Abstract

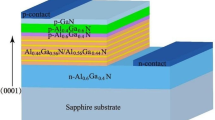

Light-emitting diodes (LEDs) become an attractive alternative to conventional light sources due to high efficiency and long lifetime. However, different material properties between GaN and sapphire cause several problems such as high defect density in GaN, serious wafer bowing, particularly in large-area wafers and poor light extraction of GaN-based LEDs. Here, we suggest a new growth strategy for high efficiency LEDs by incorporating silica hollow nanospheres (S-HNS). In this strategy, S-HNSs were introduced as a monolayer on a sapphire substrate and the subsequent growth of GaN by metalorganic chemical vapor deposition results in improved crystal quality due to nano-scale lateral epitaxial overgrowth. Moreover, well-defined voids embedded at the GaN/sapphire interface help scatter lights effectively for improved light extraction and reduce wafer bowing due to partial alleviation of compressive stress in GaN. The incorporation of S-HNS into LEDs is thus quite advantageous in achieving high efficiency LEDs for solid-state lighting.

Similar content being viewed by others

Introduction

The wide-bandgap GaN and related materials have been extensively studied and utilized in important optoelectronic device applications such as light emitting diodes (LEDs) and laser diodes1,2. However, in order to realize high-performance and reliable optoelectronic devices, high quality GaN epitaxial layers are definitely required. For these reasons, fabrication of LED using high quality bulk GaN was studied and it showed great result such as extremely low dislocation density, high output power and high electrical conductivity3,4,5. However, due to the complicated growth method and low growth rate, bulk GaN is not yet affordable. Recently, LEDs based on nanorod arrays, non- and semi-polar planes were reported6,7,8,9,10. Nanorod LEDs look promising because of the increased emission area, low dislocation density and reduced strain when compared with planar LED devices6,7. To overcome the efficiency droop problems of c-plane LEDs, non- and semi-polar LED devices have been highly investigated8,9,10. However, GaN epitaxial layers are most extensively grown on sapphire substrates because of high quality, transparency, high temperature stability and availability in large-area wafers. Large mismatches in lattice constant and thermal expansion coefficient between GaN and sapphire substrates cause severe problems in the fabrication of high efficiency optoelectronic devices11. The three major problems in the GaN-based LED structures grown on sapphire substrates are the high dislocation density in GaN due to lattice mismatch, poor light extraction and significant wafer bowing. High density dislocations, regarded as major non-radiative recombination centers in GaN-based LEDs, typically lower the LED external efficiency and shorten the device lifetime12,13. Even though high efficiency of GaN-based LEDs, despite of high density dislocation, is often attributed to In clustering in InGaN active layers14 as well as formation of side wall quantum wells15 at V-shaped pits around threading dislocations, dislocations are definitely nonradiative recombination centers, especially at high current injection. Therefore, reducing the dislocation density is one of the major issues in achieving high power LEDs. Moreover, the large difference in refractive index between GaN (2.4) and sapphire (1.7) results in poor light extraction due to total internal reflection16. Severe wafer bowing also hinders the mass production of LEDs in large-area wafers17. The thermal expansion coefficient of sapphire is much larger than that of GaN so that severe biaxial compressive stress is generated within GaN during cooling process after high temperature deposition18 (See Supplementary Information Table S1). To overcome the problems associated with conventional GaN-based LEDs, many methods such as lateral epitaxial overgrowth (LEO) and patterned sapphire substrate (PSS) and so forth were proposed19,20,21,22,23,24,25. However, in those methods, photolithography and complicated subsequent processes are necessary, resulting in the increase in fabrication cost as well as process complexity. Recently, growth of high quality GaN epitaxial layers were made on both Si substrates26 and sapphire substrates27 coated with silica spheres. In both cases, no photolithographic step was used. Micrometer-scale silica spheres were coated on GaN templates to obtain high quality regrown GaN epitaxial layers28. Nanometer-scale silica spheres were also used to get high quality a-plane GaN on r-plane sapphire substrates by selectively placing them on valley areas on three-dimensional buffer layers29. Nanometer-scale silica spheres were even selectively placed on wet etch pits formed on GaN template to obtain high quality regrown GaN epitaxial layers, which improved performance of LEDs30,31,32,33.

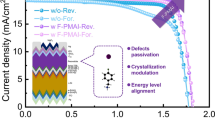

In this paper, we report a new GaN growth scheme for improved LED performance with silica (SiO2) hollow nanospheres (S-HNS), coated as a monolayer, on a sapphire substrate. Please note that all previous reports used silica solid nanospheres. Fig. 1 shows the proposed process sequence with a monolayer of S-HNS and its advantages. To realize S-HNS-coated sapphire substrates, nano-scale polystyrene (PS)/SiO2 core-shell spheres were first synthesized and coated on sapphire substrates by the modified dip coating method (Fig. 1a). The substrates were subsequently heat-treated in air atmosphere to remove the organic PS core leaving behind the spherical hollow silica structures (Fig. 1b). Then, GaN epitaxial layers were grown on S-HNS-coated sapphire substrates. GaN nucleated on the exposed sapphire areas and overgrew S-HNSs (nano-scale lateral epitaxial overgrowth) to obtain completely coalesced, flat GaN thin film (Fig. 1c and 1d). We believe that this growth scheme has three advantages over conventional growth scheme without S-HNSs. S-HNSs could induce nano-scale LEO of GaN on S-HNS coated sapphire substrates to reduce the dislocation density. In addition, GaN with S-HNSs embedded at the interface with the maximum refractive index contrast (i.e., GaN and void) enhances light scattering, resulting in the improvement of light extraction efficiencyFull size image

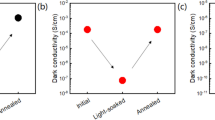

To evaluate the use of S-HNS monolayers on LED performance, LEDs with and without containing S-HNS monolayers were fabricated by conventional photolithography, dry etching and metal electrode deposition. The PL intensity maps of LED structures in the absence and presence of the S-HNS monolayers are shown in Fig. 4c and 4d, respectively. We note that the average PL intensity increases by three times by employing a S-HNS monolyer with a surface coverage of 30% at the GaN/sapphire interface. This result is in good agreement with the light extraction that was enhanced by 2.8 times from the FDTD simulation with a surface coverage of 33.5%. The output power of LED is also shown in Fig. 4e. The output power of LED in the presence of a S-HNS monolayer is two times higher than that without containing S-HNS at 20 mA input current.