Abstract

To realize a thermoelectric power generator, typically, a junction between two materials with different Seebeck coefficients needs to be fabricated. Such differences in Seebeck coefficients can be induced by do**, which renders it difficult when working with two-dimensional (2d) materials. However, do** is not the only way to modulate the Seebeck coefficient of a 2d material. Substrate-altered electron–phonon scattering mechanisms can also be used to this end. Here, we employ the substrate effects to form a thermoelectric junction in ultrathin, few-layer MoS2 films. We investigated the junctions with a combination of scanning photocurrent microscopy and scanning thermal microscopy. This allows us to reveal that thermoelectric junctions form across the substrate-engineered parts. We attribute this to a gating effect induced by interfacial charges in combination with alterations in the electron–phonon scattering mechanisms. This work demonstrates that substrate engineering is a promising strategy for develo** future compact thin-film thermoelectric power generators.

Similar content being viewed by others

Introduction

In ultrathin materials with large surface-to-bulk ratio, interactions with the substrate can have a strong impact on the material’s properties1,2,3,4,5,6. It is therefore important to understand this so-called substrate effect, especially in order to optimize the reliability of future devices based on two-dimensional (2d) semiconducting materials. As an example, the choice of substrate for mono- and few-layer MoS2 has been shown to strongly affect its Raman modes and photoluminescence (PL)7, electronic8, and thermal transport9 properties. In the following, we predict that a thermoelectric junction with a Seebeck coefficient difference of tens of µV K−1 can be fabricated when connecting regions of suspended MoS2 to supported regions based on the experimental evidence reported before9.

We assume that the Seebeck coefficient \(S\) in thermal equilibrium is composed of contributions from the energy-dependent diffusion (\({S}_{{\rm{N}}}\)), scattering (\({S}_{{\rm{\tau }}}\)) and the phonon-drag (\({S}_{{\rm{pd}}}\)), so that \(S={S}_{{\rm{N}}}+{S}_{\tau }+{S}_{{\rm{pd}}}\)9,10. Here, \({S}_{{\rm{N}}}\) and \({S}_{{\rm{\tau }}}\) terms can be written from the Mott relation assuming that MoS2 is in the highly conductive state and electrons are the majority carriers:

where \({T}\) is the temperature, \({k}_{{\rm{B}}}\) is the Boltzmann constant, \(e\) is the electron’s charge, \(\tau\) is the relaxation time, \({E}_{{\rm{F}}}\) is the Fermi energy, \({E}_{{\rm{C}}}\) is the conduction band edge energy, \(r\) is scattering parameter and \(E\) is the energy. \({F}_{m}(\eta )\) is the m-th order Fermi integral11. In the 2d limit, \(\tau\) is energy independent; thus \({S}_{\tau }\) is zero. \({S}_{{pd}}\) term can be estimated from the theory of phonon-drag in semiconductors in the first order as \({S}_{{\rm{pd}}}=-\frac{\beta {v}_{{\rm{p}}}{l}_{{\rm{p}}}}{\mu T}\) where \({v}_{{\rm{p}}}\) and \({l}_{{\rm{p}}}\) are the group velocity and the mean free path of a phonon, \(\beta\) is a parameter to modify the electron–phonon interaction strength and ranges from 0 to 1, and \(\mu\) is the electron mobility, respectively10. Importantly, \({l}_{{\rm{p}}}\) and \(\mu\) are heavily affected by the presence of a substrate12, which implies that the \({S}_{{\rm{pd}}}\) term gets strongly modified when the MoS2 flake is suspended. As a result, a thermoelectric junction can be formed on MoS2 by locally modifying the supporting substrate.

In this work, we employ the substrate effect to enable completely new functionalities in a 2d semiconductor device. To this end, we engineer the substrate that atomically thin MoS2 is deposited on. Using a combination of scanning photocurrent microscopy (SPCM) along with scanning thermal microscopy (SThM) we demonstrate that substrate engineering is a powerful way to build a thermoelectric junction.

Results and discussion

Scanning photocurrent microscopy on substrate-engineered MoS2

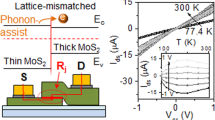

Based on the calculation outlined in the Introduction, we find that for suspended MoS2 at room temperature \({S}_{{\rm{pd}}}\approx -100\,\) µV K−1 and for MoS2 on SiO2 at room temperature \({S}_{{\rm{pd}}}\approx -230\,\) µV K−1. Similarly, \({S}_{{\rm{N}}}\) is heavily influenced by the presence or absence of the substrate as electron density depends on the interfacial Coulomb impurities and short-ranged defects11,12,13,14,15,16,17. We estimate that that for MoS2, \({S}_{N}\) ranges from −400 µV K−1 to −200 µV K−1 for carrier concentrations ranging from 1012 cm−2 (suspended few-layer MoS2) to 3 × 1013 cm−2 (SiO2 supported few layer MoS2)11,18,19. As a result, a substrate-engineered thermoelectric junction with a Seebeck coefficient difference of \(\Delta S\approx 70\) µV K−1 can be formed along the MoS2 flake (see Fig. 1a and Supplementary Note 1).

a Schematic of a substrate-engineered device: a MoS2 flake is suspended over a circular hole drilled in the substrate. Metal contacts are used for scanning photocurrent microscopy (SPCM), scanning thermal gate microscopy (SThGM) and I–V measurements. The inset shows a magnification of the area indicated by the dashed yellow square, where Seebeck coefficients of supported and suspended parts are labeled with \({S}_{1}\) and \({S}_{2}\), respectively. b Optical microscope image of a multi-layered device over circular holes with indium contacts, marked with gray overlays. Scale bar: 10 µm. c SPCM reflection map and the corresponding open-circuit photocurrent map acquired from the yellow dashed rectangle in (b) with 532 nm laser. \({\{I}_{\min },{I}_{\max }\}{\boldsymbol{=}}{\boldsymbol{\{}}{\boldsymbol{-}}0.5,\,0.5\}\) nA. d Photocurrent map from the red dashed rectangle region in (c). Black circle is the position of the hole determined from the reflection image. Right panel shows the photocurrent, \({I}_{{PC}}\) vs bias taken from point 1 (red dots) and point 2 (blue dots) over the suspended part of the crystal marked on the left panel. Lower graph is the derived photoconductance, \({G}_{{PC}}\) vs. bias.

To test this hypothesis, we fabricated substrate-engineered MoS2 devices by mechanical exfoliation and dry transfer20 of atomically thin MoS2 flakes on substrates (sapphire or oxidized silicon) with pre-patterned trenches/holes formed by focused ion beam (FIB). We contacted the flakes with Indium needles21,22,23, which are suitable for achieving Ohmic contacts to MoS224,25 (gold-contacted device measurements are shown in Supplementary Note 2 and Supplementary Fig. 1). A typical device is shown in Fig. 1b. We then used scanning photocurrent microscopy to locally heat up the junction with a focused laser beam and to measure the photothermoelectric current that is generated (see “Methods” for experimental details). Figure 1c shows the greyscale reflection intensity map and the corresponding photocurrent distribution over the device. For the few-layer suspended MoS2 devices, we observe a bipolar photoresponse at the junctions between the supported and the suspended part of the crystal. The spatial distribution of the signal agrees well with the finite element analysis simulations given in Supplementary Note 3 (and Supplementary Fig. 2 therein) and suggests the formation of a thermoelectric junction. When applying a voltage bias \(V\) to the junction, the photocurrent, \({I}_{{\rm{PC}}}\) changes linearly with bias, while the photoconductance, \({G}_{{\rm{PC}}}=\frac{{I}_{{\rm{PC}}}^{{\rm{V}}}-{I}_{{\rm{PC}}}^{0}}{V}\,\)(\({I}_{{\rm{PC}}}^{{\rm{V}}}\), \({I}_{{\rm{PC}}}^{0}\): photocurrent under \(V\) and 0 mV bias, respectively) stays constant (Fig. 1d). Such bias-independent photoconductance is typically an indication for an photothermoelectric nature of the observed signal21,23,26,27,28. Although we propose that the photocurrent in substrate-engineered MoS2 devices is dominated by the photothermal effect (PTE)29,30, other possible mechanisms have been reported that may lead to a photovoltaic response. These include (1) strain-related effects such as strain modulation of materials properties and flexo-photovoltaic effect13, and (2) substrate proximity-related effects that forms a built-in electric field31.

Thermoelectric origin of the photocurrent

Next, we present experimental evidence for a thermoelectric origin of the observed photocurrent. To this end, we employed scanning thermal gate microscopy (SThGM), where a hot AFM tip heats up the junction locally while the resulting voltage build-up on the devices is recorded (see “Methods”). Since no laser-illumination of the sample is required in this method, it can be used to ultimately exclude photovoltaic effects. Figure 2 compares SPCM and SThGM maps of the same holes. We observed the same bipolar signals in the suspended regions with both experimental methods. Thanks to its sub-100 nm lateral resolution, SThGM further allows us to observe local variations of the thermovoltage in supported MoS2 that can be attributed to charge puddles induced by local do** via the substrate32,33,34. We confirmed that the SThGM signal disappears when no power is dissipated in the probe heater, which rules out parasitic effects induced by the laser used for AFM feedback. Furthermore, SThGM allows us to estimate the magnitude of the local Seebeck coefficient variations. Using the probe-calibration data, we obtain a value of \(\Delta S=72\pm 10\) µV K−1 (See Supplementary Note 4). Despite the uncertainties regarding the real sample temperature, the obtained \(\Delta S\) value is very close to the theoretically predicted value.

a Optical micrograph of the device. Scale bar is 10 µm. b SPCM reflection map and c photocurrent map of the device shown in (a). Scale bar: 10 µm. The yellow rectangle indicates the region that was investigated by SThGM in (d) (AFM height map) and e (SThGM thermovoltage map). f SPCM map of the same region excerpted from the map given in (c). Color scale is the same as in (c). Scale bars in (d–f): 3 µm.

To understand why suspending MoS2 alters its Seebeck coefficient, we first would like to discuss the possibility of strain-induced changes in the material’s properties. MoS2, like graphene, is nominally compressed when deposited on a substrate35,36,37,38. Upon suspending the crystals, the free-standing part either adheres to the sidewalls of the hole and dimples or bulges. As a result, the strain might be present in the free-standing part of the crystal. Strain can affect both the bandgap and the Seebeck coefficient of MoS2. The indirect optical gap is modulated by −110 meV/%-strain for a trilayer MoS235,39. Ab initio studies show a ~10% decrease in the Seebeck coefficient of monolayer MoS2 per 1% tensile strain40. To estimate the biaxial strain, we performed atomic force microscopy (AFM) height trace map** on the samples. Most samples, regardless of the geometry of the hole, exhibit slight bulging of a few nanometers. For the MoS2 flakes suspended on the circular holes in the device shown in Fig. 3a, the bulge height is \(\delta t\approx 25\) nm. The SPCM map for the sample is shown in Fig. 1d. Similar \(\delta t\) values were measured for other devices. The biaxial strain can then be calculated using a uniformly loaded circular membrane model and is as low as 0.0025%41. Such a small strain on MoS2 is not sufficient to induce a significant change in bandgap or Seebeck coefficient13,42,43. Further experimental evidence regarding limited strain contribution on the observed bipolar response based on Raman map** of various samples is provided in Supplementary Notes 5 and 644,48 and thus its Seebeck coefficient. To investigate the electrostatic impact of the substrate on the MoS2 membrane, we investigated the surface potential difference (SPD) on devices using Kelvin Probe Force Microscopy (KPFM). SPD can provide an insight on the band bending of the MoS2 due to the substrate effects49. Figure 3b–d shows the AFM height trace map and the uncalibrated SPD map of the sample. SPD across the supported and suspended part of the flake is on the order of 50 mV. This shift in the SPD value hints that there is a slight change in the Fermi level of the suspended part with respect to the supported part of the crystal. The same type of charge carriers is dominant on both sides of the junction formed by the suspended and supported parts of the crystal. The band structure formed by such a junction in zero bias cannot be used in the separation of photoinduced carriers50; however, it can lead to the formation of a thermoelectric junction11,51. This is in line with the SThGM measurements.

Controlling the substrate effect via electric field

In the remainder of the paper, we aim at controlling the electrostatics that is responsible for the formation of a thermoelectric junction. Charge transport in MoS2 is dominated by electrons due to unintentional do**18,52. Modulating the density and the type of free charge carriers can be done by applying a gate voltage \(\,{V}_{{\rm{G}}}\) to the junction53. This significantly modifies the magnitude and the sign of the Seebeck coefficient as demonstrated in previous studies16,29,30,54. The Mott relation55 can be used to model the Seebeck coefficient as a function of \({V}_{{\rm{G}}}\):

Here, \(T\) is the temperature, \({k}_{{\rm{B}}}\) is the Boltzmann constant, \(e\) is the electron’s charge, \(R\) is the device resistance, \({E}_{{\rm{F}}}\) is the Fermi energy, and \(E\) is the energy.

Since hole transport is limited due to substrate-induced Fermi level pinning on SiO2 supported MoS2 field-effect devices46 to observe the sign inversion of the Seebeck coefficient (see Supplementary Note 6 for measurements on device fabricated on SiO2 and Al2O3-coated SiO2) we followed an alternative approach to emulate suspension: we fabricated heterostructure devices where the crystal is partially supported by hexagonal boron nitride (h-BN). h-BN is commonly used to encapsulate two-dimensional materials thanks to its hydrophobic and atomically smooth surface. This leads to less unintentional do** due to the interfacial charge trap** and reduced electron scattering7,56,57. A ~10 ML MoS2 is placed over a 10-nm thick h-BN crystal to form a double-junction device (see Supplementary Note 7 for a single-junction device), and indium contacts are placed over the MoS2. The device is on 1 µm thick oxide-coated Si substrate where Si is used as the back-gate electrode. Figure 4a shows the optical micrograph of the device and its schematic. The presence of h-BN modifies the SPD by 80 mV—a value very similar to the values we find for suspended devices (see Supplementary Note 7)—which is consistent with the relative n-do** by the h-BN substrate31,56. We, therefore, attribute this difference to the Fermi level shift due to the difference in interfacial charge do** by the different substrates.

a Optical micrograph of a Si back-gated MoS2 device partially placed over h-BN. Its cross-sectional schematic is shown in the lower panel. Scale bar: 10 µm. b SPCM reflection map and the photocurrent map of the device shown in (a). \({I}_{\max }=3\) nA and \({I}_{\min }=\,-3\) nA. Scale bar: 10 µm. c Current–Voltage graph versus \({V}_{G}\) from −40 to 40 V. Inset shows the resistance versus \({V}_{G}\). d \({I}_{{PC}}\) vs. \({V}_{G}\) recorded at the points marked in the SPCM map in (b).

Figure 4b shows the SPCM map under zero gate voltage. We observe a bipolar photocurrent signal from the junctions between h-BN and SiO2 supported MoS2. Raman map** (see Supplementary Fig. 12) reveals a slight intensity decrease and a small shift of the \({{\rm{A}}}_{1g}\) peak over the h-BN-supported part of the MoS2. This is consistent with the stiffening of the Raman mode due to the higher degree of charged impurities in SiO2 as compared to h-BN7. By applying a gate voltage to the device, its resistance can be tuned significantly as free charges are depleted (Fig. 4c). Under large positive gate voltages, the I–V characteristic becomes asymmetric. To investigate the dependence of the photocurrent on carrier type and concentration, the laser is held at specific positions on the device as marked in Fig. 4d, and the gate is swept from positive to negative voltages with respect to the ground terminal. For positive gate voltages, the magnitude of the photoresponse from both junctions, between h-BN and SiO2 supported MoS2, (points 2 and 3) decreases. When a negative gate voltage is applied, the magnitude of the photoresponse at both junctions increases by almost a factor of two at \({V}_{{\rm{G}}}=\,-21.5\,\) V. Once this maximum is reached, the amplitude of the photocurrent at both points decreases and has the same value as the photocurrent generated over the MoS2 (point 4) at \({V}_{{\rm{G}}}=\,-34.5\,\) V.

These observations can be qualitatively explained as follows: at a gate voltage of \({V}_{{\rm{G}}}=\,-34.5\,\) V, the majority charge carrier type in the h-BN supported part changes from electrons to holes. As a consequence, the Seebeck coefficients of MoS2 resting on h-BN and SiO2, respectively, become similar, which leads to \(\triangle S\approx 0,\) and curves 2, 3, and 4 in Fig. 4d cross. The photocurrent signal recorded near the indium contacts (points 1 and 5) decreases non-monotonically with decreasing \({V}_{{\rm{G}}}\) and reaches zero at \({V}_{{\rm{G}}}=\,-40\,\) V. This shows that the photoresponse mechanism at the Indium-MoS2 junction is not solely due to the Seebeck effect.

In conclusion, we demonstrated that substrate engineering can be used to generate a thermoelectric junction in atomically thin MoS2 devices. Similar strategies can be employed in other low-dimensional materials that exhibit large and tunable Seebeck coefficients. This might in particular be promising at low temperature where effects like band-hybridization and Kondo scattering can produce a very strong photothermoelectric effect9.

Methods

Scanning photocurrent microscopy

SPCM setup is a commercially available setup from LST Scientific Instruments Ltd., which offers a compact scanning head with easily interchangeable lasers. Two SR-830 Lock-in amplifiers are employed, one for the reflection map and the other for the photocurrent/voltage measurements. In the main text we reported the photocurrent (a measurement of the photovoltage is given in Supplementary Note 9). The incident laser beam is chopped at a certain frequency and focused onto the sample through a 40x objective. The electrical response is collected through gold probes pressed on the electrical contacts of the devices and the signal is amplified by a lock-in amplifier set to the chop** frequency of the laser beam. Although various wavelengths (406, 532, 633 nm) are employed for the measurements, unless otherwise stated we used 532 nm in the experiments reported in the main text (see Supplementary Fig. 12 for SPCM measurements with different wavelengths). All the excitation energies are above the indirect bandgap of the few-layer MoS2. We showed that devices are very durable even when they are kept under ambient for 23 months. We measured the device reported in Fig. 1 after 23 months and obtained very similar magnitudes for the photoresponse (see Supplementary Note 10).

Scanning thermal microscopy

Scanning Thermal Microscopy measurements were performed with a Dimension Icon (Bruker) AFM under ambient conditions. The probe used in the experiments is VITA-DM-GLA-1 made of a palladium heater on a silicon nitride cantilever and tip. The radius is typically in the order of 25–40 nm. The heater is part of a modified Wheatstone bridge and is driven by a combined 91 kHz AC and DC bias, as reported elsewhere. The signal is detected via a SR-830 lock-in amplifier and fed in the AFM controller. This signal monitors the probe temperature and thus allows to locally map the thermal conductance of the sample. In this work, the power supplied to the probe gives rise to a 45 K excess temperature.

While the probe is scanning the sample, we measure the voltage drop across the device using a low-noise preamplifier (SR 560). This voltage is created by the local heating induced by the hot SThM tip. It is then fed also to the AFM controller and recorded simultaneously. In this study, the thermovoltage measurements were performed without modulating the heater power. We note that it is also possible to generate similar maps by varying the heater temperature and detecting thermovoltage via lock-in detection.

Data availability

Source data is available from the corresponding author upon request.

References

Chen, J. H. et al. Charged-impurity scattering in graphene. Nat. Phys. 4, 377–381 (2008).

Zhang, Y., Brar, V. W., Girit, C., Zettl, A. & Crommie, M. F. Origin of spatial charge inhomogeneity in graphene. Nat. Phys. 5, 722–726 (2009).

Wang, Q. H. et al. Understanding and controlling the substrate effect on graphene electron-transfer chemistry via reactivity imprint lithography. Nat. Chem. 4, 724–732 (2012).

Bao, W., Cai, X., Kim, D., Sridhara, K. & Fuhrer, M. S. High mobility ambipolar MoS2 field-effect transistors: Substrate and dielectric effects. Appl. Phys. Lett. 102, 042104 (2013).

Robinson, B. J. et al. Structural, optical and electrostatic properties of single and few-layers MoS2: effect of substrate. 2D Mater. 2, 015005 (2015).

Wang, L., Nilsson, Z. N., Tahir, M., Chen, H. & Sambur, J. B. Influence of the substrate on the optical and photo-electrochemical properties of monolayer MoS2. ACS Appl. Mater. Interfaces 12, 15034–15042 (2020).

Buscema, M., Steele, G. A., van der Zant, H. S. J. & Castellanos-Gomez, A. The effect of the substrate on the Raman and photoluminescence emission of single-layer MoS2. Nano Res. 7, 561–571 (2014).

Sercombe, D. et al. Optical investigation of the natural electron do** in thin MoS2 films deposited on dielectric substrates. Sci. Rep. 3, 1–6 (2013).

Wu, J. et al. Large enhancement of thermoelectric performance in MoS2/h-BN heterostructure due to vacancy-induced band hybridization. Proc. Natl Acad. Sci. USA 117, 13929–13936 (2020).

Herring, C. Theory of the thermoelectric power of semiconductors. Phys. Rev. 96, 1163–1187 (1954).

Ng, H. K., Chi, D. & Hippalgaonkar, K. Effect of dimensionality on thermoelectric powerfactor of molybdenum disulfide. J. Appl. Phys. 121, 204303 (2017).

Cui, X. et al. Multi-terminal transport measurements of MoS2 using a van der Waals heterostructure device platform. Nat. Nanotechnol. 10, 534–540 (2015).

Jiang, J. et al. Flexo-photovoltaic effect in MoS2. Nat. Nanotechnol. 16, 894–901 (2021).

Rice, C. et al. Raman-scattering measurements and first-principles calculations of strain-induced phonon shifts in monolayer MoS2. Phys. Rev. B Condens. Matter Mater. Phys. 87, 081307 (2013).

Hippalgaonkar, K. et al. High thermoelectric power factor in two-dimensional crystals of MoS2. Phys. Rev. B 95, 115407 (2017).

Kayyalha, M., Maassen, J., Lundstrom, M., Shi, L. & Chen, Y. P. Gate-tunable and thickness-dependent electronic and thermoelectric transport in few-layer MoS2. J. Appl. Phys. 120, 134305 (2016).

Liu, L., Lu, Y. & Guo, J. On monolayer MoS2 field-effect transistors at the scaling limit. IEEE Trans. Electron Devices 60, 4133–4139 (2013).

Dagan, R. et al. Two-dimensional charge carrier distribution in MoS2 monolayer and multilayers. Appl. Phys. Lett. 114, 101602 (2019).

Chae, W. H., Cain, J. D., Hanson, E. D., Murthy, A. A. & Dravid, V. P. Substrate-induced strain and charge do** in CVD-grown monolayer MoS2. Appl. Phys. Lett. 111, 143106 (2017).

Castellanos-Gomez, A. et al. Deterministic transfer of two-dimensional materials by all-dry viscoelastic stam**. 2D Mater. 1, 011002 (2014).

Mehmood, N., Rasouli, H. R., Çakıroğlu, O. & Kasırga, T. S. Photocurrent generation in a metallic transition-metal dichalcogenide. Phys. Rev. B 97, 195412 (2018).

Rasouli, H. R. et al. Electric-field-induced reversible phase transitions in a spontaneously ion-intercalated 2D metal oxide. Nano Lett. 21, 3997–4005 (2021).

Razeghi, M., Üstünçelik, M., Shabani, F., Demir, H. V. & Kasırga, T. S. Plasmon-enhanced photoresponse of single silver nanowires and their network devices. Nanoscale Horiz. 7, 396–402 (2022).

Kim, B.-K. et al. Origins of genuine Ohmic van der Waals contact between indium and MoS2. npj 2D Mater. Appl. 5, 9 (2021).

Wang, Y. et al. Van der Waals contacts between three-dimensional metals and two-dimensional semiconductors. Nature 568, 70–74 (2019).

Kasirga, T. S. Thermal Conductivity Measurements in Atomically Thin Materials and Devices (Springer Singapore, 2020).

Kasirga, T. S. et al. Photoresponse of a strongly correlated material determined by scanning photocurrent microscopy. Nat. Nanotechnol 7, 723–727 (2012).

Çakıroğlu, O. et al. Thermal conductivity measurements in nanosheets via bolometric effect. 2D Mater. 7, 035003 (2020).

Buscema, M. et al. Large and tunable photothermoelectric effect in single-layer MoS2. Nano Lett. 13, 358–363 (2013).

Zhang, Y. et al. Photothermoelectric and photovoltaic effects both present in MoS2. Sci. Rep. 5, 1–7 (2015).

Utama, M. I. B. et al. A dielectric-defined lateral heterojunction in a monolayer semiconductor. Nat. Electron. 2, 60–65 (2019).

Harzheim, A., Evangeli, C., Kolosov, O. V. & Gehring, P. Direct map** of local Seebeck coefficient in 2D material nanostructures via scanning thermal gate microscopy. 2D Mater. 7, 041004 (2020).

Spièce, J. et al. Quantifying thermal transport in buried semiconductor nanostructures: via cross-sectional scanning thermal microscopy. Nanoscale 13, 10829–10836 (2021).

Spiece, J. et al. Improving accuracy of nanothermal measurements via spatially distributed scanning thermal microscope probes. J. Appl. Phys. 124, 015101 (2018).

Lloyd, D. et al. Band gap engineering with ultralarge biaxial strains in suspended monolayer MoS2. Nano Lett. 16, 5836–5841 (2016).

Bertolazzi, S., Brivio, J. & Kis, A. Stretching and breaking of ultrathin MoS2. ACS Nano 5, 9703–9709 (2011).

Lee, C., Wei, X., Kysar, J. W. & Hone, J. Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 321, 385–388 (2008).

Castellanos-Gomez, A. et al. Elastic properties of freely suspended MoS2 nanosheets. Adv. Mater. 24, 772–775 (2012).

Li, Z. et al. Efficient strain modulation of 2D materials via polymer encapsulation. Nat. Commun. 11, 1151 (2020).

Dimple, Jena, N. & De Sarkar, A. Compressive strain induced enhancement in thermoelectric-power-factor in monolayer MoS2 nanosheet. J. Phys. Condens. Matter 29, 225501 (2017).

Fichter, W. B. Some solutions for the large deflections of uniformly loaded circular membranes. NASA Tech. Pap 3658, 13–16 (1997).

Yang, M. M., Kim, D. J. & Alexe, M. Flexo-photovoltaic effect. Science 360, 904–907 (2018).

Huang, Y. et al. An efficient route to prepare suspended monolayer for feasible optical and electronic characterizations of two-dimensional materials. InfoMat 4, e12274 (2022).

Lee, J. U. et al. Strain-shear coupling in bilayer MoS. Nat. Commun. 8, 1–7 (2017).

Çakıroğlu, O., Island, J. O., **e, Y., Frisenda, R. & Castellanos‐Gomez, A. An automated system for strain engineering and straintronics of 2D materials. Adv. Mater. Technol. 8, 2201091 (2023).

Mootheri, V. et al. Understanding ambipolar transport in MoS2 field effect transistors: the substrate is the key. Nanotechnology 32, 135202 (2021).

Drüppel, M., Deilmann, T., Krüger, P. & Rohlfing, M. Diversity of trion states and substrate effects in the optical properties of an MoS2 monolayer. Nat. Commun. 8, 1–7 (2017).

Lu, C. P., Li, G., Mao, J., Wang, L. M. & Andrei, E. Y. Bandgap, mid-gap states, and gating effects in MoS2. Nano Lett. 14, 4628–4633 (2014).

Ochedowski, O. et al. Effect of contaminations and surface preparation on the work function of single layer MoS2. Beilstein J. Nanotechnol. 5, 291–297 (2014).

Sun, D. et al. Ultrafast hot-carrier-dominated photocurrent in graphene. Nat. Nanotechnol. 7, 114–118 (2012).

Lee, C., Hong, J., Lee, W. R., Kim, D. Y. & Shim, J. H. Density functional theory investigation of the electronic structure and thermoelectric properties of layered MoS2, MoSe2 and their mixed-layer compound. J. Solid State Chem. 211, 113–119 (2014).

Siao, M. D. et al. Two-dimensional electronic transport and surface electron accumulation in MoS2. Nat. Commun. 9, 1–12 (2018).

Jahangir, I., Koley, G. & Chandrashekhar, M. V. S. Back gated FETs fabricated by large-area, transfer-free growth of a few layer MoS2 with high electron mobility. Appl. Phys. Lett. 110, 182108 (2017).

Dobusch, L. et al. Electric field modulation of thermovoltage in single-layer MoS2. Appl. Phys. Lett. 105, 253103 (2014).

Ashcroft, N. & Mermin, D. Solid State Physics (Thomson Learning Inc., 1976).

Joo, M. K. et al. Electron excess do** and effective Schottky barrier reduction on the MoS2/h-BN heterostructure. Nano Lett. 16, 6383–6389 (2016).

Li, L. et al. Raman shift and electrical properties of MoS2 bilayer on boron nitride substrate. Nanotechnology 26, 295702 (2015).

Acknowledgements

T.S.K. acknowledges support from TUBITAK under grant no: 121F366.

Author information

Authors and Affiliations

Contributions

T.S.K. designed and conceived the experiments. T.S.K. and P.G. prepared the manuscript. M.R. fabricated devices, performed the experiment, and analyzed the results. D.P. prepared the substrates, performed simulations, and helped with the experiments. O.O. performed the AFM and KPFM measurements and A.S. performed some of the earlier measurements. U.B. prepared some samples and performed polarization-dependent measurements. J.S., Y.H., and P.G. performed the SThGM measurements and analyzed the results. P.S.D. and J.M.R.W. contributed to discussions on the implementation of VITA-DM-GLA-1 SThM probes. All authors discussed the results and reviewed the final version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Razeghi, M., Spiece, J., Oğuz, O. et al. Single-material MoS2 thermoelectric junction enabled by substrate engineering. npj 2D Mater Appl 7, 36 (2023). https://doi.org/10.1038/s41699-023-00406-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41699-023-00406-z

- Springer Nature Limited