Abstract

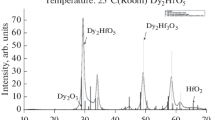

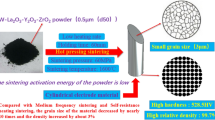

Gadolinium hafnate (Gd2HfO5) powders are obtained by mechanochemical synthesis from hafnium and gadolinium oxides. XRD, chemical analysis, and scanning and transmission electron microscopy show the transition of initial oxides into single-phase nanodisperse gadolinium hafnate after 30 min of mechanochemical synthesis. This powder is studied for its compactibility and sintering.

Similar content being viewed by others

REFERENCES

Sickafus, K.E., Grimes, R.W., Valdez, J.A., Cleave, A., Ming, T., Ishimaru, M., Corish, S.M., Stanek, C.R., and Uberuaga, B.P., Radiation-induced amorphization resistance and radiation tolerance in structurally related oxides, Nat. Mater., 2007, no. 6, pp. 217–223.

Pisovanyi, V.D., Varlashova, E.E., Fridman, S.P., Ponomarenko, V.B., and Shcheglov, A.V., Comparative characteristics of absorber cluster assemblies of VVÉR-1000 and PWR reactors, At. Energy, 1998, vol. 84, pp. 372–377. https://doi.org/10.1007/BF02413895

Belash, N.N., Kushtym, A.V., Tatarinov, V.R., and Chernov, I.A., Analysis of the development of structures and materials of pels AR CPS of increased efficiency, Yad. Radiats. Tekhnol., 2007, vol. 7, nos. 3–4, pp. 18–28.

Risovannyi, V.D., Zakharov, A.V., and Muraleva, E.M., New promising absorbing materials for thermal neutron nuclear reactors, Vopr. At. Nauki Tekh., Fiz. Radiats. Povrezh. Radiats. Materialoved., 2005, vol. 86, no. 3, pp. 87–93.

Risovany, V.D., Zakharov, A.V., Muraleva, E.M., Kosenkov, V.M., and Latypov, R.N., Dysprozium hafnate as absorbing material for control rods, J. Nucl. Mater., 2006, vol. 355, pp. 163–170.

Fridman, S.R., Risovany, V.D., et al., Radiation stability of WWER-1000 CPS AR absorber element with boron carbide, VANT. Phys. Radiat. Damages Radiat. Sci. Mater., 2001, no. 2, pp. 84–90.

Abdusalyamova, M.N., Kabgov, Kh.B., and Makhmudov, F.A., Receipt and properties of monostructured dysprosium oxide, Dokl. Akad. Nauk Resp. Tadzhikistan, 2013, vol. 56, no. 2, pp. 130–135.

Khalameida, S.V., Some new approaches in the mechanochemical synthesis of nanodisperse barium titanate, Nanosist., Nanomater., Nanotekhnol., 2009, vol. 7, no. 3, pp. 911–918.

Lyashenko, L.P., Shcherbakova, L.G., Kolbanev, I.V., Knerel’man, E.I., and Davydova, G.I., Mechanism of structure formationin samarium and holmium titanates prepared from mechanically activated oxides, Inorg. Mater., 2007, vol. 43, no. 1, pp. 46–54.

Szafraniak-Wiza, I., Hilczer, B., Talik, E., Pietraszko, A., and Malic, B., Ferroelectric perovskite nanopowders obtained by mechanochemical synthesis, Process. Appl. Ceram., 2010, no. 4, pp. 99–106.

Safronova, T.V., Sadilov, I.S., Chaikun, K.V., Shatalova, T.B., and Filippov, Ya.Yu., Ceramics based on a powder mixture of calcium hydroxyapatite, monocalcium phosphate monohydrate, and sodium hydrogen phosphate homogenized under mechanical activation conditions, Inorg. Mater.: Appl. Res., 2020, vol. 11, pp. 879–885. https://doi.org/10.1134/S2075113320040346

Shindo, D. and Oikawa, T., Analytical Electron Microscopy for Materials Science, Tokyo: Springer, 2002. https://doi.org/10.1007/978-4-431-66988-3

Zakharov, A.V., Risovanyi, V.D., Muraleva, E.M., and Sokolov, V.F., Development and development of production of dysprosium hafnate as an absorbing material for regulators of promising thermal neutron reactors, Sb. Tr. OAO “GNTs NIIAR,” 2011, vol. 2, pp. 8–13.

Perova, E.B., Spiridonov, L.N., and Komissarova, L.N., Phase equilibria in the HfO2–Dy2O3 system, Izv. Akad. Nauk SSSR. Neorg. Mater., 1982, vol. 8, no. 10, pp. 1878–1882.

Popov, V.V., Menushenkov, A.P., Zubavichus, Ya.V., Veligzhanin, A.A., Yaroslavtsev, A.A., et al., Trends in formation of the nanocrystalline structure and cationic ordering in the Dy2O3:HfO2 (1:1) system, Russ. J. Inorg. Chem., 2013, vol. 58, pp. 331–337. https://doi.org/10.1134/S0036023613030121

Popov, V.V., Menushenkov, A.P., Zubavichus, Ya.V., Korovin, S.A., Fortal’nova, E.A., et al., Structural characteristics and thermophysical properties of complex ceramic oxides in the system Dy2O3–HfO2, Glass Ceram., 2016, vol. 73, pp. 47–52. https://doi.org/10.1007/s10717-016-9823-x

Voronko, Yu.K., Sobol, A.A., and Shukshin, V.E., Monoclinic-tetragonal phase transition in zirconium and hafnium dioxides: A high-temperature Raman scattering investigation, Phys. Solid State, 2007, vol. 49, no. 10, pp. 1963–1968. https://doi.org/10.1134/S1063783407100253

Prokip, V.E., Cand. Sci. (Chem.) Dissertation, Novosibirsk, 2017.

Funding

This study was financially supported by Russian Foundation for Basic Research (project no. 19‑08‑00273).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by N. Saetova

Rights and permissions

About this article

Cite this article

Eremeeva, Z.V., Vorotylo, S.A., Kaplanskii, Y.Y. et al. Study of Pressing and Sintering of Gd2HfO5 Powder Obtained by Mechanochemical Synthesis. Inorg. Mater. Appl. Res. 13, 936–939 (2022). https://doi.org/10.1134/S2075113322040116

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2075113322040116