Abstract

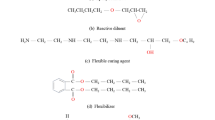

The idea of sustainable and circular utilization of difficult to decompose plastics is pursued to add value to other products. New epoxy mortars suitable for construction repair made from epoxy oligomer, amine and modified PET waste hardeners mixed with sand were prepared. Three types of carboxyl terminated PET (CTPET) were used as co-hardeners, along with an amine, to prepare new combination linkage epoxy mortars. Investigation of the viscoelastic properties revealed that the CTPETs influenced the storage modulus at glassy state and the rubbery plateau, indicative of interfacial adhesion between the epoxy matrix and sand aggregates. Additionally, the dam** behavior and glassy temperature were increased with the addition of CTPET. Moreover, the combination linkage of ester groups from the CTPET likely contribute to the enhancement of compressive strength and flexural strength in the epoxy mortar. The results of absorption and flexural change after immersion in solution, as well as the interfacial flexural bonding strength with ordinary cement-based material were also investigated.

Similar content being viewed by others

REFERENCES

E. Ozeren Ozgul and M. H. Ozkul, Constr. Build. Mater. 187, 360 (2018).

F. L. **, X. Li, and S. J. Park, J. Ind. Eng. Chem. 29, 1 (2015).

N. J. **, J. Yeon, I. Seung, and K. S. Yeon, Constr. Build. Mater. 156, 933 (2017).

S. Ma, T. Li, X. Liu, and J. Zhu, Polym. Int. 65, 164 (2016).

P. Ruamcharoen, S. Umaree, and J. Ruamcharoen, J. Mater. Sci. Eng. 5, 504 (2011).

Z. Ge, R. Sun, K. Zhang, Z. Gao, and P. Li, Constr. Build. Mater. 44, 81 (2013).

G. Lazorenko, A. Kasprzhitskii, and E. H. Fini, J. Clean. Prod. 375, 134083 (2022).

B. Dębska and L. Lichołai, Constr. Build. Mater. 94, 579 (2015).

B. Dębska and L. Lichołai, Constr. Build. Mater. 124, 11 (2016).

C. W. Phetphaisit, R. Bumee, J. Namahoot, J. Ruamcharoen, and P. Ruamcharoen, Int. J. Adhes. Adhes. 41, 127 (2013).

V. Rebizant, A. S. Venet, F. Tournilhac, E. Girard-Reydet, C. Navarro, J. P. Pascault, and L. Leibler, Macromolecules 37, 8017 (2004).

D. Foix, Y. Yu, A. Serra, X. Ramis, and J. M. Salla, Eur. Polym. J. 45, 1454 (2009).

S. J. Park and F. L. Polym. Degrad. Stab. 86, 515 (2004).

F. Mustata and N. Tudorachi, Appl. Therm. Eng. 125, 285 (2017).

Y. Chen, N. Hossiney, X. Yang, and H. Wang, Adv. Mater. Sci. Eng. 2021, 3454029 (2021).

M. T. Lakhiar, Y. Bai, L. S. Wong, S. C. Paul, V. Anggraini, and S. Y. Kong, Constr. Build. Mater. 315, 125677 (2022).

B. Debska and L. Licholai, Constr. Build. Mater. 65, 604 (2014).

M. C. S. Ribeiro, C. M. L. Tavares, and A. J. M. Ferreira, J. Polym. Eng. 22, 27 (2002).

L. K. Aggarwal, P. C. Thapliyal, and S. R. Karade, Constr. Build. Mater. 21, 379 (2007).

O. Y. Alothman, M. Jawaid, K. Senthilkumar, M. Chandrasekar, B. A. Alshammari, H. Fouad, M. Hashem, and S. Siengchin, J. Mater. Res. Technol. 9, 15537 (2020).

R. Senthilkumar, M. P. Natarajan, S. Ponnuvel, and R. Sathyamurthy, J. Mater. Res. Technol. 17, 819 (2022).

H. Yin, H. **, C. Wang, Y. Sun, Z. Yuan, H. **e, Z. Wang, and R. Cheng, J. Therm. Anal. Calorim. 115,1073 (2014).

X. Zhou, G. Zhang, W. Zhang, W. Guo, and J. Wang, Polym. J. 44, 382 (2012).

N. Z. Tomic, M. Saeedifar, M. N. Saleh, A. Marinkovic, D. Zarouchas, and S. Texixeira de Freitas, Polym. Test. 106, 107444 (2022).

S. Srisuwan, N. Prasoetsopha, N. Suppakarn, and P. Chumsamrong, Energy Proced. 56, 19 (2014).

S. Y. Guo, X. Zhang, J. Z. Chen, B. Mou, H. S. Shang, P. Wang, and L. J. R. Zhang, Constr. Build. Mater. 264, 120715 (2020).

Z. Zheng, Y. Li, S. He, X. Ma, X. Zhu, and S. Li, Constr. Build. Mater. 197, 319 (2019).

S. Y. Guo, X. Zhang, J. Ren, J. Z. Chen, T. J. Zhao, T. W. Li, and L. Zhang, Constr. Build. Mater. 272, 121960 (2021).

Funding

This work was supported by ongoing institutional funding. No additional grants to carry out or direct this particular research were obtained.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note.

Pleiades Publishing remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Phetphaisit, C.W., Singthong, W., Hemavibool, S. et al. Viscoelastic and Mechanical Properties of Repair Epoxy Mortar from Modified Poly(ethylene terephthalate) Waste. Polym. Sci. Ser. A 65, 568–579 (2023). https://doi.org/10.1134/S0965545X23701183

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0965545X23701183