Abstract

Develo** suitable light management layers can improve the lifetime and efficiency of solar cells and other optoelectronics. Here, a bioinspired approach to produce all-biobased films with high anisotropic light scattering and superhydrophobicity is presented as a route toward sustainable light management layers for photovoltaics. The multifunctional films are achieved by replicating leek leaves onto cellulose acetate, producing hierarchical surface structures. The free-standing films show a transmittance of ≈94% and a haze of ≈54% at the wavelength of 550 nm. Moreover, anisotropic advancing contact angles of up to 160° and 156° in cross directions are achieved through tailoring a carnauba wax coating. Using the replica as the light management layer on perovskite solar cells improved the power conversion efficiency by 6 ± 0.3%. Meanwhile, the surface water repellency facilitates self-cleaning, ensuring maximum incident light over time by tackling dirt accumulation. Furthermore, the method can be potentially employed to fabricate substrates from virtually any leaf or patterned surface as the initial replication template.

Similar content being viewed by others

Introduction

Maximizing and maintaining the total incident light is a crucial factor for solar cell performance, highlighting the importance of proper light management and removing dirt or other obstructions that can block light1,2,3. A self-cleaning superhydrophobic light management layer on solar cells can greatly tackle the accumulation of dust and dirt, which is estimated to decrease the output power by up to 50%4,5 The combination of self-cleaning and high transparency can be achieved by tailoring the surface microstructure on the outmost layer of solar cells6,7,8,9,10,11. A surface roughness also contributes to haze which extends the light path in the photoactive material of solar cells and results in increased power conversion efficiency12,13. Patterned polymers, such as polydimethylsiloxane (PDMS)3,14, Norland Optical Adhesive (NOA) 6315, and ethylene-tetrafluoro-ethylene (ETFE)16 on multi-junction, dye-sensitized, perovskite, and polycrystalline silicon solar cells have been shown to increase the power conversion efficiency4,5. Free-standing, flexible, and environmentally-friendly films with such properties can be implemented in the optical components, often without additional manufacturing complications17,18,19. Fabrication of films with desirable wetting and optical properties, however, has been challenging due to the counteracting roughness requirements of superhydrophobicity and transparency16,17,18,19,20. While superhydrophobicity is associated with a high level of roughness, it is often at the expense of lower transparency20,21,22,23,24.

In nature, plenty of transparent superhydrophobic surfaces have evolved, for instance, wings of cicada25,26 and glasswing butterflies27 which double in camouflage function, and moth eyes coating28,29 which is vital for their night vision. Extensive investigation on the preparation of superhydrophobic polymeric surfaces has been carried out after comprehensive surface structure descriptions of several natural plant leaves, notably the lotus leaf in 199730,31. Superhydrophobic surfaces are sought to exploit the high mobility of water for various reasons, such as self-cleaning32,33,34, anti-icing44, spin-coating, dip-coating45,46, spray coating47,48, and lithography49. Due to its simplicity, low cost, and high precision, imprint lithography tends to be a common method to fabricate various nano/micro-scale structures50,51. Moreover, fine-tuning the surface structure can enable anisotropic wettability which assists in directing the liquid flow in the desired direction and has been realized by sequential imprinting52, as well as by grating and wrinkling53,54. For instance, in a bio-inspired approach, Lee et al.55. mimicked rice-leaf hierarchical surface structure and achieved superhydrophobic and anisotropic properties. Nonetheless, considerable attention has been focused on a limited number of nature’s functional surfaces, such as lotus leaves56,57, butterfly wings58, shark skin59, and rose petals60,61, leaving many potential bio-templates unexplored.

Recent advances have shown great potential for bio-based materials in optoelectronics13,62. Employing cellulose-based substrates has been attempted as environmentally friendly and renewable materials in solar cells22,63,64,65,66,67,68. As a cellulose derivative, cellulose acetate (CA) can be produced through acetylation of cellulose69,70, and recycling papers71 and textiles72. It benefits from tunable optical clarity73, good processability74,75, compostability76, and biocompatibility77 which make CA a good candidate in a variety of applications, e.g., membranes78,79, textiles80,81, and tissue engineering77,82. Despite the common usage of fluorinated reagents for reducing the surface energy and realizing hydrophobicity in cellulose-based materials83,84,85,86, the modified fluorine-containing molecules are usually costly and nonbiodegradable, and exposure to them through environmental contamination can cause nerve growth hindrance in children87,88,89. In contrast, usage of fluorine-free natural waxes as a water-repellent component is cost-effective, safe, and even reported to delay the photodegradation of wood-based substrates owing to their slight UV absorption90,91.

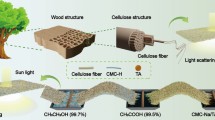

Addressing the requirements for light management layers in solar cells and drawing inspiration from nature, we hypothesized that bioinspired cellulose-based materials could not only emulate the self-cleaning effect of common leek leaves but also exhibit desired optical criteria for solar cells, namely, high diffusive light transmittance. Hence, to explore new approaches for multifunctional films, a facile replication method was developed. The surface morphology of films were investigated by scanning electron microscope (SEM), and the effect of process parameters was then assessed on the optical properties and surface hydrophobicity by using UV-vis spectroscopy and water contact angle measurement, respectively. The films were then tested as the light management layer on perovskite solar cells and the photovoltaic performance was characterized in a solar simulator. The produced cellulose-based light management layers are expected to pave the path toward replacing inorganic and organic fluorine-containing coatings of substrates in various photovoltaic technologies.

Results and discussion

Replication

The optical tunability of cellulose, as an abundant and renewable biopolymer, makes cellulose-based materials ideal for light management in optoelectronic devices13,92. Here we used a 5% cellulose acetate (CA) solution to replicate the surface structure of leek leaves. Leek plant shows anisotropic superhydrophobicity, and very recently, prevention of bacterial binding was shown93 by mimicking its surface structure onto dental wax. The replicated CA films were then coated with carnauba wax (CW), the hardest natural wax with the highest melting point among commercial vegetable waxes (≈84 °C)94. All in all, this replication process can be potentially used to prepare films with different optical and wetting properties using other types of leaves as the template.

As shown in Fig. 1a, the SEM images of leek leaf reveal a surface covered by µm-sized grooves and a nanoscale epicuticular wax layer. Figure 1b shows the successful replication of the microscale features onto the 5% CA film, including stomata and grooves. However, the leek’s epicuticular wax was not translated during the replication process (See Supplementary Fig. 3 for the high-resolution wax nanostructure). Further, solvent evaporation during the CA replica formation generated smaller-scale wrinkles. Similar wrinkles are also visible on a flat CA film (Supplementary Fig. 4). Figure 1c shows the 2% carnauba wax (CW) coated replica with high and homogenous wax coverage on the surface. The CW-coated replica illustrates both the replicated anisotropic surface structure and the isotropic porous flake-like CW bundles. Altering the CW concentration from 0.5% to 3% changes the wax morphology from sparse to large clusters of CW flakes (Supplementary Fig. 5a–d). Overall, it can be observed that hierarchical structures ranging over two distinct length scales were successfully created by the combination of replication of leek surface features and adding the carnauba wax coating.

Wetting properties

Figure 2 shows the wetting properties of the leek and the replicas (5% CA) with and without the CW coating. The advancing and receding contact angles (θadv and θrec) and their difference (contact angle hysteresis, Δθ) are shown in Fig. 2a. The water contact angle measurements were performed at different orientations relative to the orientation of the grooves, as illustrated in Fig. 2b. The leek leaf had a θadv of 159° and a small Δθ of 3° when the droplet is spreading across the leaf grooves, as compared to θadv of 150° and Δθ of 6° when spreading along the grooves. The high contact angles and low hysteresis are achieved when the droplet is in the Cassie-Baxter state95, and they are the key characteristics of superhydrophobic surfaces96,97,98. These properties make water droplets highly mobile on the surface99. The data also shows anisotropic wetting properties of the leek leaf as both contact angles are higher when the triple phase contact line is moving across the ridge structures as opposed to when moving along the ridges100. The wetting properties of the leek leaf are due to the combination of the nanostructured inherently hydrophobic waxy layer (Supplementary Fig. 3), the grooves, and stomata, resulting in the anisotropic superhydrophobicity of the plant.

a contact angles of the films, b schematic representation of the terms across and along, as well as the optical image of water droplet advancing c across and d along the grooves for the film with 2% CW coating, showing anisotropic superhydrophobic behavior. The scale bar at the bottom left indicates 1 mm.

The contact angles of the uncoated replica are about 19° lower, and the hysteresis is about 21° higher than the original leaf. Therefore, the beneficial anti-wetting properties of the leek leaf were lost in the fabrication process. The reason for this is likely the impossibility of replicating the epicuticular wax overhanging features (Supplementary Fig. 5) and the less hydrophobic surface chemistry of CA. When the epicuticular wax is replaced by a 2% CW coating, the replica then shows θadv of 157° and Δθ of 7° in the across direction and θadv of 143° and Δθ of 9° in the along direction, showing that this sample replicated the wetting properties of the original leaf. The wetting anisotropy of the leek leaf is also preserved after the film fabrication steps. As the CW micro-flakes are randomly distributed, the wetting anisotropy is primarily attributed to the direction of the grooves. Furthermore, a CW coating on plain CA film only increases the hydrophobicity to a θadv of 136°. This indicates the importance of grooves and stomata on the replicated leek surface structure in the final superhydrophobicity of the films. A comprehensive comparison between the contact angles using different CW concentrations can be found in supporting information, Supplementary Fig. 6.

To investigate the self-cleaning property arising from the superhydrophobicity, graphite powder was spread on the 2% CW-coated replica (Supplementary Fig. 7a) and 200 µL was released using a pipette onto the sample. The relationship between the cleaned area and the angle of tilt is presented in Supplementary Fig. 7b. It was observed that at a minimal tilt of 5 degrees, the cleaning effect was virtually nonexistent. However, higher angles facilitating more effective removal of the graphite powder, in which the cleaned area expanded to 9% for 10°, 11% for 20°, and 16% for 30° tilts. Supplementary Fig. 7c–f represents photographs of the films and area selection in image analysis for calculation of the cleaned area.

While our primary focus was not on assessing the durability of the films, the effect of abrasion on surface structure and the water contact angle did not escape our attention. Supplementary Fig. 2c-f revealed alterations in the surface morphology of the samples, which are expected due to the soft material composition of the replicas, and as the result a decrease in the water contact angles (Supplementary Fig. 3b).

Optical properties

In addition to exhibiting anisotropic wetting properties, the surface structures were found to result in intriguing optical capabilities. Figure 3 shows the optical properties of the fabricated films using a 5% CA solution. While the high light transmittance results in the clear appearance of the film when placed on a brick-like background (Fig. 3a), high anisotropic light scattering fades the vertical lines when the film is lifted. This optical anisotropy results in visual effects, as shown in Fig. 4b, c. The effect of CW concentration on the total light transmittance and haze of the replica is demonstrated in Fig. 4d, e. While the CA replica shows a light transmittance of 94% at 550 nm, increasing the CW concentration predictably reduced the light transmittance to 91, 85, and 79% for 1, 2, and 3% CW-coated replicas, respectively. This is due to the formation of rough and larger surface features at higher CW concentrations (Supplementary Fig. 5a–d). The effect of CW morphology is even more pronounced in case of scattered light, where the coating increases the haze at 550 nm from 55% with the plain CA replica to 75% for the 2% CW coating. However, the higher CW concentration of 3 wt% declines haze due to the formation of large clusters of CW micro-flakes (Supplementary Fig. 5d).

a Photograph of the replica while placed on the background, b about 2 cm above, showing disappearance of the vertical lines due to anisotropic light scattering in the perpendicular direction and c forming hexagons after ca. 60° rotation, d transmittance and e haze spectra of flat CA, replica, and CW-coated films (the lines and bands represent the mean values and standard deviations of three measurements), f schematic of laser beam interference with the film and anisotropic scattering of light, g photograph of white halogen light beam (top), after passing through a plain CA film (middle), and replica (bottom) while the scale bar shows 5 mm, and h their corresponding relative intensities for a horizontal profile line.

a Replica-integrated PSC with the architecture of glass/FTO/c-TiO2/m-TiO2/Cs0.05(FA0.83MA0.17)0.95Pb(I0.83 Br0.17)3/spiro-OMeTAD/Au, as well as the average and standard error from the mean of J–V curves of PSCs with b replica and c 2% CW-coated replica as compared to the pristine devices. The average and standard error of the means are taken from seven devices for each sample.

Figure 3f illustrates the anisotropic scattering of light due to the surface structure. The presence of leek surface structure, including both the grooves and stomata, favors the light scattering in the direction perpendicular to the grooves. The results of the light beam interference with the plain CA and the replica are demonstrated in Fig. 3g, h. The interference of light with plain CA leads to a similar result as with no film due to the high transmittance and extremely low haze of this film (see Supplementary Fig. 8). This near-intact transmission of light is due to the fairly smooth surface of film (Supplementary Fig. 4). Interference of light with the CA replica, however, diverges the light in the perpendicular direction of the grooves’ alignment. Consequently, the initial ca. 0.5 cm light beam diameter is horizontally diffused to ca. 3.5 cm with a wide intensity distribution. Furthermore, changing the initial CA concentration alters the thickness and, thus, the optical properties of the replicas. The effect of thickness on the optical properties is illustrated in Supplementary Fig. 8, showing a decrease in the light transmittance and an increase in the haze with increasing thickness.

Supplementary Fig. 9 reports the thermal stability of replicas under a solar simulator over 240 h. A surface temperature of 66 °C was recorded immediately after the exposure (Supplementary Fig. 9a). The SEM images (Supplementary Fig. 9d) reveal that the fine wax features had rearranged due to high temperature, leading to a diminished surface area and, consequently, a reduction in hydrophobicity. As the result, the θadv of 157° in the across direction is reduced to 146° (Supplementary Fig. 9b). Additionally, UV–vis spectroscopy results showed that the replica maintained its total light transmittance (Supplementary Fig. 9c). However, the CW-coated replica suffered a loss in UV-blockage, presumably due to photocatalytic degradation. The observed changes warrant further investigation, and addressing them through future work is imperative for enhancing their durability and reliability in applications.

Application in solar cells

The optical properties of these films, showing both high transmittance and haze, make them ideal for light management in photovoltaics to improve their performance. Furthermore, their superhydrophobicity makes them good candidates to tackle the degradation of photovoltaics by repelling water. Also, self-cleaning facilitates the removal of dirt (Supplementary Movie 1), which often blocks the incident light in outdoor conditions of solar cells and deteriorates efficiency over time. To demonstrate the effectiveness of their optical properties, the replica and 2% CW-coated replica were optically coupled with perovskite solar cell (PSC) devices —an emerging photovoltaic technology that has found widespread application in various practical contexts101— using polyvinyl alcohol that has high transparency and a matching refractive index of ca. 1.5 in the visible wavelength range102,103. Figure 4a illustrates the PSC devices based on the mesoporous structure with the architecture of Glass/FTO/c-TiO2/m-TiO2/ Cs0.05(FA0.83MA0.17)0.95Pb(I0.83 Br0.17)3/spiro-OMeTAD/Au. A silver painted device is also presented in Supplementary Fig. 10. The performance average and the standard error of the mean of devices with CA replica and 2% CW-coated replica are reported in Fig. 4b-c. The uncoated replica improved the power conversion efficiency (PCE) by 6 ± 0.3% on average. The averages and standard deviations were taken from seven samples made in multiple batches to ensure the statistical significance and reproducibility of the results (Supplementary Fig. 11). Interestingly, despite the ca. 6% (Fig. 3d) lowered light transmission into the cell by the replica, the PCE was improved due to the slightly improved short-circuit current (JSC) and particularly higher open-circuit voltage (VOC) (Fig. 4b). One would expect a lower light transmission to the cell to decrease the photocurrent generation in the cell. The replica must, therefore, have improved light absorption inside the cell to compensate for the transmission loss.

Owing to their high haze (Fig. 3e), the CA replica films successfully improved the light absorption by extending the light path in the active layer of the cell. This improvement in performance is similar to the effect observed with transparent wood65 on GaAs solar cells, transparent paper22 on organic solar cells, and cellulose composites68 on perovskite solar cells as the light management layer. The performance of CW-coated replica-integrated cells, however, was on average 2.8% lower compared to the uncoated ones. In this case, the increased light absorption efficiency by path lengthening was not sufficiently high to compensate for the additional transmission loss by the CW coating (Fig. 3d) which led to lowered JSC (Fig. 4c). Both the uncoated and CW-coated replica film increased the VOC of the cell, however, the mechanism for this improvement is unclear. VOC would be expected to increase if the replica films increased the light absorption rate in the active layer. However, this did not happen because the results show that JSC was either slightly increased (Fig. 4b) or decreased (Fig. 4c) by the films. All in all, a detailed investigation into the effects of external factors on VOC is needed and will be explored in future work. Finally, with a UVA (320-400 nm) block percentage of 21% (Fig. 3d), the CW-coated replica is expected to enhance the UV stability of the cells. Integrating the proposed light management layers with proper cell encapsulation can guarantee better performance and longevity.

Overall, the results confirmed the hypothetical idea of the self-cleaning capabilities and high diffusive light transmittance of bio-inspired cellulose acetate films. To reach the necessary level of hydrophobicity required for efficient self-cleaning, a bio-based CW coating needed to be added. This work also uncovered a trade-off between achieving optimal self-cleaning performance and maintaining high levels of light transmittance and provides design guidelines for simultaneous optimization of both properties. In terms of technological readiness level (TRL), the current performance of the films on the solar cell devices, particularly regarding their durability, falls short of the TRL required to compete with established market solutions. Therefore, we leave the door open for future studies in order to elevate this coating to a higher TRL which will necessitate extensive research focused on enhancing its mechanical properties. Ultimately, the advantage of the developed light management layer becomes more evident when the self-cleaning property of the CW-coated replica ensures maximum incident light by eliminating the accumulated dirt, which can maintain cell performance in real-life outdoor conditions.

Conclusion

A facile bio-inspired route is presented to produce free-standing cellulose-based films with desirable properties for solar cells and optoelectronic applications. Compared to previously reported routes, we employed abundant leek leaves that are widely accessible, and obtained hydrophobicity by simple deposition of a plant-based wax, avoiding the usage of commonly used fluorinated compounds. Film parameters can be determined by tuning the initial solution concentrations. Anisotropic scattering of light, as well as high total light transmittance of 94%, can be achieved. Applying the films on perovskite solar cells was shown to improve the relative cell efficiency by 6%. Furthermore, the anisotropic superhydrophobicity can assist the fluid transfer in a favored direction based on the application. Despite the lower transmittance of the CW-coated replica, in a trade-off between optical transparency and superhydrophobicity/self-cleaning, the developed films as the light management layer can ensure the performance of photovoltaics over time. Thus, the developed route to produce all-biobased light management layers can provide an opportunity for future investigation to replace inorganic optical coatings and substrates with bio-inspired organic coatings.

Methods

Materials

All chemicals were used as received. Polydimethylsiloxane (PDMS, 10:1 ratio of base component:curing agent, viscosity of the mixture 3.5 Pa.s, product number: 01673921, SylgardTM 184 silicone elastomer kit, Dow Chemical Co., USA), cellulose acetate (CA) with an average Mn ~50,000 (39.7 wt% acetyl, product number: 419028-500 G), and Carnauba wax No.1 yellow (CW, containing aliphatic esters, ω-hydroxy esters and unsaturated alcohols, product number 243213-250 G) from Sigma-Aldrich, acetone (≥99%, Honeywell Riedel de-Häen, Germany), ethanol (Etax A7, Altia Industrial Ojy, Finland), toluene (99.8%, Sigma-Aldrich, Germany), polyvinyl alcohol (PVA, Mw 85,000-124,000, Sigma-Aldrich, USA), fluorine-doped tin oxide glass substrates (Greatcell solar, TEC15), TiO2 paste (30 NR-D, Dyesol), acetylacetone (Sigma-Aldrich, P7754), titanium diisopropoxide (Sigma-Aldrich), lead iodie-PbI2(TCI, L0279), lead bromide-PbBr2 (TCI, L0288), cesium iodide-CsI (abcr GmbH, AB207757), formamidinium iodide (Greatcell solar), methylamonium bromide (Greatcell solar), dimethylformamide-DMF (anhydrous-Sigma-Aldrich), dimethyl sulfoxide-DMSO (anhydrous- Sigma Aldrich), chlorobenzene (anhydrous-Sigma-Aldrich), acetonitrile (anhydrous-Sigma-Aldrich), Spiro-OMETAD (Sigma-Aldrich), tert-butylpyridine-tBP (Sigma-Aldrich), Lithium bis(trifluoromethanesulfonyl)imide-LITFSI (Sigma-Aldrich), FK 209 Co(II) PF6 salt (Sigma-Aldrich), gold (Kurt J. Lesker Company), graphite (flakes, 99% Carbon, −100 mesh ≥80%, Sigma-Aldrich) were used. Leeks were purchased from a local market.

Fabrication process

The fabrication process is illustrated in Fig. 5. Leek leaves were used as the master mold. The leaves (ca. 5 cm × 5 cm) were placed on the bottom of a petri dish, and PDMS with the ratio of 10:1 (monomer to the crosslinking agent) was cast on top. The curing process was performed at room temperature (RT) to form the mold. Cellulose acetate solutions were prepared by dissolving the as-received powder with concentrations of 2, 5, and 10 wt% in a 4:1 mixture of acetone and ethanol in order to tune film thicknesses. The films were produced by drop** ca. 25 µL cm−2 of solution on the PDMS mold. To assist the film formability, solvent evaporation was delayed by placing the replica in a permeable container to increase the vapor pressure.

The chemical structure of carnauba wax includes a complex mixture of long-chain esters, along with free fatty acids and alcohols104. The carnauba wax flakes were dissolved in toluene by heating in an oil bath at 90 °C and magnetic stirring at 500 rpm. Carnauba wax solutions with concentrations of 0.5, 1, 2, and 3 wt% were prepared. The CA films were attached to glass slide substrates using PVA solution as the adhesive (5 wt% in water) and then spin-coated using Laurell WS-650MZ-23NPPB. The process was carried out by depositing 50 µL of the CW solution on the CA replica, resting for 30 s, and spin-coating for 30 s at 500 rpm.

Film characterization

To characterize the optical properties of the films, the total transmittance and haze were measured using a UV-visible spectrophotometer (UV-2600 with ISR-2600Plus integrating sphere attachment, Shimadzu, Japan). The optical properties were measured from 300 nm to 800 nm. The transmittance and haze were calculated using the following equations105, and the results were reported for 3 sets of measurements:

where T is the total transmittance, T1 is the reference transmitted light without the sample, T2 is the total light transmitted with the presence of the sample, T3 is light beam scattering by the device, and T4 is the diffusive transmittance, referring to the light transmitted by both the sample and the device.

The UVA (320–400 nm) block percentage was calculated using the following equation106:

A halogen white light source (DH-2000, Ocean optics) was utilized to investigate the behavior of light after interference with the films. The beam was illuminated after coupling the light source with a 400 µm optical fiber (Ocean optics QP400-2-SR-BX) and a collimating lens (Ocean optics 74-UV). The films were then placed between the light source and a paper white background (as illustrated in Supplementary Fig. 1), and the results were photographed after illumination using Sony IMX586 48-megapixel sensor. The corresponding relative intensities were then derived for a horizontal profile line passing through the center of the beam using ImageJ software (version 1.53e, National Institutes of Health, USA).

The water contact angles were measured by Theta Flex optical tensiometer (Biolin scientific). The advancing and receding contact angles (θadv and θrec) were measured using the needle-in-sessile droplet method by increasing the volume from 5 to 8 µL droplet size and decreasing from 8 to 0 µL with a droplet pum** rate of 0.1 µL s−1. Contact angle values are averaged over 6 measurements for leek and 3-4 measurements for the fabricated films from different areas and reported along with the standard deviations.

The self-cleaning tests were performed by covering the surface of the samples with graphite powder in a doctor blade method, leaving ∼120 mg of powder on the sample. The samples were then titled 5°, 10°, 20°, and 30° and 200 µL of distilled water was dispensed using a pipette on them from a ca. 10 cm height. The cleaned area of the samples was then calculated by image analysis using ImageJ software. Furthermore, the self-cleaning behavior of garden soil-polluted substrates was qualitatively examined by titling the samples to 10°, placing 50 µL water droplets for four times on the surfaces, and recording it using a Sony IMX586 48-megapixel sensor.

The falling sand abrasion test was conducted by releasing 10, 20, and 40 g of sand (sieved to 0.5—1 µm, product number: 175401, Biltema, Finland) out of a funnel with a diameter of 5 mm. The funnel was positioned at a height of 30 cm above the test samples, which were mounted at a 45° angle. The test setup is depicted in Supplementary Fig. 2a.

A solar simulator (11002 SunLite, ABET Technologies) was utilized to test the optical and thermal stability of the fabricated films over time. For this means, the films were attached on solar cells using PVA solution and placed under one sun (100 mW cm−2) white light intensity for 240 hours. The temperature of the surface right after the test was measured using an FLIR i7 thermal camera.

The morphologies of the leek master mold and replicas were characterized using Tescan Mira3 scanning electron microscope (SEM) after sputter-coating with 5 nm of Au/Pd (80/20). Before sputtering, the leek leaves were dried using the freeze-drying method.

PSC fabrication

Triple-cation perovskite solar cells were fabricated using the one-step fabrication technique107. First, fluorine-doped tin oxide glass substrates were etched using a laser scriber. The pre-cut substrates were cleaned by washing with detergent, rinsing with DI water, and 15 min sonication in all the following solvents, Hellmanex diluted in DI water (2%), Ethanol, and Isopropanol, successively. After drying in a hydrothermal oven at 120 °C, the substrates were treated with UV ozone cleaning to ensure the removal of organic residuals. TiO2 compact layer (c-TiO2) was deposited on FTO substrates by spray pyrolysis of the solution containing acetylacetone (0.4 mL), titanium diisopropoxide bis(acetylacetonate) (0.26 mL) in 6 mL of ethanol, at 450 °C. A mesoporous TiO2 (m-TiO2) scaffold layer was deposited on top of the c-TiO2 by spin coating the dispersion of 30NRD TiO2 paste in ethanol (150 mg TiO2 paste in 1 mL ethanol) at 4000 rpm for 10 s, then annealing at 450 °C. After cooling down to room temperature, the samples were transferred to the nitrogen-filled glovebox. In order to make the triple cation perovskite layer, perovskite precursor was prepared from FAI (0.97 M), PbI2 (1.06 M), MABr (0.2 M), and PbBr2 (0.22 M) in a mixed solvent of DMF: DMSO (4:1, v:v). CsI (0.078 M) was made using DMSO as solvent. Then 80 µL of the above solution was spin-coated onto the as-prepared FTO/c-TiO2/m-TiO2 substrate with a two-step spin coating program (1000 rpm for 10 s, followed by 6000 rpm for 20 s). Five seconds before the end of the last step, 180 µL of chlorobenzene was dropped on the center of the spinning substrate as the antisolvent treatment step. The resulting perovskite films with the chemical formula of Cs0.05(FA0.83MA0.17)0.95Pb(I0.83 Br0.17)3 were annealed at 100 °C for 1 h. The Spiro-OMeTAD solution was made by mixing Spiro-OMeTAD (64.3 mg), tert-butylpyridine (25.3 μL), LITFSI (14.5 μL), FK 209 Co(II) PF6 salt (7.9 µL) and chlorobenzene (702 µL). To form the hole transport layer (HTL), 50 µL of the above solution was dropped on the as-prepared perovskite films at 4000 rpm, and then the substrates were spin-coated for 10 s. Finally, the gold electrode was thermally evaporated on top of the HTL. The electrodes were then painted with silver paste to ensure better contact and less resistance. The devices were kept for one night in the glovebox before the current-voltage characterization.

I–V measurement

The current (I)–voltage (V) characteristics of the cells were scanned using a Keithley 2450 source measure unit, under air mass (AM) 1.5 simulated sunlight (100 mW cm−2). The sun simulator was calibrated with a silicone reference solar cell. After the fabrication of the cells, the I–V behavior of the plain PSCs was recorded. The replicas were then glued on top of the glass and immediately after drying the I–V characteristics were measured. The averages and standard deviations were then reported from seven devices for each sample.

Data availability

The ultraviolet-visible spectra, relative intensity spectra, and current density-voltage spectra reported in this article are available in Zenodo repository: https://doi.org/10.5281/zenodo.10814421

References

Aitola, K. et al. Encapsulation of commercial and emerging solar cells with focus on perovskite solar cells. Sol. Energy 237, 264–283 (2022).

Chen, J.-D. et al. Enhanced light harvesting in organic solar cells featuring a biomimetic active layer and a self-cleaning antireflective coating. Adv. Energy Mater. 4, 1301777 (2014).

Heo, S. Y. et al. Bifunctional moth-eye nanopatterned dye-sensitized solar cells: light-harvesting and self-cleaning effects. Adv. Energy Mater. 4, 1300632 (2014).

Tanesab, J., Parlevliet, D., Whale, J., Urmee, T. & Pryor, T. The contribution of dust to performance degradation of PV modules in a temperate climate zone. Sol. Energy 120, 147–157 (2015).

Maghami, M. R. et al. Power loss due to soiling on solar panel: a review. Renew. Sustain. Energy Rev. 59, 1307–1316 (2016).

Gao, L. & He, J. A facile dip-coating approach based on three silica sols to fabrication of broadband antireflective superhydrophobic coatings. J. Colloid Interface Sci. 400, 24–30 (2013).

Zhang, X. et al. A transparent and photo-patternable superhydrophobic film. Chem. Commun. 4949–4951 (2007) https://doi.org/10.1039/b713432k.

Yildirim, A. et al. Superhydrophobic and omnidirectional antireflective surfaces from nanostructured ormosil colloids. ACS Appl Mater. Interfaces 5, 853–860 (2013).

Shang, Q. & Zhou, Y. Fabrication of transparent superhydrophobic porous silica coating for self-cleaning and anti-fogging. Ceram. Int 42, 8706–8712 (2016).

Bayer, I. S. On the durability and wear resistance of transparent superhydrophobic coatings. Coatings 7, 12 (2017).

Wang, P., Yan, X., Zeng, J., Luo, C. & Wang, C. Anti-reflective superhydrophobic coatings with excellent durable and Self-cleaning properties for solar cells. Appl Surf. Sci. 602, 154408 (2022).

Peter Amalathas, A. & Alkaisi, M. Nanostructures for light trap** in thin film solar cells. Micromachines (Basel) 10, 619 (2019).

Kaschuk, J. J. et al. Plant‐based structures as an opportunity to engineer optical functions in next‐generation light management. Adv. Mater. 34, 2104473 (2022).

Kim, D. H., Dudem, B., Jung, J. W. & Yu, J. S. Boosting light harvesting in perovskite solar cells by biomimetic inverted hemispherical architectured polymer layer with high haze factor as an antireflective layer. ACS Appl Mater. Interfaces 10, 13113–13123 (2018).

Woo Leem, J., Guan, X.-Y., Choi, M. & Su Yu, J. Broadband and omnidirectional highly-transparent coverglasses coated with biomimetic moth-eye nanopatterned polymer films for solar photovoltaic system applications. Sol. Energy Mater. Sol. Cells 134, 45–53 (2015).

Wang, M. et al. Microstructured superhydrophobic anti-reflection films for performance improvement of photovoltaic devices. Mater. Res Bull. 91, 208–213 (2017).

Dong, T. et al. Free-standing, flexible, multifunctional, and environmentally stable superhydrophobic composite film made of self-assembled organic micro/super-nanostructures through solution process. J. Colloid Interface Sci. 445, 213–218 (2015).

Iijima, M., Omori, S., Hirano, K. & Kamiya, H. Free-standing, roll-able, and transparent silicone polymer film prepared by using nanoparticles as cross-linking agents. Adv. Powder Technol. 24, 625–631 (2013).

Liu, Y., Xu, Q. F. & Lyons, A. M. Durable, optically transparent, superhydrophobic polymer films. Appl Surf. Sci. 470, 187–195 (2019).

Ebert, D. & Bhushan, B. Transparent, superhydrophobic, and wear-resistant coatings on glass and polymer substrates using SiO2, ZnO, and ITO nanoparticles. Langmuir 28, 11391–11399 (2012).

Teisala, H., Tuominen, M. & Kuusipalo, J. Superhydrophobic coatings on cellulose-based materials: fabrication, properties, and applications. Adv. Mater. Interfaces 1, 1300026 (2014).

Fang, Z. et al. Novel nanostructured paper with ultrahigh transparency and ultrahigh haze for solar cells. Nano Lett. 14, 765–773 (2014).

Nakajima, A. et al. Transparent superhydrophobic thin films with self-cleaning properties. Langmuir 16, 7044–7047 (2000).

Xu, L., Karunakaran, R. G., Guo, J. & Yang, S. Transparent, superhydrophobic surfaces from one-step spin coating of hydrophobic nanoparticles. ACS Appl Mater. Interfaces 4, 1118–1125 (2012).

Watson, G. S. & Watson, J. A. Natural nano-structures on insects—possible functions of ordered arrays characterized by atomic force microscopy. Appl Surf. Sci. 235, 139–144 (2004).

Wagner, T., Neinhuis, C. & Barthlott, W. Wettability and contaminability of insect wings as a function of their surface sculptures. Acta Zoologica 77, 213–225 (1996).

Siddique, R. H., Gomard, G. & Hölscher, H. The role of random nanostructures for the omnidirectional anti-reflection properties of the glasswing butterfly. Nat. Commun. 6, 6909 (2015).

Sun, C.-H., Gonzalez, A., Linn, N. C., Jiang, P. & Jiang, B. Templated biomimetic multifunctional coatings. Appl Phys. Lett. 92, 051107 (2008).

Min, W.-L., Jiang, B. & Jiang, P. Bioinspired self-cleaning antireflection coatings. Adv. Mater. 20, 3914–3918 (2008).

NEINHUIS, C. Characterization and distribution of water-repellent, self-cleaning plant surfaces. Ann. Bot. 79, 667–677 (1997).

Barthlott, W. & Neinhuis, C. Purity of the sacred lotus, or escape from contamination in biological surfaces. Planta 202, 1–8 (1997).

Zhang, X. F., Zhao, J. P. & Hu, J. M. Abrasion-resistant, hot water-repellent and self-cleaning superhydrophobic surfaces fabricated by electrophoresis of nanoparticles in electrodeposited sol–gel films. Adv. Mater Interf. 4, 1700177 (2017).

Blossey, R. Self-cleaning surfaces - Virtual realities. Nat. Mater. 2, 301–306 (2003).

Jung, Y. C. & Bhushan, B. Mechanically durable carbon nanotube - Composite hierarchical structures with superhydrophobicity, self-cleaning, and low-drag. ACS Nano 3, 4155–4163 (2009).

Wang, N., **ong, D., Deng, Y., Shi, Y. & Wang, K. Mechanically robust superhydrophobic steel surface with anti-icing, UV-durability, and corrosion resistance properties. ACS Appl Mater. Interfaces 7, 6260–6272 (2015).

Maitra, T. et al. On the nanoengineering of superhydrophobic and impalement resistant surface textures below the freezing temperature. Nano Lett. 14, 172–182 (2014).

Sun, Z. et al. Fly-eye inspired superhydrophobic anti-fogging inorganic nanostructures. Small 10, 3001–3006 (2014).

Gao, L. & McCarthy, T. J. The “Lotus Effect” explained: two reasons why two length scales of topography are important. Langmuir 22, 2966–2967 (2006).

Öner, D. & McCarthy, T. J. Ultrahydrophobic surfaces. effects of topography length scales on wettability. Langmuir 16, 7777–7782 (2000).

Bhushan, B. & Jung, Y. C. Natural and biomimetic artificial surfaces for superhydrophobicity, self-cleaning, low adhesion, and drag reduction. Prog. Mater. Sci. 56, 1–108 (2011).

Shirtcliffe, N. J., McHale, G., Atherton, S. & Newton, M. I. An introduction to superhydrophobicity. Adv. Colloid Interface Sci. 161, 124–138 (2010).

Upadhyay, R. K. & Waghmare, P. R. Underwater oil drop storage, guided transport, and oil/water separation using surfaces with wettability contrast prepared through a vapor-based etching method. ACS Appl Mater. Interfaces 12, 11144–11154 (2020).

Roach, P., Shirtcliffe, N. J. & Newton, M. I. Progess in superhydrophobic surface development. Soft Matter 4, 224–240 (2008).

Yan, Y. Y., Gao, N. & Barthlott, W. Mimicking natural superhydrophobic surfaces and gras** the wetting process: a review on recent progress in preparing superhydrophobic surfaces. Adv. Colloid Interface Sci. 169, 80–105 (2011).

Yilgor, I., Bilgin, S., Isik, M. & Yilgor, E. Facile preparation of superhydrophobic polymer surfaces. Polym. (Guildf.) 53, 1180–1188 (2012).

Yilgor, I., Bilgin, S., Isik, M. & Yilgor, E. Tunable wetting of polymer surfaces. Langmuir 28, 14808–14814 (2012).

Polizos, G. et al. Transparent superhydrophobic surfaces using a spray coating process. Sol. Energy Mater. Sol. Cells 176, 405–410 (2018).

Hwang, H. S. et al. Facile fabrication of transparent superhydrophobic surfaces by spray deposition. ACS Appl Mater. Interfaces 3, 2179–2183 (2011).

Dong, L. et al. Controllable superhydrophobic surfaces with tunable adhesion fabricated by laser interference lithography. Surf. Coat. Technol. 372, 434–441 (2019).

Lan, H., Ding, Y., Liu, H. & Lu, B. Review of the wafer stage for nanoimprint lithography. Microelectron. Eng. 84, 684–688 (2007).

Guo, L. J. Nanoimprint lithography: methods and material requirements. Adv. Mater. 19, 495–513 (2007).

Zhang, F. & Low, H. Y. Anisotropic wettability on imprinted hierarchical structures. Langmuir 23, 7793–7798 (2007).

Li, Y., Dai, S., John, J. & Carter, K. R. Superhydrophobic surfaces from hierarchically structured wrinkled polymers. ACS Appl Mater. Interfaces 5, 11066–11073 (2013).

Daghigh Shirazi, H. et al. Multiscale hierarchical surface patterns by coupling optical patterning and thermal shrinkage. ACS Appl Mater. Interfaces 13, 15563–15571 (2021).

Lee, S. G., Lim, H. S., Lee, D. Y., Kwak, D. & Cho, K. Tunable anisotropic wettability of rice leaf-like wavy surfaces. Adv. Funct. Mater. 23, 547–553 (2013).

Zhang, J., Sheng, X. & Jiang, L. The dewetting properties of Lotus leaves. Langmuir 25, 1371–1376 (2009).

Latthe, S. S., Terashima, C., Nakata, K. & Fujishima, A. Superhydrophobic surfaces developed by mimicking hierarchical surface morphology of lotus leaf. Molecules 19, 4256–4283 (2014).

Bixler, G. D. & Bhushan, B. Bioinspired rice leaf and butterfly wing surface structures combining shark skin and lotus effects. Soft Matter 8, 11271–11284 (2012).

Dean, B. & Bhushan, B. Shark-skin surfaces for fluid-drag reduction in turbulent flow: A review. Philos. Trans. R. Soc. A: Math., Phys. Eng. Sci. 368, 4775–4806 (2010).

Feng, L. et al. Petal effect: a superhydrophobic state with high adhesive force. Langmuir 24, 4114–4119 (2008).

Bhushan, B. & Nosonovsky, M. The rose petal effect and the modes of superhydrophobicity. Philos. Trans. R. Soc. A: Math., Phys. Eng. Sci. 368, 4713–4728 (2010).

Kaschuk, J. J. et al. Processing factors affecting roughness, optical and mechanical properties of nanocellulose films for optoelectronics. Carbohydr. Polym. 332, 121877 (2024).

Bella, F., Pugliese, D., Zolin, L. & Gerbaldi, C. Paper-based quasi-solid dye-sensitized solar cells. Electrochim. Acta 237, 87–93 (2017).

Wang, B. & Kerr, L. L. Dye sensitized solar cells on paper substrates. Sol. Energy Mater. Sol. Cells 95, 2531–2535 (2011).

Zhu, M. et al. Transparent and haze wood composites for highly efficient broadband light management in solar cells. Nano Energy 26, 332–339 (2016).

Jia, C. et al. Scalable, anisotropic transparent paper directly from wood for light management in solar cells. Nano Energy 36, 366–373 (2017).

Ha, D., Fang, Z., Hu, L. & Munday, J. N. Paper-based anti-reflection coatings for photovoltaics. Adv. Energy Mater. 4, 1301804 (2014).

Hou, G. et al. Approaching theoretical haze of highly transparent all-cellulose composite films. ACS Appl Mater. Interfaces 12, 31998–32005 (2020).

Sassi, J.-F. & Chanzy, H. Ultrastructural aspects of the acetylation of cellulose. Cellulose 2, 111–127 (1995).

Glegg, R. E., Ingerick, D., Parmerter, R. R., Salzer, J. S. T. & Warburton, R. S. Acetylation of cellulose I and II studied by limiting viscosity and X-ray diffraction. J. Polym. Sci. Part A-2: Polym. Phys. 6, 745–773 (1968).

Rodrigues Filho, G. et al. Synthesis and characterization of cellulose acetate produced from recycled newspaper. Carbohydr. Polym. 73, 74–82 (2008).

Homem, N. C. & Amorim, M. T. P. Synthesis of cellulose acetate using as raw material textile wastes. Mater. Today Proc. 31, S315–S317 (2020).

Meier, M. M., Kanis, L. A., de Lima, J. C., Pires, A. T. N. & Soldi, V. Poly(caprolactone triol) as plasticizer agent for cellulose acetate films: influence of the preparation procedure and plasticizer content on the physico-chemical properties. Polym. Adv. Technol. 15, 593–600 (2004).

Rodríguez, F. J., Galotto, M. J., Guarda, A. & Bruna, J. E. Modification of cellulose acetate films using nanofillers based on organoclays. J. Food Eng. 110, 262–268 (2012).

Hassan-Nejad, M., Ganster, J., Bohn, A., Pinnow, M. & Volkert, B. Bio-based nanocomposites of cellulose acetate and nano-clay with superior mechanical properties. Macromol. Symp. 280, 123–129 (2009).

Gardner, R. M. et al. Compostability of cellulose acetate films. J. Appl Polym. Sci. 52, 1477–1488 (1994).

Hickey, R. J. & Pelling, A. E. Cellulose biomaterials for tissue engineering. Front Bioeng. Biotechnol. 7, 45 (2019).

Gill, A., Lillie, G., Farace, G. & Vadgama, P. Biocompatible interfaces for biosensors. Int J. Environ. Anal. Chem. 85, 699–725 (2005).

Vatanpour, V. et al. Cellulose acetate in fabrication of polymeric membranes: a review. Chemosphere 295, 133914 (2022).

Law, R. C. 5. Applications of cellulose acetate 5.1 Cellulose acetate in textile application. Macromol. Symp. 208, 255–266 (2004).

Salleh, K. M., Armir, N. A. Z., Mazlan, N. S. N., Wang, C. & Zakaria, S. Cellulose and its derivatives in textiles: primitive application to current trend. in Fundamentals of Natural Fibres and Textiles Chapter 2, 33–63 (Elsevier, 2021). https://doi.org/10.1016/B978-0-12-821483-1.00014-0.

Vatankhah, E., Prabhakaran, M. P., **, G., Mobarakeh, L. G. & Ramakrishna, S. Development of nanofibrous cellulose acetate/gelatin skin substitutes for variety wound treatment applications. J. Biomater. Appl. 28, 909–921 (2014).

Ou, J. et al. Washable and antibacterial superhydrophbic fabric. Appl Surf. Sci. 364, 81–85 (2016).

Mondal, S., Pal, S. & Maity, J. Hydrophobic thin fluoropolymer coating on cotton surfaces. Int. J. Polym. Anal. Charact. 23, 376–382 (2018).

Mondal, S., Pal, S., Chaudhuri, A. & Maity, J. Fabrication of fluoropolymer-modified hydrophobic functionalization of cotton fabric by admicellar polymerization. J. Text. Inst. 110, 1747–1754 (2019).

Samyn, P. Wetting and hydrophobic modification of cellulose surfaces for paper applications. J. Mater. Sci. 48, 6455–6498 (2013).

Scarratt, L. R. J., Hoatson, B. S., Wood, E. S., Hawkett, B. S. & Neto, C. Durable superhydrophobic surfaces via spontaneous wrinkling of teflon AF. ACS Appl Mater. Interfaces 8, 6743–6750 (2016).

Gao, S. et al. Transferrable superhydrophobic surface constructed by a hexagonal cui powder without modification by low-free-energy materials. ACS Appl Mater. Interfaces 1, 2080–2085 (2009).

Choi, A. L., Sun, G., Zhang, Y. & Grandjean, P. Developmental fluoride neurotoxicity: A systematic review and meta-analysis. Environ. Health Perspect. 120, 1362–1368 (2012).

Lesar, B., Pavlič, M., Petrič, M., Škapin, A. S. & Humar, M. Wax treatment of wood slows photodegradation. Polym. Degrad. Stab. 96, 1271–1278 (2011).

Freeman, M. H., Nicholas, D. D. & Schultz, T. P. Non-arsenical wood protection: alternatives for CCA, Creosote, and Pentachlorophenol. In Environmental Impacts of Treated Wood (eds. Townsend, T. G. & Solo-Gabriele, H.) 19–36 (CRC/Taylor and Francis, 2006).

Reimer, M. & Zollfrank, C. Cellulose for light manipulation: methods, applications, and prospects. Adv. Energy Mater. 11, 2003866 (2021).

Gomes, L. C. et al. A comparison of vegetable leaves and replicated biomimetic surfaces on the binding of Escherichia coli and Listeria monocytogenes. Food Bioprod. Process. 137, 99–112 (2023).

Shellhammer, T. H., Rumsey, T. R. & Krochta, J. M. Viscoelastic properties of edible lipids. J. Food Eng. 33, 305–320 (1997).

Cassie, A. B. D. & Baxter, S. Wettability of porous surfaces. Trans. Faraday Soc. 40, 546 (1944).

Lafuma, A. & Quéré, D. Superhydrophobic states. Nat. Mater. 2, 457–460 (2003).

Kota, A. K., Li, Y., Mabry, J. M. & Tuteja, A. Hierarchically structured superoleophobic surfaces with ultralow contact angle hysteresis. Adv. Mater. 24, 5838–5843 (2012).

Kota, A. K., Mabry, J. M. & Tuteja, A. Superoleophobic surfaces: design criteria and recent studies. Surf. Innov. 1, 71–83 (2013).

Quéré, D. Wetting and roughness. Annu Rev. Mater. Res. 38, 71–99 (2008).

Chen, Y., He, B., Lee, J. & Patankar, N. A. Anisotropy in the wetting of rough surfaces. J. Colloid Interface Sci. 281, 458–464 (2005).

Bati, A. S. R. et al. Next-generation applications for integrated perovskite solar cells. Commun. Mater. 4, 2 (2023).

Somesh, T. E., Al-Gunaid, M. Q. A., Madhukar, B. S. & Siddaramaiah. Photosensitization of optical band gap modified polyvinyl alcohol films with hybrid AgAlO2 nanoparticles. Journal of Materials Science: Materials in Electronics 30, 37–49 (2019).

Hatamoto, K., Shimada, H., Kondo, M., Nobukawa, S. & Yamaguchi, M. Effect of acetyl substitution on the optical anisotropy of cellulose acetate films. Cellulose 25, 4453–4462 (2018).

Wang, L. et al. Quantitative and discriminative analysis of carnauba waxes by reactive pyrolysis-GC in the presence of organic alkali using a vertical microfurnace pyrolyzer. J. Anal. Appl Pyrolysis 58–59, 525–537 (2001).

Zou, F., Li, H., Dong, Y., Tewari, G. C. & Vapaavuori, J. Optically transparent pectin/poly(methyl methacrylate) composite with thermal insulation and UV blocking properties based on anisotropic pectin cryogel. Chem. Eng. J. 439, 135738 (2022).

Niu, X. et al. Highly Transparent, Strong, and Flexible Films with Modified Cellulose Nanofiber Bearing UV Shielding Property. Biomacromolecules 19, 4565–4575 (2018).

Saliba, M. et al. How to Make over 20% Efficient Perovskite Solar Cells in Regular (n–i–p) and Inverted (p–i–n) Architectures. Chem. Mater. 30, 4193–4201 (2018).

Acknowledgements

This work was financially supported and part of the Academy of Finland’s Flagship Program under Projects No. 318890 and 318891 (Competence Center for Materials Bioeconomy, FinnCERES). In addition, M.M. acknowledges Fortum and Neste Foundation (Grant No. 20210045) and PREIN flagship project (Grant No. 346529) for generous funding. J.V. acknowledges Academy of Finland project No. 341459. BioEconomy, OtaNano and RaMi infrastructures were employed in this work.

Author information

Authors and Affiliations

Contributions

Hamidreza Daghigh Shirazi: Conceptualization, Methodology, Investigation, Writing - Original Draft, Visualization, Funding acquisition. Seyed Mehran Mirmohammadi: Conceptualization, Investigation, Writing - Review & Editing. Seyede Maryam Mousavi: Writing - Original Draft, Investigation, Validation. Magnus Markkanen: Investigation. Janne Halme: Writing - Review & Editing. Ville Jokinen: Methodology, Writing - Review & Editing, Resources. Jaana Vapaavuori: Supervision, Conceptualization, Funding acquisition, Resources, Writing - Review & Editing.

Corresponding author

Ethics declarations

Competing interests

All other authors declare no competing interests.

Peer review

Peer review information

Communications Materials thanks the anonymous reviewers for their contribution to the peer review of this work. Primary Handling Editor: Jet-Sing Lee. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Daghigh Shirazi, H., Mirmohammadi, S.M., Mousavi, S.M. et al. Bio-inspired surface structures promote optical transmittance and hydrophobicity in cellulose-based films for self-cleaning perovskite solar cells. Commun Mater 5, 88 (2024). https://doi.org/10.1038/s43246-024-00523-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s43246-024-00523-2

- Springer Nature Limited