Abstract

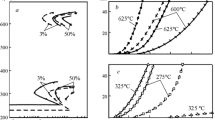

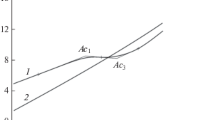

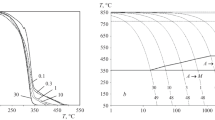

The influence of thermomechanical treatment conditions on the behavior of sparingly alloyed die steel with controlled austenitic transformation during operation (CATO) during deformation at 450–750°C is studied. Austenization at 1150°C, multiple tensile deformation at 450°C, cooling to room temperature, and rapid heating up to 750°C are shown to stabilize the state of hot working and provide the highest hardening of the steel at this temperature.

Similar content being viewed by others

REFERENCES

G. Roberts, G. Krauss, and R. Kennedy, Tool Steels (ASM Int., 1998).

Yu. N. Loginov and Yu. V. Inatovich, Tool for Pressing Metals (Izd. Ural Univ., 2014).

A. Alimi, J. Fajoui, M. Kchaou, S. Branchu, R. Elleuch, and F. Jacquemin, “Multi-scale hot working tool damage (X40CrMoV5-1) analysis in relation to the forging process,” Eng. Failure Analysis 62, 142–155 (2016).

V. N. Fedulov, “Influence of quantitative alloying of tool steels for hot deformation on the level of their hardening,” Lit’e Metallurg., No. 3, 123–131 (2015).

S. E. Krylova, O. A. Kletsova, V. I. Gryzunov, A. P. Fot, and I. S. Tavtilov, “Effect of heat treatment on the structure and properties of die steel 70Kh3G2FTR,” Metalloved. Term. Obrab. Met., No. 10, 4–10 (2017).

F. Deirmina, M. Pellizzari, and M. Federici, “Production of a powder metallurgical hot work tool steel with harmonic structure by mechanical milling and spark plasma sintering,” Metall. Mater. Trans. 48, 1910–1920 (2017).

J. Marashi, E. Yakushina, P. **rouchakis, R. Zante, and J. Foster “An evaluation of H13 tool steel deformation in hot forging conditions,” J. Mater. Process. Technol. 246, 276–284 (2017).

R. A. Petković, M. J. Luton, and J. J. Jonas, “Recovery and recrystallization of carbon steel between intervals of hot working,” Canadian Metall. Quarterly 14, 137–145 (2013).

D.-X. Wen, Y. C. Lin, X.-H. Li, and S. K. Singh, “Hot deformation characteristics and dislocation substructure evolution of a nickel-base alloy considering effects of δ phase,” J. Alloys Compd. 764, 1008–1020 (2018).

S. S. S. Kumar, T. Raghu, P. P. Bhattacharjee, G. A. Rao, and and U. Borah, “Work hardening characteristics and microstructural evolution during hot deformation of a nickel superalloy at moderate strain rates,” J. Alloys Compd. 709, 394–409 (2017).

Y. Cao, H. Di, J. Zhang, J. Zhang, T. Ma, and R. D. K. Misra, “An electron backscattered diffraction study on the dynamic recrystallization behavior of a nickel–chromium alloy (800H) during hot deformation,” Mater. Sci. Eng., A 585, 71–85 (2013).

Y. Liu, R. Hu, J. Li, H. Kou, H. Li, H. Chang, and H. Fu, “Hot working characteristic of as-cast and homogenized Ni–Cr–W superalloy,” Mater. Sci. Eng., A 508, 141–147 (2009).

Yu. G. Orlov and L. R. Dudetskaya, Materials and Manufacturing Technologies of Cast Die Tools (Belorusskaya Navuka, Minsk, 2010).

L. A. Poznyak, Tool Steels (Naukova Dumka, Kiev, 1996).

A. A. Kruglyakov, “Effect of alloying elements on the hardening of die steels in the austenitic state during high-temperature plastic deformation,” Russ. Metall. (Metally) 2019 (10), 1096–1101 (2019).

A. A. Kruglyakov, S. A. Nikulin, S. O. Rogachev, N. V. Lebedeva, G. A. Panova, Nguen Hoan Suan, and E. V. Serikov, “Effect of annealing on the structure and the hardness of die steel with a controllable austenitic transformation during operation,” Russ. Metall. (Metally) 2019 (9), 894–900 (2019).

A. A. Krugljakow, S. A. Nikulin, S. O. Rogachev, H. X. Nguyen, N. V. Lebedeva, and G. A. Panova, “Hot-hardening phenomenon in die steel during thermomechanical treatment,” Mater. Lett. 266, 127475 (2020).

S. A. Nikulin, A. A. Kruglyakov, S. O. Rogachev, G. A. Panova, and N. V. Lebedeva, “Die steel,” RF Patent 2744584, 2021.

S. I. Gubenko, Physical Nature of the Plasticity and Hardening of Metals during Deformation (Lambert Academic Publ., Saarbrücken, 2020).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by K. Shakhlevich

Rights and permissions

About this article

Cite this article

Kruglyakov, A.A., Rogachev, S.O., Nikulin, S.A. et al. Stabilization of the Hot-Working State of Die Steel during Thermomechanical Treatment. Russ. Metall. 2022, 1278–1283 (2022). https://doi.org/10.1134/S0036029522100147

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029522100147