilated walk-in fume hood [63]. The pretreated switchgrass was removed and dried overnight in a custom drying box with laminar airflow to prevent microbial contamination during drying. The dried biomass was bagged in airtight Ziploc bags until further use.

Solvent extraction

Untreated and AFEX-pretreated switchgrass were solvent extracted using a Dionex ASE 350 Accelerated Solvent Extractor (Thermo Scientific). Samples were placed in 100 mL stainless steel extraction cells and extracted at 1600 psi and 100 °C, 70 °C, and 77 °C for water, ethanol, and ethyl acetate, respectively [12, 19, 64]. The cells were heated for about 5 min to reach the target extraction temperature, followed by 7 min of static time to achieve maximum extraction. Three extraction cycles of 100 mL rinse volumes were used to extract compounds selectively using a single extraction cell. The extracted biomass was washed thrice, using 100 mL of room temperature distilled autoclaved water in each wash, to remove any residual solvent from the extraction process [31]. Washed biomass was dried in a custom-designed laminar airflow drying box for 3–6 days until the moisture content was less than 11%. Dried biomass was bagged in airtight Ziploc bags. AFEX pretreatment was then performed, as described previously, on solvent-extracted untreated biomass before enzymatic hydrolysis.

Production of switchgrass hydrolysate

High solids loading enzymatic hydrolysis was performed with 7% glucan loading on each sample for 72 h. Glucan content for the extracted biomass was estimated using mass balances, assuming the solvents did not extract glucan. The sample loading was calculated based on this value to maintain 7% glucan loading for the hydrolysis experiments. Cellulase enzyme Novozyme 22257 and hemicellulase enzyme Novozyme 22244 (Novozymes, Franklinton NC, USA) were desalted using a disposable column (PD-10, Cytiva, VWR 95017-001) and protein concentration was determined using the Pierce™ BCA Protein Assay Kit (Pierce Biotechnology). An enzyme cocktail containing 70% cellulase and 30% hemicellulase by volume was used with a total loading of 25 mg protein per g glucan in the hydrolysate. Monobasic and dibasic potassium phosphates were used to prepare a 1 M stock buffer solution. Phosphate buffer at pH 3.0 and 0.1 M concentration was used to maintain hydrolysis pH between 4.5 and 5.2. Make-up water was added to reach the desired total working volume. Geneticin at a concentration of 12.5 µg/mL was used as an antibiotic to prevent contamination. Hydrolysates were sampled at 0, 24, 48, and 72 h to analyze sugar, alcohol, and acid content. The starting pH of the fermentation hydrolysate was maintained between 5.0 and 5.2 using 12 M hydrochloric acid or 10 M sodium hydroxide. The hydrolysates were sterile filtered using 0.2 µm Stericups© to separate liquid hydrolysates from solids, which were discarded. The sterile filtered liquid hydrolysates were stored at − 20 °C until further use. Two of the replicates (water extracted and ethyl acetate extracted 2010 AFEX switchgrass) experienced contamination during the experiment and were not included in the reported results. A previous study optimized the conditions for high solids loading for AFEX pretreated switchgrass at 7% glucan loading in the hydrolysate [37]. The glucan loading was adjusted to 7% for all extracted samples using mass balances based on the starting glucan composition of each feedstock and the amount of material extracted from each sample. The glucan conversion and glucose yield were calculated using the following formulae.

Fermentation of switchgrass hydrolysate

Fermentations of switchgrass hydrolysates into ethanol by yeast were performed as previously described [33] with modifications. Sterile serum bottles were aliquoted with 4 mL of switchgrass hydrolysate. The Saccharomyces cerevisiae strain GLBRCY945, which was derived from GLBRCY560 [65] and contains an additional flo8 deletion mutation was used for fermentation testing. GLBRCY945 yeast were cultured overnight in YPD (10 g/L yeast extract, 20 g/L peptone, 20 g/L dextrose) and diluted in YPD until the culture reached an OD600 (optical density at 600 nm wavelength) of 0.5 to 1.0. The yeast culture was subsequently centrifuged, resuspended in sterile distilled water and inoculated at an OD600 of 0.2 into sterile 60 mL Wheaton serum bottles containing 4 mL of specific switchgrass hydrolysates. Inoculated serum bottles were sealed with blue butyl 20 mm rubber caps (Chemglass Life Sciences) and then sparged with N2 gas to render the cultures anaerobic. The bottles were shaken on a platform at 120 rpm in a growth chamber set at 30 °C. The serum bottles were connected to respirometer cartridges using BD PrecisionGlide 23GX1 (0.6 mm × 25 mm) sterile needles pierced through the butyl caps. The volume of carbon dioxide generated during the fermentation experiment was quantified using the respirometer (AER-800; Challenge Technology; Springdale, AR, USA) for 45 h. Samples were centrifuged, and supernatants were analyzed at the end of the experiment using high-performance liquid chromatography (HPLC) coupled with refractive index detection (RID) to evaluate sugar and ethanol content [66]. A Beckman DU720 spectrophotometer was used to measure the final background-subtracted cell density (OD600). All experiments were performed in triplicates spread across three different fermentation batches to accommodate biological variability. Moreover, each drought-year sample was paired with the control-year sample to achieve this.

Amino acid analysis

Hydrolysate samples were sent to Creative Proteomics for analysis of 18 different amino acids. Free amino acids were quantitatively analyzed using AB SCIEX API 4000 mass spectrometry (with positive mode electro-spray ionization) connected with a Waters Acquity UPLC. Standards for 21 amino acids were dissolved in 0.1N HCl to prepare a stocking solution of 2.5 µmol/mL. Standards were mixed together and diluted in 0.1% formic acid in water to obtain gradient concentrations from 0.01 nmol/mL to 20 nmol/mL. UPLC–MS/MS was injected with 10 µL of the standards for analysis. Ice-cold methanol with 300 µL was mixed with 100 µL of each sample in a 2 mL tube and vortexed for 1 min. The mixture was centrifuged at 12,000 rpm (17,709×g) and 4 °C for 10 min. The supernatant was passed through 0.22 µm membrane filter into another tube. 10 µL of the prepared sample was injected into the UPLC–MS/MS for the analysis. Water Acquity UPLC HSS T3 column (2.1 × 150 mm 1.8 µm) coupled with a VanGuard precolumn (2.1 × 5 mm 1.8 µm). Mobile phase A consisted pure water with 0.1% formic acid and mobile phase B consisted of acetonitrile with 0.1% formic acid. The column temperature was held at 25 °C with sample chamber temperature at 8 °C. The flow rate was maintained at 0.2 mL/min. The elution gradient was set at (time (min), (%A/%B)): 0(100/0), 8(100/0), 10(90/10), 20(90/10), 20.5(10/90), 22.5(10/90), 23(100/0), 27(100/0).

Non-targeted characterization of liquid chromatography–mass spectrometry (LC–MS)

Extracts were diluted in 1:10 acetonitrile containing 0.1 µM telmisartan as an internal standard. Aliquots of 50 µL were mixed with 50 µL of MilliQ water to improve chromatographic performance, and the solutions were transferred to glass autosampler vials for analysis. Extracts were analyzed using liquid chromatography/mass spectrometry (LC/MS) on a Xevo G2-XS mass spectrometer interfaced to an Acquity I-class UPLC system and model 2777 autosampler (Waters Corp., Milford, MA USA). Separations were performed using a BEH C18 column (2.1 × 100 mm, 1.7 µm particles, Waters) held at 40 °C using linear gradient elution based on solvent A = 10 mM aqueous ammonium formate and solvent B = acetonitrile programmed as follows (time (min), %A/%B): 0.0 (99/1), 1.0 (99/1), 15.0 (1/99), 18.0 (1/99); 18.01 (99/1), 20.0 (99/1) at a total flow rate of 0.40 mL/min, with injection of 10 µL of extract. Mass spectra were acquired over the range of m/z 80–1500 using electrospray ionization in positive-ion continuum mode and extended dynamic range. Quasi-simultaneous of low-energy (6 V) and high-energy (ramp from 15 to 80 V) spectra (MSE acquisition, using argon as collision gas) was performed using a scan time of 0.2 s/function with the acquisition of spectra of leucine enkephalin (lock mass reference) sampled every 10 s, but real-time mass correction was not applied. Separate injections were made with analysis in negative-ion mode, with all other parameters remaining the same. All instrument control was managed using MassLynx v 4.2 software (Waters Corp.).

LC–MS data processing

Raw MassLynx data files were imported into Progenesis QI software (v 2.4; Waters Corp.). Default parameters were used for thresholding, and Progenesis software performed peak detection, chromatographic retention time alignment, mass correction using leucine enkephalin lock mass reference, peak integration, isotopic, and adduct deconvolution, and normalization to the signal from the telmisartan internal standard. To aid annotation, experimental compound masses were used to calculate relative mass defect (RMD) values which reflect the fractional hydrogen content of each [67, 68]. Metabolite annotations were performed using a combination of manual spectrum interpretation supported by searches of multiple ChemSpider spectrum databases with a mass tolerance of 10 ppm.

Microplate fermentation experiment

Seed culture was prepared by inoculating 6 individual colonies of Saccharomyces cerevisiae (GLBRCY945) from a freshly prepared agar plate in 100 mL of YPD media (10 g/L yeast extract and 20 g/L peptone was autoclaved, and 75 g/L dextrose solution was passed through 0.2 µm PES filter) in a shake flask for 12 h. Inoculum volume of seed culture was calculated to target OD of 7.4, so that the final microplate OD of ~ 0.1 was reached. Cells were centrifuged at 4000 rpm (3220×g) for 5 min at 22 °C. The supernatant was removed, and cell pellet was resuspended in freshly prepared YPD media (10 g/L yeast extract and 20 g/L peptone was autoclaved, and 20 g/L dextrose solution (0.2 µm sterile-filtered)). Fermentation experiments were performed in a flat-bottom 96-well plate with a well volume of 300 µL. A working volume was maintained at 200 µL with three technical replicates for each sample. Blank samples with no inoculum were present for each media. Eppendorf Research® plus 8-channel mechanical pipette was used to inoculate 65 µL of seed culture at the same time for each replicate. Sterile transparent microplate sealing film was used to seal the microplate for fermentation. Each well was pierced with 2 tiny holes that were diagonally opposite at the edge of each well to prevent carbon dioxide build-up and formation of large condensation bubbles over the course of fermentation. The microplate was placed inside a VWR® Barnstead static incubator at a temperature of 30 °C throughout the course of the experiment. The absorbance of the samples was quantified at 600 nm over 24 h using a microplate reader (Epoch 238451, BioTek Instruments, Inc.). YPD (10 g/L yeast extract and 20 g/L peptone was autoclaved, and 20 g/L dextrose solution (0.2 µm sterile-filtered)) was used as positive control and distilled autoclaved water was used as a negative control for S. cerevisiae growth.

References

Barragán-Ocaña A, Silva-Borjas P, Olmos-Peña S, Polanco-Olguín M. Biotechnology and bioprocesses: their contribution to sustainability. Processes. 2020;8(4):436.

Dale BE, Bals BD, Kim S, Eranki P. Biofuels done right: land efficient animal feeds enable large environmental and energy benefits. Environ Sci Technol. 2010;44(22):8385–9.

Geddes CC, Nieves IU, Ingram LO. Advances in ethanol production. Curr Opin Biotechnol. 2011;22(3):312–9.

Taha M, Foda M, Shahsavari E, Aburto-Medina A, Adetutu E, Ball A. Commercial feasibility of lignocellulose biodegradation: possibilities and challenges. Curr Opin Biotechnol. 2016;38:190–7.

Lee JW, Trinh CT. Microbial biosynthesis of lactate esters. Biotechnol Biofuels. 2019;12:226.

Liu Y, Zhang X, Tran H, Shan L, Kim J, Childs K, Ervin EH, Frazier T, Zhao B. Assessment of drought tolerance of 49 switchgrass (Panicum virgatum) genotypes using physiological and morphological parameters. Biotechnol Biofuels. 2015;8:152.

Wang C, Chen L, et al. Dynamic variations in multiple bioactive constituents under salt stress provide insight into quality formation of licorice. ProQuest Molecules. 2019;24(20):3670.

Germec M, Ozcan A, Turhan I. Bioconversion of wheat bran into high value-added products and modelling of fermentations. Ind Crops Prod. 2019;139:111565.

Ben Mansour-Gueddes S, Saidana-Naija D, Bchir A, Braham M. Climate change effects on phytochemical compounds and antioxidant activity of Olea europaea. Notulae Botanicae Horti Agrobotanici Cluj-Napoca. 2020;48(1):436–55.

Herrera MD, Acosta-Gallegos JA, Reynoso-Camacho R, Perez-Ramirez IF. Common bean seeds from plants subjected to severe drought, restricted- and full-irrigation regimes show differential phytochemical fingerprint. Food Chem. 2019;294:368–77.

Al-Rowaily SL, Abd-ElGawad AM, Alghanem SM, Al-Taisan WA, El-Amier YA. Nutritional value, mineral composition, secondary metabolites, and antioxidant activity of some wild geophyte sedges and grasses. Plants. 2019;8(12):569.

Lindsey K, Johnson A, Kim P, Jackson S, Labbé N. Monitoring switchgrass composition to optimize harvesting periods for bioenergy and value-added products. Biomass Bioenerg. 2013;56:29–37.

Gregorova Z, Kovacik J, Klejdus B, Maglovski M, Kuna R, Hauptvogel P, Matusikova I. Drought-induced responses of physiology, metabolites, and PR proteins in Triticum aestivum. J Agric Food Chem. 2015;63(37):8125–33.

Maritim TK, Kamunya SM, Mireji P, Mwendia C, Muoki RC, Cheruiyot EK, Wachira FN. Physiological and biochemical response of Tea [Camellia sinensis (L.) O Kuntze] to Water-Deficit Stress. J Hortic Sci Biotechnol. 2015;90(4):395–400.

Arias C, Serrat X, Moysset L, Perissé P, Nogués S. Morpho-physiological responses of alamo switchgrass during germination and early seedling stage under salinity or water stress conditions. BioEnergy Res. 2018;11(3):677–88.

Lee ST, Mitchell RB, Wang Z, Heiss C, Gardner DR, Azadi P. Isolation, characterization, and quantification of steroidal saponins in switchgrass. J Agric Food Chem. 2009;57:2599–604.

Ong RG, Higbee A, Bottoms S, Dickinson Q, **e D, Smith SA, Serate J, Pohlmann E, Jones AD, Coon JJ, et al. Inhibition of microbial biofuel production in drought-stressed switchgrass hydrolysate. Biotechnol Biofuels. 2016;9:237.

Zhao X, Zhang L, Liu D. Biomass recalcitrance. Part II: fundamentals of different pre-treatments to increase the enzymatic digestibility of lignocellulose. Biofuels Bioprod Biorefin. 2012;6(5):561–79.

Chundawat SP, Vismeh R, Sharma LN, Humpula JF, da Costa SL, Chambliss CK, Jones AD, Balan V, Dale BE. Multifaceted characterization of cell wall decomposition products formed during ammonia fiber expansion (AFEX) and dilute acid based pretreatments. Biores Technol. 2010;101(21):8429–38.

Ong RG, Shinde S, da Costa SL, Sanford GR. Pre-senescence harvest of switchgrass inhibits xylose utilization by engineered yeast. Front Energy Res. 2018;6:52.

Sun C, **a A, Liao Q, Guo X, Fu Q, Huang Y, Zhu X, Ding L, Chen C. Inhibitory effects of furfural and vanillin on two-stage gaseous biofuel fermentation. Fuel. 2019;252:350–9.

Hou J, Tang J, Chen J, Zhang Q. Quantitative structure-toxicity relationship analysis of combined toxic effects of lignocellulose-derived inhibitors on bioethanol production. Biores Technol. 2019;289: 121724.

Du B, Sharma LN, Becker C, Chen SF, Mowery RA, van Walsum GP, Chambliss CK. Effect of varying feedstock-pretreatment chemistry combinations on the formation and accumulation of potentially inhibitory degradation products in biomass hydrolysates. Biotechnol Bioeng. 2010;107(3):430–40.

Dickinson Q, Bottoms S, Hinchman L, McIlwain S, Li S, Myers CL, Boone C, Coon JJ, Hebert A, Sato TK, et al. Mechanism of imidazolium ionic liquids toxicity in ī and rational engineering of a tolerant, xylose-fermenting strain. Microb Cell Fact. 2016;15:17.

Bottoms S, Dickinson Q, McGee M, Hinchman L, Higbee A, Hebert A, Serate J, **e D, Zhang Y, Coon JJ, et al. Chemical genomic guided engineering of gamma-valerolactone tolerant yeast. Microb Cell Fact. 2018;17(1):5.

Tao J, Rajan K, Ownley B, Gwinn K, D’Souza D, Moustaid-Moussa N, Tschaplinski TJ, Labbé N. Natural variability and antioxidant properties of commercially cultivated switchgrass extractives. Ind Crops Prod. 2019;138:111474.

Cowan MM. Plant products as antimicrobial agents. Clin Microbiol Rev. 1999;12(4):564–82.

Li X, Sarma SJ, Sumner LW, Jones AD, Last RL. Switchgrass metabolomics reveals striking genotypic and developmental differences in specialized metabolic phenotypes. J Agric Food Chem. 2022;70(26):8010–23.

Qi HY, Li L, Ma H. Cellular stress response mechanisms as therapeutic targets of ginsenosides. Med Res Rev. 2018;38(2):625–54.

Barros F, Dykes L, Awika JM, Rooney LW. Accelerated solvent extraction of phenolic compounds from sorghum brans. J Cereal Sci. 2013;58(2):305–12.

Xue S, Jones AD, Sousa L, Piotrowski J, ** M, Sarks C, Dale BE, Balan V. Water-soluble phenolic compounds produced from extractive ammonia pretreatment exerted binary inhibitory effects on yeast fermentation using synthetic hydrolysate. PLoS ONE. 2018;13(3): e0194012.

Garlock RJ, Balan V, Dale BE, Pallapolu VR, Lee YY, Kim Y, Mosier NS, Ladisch MR, Holtzapple MT, Falls M, et al. Comparative material balances around pretreatment technologies for the conversion of switchgrass to soluble sugars. Biores Technol. 2011;102(24):11063–71.

Chandrasekar M, Joshi L, Krieg K, Chipkar S, Burke E, Debrauske DJ, Thelen KD, Sato TK, Ong RG. A high solids field-to-fuel research pipeline to identify interactions between feedstocks and biofuel production. Biotechnol Biofuels. 2021;14(1):1–7.

Li C, Cheng G, Balan V, Kent MS, Ong M, Chundawat SP, Sousa L, Melnichenko YB, Dale BE, Simmons BA, et al. Influence of physico-chemical changes on enzymatic digestibility of ionic liquid and AFEX pretreated corn stover. Biores Technol. 2011;102(13):6928–36.

Flores-Gomez CA, Escamilla Silva EM, Zhong C, Dale BE, da Costa SL, Balan V. Conversion of lignocellulosic agave residues into liquid biofuels using an AFEX-based biorefinery. Biotechnol Biofuels. 2018;11:7.

Bals BD, Gunawan C, Moore J, Teymouri F, Dale BE. Enzymatic hydrolysis of pelletized AFEX-treated corn stover at high solid loadings. Biotechnol Bioeng. 2014;111(2):264–71.

Serate J, **e D, Pohlmann E, Donald C Jr, Shabani M, Hinchman L, Higbee A, McGee M, La Reau A, Klinger GE, et al. Controlling microbial contamination during hydrolysis of AFEX-pretreated corn stover and switchgrass: effects on hydrolysate composition, microbial response and fermentation. Biotechnol Biofuels. 2015;8:180.

Michel M, Meier-Dörnberg T, Jacob F, Schneiderbanger H, Hutzler M. Optimisation of yeast vitality measurement to better predict fermentation performance. J Inst Brew. 2020;126(2):161–7.

Gea C. Improved control of brewery yeast pitching using image analysis. J Am Soc Brew Chem. 1999;57(2):72–8.

Lau MW, Dale BE, Balan V. Ethanolic fermentation of hydrolysates from ammonia fiber expansion (AFEX) treated corn stover and distillers grain without detoxification and external nutrient supplementation. Biotechnol Bioeng. 2008;99(3):529–39.

Lama-Munoz A, Contreras MDM, Espinola F, Moya M, Romero I, Castro E. Content of phenolic compounds and mannitol in olive leaves extracts from six Spanish cultivars: extraction with the Soxhlet method and pressurized liquids. Food Chem. 2020;320: 126626.

Alcázar M, Kind T, Gschaedler A, Silveria M, Arrizon J, Fiehn O, Vallejo A, Higuera I, Lugo E. Effect of steroidal saponins from Agave on the polysaccharide cell wall composition of Saccharomyces cerevisiae and Kluyveromyces marxianus. LWT Food Sci Technol. 2017;77:430–9.

Kaczorek E, Chrzanowski L, Pijanowska A, Olszanowski A. Yeast and bacteria cell hydrophobicity and hydrocarbon biodegradation in the presence of natural surfactants: Rhamnolipides and saponins. Bioresour Technol. 2008;99(10):4285–91.

Dewick PM. Steroidal saponins. In: Medicinal Natural Products - A Biosynthetic Approach. Wiley; 2011: 90–97.

Mathew AK, Parameshwaran B, Sukumaran RK, Pandey A. An evaluation of dilute acid and ammonia fiber explosion pretreatment for cellulosic ethanol production. Biores Technol. 2016;199:13–20.

Sundaram V, Muthukumarappan K, Gent S. Understanding the impacts of AFEX pretreatment and densification on the fast pyrolysis of corn stover, prairie cord grass, and switchgrass. Appl Biochem Biotechnol. 2017;181(3):1060–79.

** M, da Costa SL, Schwartz C, He Y, Sarks C, Gunawan C, Balan V, Dale BE. Toward lower cost cellulosic biofuel production using ammonia based pretreatment technologies. Green Chem. 2016;18(4):957–66.

Sundaram V, Muthukumarappan K, Kamireddy SR. Effect of ammonia fiber expansion (AFEX™) pretreatment on compression behavior of corn stover, prairie cord grass and switchgrass. Ind Crops Prod. 2015;74:45–54.

Zhang Y, Oates LG, Serate J, **e D, Pohlmann E, Bukhman YV, Karlen SD, Young MK, Higbee A, Eilert D, et al. Diverse lignocellulosic feedstocks can achieve high field-scale ethanol yields while providing flexibility for the biorefinery and landscape-level environmental benefits. GCB Bioenergy. 2018;10(11):825–40.

Lau MD, Bruce DE. Cellulosic ethanol production from AFEX-treated corn stover using Saccharomyces cerevisiae 424A(LNH-ST). PNAS. 2009;106(5):1368–73.

Puente-Garza CA, Meza-Miranda C, Ochoa-Martinez D, Garcia-Lara S. Effect of in vitro drought stress on phenolic acids, flavonols, saponins, and antioxidant activity in Agave salmiana. Plant Physiol Biochem. 2017;115:400–7.

Karamian R, Ghasemlou F, Amiri H. Physiological evaluation of drought stress tolerance and recovery in Verbascum sinuatum plants treated with methyl jasmonate, salicylic acid and titanium dioxide nanoparticles. Plant Biosyst. 2019;154(3):277–87.

Zhou L. Physiological mechanisms of salt and drought induced stress effects on root biomass and secondary metabolites in Stellaria dichotoma. Int J Agric Biol. 2019;22(6):1285–92.

Li KK, Li SS, Xu F, Gong XJ. Six new dammarane-type triterpene saponins from Panax ginseng flower buds and their cytotoxicity. J Ginseng Res. 2020;44(2):215–21.

Sastre F, Ferreira F, Pedreschi F. TLC fingerprint of phenolics and saponins in commercial extracts of Yucca schidigera Roezl. J Liq Chromatogr Relat Technol. 2016;39(15):698–701.

Nyberg N, Baumann H, Kenne L. Solid-phase extraction NMR studies of chromatographic fractions of saponins from Quillaja saponaria. Anal Chem. 2003;75:268–74.

Ibrahim M, Khan AA, Tiwari SK, Habeeb M-A, Khaja M-N, Habibullah C-M. Antimicrobial activity of Sapindus mukorossi and Rheum emodi extracts against H. pylori: in vitro and in vivo studies. World J Gastroenterol. 2006;12:7136–42.

Heng W, Ling Z, Na W, Youzhi G, Zhen W, Zhiyong S, De** X, Yunfei X, Weirong Y. Analysis of the bioactive components of Sapindus saponins. Ind Crops Prod. 2014;61:422–9.

Juang YP, Liang PH. Biological and pharmacological effects of synthetic saponins. Molecules. 2020;25(21):4974.

Shao Q, Zhao C. Assessment of the lignin-derived inhibition of enzymatic hydrolysis by adding untreated and ammonia-fiber-expansion-treated lignin isolated from switchgrass. Energy Fuels. 2016;30(11):9517–23.

National Weather Website (https://www.weather.gov/)

Alsuhaim H, Vojisavljevic V, Pirogova E. Effects of non-thermal microwave exposures on the proliferation rate of Saccharomyces cerevisiae Yeast. In: World Congress on Medical Physics and Biomedical Engineering May 26–31, 2012, Bei**g, China. 2013: 48–51.

Chundawat SPS, Pal RK, Zhao C, Campbell T, Teymouri F, Videto J, Nielson C, Wieferich B, Sousa L, Dale BE, et al. Ammonia fiber expansion (AFEX) pretreatment of lignocellulosic biomass. J Vis Exp. 2020. https://doi.org/10.3791/57488.

Pearson CH, Cornish K, Rath DJ. Extraction of natural rubber and resin from guayule using an accelerated solvent extractor. Ind Crops Prod. 2013;43:506–10.

Lee SB, Tremaine M, Place M, Liu L, Pier A, Krause DJ, **e D, Zhang Y, Landick R, Gasch AP, et al. Crabtree/Warburg-like aerobic xylose fermentation by engineered Saccharomyces cerevisiae. Metab Eng. 2021;68:119–30.

Schwalbach MS, Keating DH, Tremaine M, Marner WD, Zhang Y, Bothfeld W, Higbee A, Grass JA, Cotten C, Reed JL, et al. Complex physiology and compound stress responses during fermentation of alkali-pretreated corn stover hydrolysate by an Escherichia coli ethanologen. Appl Environ Microbiol. 2012;78(9):3442–57.

Ekanayaka EA, Celiz MD, Jones AD. Relative mass defect filtering of mass spectra: a path to discovery of plant specialized metabolites. Plant Physiol. 2015;167(4):1221–32.

Stagliano MC, DeKeyser JG, Omiecinski CJ, Jones AD. Bioassay-directed fractionation for discovery of bioactive neutral lipids guided by relative mass defect filtering and multiplexed collision-induced dissociation. Rapid Commun Mass Spectrom. 2010;24(24):3578–84.

Acknowledgements

The authors thank Novozymes for providing the enzymes used for enzymatic hydrolysis experiments. They are grateful to M. McGee and the GLBRC Metabolomics Core Facility for performing HPLC analysis on enzymatic and fermentation hydrolysates, Dr. Afrand Kamali Sarvestani for preliminary investigations documenting high levels of saponins in switchgrass, Drs. Tony Schilmiller and Cassandra Johnny of the Mass Spectrometry and Metabolomics Core at Michigan State University for performing LC/MS metabolite profiling, Dr. Maggie Taylor and Sophie Ren of Creative Proteomics for analysing amino acids in switchgrass hydrolysates and Sulihat Aloba for performing HPLC analysis on extracts for composition analysis of extracted biomass.

Funding

This study was supported by the Great Lakes Bioenergy Research Center, U.S. Department of Energy, Office of Science, Office of Biological and Environmental Research under Award Number DE-SC0018409. ADJ acknowledges support from the USDA National Institute of Food and Agriculture, Hatch project number MICL02474.

Author information

Authors and Affiliations

Contributions

RGO designed the hydrolysis and fermentation experiment. SC performed extractions, AFEX pretreatment and enzymatic hydrolysis experiments; designed and performed microplate fermentation experiments; prepared samples for LC–MS and lignotoxins analysis; performed composition analysis on extracted biomass and, co-ordinated the entire project. MG contributed toward extraction on Accelerated solvent extractor (ASE 350), while KS and LHM assisted in AFEX-pretreatment. EMW, DJD and TKS conducted fermentation experiments using respirometer apparatus. AJ, KAO, JJC and ADJ ran and analyzed the lignotoxins assay and LC–MS data. AS assisted in performing composition analysis on the extracted biomass. SC led the manuscript writing with valuable inputs from RGO and all the authors. All authors edited and revised the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests. JJC is a consultant for Thermo Fisher Scientific.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Additional file 1.

Supplemental methods and data: biomass composition, hydrolysate composition, and statistical analyses.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated in a credit line to the data.

About this article

Cite this article

Chipkar, S., Smith, K., Whelan, E.M. et al. Water-soluble saponins accumulate in drought-stressed switchgrass and may inhibit yeast growth during bioethanol production. Biotechnol Biofuels 15, 116 (2022). https://doi.org/10.1186/s13068-022-02213-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s13068-022-02213-y