Abstract

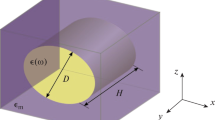

The light reflection properties of Ge disk lattices on Si substrates are studied as a function of the disk height and the gap width between disks. The interdisk spacing effect is observed even at such large gap widths as 500 nm. The gap width decrease leads to the appearance of the reflection minimum in the short wavelength region relative to one originated from the magnetic and electric dipole resonances in individual Ge disks, thereby essentially widening the antireflection properties. This minimum becomes significantly deeper at small gap widths. The observed behavior is associated with the features of the resonant fields around closely spaced disks according to numerical simulation data. The result shows the importance of using structures with geometrical parameters providing the short-wavelength minimum. This can essentially enhance their other resonant properties, which are widely used for applications, in particular, based on collective lattice resonances.

Similar content being viewed by others

Introduction

The efficiency of optoelectronic devices, such as solar cells and photodetectors, depends on their surface properties related to light reflection and transmission1,2. To reduce reflection, surface texturing and coating with antireflection dielectric films are usually used3,4. Recently, intensive research has been carried out on coatings of metal and/or dielectric particles as an alternative to continuous antireflection films5,6,7,8,9. Their action is based on the excitation of plasmonic10,11 or electromagnetic (EM) resonances12,13,14,15 in metal and dielectric particles, respectively. Compared to continuous films, the capabilities of antireflection coatings made of particles are wider. They can be less dependent on the EM radiation incidence angle5. In addition, they can be more broadband5,9, or, on the contrary, have a greater spectral selectivity6,8,16,17 due to using various resonance effects.

The characteristics of optical resonances are well studied for individual dielectric particles, while their arrays are used for practical applications. An experimental study of metal particle arrays revealed the effects of collective lattice resonances which provide laser generation17,18, biosensing applications19,20 and amplification of light radiation21,22,23. In addition to creating antireflection coatings, arrays of ordered dielectric particles can be used in optical waveguides24,25 and also as metasurfaces and metamaterials23,26. Particular attention is paid to the study of the interaction of resonant modes, excited in individual dielectric particles, with lattice modes. In this case, it is reasonable to expect that the role of lattice modes will increase with a decrease in the interparticle spacing as a result of an increase in the overlap of their fields and the appearance of diffraction effects27,28,37. Despite the absence of narrow minima due to collective lattice resonances, their effect, nevertheless, manifests itself in a greater depth of the efficient broad minimum in the short-wavelength region of our spectra. This agrees to the results of38, which showed that the scattering maxima caused by lattice resonances can be located far from the strongest EM resonances of individual particles, which, in our case, are of the dipole type located in the region of relatively longer wavelengths.

Conclusion

In this study we found that the influence of the close spacing of dielectric disks in their lattices on the reflection spectra is observed even at such large gap widths between the disks as 500 nm. The gap width value effect turns out to be stronger in the short-wavelength region of the measured spectra. According to our numerical simulations, this is due to the participation of quadrupole resonances and stronger resonant fields in the disk area caused by the close proximity of the disks. As a result, at small gap widths, the appearing reflection minimum in the short-wavelength region of the spectra is essentially deeper than the minimum in their long-wavelength region, which originated from magnetic and electric dipole resonances in individual dielectric disks. The stronger gap width value that influences the reflection in the short-wavelength region should be taken into account both in the manufacture of antireflection coatings and sensors which operation is based on the use of local resonant EM fields. As for collective lattice resonances designed for the conditions of the short-wavelength reflection minimum, they can be more efficient in their various applications, compared to those created for the conditions of magnetic and electric dipole resonances.

Methods

Ge disk fabrication

Ge disk arrays were fabricated on Si substrates coated with a 5 nm thick thermal SiO2 film, similar to how it was made in14. After a positive resist PMMA 950 K A4 film deposition on the substrate, it was exposed to a 20 keV electron beam at the aperture of 10 μm using the Raith PIONEER lithography system. Circle-shaped holes were formed by selective dissolving the PMMA films in the methyl isobutyl ketone and isopropyl alcohol (IPA) solution taken as 1:3, respectively, at room temperature for 30 s. The fabricated masks consisted of holes of about 200 nm in diameter arranged in a square lattice. The distance between hole centers was varied from about 250 to 700 nm. Ge films of different thicknesses were deposited onto the prepared samples by the Ge evaporation from a Knudsen cell in an Omicron ultrahigh vacuum system. To obtain Ge disk arrays, excess Ge was removed from the sample surface through the lift-off process in an ultrasonic bath with acetone for 1 min.

Methods of characterization

The shape of Ge disks after their formation and the distance between them were determined using the PIONEER lithography system (in the microscope mode) or a scanning electron microscope (SEM) manufactured by Hitachi (SU 8020). The reflection spectra at a normal light incidence were measured with the microscope-spectrophotometer MSFU-K supplied with a 40 × objective (WD = 0.6 mm, NA = 0.65). This optical setup collects reflected light within the objective aperture angle α = 40.5°. The sample position was shifted about 0.2 mm relative to the objective focal plane for the irradiation of a wide (~ 80 μm) area containing a large number of Ge disks. The reflection spectra for Ge disk arrays were normalized to those of bare substrates.

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Lee, Y. Y., Ho, W. J. & Yeh, C. W. Fabrication of silicon solar cell with >18% efficiency using spin-on-film processing for phosphorus diffusion and SiO2/graded index TiO2 anti-reflective coating. Appl. Surf. Sci. 354, 20–24 (2015).

Yakimov, A., Kirienko, V., Bloshkin, A., Dvurechenskii, A. & Utkin, D. Quantum dot based mid-infrared photodetector enhanced by a hybrid metal-dielectric optical antenna. J. Phys. D Appl. Phys. 53, 335105 (2020).

Magnusson, R. & Shin, D. Diffractive optical components. in Encyclopedia of Physical Science and Technology. 421–440. (2003).

Ota, Y. et al. Impact of size distributions of Ge islands as etching masks for anisotropic etching on formation of anti-reflection structures. Jpn. J. Appl. Phys. 58, 045505 (2019).

Spinelli, P., Verschuuren, M. A. & Polman, A. Broadband omnidirectional antireflection coating based on subwavelength surface Mie resonators. Nat. Commun. 3, 692 (2012).

Moitra, P. et al. Large-scale all-dielectric metamaterial perfect reflectors. ACS Photon. 2, 692–698 (2015).

Baryshnikova, K. V., Petrov, M. I., Babicheva, V. E. & Belov, P. A. Plasmonic and silicon spherical nanoparticle antireflective coatings. Sci. Rep. 6, 22136 (2016).

Visser, D., Basuvalingam, S. B., Désières, Y. & Anand, S. Optical properties and fabrication of dielectric metasurfaces based on amorphous silicon nanodisk arrays. Opt. express 27, 5354–5367 (2019).

Shklyaev, A. A. & Tsarev, A. V. Broadband antireflection coatings made of resonant submicron- and micron-sized SiGe particles grown on Si substrates. IEEE Photon. J. 13, 2200212 (2021).

Kumar, R. & Ramakrishna, S. A. Enhanced infra-red transmission through subwavelength hole arrays in a thin gold film mounted with dielectric micro-domes. J. Phys. D Appl. Phys. 51, 165104 (2018).

Anikin, K. et al. Localized surface plasmon resonance in gold nanocluster arrays on opaque substrates. Plasmonics 14, 1527–1537 (2019).

Kuznetsov, A. I., Miroshnichenko, A. E., Fu, Y. H., Zhang, J. B. & Luk’yanchuk, B. Magnetic light. Sci. Rep. 2, 492 (2012).

Lepeshov, S. I., Krasnok, A. E., Belov, P. A. & Miroshnichenko, A. E. Hybrid nanophotonics. Phys. Usp. 61, 1035–1050 (2018).

Utkin, D. E., Anikin, K. V., Veber, S. L. & Shklyaev, A. A. Dependence of light reflection of germanium Mie nanoresonators on their aspect ratio. Opt. Mater. 109, 110466 (2020).

Razmjooei, N., Ko, Y. H., Simlan, F. A. & Magnusson, R. Resonant reflection by microsphere arrays with AR-quenched Mie scattering. Opt. Exp. 29, 19183–19192 (2021).

Babicheva, V. E. & Evlyukhin, A. B. Resonant lattice Kerker effect in metasurfaces with electric and magnetic optical responses. Laser Photon. Rev. 11, 1700132 (2017).

Wang, D. et al. Lasing from finite plasmonic nanoparticle lattices. ACS Photon. 7, 630–636 (2020).

Hakala, T. K. et al. Lasing in dark and bright modes of a finite-sized plasmonic lattice. Nat. Commun. 8, 13687 (2017).

Danilov, A. et al. Ultra-narrow surface lattice resonances in plasmonic metamaterial arrays for biosensing applications. Biosens. Bioelectron. 104, 102–112 (2018).

Altug, H., Oh, S. H., Maier, S. A. & Homola, J. Advances and applications of nanophotonic biosensors. Nat. Nanotechnol. 17, 5–16 (2022).

Ramezani, M., Lozano, G., Verschuuren, M. A. & Gómez-Rivas, J. Modified emission of extended light emitting layers by selective coupling to collective lattice resonances. Phys. Rev. B 94, 125406 (2016).

Fan, X., Hao, Q., Qiu, T. & Chu, P. K. Improving the performance of light-emitting diodes via plasmonic-based strategies. J. Appl. Phys. 127, 040901 (2020).

Capers, J. R., Boyes, S. J. & Hibbins, A. P. Designing the collective non-local responses of metasurfaces. Commun. Phys. 4, 209 (2021).

Savelev, R. S., Slobozhanyuk, A. P., Miroshnichenko, A. E., Kivshar, Y. S. & Belov, P. A. Subwavelength waveguides composed of dielectric nanoparticles. Phys. Rev. B 89, 035435 (2014).

Ding, L. et al. Low loss waveguiding and slow light modes in coupled subwavelength silicon Mie resonators. Nanoscale 12, 21713–21718 (2020).

Bi, K. et al. All-dielectric metamaterial fabrication techniques. Adv. Opt. Mater. 9, 2001474 (2020).

Babicheva, V. E. & Moloney, J. V. Lattice effect influence on the electric and magnetic dipole resonance overlap in a disk array. Nanophotonics 7, 1663–1668 (2018).

Utyushev, A. D. et al. Collective lattice resonances in all-dielectric nanostructures under oblique incidence. Photonics 7, 24 (2020).

**ong, L., Ding, H., Lu, Y. & Li, G. Extremely narrow and actively tunable Mie surface lattice resonances in GeSbTe metasurfaces: Study. Nanomaterials 12, 701 (2022).

Hopkins, B., Miroshnichenko, A. E. & Kivshar, Y. S. All-dielectric nanophotonic structures: Exploring the magnetic component of light. in Recent Trends in Computational Photonics (eds. Agrawal, A., Benson, T., De La Rue, R. M. & Wurtz, G. A.). Chap. 10. (2017).

Staude, I. et al. Tailoring directional scattering through magnetic and electric resonances in subwavelength silicon nanodisks. ACS Nano 7, 7824–7832 (2013).

Moitra, P., Slovick, B. A., Yu, Z. G., Krishnamurthy, S. & Valentine, J. Experimental demonstration of a broadband all-dielectric metamaterial perfect reflector. Appl. Phys. Lett. 104, 171102 (2014).

Tian, J. et al. Near-infrared super-absorbing all-dielectric metasurface based on single-layer germanium nanostructures. Laser Photon. Rev. 12, 1800076 (2018).

Zywietz, U. et al. Electromagnetic resonances of silicon nanoparticle dimers in the visible. ACS Photon. 2, 913–920 (2015).

Yang, Z. J. et al. Dielectric nanoresonators for light manipulation. Phys. Rep. 701, 1–50 (2017).

Chong, K. E. et al. Observation of fano resonances in all-dielectric nanoparticle oligomers. Small 10, 1985–1990 (2014).

Utyushev, A. D. et al. Engineering novel tunable optical high-Q nanoparticle array filters for a wide range of wavelengths. Opt. Exp. 28, 1426–1438 (2020).

Ko, Y. H., Razmjooei, N., Hemmati, H. & Magnusson, R. Perfectly-reflecting guided-mode-resonant photonic lattices possessing Mie modal memory. Opt. Exp. 29, 26971–26982 (2021).

Alaee, R., Filter, R., Lehr, D., Lederer, F. & Rockstuhl, C. A generalized Kerker condition for highly directive nanoantennas. Opt. Lett. 40, 2645–2648 (2015).

Poborchii, V. et al. Photonic metasurface made of array of lens-like SiGe Mie resonators formed on (100) Si substrate via dewetting. Appl. Phys. Exp. 10, 125501 (2017).

Poborchii, V., Shklyaev, A., Bolotov, L. & Uchida, N. Nanoscale characterization of photonic metasurface made of lens-like SiGe Mie-resonators formed on Si(100) substrate. J. Appl. Phys. 126, 123102 (2019).

Rsoft FullWave by SYNOPSYS. Version 2020.09-1.

Taflove, A. & Hagness, S. C. Computational Electrodynamics: The Finite-Difference Time-Domain Method. 3rd edn. 1–997. (Artech, 2005).

E. D. Palik, Handbook of OpticalConstants of Solids. 1–999. (Academic, 1998).

Auguié, B., Bendaña, X. M., Barnes, W. L. & de Abajo, F. J. G. Diffractive arrays of gold nanoparticles near an interface: Critical role of the substrate. Phys. Rev. B 82, 155447 (2010).

Acknowledgements

The work is supported by the Ministry of Science and Higher Education of the Russian Federation, project # 075-15-2020-797 (13.1902.21.0024). The authors acknowledge the Shared Equipment Centers CKP “NANOSTRUKTURY” of the Rzhanov Institute of Semiconductor Physics SB RAS and CKP “VTAN” (ATRC) of the NSU Physics Department for the instrumental and technological support.

Author information

Authors and Affiliations

Contributions

A.A.S. and D.E.U. fabricated the structures and carried out the experimental measurements. A.V.T., S.A.K. and K.V.A. performed the numerical simulation. All authors discussed the results and analyzed the data. A.A.S. wrote the paper. A.V.L. reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Shklyaev, A.A., Utkin, D.E., Tsarev, A.V. et al. Interdisk spacing effect on resonant properties of Ge disk lattices on Si substrates. Sci Rep 12, 8123 (2022). https://doi.org/10.1038/s41598-022-11867-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-022-11867-5

- Springer Nature Limited