Abstract

The (R)-phenylacetylcarbinol (PAC) batch biotransformation kinetics for partially purified Candida tropicalis TISTR 5350 pyruvate decarboxylase (PDC) were determined to validate a comprehensive mathematical model in 250 mL scale with 250 mM phosphate buffer/pH 7.0. PDC could convert initial 100/120 mM benzaldehyde/pyruvate substrates to the statistical significantly highest (p ≤ 0.05) maximum PAC concentration (95.8 ± 0.1 mM) and production rate (0.639 ± 0.001 mM min−1). A parameter search strategy aimed at minimizing overall residual sum of square (RSST) based on a system of six ordinary differential equations was applied to PAC biotransformation profiles with initial benzaldehyde/pyruvate concentration of 100/120 and 30/36 mM. Ten important biotransformation kinetic parameters were then elucidated including the zeroth order activation rate constant due to phosphate buffer species (ka) of (9.38 ± < 0.01) × 10–6% relative PDC activity min−1 mM−1. The validation of this model to independent biotransformation kinetics with initial benzaldehyde/pyruvate concentration of 50/60 mM resulted in relatively good fitting with RSST, mean sum of square error (MSE), and coefficient of determination (R2) values of 662, 17.4, and 0.9863, respectively.

Similar content being viewed by others

Introduction

Microbial biotransformation has been extensively used worldwide in the pharmaceutical industry followed by the food and agriculture sectors1,2 for almost 20 years. Revenue generated by microbial biotransformation steadily increased from USD 0.39 trillion in 2001 to USD 1.25 trillion in 2019 within the pharmaceutical industry. The food and agriculture sectors had estimated USD 1.13 trillion (2019) and USD 1.84 billion (2018) in revenue respectively from microbial biotransformation3,4,5. Although chemocatalysts can offer the relatively high catalytic activity and selectivity for some reactions6,7, a number of organic compounds transformation processes still rely heavily on biocatalysts to achieve the desired level of enantioselectivity8,9,10. Thus, biocatalysts including enzymes, cells organelles, and whole cells in either native or artificially constructed forms11 have been widely used in the production of both high-volume/low-value compounds such as ethanol12,13,14,15,16,17 and low-volume/high-value chemical species including (R)-phenylacetylcarbinol (PAC)2,15,18,19,20,21,22,23,24.

The biochemical production of PAC was firstly demonstrated in Germany and later commercialized for ephedrine production25,26,27. PAC could be produced through in vivo direct microbial transformation process with some strategies of benzaldehyde feeding using growing cells of yeasts, fungi, and bacteria28,29,30. This biotransformation process can be conducted in vitro by using non-viable whole cells15,17,24 and partially purified pyruvate decarboxylase (PDC) enzyme18,20,28,29,31,32,33,34. The detailed reaction mechanism of PAC biotransformation was clearly elucidated18 (Fig. 1). Advantages of using partially purified PDC include prevention of benzyl alcohol or PAC-diol formation. These are by-products that are often formed when PAC biotransformation is carried out in parallel with microbial cultivation process32,35. Moreover, the isolated enzymes could be recycled and reused during a biotransformation process27. The partially purified Candida utilis (ICI Australia) could produce 190.4 mM PAC with molar yield as high as 95.3% based on benzaldehyde31,32,35. The PAC concentration could generally be increased through fed-batch processes with either pyruvate (in the form of pyruvic acid) or benzaldehyde dosing protocols using 2.5 M or 20 mM of 3–morpholinopropane–1–sulfonic acid (MOPS) buffer18,19,20,33. However, the heat labile property and cost-prohibitive nature of MOPS buffer (USD 1.09/g in comparison with only USD 0.02/g for phosphate buffer) were considered major obstacles to the industrial scale application of this buffering compound34.

Schematic reaction mechanism of proton consuming PAC biotransformation from benzaldehyde and pyruvate substrates catalyzed by PDC with Mg2+ and thiamine pyrophosphate (TPP) as cofactors. The structures of acetaldehyde and acetoin by-products, resulting from direct decarboxylation of pyruvate generating free acetaldehyde and subsequent carboligation reaction of active acetaldehyde and free acetaldehyde, are also included (modified from Leksawasdi et al.18,19,20).

Our previous research showed that, among fifty microbial strains, C. tropicalis TISTR 5350 and 5306 were the best yeast strains for PAC production. The two strains yielded 70% increase in volumetric PDC carboligase activity (0.39 ± 0.06 U mL−1) and 58% increased PAC production (19.8 ± 3.4 mM)21. However, the strain TISTR 5306 was most suitable for longan extract medium16,21,22,23,34. In order to minimize cost, prevent relatively high overall losses of enzyme activity through purification process, and avoid utilization of cost ineffective MOPS buffer, Khemacheewakul et al.34 used whole cells C. tropicalis TISTR 5350 in single phase PAC production and benzaldehyde deactivation studies with various concentrations of phosphate buffer (20 mM–1.0 M). A thorough examination indicated that 1 M phosphate buffer was optimal for PAC production (28.6 ± 2.3 mM) and provided additional activation effect to PDC stability with the average PDC activation rate constant of 1.34 × 10–2% min−1. This value was higher than that observed in 20 mM phosphate buffer (1.48 × 10–6% min−1) by more than 9,050 times. Leksawasdi et al.2 projected that in a circulated system of recycled phosphate buffer and related co-factors utilizing whole cells of Saccharomyces cerevisiae and C. tropicalis co-culture as biocatalysts, the costing of phosphate buffer would be USD 0.751 per 1 kg of produced PAC. The similar investigation on the partially purified C. tropicalis TISTR 5350 PDC is thus required to evaluate relevant PAC production characteristics and assess whether the deactivation rate equation which incorporates activation effect by buffering species can interact well to the other five rate equations in a PAC biotransformation mathematical model.

The objectives of present study are to investigate the effects of initial substrates concentration pairs (benzaldehyde/pyruvate of 30/36, 50/60, and 100/120 mM) and phosphate buffer concentration levels (20, 250, 500 mM, and 1 M; pH 7.0) on PAC production, PAC formation rate, and PAC molar yields using partially purified C. tropicalis TISTR 5350 PDC in the 250-mL single phase batch biotransformation system. In addition, the recently improved mathematical model comprised six ordinary differential equations plus PDC-activation effect by phosphate buffering species is used to determine ten kinetic parameters based on biotransformation profiles of the 30/36 and 100/120 mM initial benzaldehyde/pyruvate concentration pairs. The model is then validated with an independent batch biotransformation system using initial substrates concentration pair of 50/60 mM followed by assessment of relevant statistical parameters.

Materials and methods

Microorganism

C. tropicalis TISTR 5350 was purchased from Thailand Institute of Scientific and Technological Research (TISTR, Pathum Thani, Thailand) before subculturing into primary stock21. The microbial stock was kept in 60% (v/v) glycerol solution and maintained at − 70 °C with regular assessments of cells viability by using a haemocytometer16. The viable cells count was 92.5 ± 1.8%21. C. tropicalis TISTR 5350 was chosen based on optimal PAC production and volumetric PDC carboligase activity in Yeast—Malt (YM) medium16,21,22,23,34.

Cultivation of microbes and production of partially purified PDC

The cultivation of preseed and seed was done in 0.1 and 1 L yeast media as described by Khemacheewakul et al.34. In order to produce enough wet biomass for the production of partially purified PDC, the cultivation was carried out at 30 °C for 36 h in a 16 L stainless steel bioreactor containing 10 L inoculum medium with a composition similar to those published previously by our group23. The methodologies for preparation of cells pellet, glass bead pretreatment, subsequent precipitation with 50%(v/v) acetone, and production of partially purified PDC have already been stated elsewhere22,23.

PAC production in phosphate buffer with various buffer and initial substrate concentration levels

The pH-controlled single-phase batch biotransformation system was done in a modified 500 mL Erlenmeyer flask containing 250 mL phosphate buffer (pH 7.0/0.1 M H3PO4) at 4 °C for 210 min with a sampling interval of 30 min34. Mixing was achieved by mounting the reactor on a magnetic stirrer (LMS, Model No. MGS–1001, Japan) with a magnetic bar (dia. × length of 7 × 30 mm) and speed setting of 5.0. This phosphate buffer is also known as the Gomori buffer because it contains the K2HPO4 and KH2PO4 conjugated acid–base pair36. A full factorial design experiment with four phosphate buffer concentration levels (20, 250, 500, and 1 M) and three pairs of initial benzaldehyde/pyruvate substrate concentration levels (30/36, 50/60 and 100/120 mM) were conducted. The molar ratio of initial pyruvate to benzaldehyde concentration was set to 1.2/ 1.0 as suggested by Leksawasdi et al.18,19,20 in order to compensate for possible pyruvate losses to by-products formation including acetaldehyde and acetoin during biotransformation process. A total of 4 × 3 = 12 groups was studied in quintuplicates. The rationale for selecting phosphate buffer at these four concentration levels utilized also by previous studies had already been elaborated in details elsewhere34. Partially purified PDC was added as a biocatalyst while 1 mM thiamine pyrophosphate (TPP) and 1 mM MgSO4.7H2O were also included as cofactors29,35. Maximum PAC production level (mM), maximum PAC formation rate (mM min−1), and corresponding maximum PAC molar yield (the ratio of maximum PAC being produced over substrate being consumed) for each substrate pair at the maximum PAC production level were measured using high performance liquid chromatography (HPLC). The maximum PAC molar yields based on pyruvate and benzaldehyde being consumed were denoted as YPmax/A and YPmax/B. The maximum PAC formation rate was computed by dividing maximum PAC production level at each time point with its corresponding reaction time (30, 60, 90, 120, 150, 180, and 210 min). The initial volumetric PDC carboligase activity in each experiment was maintained between 1.1 and 1.5 U carboligase mL−1.

Analytical methods

The collected samples were separated into liquid buffering and enzymatic portions through centrifugation process prior to respective sample pretreatment stages as described in literatures19,20,29,32,33,35. PAC, benzaldehyde, benzyl alcohol, and benzoic acid concentration levels were determined by using HPLC as previously described by Rosche et al.29. Acetoin was analyzed by HPLC equipped with the HPX-87H column37. Pyruvate concentration was determined spectrophotometrically by using the enzymatic NADH + H+ coupled assay method with lactate dehydrogenase based on the modified method from Czok and Lamprecht38. Acetaldehyde concentration was determined in the same manner as the pyruvate assay with the replacement of lactate dehydrogenase with alcohol dehydrogenase based on a modified method from Bernt and Bergmeyer39. One unit PDC carboligase activity was defined as the rate of which 1 µmol PAC was produced from equimolar benzaldehyde and pyruvate per min in carboligase buffer at pH 6.0 and 25 °C18.

Hypothesis testing

Averages and standard errors were calculated from experimental data in quintuplicates. The results obtained were statistically analyzed using SPSS for Windows 22.0 (SPSS Inc., Chicago, IL, USA) and the analysis of variance using Duncan ‘s Multiple Range Test (DMRT) at p ≤ 0.0515,24,40.

Construction of PAC biotransformation model

The PAC biotransformation model for partially purified C. tropicalis TISTR 5350 PDC in this study consisted of six rate equations that described the main product (PAC) formation (1), substrates (pyruvate and benzaldehyde) consumption (2, 3), by-products (acetaldehyde and acetoin) formation (4,5) as well as deactivation of pyruvate decarboxylase with inorganic phosphate activation effect (6). Equations (1) to (5) were derived and determined based on the combined King and Altman schematic strategy as well as the initial rate studies by Leksawasdi et al.18,19,20. The original parameter constants in these rate equations were determined specifically for PAC biotransformation in 20 mM or 2.5 M MOPS buffer with partially purified C. utilis PDC18,19,20. Equation (6) was modified and developed by Khemacheewakul et al.34 for whole cells C. tropicalis TISTR 5350 PDC. This equation combined both the PDC deactivation effect by background species excluding buffer concentration and benzaldehyde (kd1, kd2) as well as the PDC activation effect by inorganic phosphate species (K2HPO4/KH2PO4) within the 20 mM to 1 M concentration range (ka). The PDC refolding effect resulting in the initial period of constant enzyme stability was also added28 and was denoted tlag in Eq. (6). The variable Ei generated from this equation is crucial to the overall biotransformation system as it acts as a driving force and appears in all rate equations. The original parameter constants in this rate equation were determined from PDC deactivation kinetics in 20 mM–1 M phosphate buffer with whole cells C. tropicalis TISTR 535034. Equation (6) has not yet been incorporated elsewhere to the PAC biotransformation model. The current study combined all six rate equations to create a PAC biotransformation model to be validated by PAC biotransformation kinetics in 250 mM phosphate buffer with partially purified C. tropicalis TISTR 5350 PDC.It is the first time in current study that Eq. (6) has been combined to other rate equations describing the pyruvate and benzaldehyde consumption as well as PAC and other related by-products formation to assess the overall improvement in quality of fit of mathematical model to PAC biotransformation kinetics. The complete simulation profile for each species of PAC biotransformation kinetics was constructed based on Euler–Cauchy numerical integration with a time increment of 0.01 h18. The description for each parameter/variable is given in the nomenclature section.

Strategy for parameters estimation and model validation

The initial values of each parameter for Eqs. (1)–(5) were averaged from values reported in previous initial rate and simulation studies of a high-buffering-capacity biotransformation system18,19 using partially purified PDC from C. utilis in 2.5 M MOPS buffer (Table 2). The initial values for the zeroth order activation rate constant due to phosphate buffer species (ka) as well as the other three parameters (kd1, kd2 and tlag) in Eq. (6) were obtained from a recent PDC deactivation study using whole cells C. tropicalis TISTR 535034 in 20 mM–1 M phosphate buffer. Parameter estimation and model validation were performed using the customized and well—established subroutines written in Microsoft Visual Basic for Applications (VBA) 6.3 for Microsoft Excel12,14,18,19,34. Specifically, the minimization of total residual sum of square (RSST) between experimental data and simulated values from the model, and the convergence search criterion (CSC) of lesser than 1% of RSST were set as objective functions while the mean square error (MSE) and the coefficient of determination (R2) were calculated simultaneously. RSST for each set of biotransformation profiles is the summation of individual RSS values for product and by-products formation, substrates consumption, and enzyme deactivation profiles as shown in Eq. (7). MSE is the ratio of RSST and available degree of freedom (DOF) for each system. DOF is the number of experimental data points being regressed minus the total number of parameters in the mathematical model. Biotransformation profile data from the 30/36 and the 100/120 mM initial benzaldehyde/pyruvate concentration pairs were used for parameter estimation in this biotransformation model. The error estimation of each parameter was evaluated using the standard error of each time point as described by Khemacheewakul et al.34.

where A refers to pyruvate concentration, B refers to benzaldehyde concentration, Q refers to acetaldehyde concentration, R refers to acetoin concentration, and E refers to relative enzyme activity.

The estimated parameters were then validated by being implemented in Eqs. (1)–(6) and numerically integrated to simulate the biotransformation profiles of an independent data set obtained from the 50/60 mM substrate pair. The assessment of relevant statistical parameters (RSST, MSE, R2) was then made to evaluate the quality of fit.

Results

PAC production in phosphate buffer with various buffer and initial substrate concentration levels

The current study investigated a single-phase batch biotransformation process using partially purified C. tropicalis TISTR 5350 PDC as a biocatalyst. The maximum PAC production levels (Pmax), maximum PAC formation rates (rPmax), and maximum PAC molar yields with respect to each substrate (YPmax/B and YPmax/A) under different initial substrate and phosphate buffer concentration levels are tabulated in Table 1. The 100/120 mM initial benzaldehyde/pyruvate substrate pair in 250 mM phosphate buffer showed the highest statistical significantly highest (p ≤ 0.05) Pmax (95.8 ± 0.1 mM) and rPmax (0.639 ± 0.001 mM min−1) with corresponding YPmax/B and YPmax/A of 0.99 ± 0.01 and 0.88 ± 0.01 based on benzaldehyde and pyruvate, respectively.

PAC biotransformation model and model validation

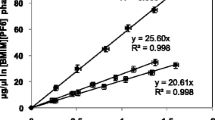

Simultaneous numerical integration of rate equations Eqs. (1)–(6) was implemented to simulate a combined biotransformation kinetic profile of two benzaldehyde/pyruvate concentration pairs: 30/36 and 100/120 mM. The simulation profiles of the optimized parameters are shown in Fig. 2a,b. The initial searching values were extracted from Leksawasdi et al.18,19 and Khemacheewakul et al.34 (Table 2). Optimization of these kinetic values by a grid-search parameter estimation strategy improved fitting of the model as evident by lowering of RSST from 67,465 to 3,462 and MSE from 1,775 to 91.1 (19.5 times improvement). Model fitting statistics RSST, MSE and R2 for individual biotransformation kinetic profiles are presented in Table 3. These were 936, 24.6 and 0.9717 for the 30/36 mM initial benzaldehyde/pyruvate concentration levels and 2,526, 66.5 and 0.9787 for the 100/120 mM levels, respectively.

Simulated profiles of PAC (P, filled circle) biotransformation systems with experimental initial substrates (pyruvate—(A, filled square) and benzaldehyde (B, filled triangle)) concentration levels (mM) of (a): (30/36) and (b): (100/ 120) after RSST minimization as well as predicted profile for validation purpose with initial substrates concentration level of (c): (50/60) mM based on optimized parameter values as indicated in Table 2. The corresponding values of RSST, MSE, and R2 for each profile are shown in Table 3. The error bars had already been incorporated to all experimental data sets but were found to be relatively small for most of data sets. The initial volumetric enzyme activity (E, white square) was 1.1–1.5 U mL−1. The formation of by-products such as acetaldehyde (Q, ×) and acetoin (R, +) was not detected.

The model validation was done on an independent biotransformation kinetic profile with initial benzaldehyde/pyruvate concentration levels of 50/60 mM. The relatively good quality of fitting could be observed visually as shown in Fig. 2c. RSST, MSE, and R2 of the fitted model were 662, 17.4, and 0.9863, respectively (Table 3).

Discussion

The results from the effects of phosphate buffer and initial substrates concentration levels could be compared to those reported by Khemacheewakul et al.34 when whole cells of C. tropicalis TISTR 5350 was used as biocatalyst instead. Whole cells biotransformation in 1 M phosphate buffer using initial 30/40 mM benzaldehyde/pyruvate substrates concentration levels could produce Pmax, equivalent rPmax, YPmax/B, and YPmax/A of 28.6 ± 2.3 mM, 0.566 ± 0.014 mM min−1, 0.95 ± 0.08 and 0.71 ± 0.06, respectively. The values of Pmax from both studies could not be directly compared due to different initial substrate concentration levels. Nevertheless, the results of rPmax and YPmax/A were still comparable and statistically higher (p ≤ 0.05) by 12.9 ± 0.3% and 23.9 ± 2.0%, respectively for the current study which might suggest the beneficial effect of using a lower phosphate buffer concentration level (250 mM) for PAC biotransformation system with partially purified PDC. In fact, Pmax (15.5 ± 0.1 mM) and rPmax (0.103 ± 0.001 mM min−1) of partially purified C. tropicalis TISTR 5350 PDC were significantly affected (p ≤ 0.05) by 1 M phosphate buffer in comparison with the whole cells counterpart (45.8 ± 4.4% and 81.8 ± 0.5% lowered, respectively) when subjected to similar initial substrates concentration level as shown in Table 1. As PDC is an intracellular enzyme, the application of this enzyme in the form of whole cells may protect the enzyme against high phosphate buffer concentrations through the mechanism of mass transfer limitation due to diffusion hindrance. However, catalytic rates may be compromised 41. This was also in agreement with Rosche et al.32 who revealed that 600 mM phosphate buffer had greater level of inhibitory effect to partially purified PDC from Rhizopus javanicus NRRL 13,161 than MOPS buffer at a similar concentration level resulting in lower PAC concentration being produced. MOPS buffer was then chosen as buffer of choice for subsequent studies18,19,20,28,33. In fact, partially purified C. utilis PDC in 2.5 M MOPS buffer also expressed the highest rPmax when initial benzaldehyde/pyruvate concentration level was 100/120 mM18. Evidently, YPmax/B was not affected by phosphate buffer concentration at 250 mM and 1 M as both molar yields were in the vicinity of unity and not statistically significant different (p > 0.05) from one another.

Several authors had discussed advantages and disadvantages of using phosphate species as reaction buffers for PDC2,25,32,34,42. Juni et al.42 pointed out that high phosphate concentration might help prevent proteolytic enzymes from deactivating PDC, thereby enhancing the PDC stability while strengthening association of important prosthetic cofactors such as TPP with the enzyme. Such protective effect from a high phosphate buffer concentration observed in this study may also be applicable to PDC from R. javanicus NRRL 13161, because it possesses a relatively high PAC formation rate32. R. javanicus was formerly ranked as a potential candidate for the best PAC producer. However, the possibility of large-scale enzyme production from this filamentous fungal strain was eventually abandoned due to unsolvable proteolytic enzyme problems (unpublished result). Van Urk et al.25 discovered allosteric inhibition of phosphate species on S. cerevisiae PDC in a greater extent than that of C. utilis. Using phosphate buffer for PAC biotransformation with C. tropicalis TISTR 5350 PDC may be advantageous when conducted in an optimal concentration for each enzyme form (i.e., 1 M for whole cells PDC34 and 250 mM for partially purified PDC (this study)). Phosphate buffer also offers cost-saving advantage. Leksawasdi et al.17 proposed that utilization of phosphate buffer in a 1 kg PAC production system would maintain the cost ratio of reaction buffer to total production at 25.9%, which is much lower than a cost ratio of 94.9% for MOPS buffer34.

Evidently, the developed PAC biotransformation model provided good fitting within the investigated range of 30/36 to 100/120 mM initial benzaldehyde/pyruvate concentration levels for partially purified C. tropicalis TISTR 5350 PDC. Comparison of all ten kinetic parameters determined in the current study to those with comparable normalized units in the literature is given in Table 4. ka was included to PAC biotransformation for the first time in current study. Khemacheewakul et al.34 reported ka value of (13.4 ± 8.6) × 10–6% min−1 mM−1 which was not statistical significantly different (p > 0.05) from current study suggesting similar activation effect between 1 M phosphate buffer on whole cells C. tropicalis TISTR 5350 and 250 mM phosphate buffer on partially purified C. tropicalis TISTR 5350 PDC. The inclusion of ka.P term in Eq. (6) allowed the effect of buffering species to be separated out from the original enzyme deactivation model which contained only kd1, kd2, and tlag. The absence of ka.P term in previous studies would result in averaging out of buffer species activation effect to aforementioned three parameters with relatively less quality of fit as shown in Table 4. The activation effect due to buffering species and corresponding buffer concentration should therefore be included as separated term in enzyme deactivation rate equation for overall improvement of PAC biotransformation model’s predictive capability. The developed PAC biotransformation model could also be applied in a wider range to assess quantitatively the effect of buffering species on PAC biotransformation under different conditions by comparing the respective ka value in each system. The statistical significantly highest (p ≤ 0.05) overall rate constant for the formation of PAC (Vp) by using partially purified C. tropicalis TISTR 5350 PDC indicated that PDC from this strain produces PAC faster than that from C. utilis by 4–5 times18,19. The improvement in value of Vp was thus in agreement with finding in previous section where 250 mM phosphate buffer was utilized. Further comparison was made between intrinsic binding constant (Kb) and Hill coefficient (h) for benzaldehyde whose values for both partially purified PDC from C. utilis and C. tropicalis was not statistical significantly different (p > 0.05) with validated range of mean between (0.80–1.01) × 10–4 mM1−h and 1.77–2.18, respectively18,19. It was possible that partially purified PDC from both strains exhibited similar allosteric and sigmoidal behaviors toward benzaldehyde. In addition, h value of ~ 2 suggests that PDC might operate in a dimeric subunit form during PAC biotransformation18,19,20. The lower affinity constant value for pyruvate (Kma) in the current study implies a greater level of binding between partially purified PDC from C. tropicalis TISTR 5350 and pyruvate than the C. utilis counterpart by 9–11 times. In fact, the observably higher overall rate constants for the formation of both acetaldehyde (Vq) and acetoin (Vr) in the current study may be the result of increased affinity toward pyruvate of this decarboxylating enzyme18,19,20,25,31. Partially purified PDC from C. tropicalis TISTR 5350 was more prone to deactivation effect by benzaldehyde than the C. utilis counterpart as indicated by a much higher first-order benzaldehyde deactivation coefficient (kd2) and shorter lag time for C. tropicalis PDC. However, the use of phosphate buffer could negate a portion this deactivating effect by providing additional activation effect. The multiplication between zeroth-order activation rate constant due to phosphate buffer (ka) with PDC stabilizing effect of 250 mM phosphate buffer resulted in an activation rate of (2.34 ± < 0.02) × 10–3% min−1. This rate was lower/higher than the activation rates when whole cell PDC in 1 M (1.34 × 10–2% min−1) and 20 mM (1.48 × 10–6% min−1) phosphate buffer were used34.

The molarity balancing of PAC formation was examined by observing PAC molar yield based on each substrate. The ranges for YPmax/B were 0.85–0.97, 0.89–0.99, and 0.93–0.99 for the initial benzaldehyde and pyruvate concentration pairs of 30/36, 50/60, and 100/120 mM, respectively, indicating the closing molarity balance. On the contrary, corresponding ranges of of YPmax/A of 0.80–0.97, 0.81–0.93, and 0.78–0.89 were not uniform among the tested concentration pairs. Similar phenomenon was also observed in other PAC biotransformation systems18,19,20,29,31,32,34,35. The formation of relatively volatile by-products such as acetaldehyde from pyruvate generally resulted in lower ranges of YPmax/A in comparison with YPmax/B. The absence of acetaldehyde concentration in the reaction buffer and some losses in pyruvate molarity balance confirmed the volatility nature of this compound18,19,20. Benzyl alcohol, benzoic acid and acetoin were also not detected in the current study. Benzyl alcohol and its derivatives are often formed from side reactions of either alcohol dehydrogenase or other oxidoreductases when growing yeast cells were used in a PAC biotransformation process, resulting in a loss of up to 30–40% benzaldehyde26,43.

Conclusions

The partially purified C. tropicalis TISTR 5350 PDC with initial volumetric enzyme activity between 1.1 and 1.5 U mL−1 produced PAC at the optimized levels (95.8 ± 0.1 mM and 0.639 ± 0.001 mM min−1) in 250 mM phosphate buffer. The improved mathematical model fitted well to the PAC biotransformation kinetics of two initial benzaldehyde and pyruvate concentration levels at 30/36 and 100/120 mM. The independent prediction of 50/60 mM benzaldehyde/pyruvate profile validated the interpolation ability of the developed model with corresponding RSST, MSE, and R2 of 662, 17.4, and 0.9863, respectively. Such mathematical model will be useful for further optimization of a more complex biotransformation process, for instance, development of feeding strategies in fed batch or continuous systems.

Data availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

Abbreviations

- A :

-

Pyruvate concentration (mM)

- B :

-

Benzaldehyde concentration (mM)

- CSC:

-

Convergence search criterion (no unit)

- E :

-

Relative enzyme activity (%)

- h :

-

Hill coefficient for benzaldehyde (no unit)

- i :

-

Iteration loop identifier for numerical integration

- k a :

-

Zeroth order activation rate constant due to phosphate buffer (% relative enzyme activity min−1 mM−1 of phosphate buffer)

- k d1 :

-

First order reaction time deactivation constant (min−1)

- k d2 :

-

First order benzaldehyde deactivation coefficient (mM−1 min−1)

- K b :

-

Intrinsic binding constant for benzaldehyde (mM1−h)

- K ma :

-

Affinity constant for pyruvate (mM)

- MSE:

-

Mean square error (no unit)

- N/a:

-

Not available

- P :

-

R-phenylacetylcarbinol concentration (mM)

- PAC:

-

R-phenylacetylcarbinol

- Ph b :

-

Phosphate buffer concentration (mM)

- PDC:

-

Pyruvate decarboxylase enzyme

- Q :

-

Acetaldehyde concentration (mM)

- r:

-

Formation rate(mM min−1)

- R :

-

Acetoin concentration (mM)

- R2 :

-

Coefficient of determination (no unit)

- RSS:

-

Residual sum of squares (no unit)

- t :

-

Time (min)

- T :

-

Total substrates and products species within the reaction buffer

- t lag :

-

Lag time due to enzyme refolding effect describing period of constant stability (min)

- U:

-

Carboligase activity of PDC (unit)

- V p :

-

Overall rate constant for the formation of PAC (mM min−1%−1)

- V q :

-

Overall rate constant for the formation of acetaldehyde (min−1%−1)

- V r :

-

Overall rate constant for the formation of acetoin (min−1 mM−1%−1)

- Y:

-

Molar yield of R-phenylacetylcarbinol on each substrate (no unit)

References

Smitha, M. S., Singh, S. & Singh, R. Microbial biotransformation: a process for chemical alterations. J. Bacteriol. Mycol. Open Access 4, 85 (2017).

Leksawasdi, N. et al. Longan syrup and related products: processing technology and new product developments. In Asian Berries (eds **ao, G. et al.) 123–148 (CRC Press, 2021).

Fortune Business Insights. Connected Agriculture Market Size, Share | Global Report, 2026. https://www.fortunebusinessinsights.com/connected-agriculture-market-102061.

Mikulic, M. Revenue of the worldwide pharmaceutical market from 2001 to 2019. https://www.statista.com/topics/1764/global-pharmaceutical-industry/ (2020).

Oloruntoba, A. Revenue of the food market worldwide by country 2019 | Statista. https://www.statista.com/forecasts/758620/revenue-of-the-food-market-worldwide-by-country (2020).

Seesuriyachan, P. et al. Improvement in efficiency of lignin degradation by Fenton reaction using synergistic catalytic action. Ecol. Eng. 85, 283–287 (2015).

Li, X. et al. Preparation and investigation of highly selective solid acid catalysts with sodium lignosulfonate for hydrolysis of hemicellulose in corncob. RSC Adv. 8, 10922–10929 (2018).

Straathof, A. J. J., Panke, S. & Schmid, A. The production of fine chemicals by biotransformations. Curr. Opin. Biotechnol. 13, 548–556 (2002).

Hegazy, M. E. et al. Microbial biotransformation as a tool for drug development based on natural products from mevalonic acid pathway: A review. J. Adv. Res. 6, 17–33 (2015).

Zhang, N. et al. Cell permeability and nuclear DNA staining by propidium iodide in basidiomycetous yeasts. Appl. Microbiol. Biotechnol. 102, 4183–4191 (2018).

Takenaka, S. et al. Characterization of the native form and the carboxy-terminally truncated halotolerant form of α-amylases from Bacillus subtilis strain FP-133. J. Basic Microbiol. 55, 780–789 (2015).

Leksawasdi, N., Joachimsthal, E. L. & Rogers, P. L. Mathematical modelling of ethanol production from glucose/xylose mixtures by recombinant Zymomonas mobilis. Biotechnol. Lett. 23, 1087–1093 (2001).

Prommajak, T., Leksawasdi, N. & Rattanapanone, N. Biotechnological valorization of cashew apple: A review. Chiang Mai Univ. J. Nat. Sci. 13, 159–182 (2014).

Yuvadetkun, P., Leksawasdi, N. & Boonmee, M. Kinetic modeling of Candida shehatae ATCC 22984 on xylose and glucose for ethanol production. Prep. Biochem. Biotechnol. 47, 268–275 (2017).

Nunta, R. et al. Batch and continuous cultivation processes of Candida tropicalis TISTR 5306 for ethanol and pyruvate decarboxylase production in fresh longan juice with optimal carbon to nitrogen molar ratio. J. Food Process Eng. 42, e13227 (2019).

Wattanapanom, S. et al. Kinetic parameters of Candida tropicalis TISTR 5306 for ethanol production process using an optimal enzymatic digestion strategy of assorted grade longan solid waste powder. Chiang Mai J. Sci. 46, 1–19 (2019).

Mahakuntha, C., Reungsang, A., Nunta, R. & Leksawasdi, N. Kinetics of whole cells and ethanol production from Candida tropicalis TISTR 5306 cultivation in batch and fed-batch modes using assorted grade fresh longan juice. An. Acad. Bras. Cienc. In Press (2021).

Leksawasdi, N. et al. Kinetic analysis and modelling of enzymatic (R)-phenylacetylcarbinol batch biotransformation process. J. Biotechnol. 111, 179–189 (2004).

Leksawasdi, N., Rosche, B. & Rogers, P. L. Mathematical model for kinetics of enzymatic conversion of benzaldehyde and pyruvate to (R)-phenylacetylcarbinol. Biochem. Eng. J. 23, 211–220 (2005).

Leksawasdi, N., Rogers, P. L. & Rosche, B. Improved enzymatic two-phase biotransformation for (R)-phenylacetylcarbinol: Effect of dipropylene glycol and modes of pH control. Biocatal. Biotransform. 23, 445–451 (2005).

Tangtua, J. et al. Screening of 50 microbial strains for production of ethanol and (R)-phenylacetylcarbinol. Chiang Mai J. Sci 40, 299–304 (2013).

Tangtua, J. et al. Evaluation of cells disruption for partial isolation of intracellular pyruvate decarboxylase enzyme by silver nanoparticles method. Acta Aliment. 44, 436–442 (2015).

Tangtua, J. et al. Partial purification and comparison of precipitation techniques of pyruvate decarboxylase enzyme. Chiang Mai J. Sci. 44, 184–192 (2017).

Nunta, R. et al. Ethanol and phenylacetylcarbinol production processes of Candida tropicalis TISTR 5306 and Saccharomyces cerevisiae TISTR 5606 in fresh juices from longan fruit of various sizes. J. Food Process. Preserv. 42, e13815 (2018).

Van Urk, H. et al. Localization and kinetics of pyruvate-metabolizing enzymes in relation to aerobic alcoholic fermentation in Saccharomyces cerevisiae CBS 8066 and Candida utilis CBS 621. BBA - Gen. Subj. 992, 78–86 (1989).

Rogers, P. L., Shin, H. S. & Wang, B. Biotransformation for L-ephedrine production. Adv. Biochem. Eng. Biotechnol. 56, 33–59 (1997).

Ward, O. P. & Singh, A. Enzymatic asymmetric synthesis by decarboxylases. Curr. Opin. Biotechnol. 11, 520–526 (2000).

Leksawasdi, N., Breuer, M., Hauer, B., Rosche, B. & Rogers, P. L. Kinetics of pyruvate decarboxylase deactivation by benzaldehyde. Biocatal. Biotransform. 21, 315–320 (2003).

Rosche, B., Sandford, V., Breuer, M., Hauer, B. & Rogers, P. Biotransformation of benzaldehyde into (R)-phenylacetylcarbinol by filamentous fungi or their extracts. Appl. Microbiol. Biotechnol. 57, 309–315 (2001).

Iranmanesh, E., Asadollahi, M. A. & Biria, D. Improving L-phenylacetylcarbinol production in Saccharomyces cerevisiae by in silico aided metabolic engineering. J. Biotechnol. 308, 27–34 (2020).

Shin, H. S. & Rogers, P. L. Production of L-phenylacetylcarbinol (L-PAC) from benzaldehyde using partially purified pyruvate decarboxylase (PDC). Biotechnol. Bioeng. 49, 52–62 (1996).

Rosche, B. et al. Enzymatic (R)-phenylacetylcarbinol production in benzaldehyde emulsions. Appl. Microbiol. Biotechnol. 60, 94–100 (2002).

Leksawasdi, N., Rosche, B. & Rogers, P. Enzymatic processes for fine chemicals and pharmaceuticals: Kinetic simulation for optimal R-phenylacetylcarbinol production. In Studies in Surface Science and Catalysis, New Developments and Application in Chemical Reaction Engineering 27–34 (Elsevier Inc., 2006).

Khemacheewakul, J. et al. Development of mathematical model for pyruvate decarboxylase deactivation kinetics by benzaldehyde with inorganic phosphate activation effect. Chiang Mai J. Sci 45, 1426–1438 (2018).

Rosche, B., Sandford, V., Breuer, M., Hauer, B. & Rogers, P. L. Enhanced production of R-phenylacetylcarbinol (R-PAC) through enzymatic biotransformation. J. Mol. Catal. B Enzym. 19, 109–115 (2002).

Gomori, G. [16] Preparation of buffers for use in enzyme studies. Methods Enzymol. 1, 138–146 (1955).

Zeppa, G., Conterno, L. & Gerbi, V. Determination of organic acids, sugars, diacetyl, and acetoin in cheese by high-performance liquid chromatography. J. Agric. Food Chem. 49, 2722–2726 (2001).

Czok, R. & Lamprecht, W. Pyruvate, phosphoenolpyruvate and D-glycerate-2-phosphate. In Methods of Enzymatic Analysis (ed. Bergmeyer, H. U.) 403–410 (1974).

Bernt, E. & Bergmeyer, H. U. Acetaldehyde: determination with alcohol dehydrogenase from yeast. In Methods of Enzymatic Analysis (ed. Bergmeyer, H.-U.) 1696–1700 (Academic Press, 1965).

Skoog, D. A., West, D. M., Holler, F. J., Crouch, S. R. & Cengage, R. C. Skoog and West’s Fundamentals of Analytical Chemistry 9th edn. (Cengage Learning, 2014).

Ladkau, N., Hermann, I., Bühler, B. & Schmid, A. Enzyme-catalyzed laurolactam synthesis via intramolecular amide bond formation in aqueous solution. Adv. Synth. Catal. 353, 2501–2510 (2011).

Juni, E. & Heym, G. A. Properties of yeast pyruvate decarboxylase and their modification by proteolytic enzymes: I: stability of decarboxylases from wild-type and mutant strains. Arch. Biochem. Biophys. 127, 79–88 (1968).

Kunjapur, A. M. & Prather, K. L. J. Microbial engineering for aldehyde synthesis. Appl. Environ. Microbiol. 81, 1892–1901 (2015).

Acknowledgements

This project is funded by National Research Council of Thailand (NRCT) (Grant Number: NRCT5-RSA63004-08), TRF Senior Research Scholar (Grant Number: RTA6280001), Chiang Mai University (CMU), and Bioprocess Research Cluster (BRC), Faculty of Agro-Industry, CMU. Thailand Institute of Scientific and Technological Research (TISTR) is also thanked for microbial strain support.

Author information

Authors and Affiliations

Contributions

J.K. and N.L. designed the study. J.K. performed the experiments, collected, and analyzed the data. N.L. and Y.P. checked the validity of model. J.K., N.L., K.P., S.S., and C.M. performed statistical analyses. J.K. and N.L. wrote the initial draft of the manuscript. S.T., R.N., C.T., Y.P., P.R., K.J., K.P., S.S., C.M., T.C., P.S., A.R., N.T.N.T., S.W., S.R.S. revised the manuscript. J.K. and N.L. wrote the final version of the manuscript. All authors reviewed the final version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Khemacheewakul, J., Taesuwan, S., Nunta, R. et al. Validation of mathematical model with phosphate activation effect by batch (R)-phenylacetylcarbinol biotransformation process utilizing Candida tropicalis pyruvate decarboxylase in phosphate buffer. Sci Rep 11, 11813 (2021). https://doi.org/10.1038/s41598-021-91294-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-021-91294-0

- Springer Nature Limited

This article is cited by

-

Extraction of gymnemic acid from Gymnema inodorum (Lour.) Decne. leaves and production of dry powder extract using maltodextrin

Scientific Reports (2023)

-

Valorization of rice straw, sugarcane bagasse and sweet sorghum bagasse for the production of bioethanol and phenylacetylcarbinol

Scientific Reports (2023)