Abstract

We performed high-temperature treatment of the Ni–C, Al–C, and Ni–Al–C powder mixtures (5 wt % C (soot)) up to the melting point of the respective metals and found that the melt particles coagulate with formation of Ni, Al, and NiAl (intermetallic) spherical particles, respectively. The Ni particles have almost perfect spherical shape and a multilayer graphite coating. The NiAl particles have a thin graphene (graphite) coating.

Similar content being viewed by others

REFERENCES

Liu, Y.-L., Dai, Z.-H., and Wang, W.-T., Influence of carbon – vacancy interaction on carbon and vacancy diffusivity in tungsten, Comput. Mater. Sci., 2014, vol. 83, pp. 1–4. https://doi.org/10.1016/j.commatsci.2013.10.034

Liu, Y.-L., Zhou, H.-B., Zhang, Y., and Duan, C., Point defect concentrations of impurity carbon in tungsten, Comput. Mater. Sci., 2012, vol. 62, pp. 282–284. https://doi.org/10.1016/j.commatsci.2012.05.012

Liu, Y.-L., Zhou, H.-B., Zhang, Y., Lu, G.-H., and Luo, G.-N., Interaction of C with vacancy in W: A first-principles study, Comput. Mater. Sci., 2011, vol. 50, no. 11, pp. 3213–3217. https://doi.org/10.1016/j.commatsci.2011.06.003

Hua, X., Ma, J., Dou, H., Niu, Y., Zhang, Y., and Song, Q., Effects of C impurities on the elastic properties of NiAl intermetallics, Prog. Nat. Sci.: Mater. Int., 2014, vol. 24, no. 6, pp. 637–641. https://doi.org/10.1016/j.pnsc.2014.10.007

Razumovskii, I.M., Ruban, A.V., Razumovskiy, V.I., Logunov, A.V., Larionov, V.N., Ospennikova, O.G., Poklad, V.A., and Johansson, B., New generation of Ni-based superalloys design on the basis of first principles calculations, Mater. Sci. Eng., A 2008, vol. 497, nos. 1–2, pp. 18–24. https://doi.org/10.1016/j.msea.2008.08.013

Razumovskiy, V.I., Lozovoi, A.Y., and Razumovskii, I.M., First principles-aided design of new Ni-base superalloy. Influence of transition metal alloying elements on grain boundary and bulk cohesion, Acta Mater., 2015, vol. 82, pp. 369–377. https://doi.org/10.1016/j.actamat.2015.12.030

Modern Methods of Crystal Structure Prediction, Oga-nov, A.R., Ed., Berlin: Wiley-VCH, 2010. ISBN 978-3-527-40939-6

Zhang, H.F., Dohnalkova, A.C., Wang, C.M., Young, J.S., Buck, E.C., and Wang, L.S., Lithium-assisted self-assembly of aluminum carbide nanowires and nanoribbons, Nano Lett., 2002, vol. 2, no. 2, pp. 105–108. https://doi.org/10.1021 / nl015656k

He, C.N., Zhao, N.Q., Shi, C.S., and Song, S.Z., Fabrication of aluminum carbide nanowires by a nano-template reaction, Carbon, 2010, vol. 48, pp. 931–938. https://doi.org/10.1016/j.carbon.2009.10.004

Sun, Y., Cui, H., Gong, L., Chen, J., Shen, P.K., and Wang, C.X., Field nanoemitter: One-dimension Al4C3 ceramics, Nanoscale, 2011, vol. 3, pp. 2978–2982. https://doi.org/10.1039/c1nr10194c

Portnoi, V.K., Leonov, A.V., Logacheva, A.I., and Logacheva, A.V., Mechanochemical synthesis and compaction of intermetallic alloys containing nanocrystalline substructure elements, Bull. Russ. Acad. Sci.: Phys., 2012, vol. 76, no. 1, pp. 61–63. https://doi.org/10.3103/S1062873812010236

Portnoi, V.K., Leonov, A.V., Logachev, A.V., Streletskii, A.N., and Popov, V.A., Mechanical alloying as method for introducing carbon in Ni3Al intermetallide, Phys. Met. Metallogr., 2012, vol. 113, pp. 1169–1181. https://doi.org/10.1134/S0031918X12120083

Portnoi, V.K., Leonov, A.V., Fadeeva, V.I., and Fedotov, S.A., Mechanochemical synthesis in the Ni–Al–C system, Bull. Russ. Acad. Sci.: Phys., 2007, vol. 71, no. 12, pp. 1693–1696.

Bubnenkov, I.A., Shevyakov, V.P., Shipkov, N.N., Nikelina, T.A., and Bubnenkov, V.I., Influence of carbon concentration in nickel melt on the process of interaction with various carbon materials, Tsvetn. Met., 1998, no. 4, pp. 55–57.

Ip, S.W., Sridhar, R., Toguri, J.M., Stephenson, T.F., and Warner, A.E.M., Wettability of nickel coated graphite by aluminum, Mater. Sci. Eng., A, 1998, vol. 244, no. 1, pp. 31–38. https://doi.org/10.1016/S0921-5093(97)00823-X

Merzhanov, A.G., The chemistry of self-propagating high-temperature synthesis, J. Mater. Chem., 2004, vol. 14, pp. 1779–1791. https://doi.org/10.1039/B401358C

Shelton, J.C., Patil, H.R., and Blakely, J.M., Equilibrium segregation of carbon to a nickel (111) surface: A surface phase transition, Surf. Sci., 1974, vol. 43, pp. 493–520. https://doi.org/10.1016/0039-6028(74)90272-6

Rut’kov, E.V., Afanas’eva, E.Yu., Petrov, V.N., and Gall, N.R., Fabrication of graphene and graphite films on the Ni(111) surface, Tech. Phys., 2016, vol. 61, no. 11, pp. 1724–1728. https://doi.org/10.1134/S1063784216110219

Bleu, Y., Barnier, V., Christien, F., Bourquard, F., Loir, A.-S., and Garrelie, F., Dynamics of carbon diffusion and segregation through nickel catalyst, investigated by in-situ XPS, during the growth of nitrogen-doped grapheme, Carbon, 2019, vol. 155, pp. 410–420. https://doi.org/10.1016/j.carbon.2019.08.084

Sytschev, A.E., Vadchenko, S.G., Boyarchenko, O.D., and Shchukin, A.S., Ni3Al/C composites by thermal explosion, Int. J. Self-Propag. High-Temp. Synth., 2018, vol. 27, no. 1, pp. 64–65. https://doi.org/10.3103/S1061386218010090

Sytschev, A.E., Kochetov, N.A., Vadchenko, S.G., Kovalev, D.Yu., and Shchukin, A.S., Processing of Ni–Al intermetallic with 2D carbon components, Mater. Chem. Phys., 2019, vol. 238, art. ID 121898. https://doi.org/10.1016/j.matchemphys.2019.121898

Shcherbakov, A.V. and Sychev, A.E., Synthesis of Ni–Al–C composite with multilayer carbon components by electrothermal explosion under pressure, Fiz. Goreniya Vzryva (in press).

Sytschev, A.E., Kochetov, N.A., and Shchukin, A.S., Structure and properties of SPS-produced carbon-containing NiAl, Int. J. Self-Propag. High-Temp. Synth., 2020, vol. 29, no. 2, pp. 58–60. https://doi.org/10.3103/S1061386220010124

Kochetov, N.A. and Sychev, A.E., Effect of carbon content and mechanical activation on the combustion of a Ni–Al–C system, Combust., Explos. Shock Waves, 2019, vol. 55, no. 6, pp. 686–691. https://doi.org/10.1134/S001050821906008X

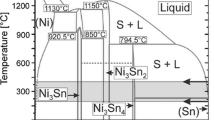

Lyakishev, N.P., Diagrammy sostoyaniya dvoinykh metallicheskikh sistem (Constitution Diagrams of Binary Metallic Systems), Moscow: Mashinostroenie, 1996, vols. 1–3.

Loktyushin, V.A., Adamenko, N.A., and Gurevich, L.M., Kontaktnye vzaimodeistviya v kompozitsionnykh materialakh: Uchebnoe posobie (Contact Interactions in Composite Materials: Handbook), Volgograd: Volgograd State Tech. Univ., 2003.

Nikolenko, Yu.M. and Ziatdinov, A.M., Nanographites and their film structures on various substrates, Khim. Khim. Tekhnol., 2015, vol. 58, no. 7, pp. 36–40.

Titorov, D.B., Self-organization of atoms into nanostructures, Materialovedenie, 2011, no. 12, pp. 2–10.

Schuster, J.C. and Nowotny, H., The ternary system Nickel– Aluminum–Carbon, Monatsh. Chem., 1982, vol. 113, pp. 163–170.

Shustin, E.G., Isaev, N.V., Luzanov, V.A., and Temiryazeva, M.P., Formation of thin graphite films upon carbon diffusion through nickel, Tech. Phys., 2017, vol. 62, no. 7, pp. 1069–1072. https://doi.org/10.1134/S1063784217070210

Amini, S., Kalaantari, H., Garay, J., Balandin, A.A., and Abbaschian, R., Growth of graphene and graphite nanocrystals from a molten phase, J. Mater. Sci., 2011, vol. 46, pp. 6255–6263.

Funding

This work was supported by the Russian Foundation for Basic Research, project no. 18‑08‑00181.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by I. Dikhter

Rights and permissions

About this article

Cite this article

Vadchenko, S.G., Shchukin, A.S., Sytschev, A.E. et al. Peculiarities of Structure Formation in Ni–C, Al–C, and Ni–Al–C Systems at High-Temperature Heating. Inorg. Mater. Appl. Res. 13, 1–6 (2022). https://doi.org/10.1134/S2075113322010385

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2075113322010385