Abstract

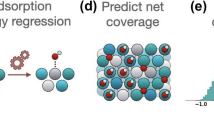

The electrochemical ammonia oxidation to dinitrogen as a means for energy and environmental applications is a key technology toward the realization of a sustainable nitrogen cycle. The state-of-the-art metal catalysts including Pt and its bimetallics with Ir show promising activity, albeit suffering from high overpotentials for appreciable current densities and the soaring price of precious metals. Herein, the immense design space of ternary Pt alloy nanostructures is explored by graph neural networks trained on ab initio data for concurrently predicting site reactivity, surface stability, and catalyst synthesizability descriptors. Among a few Ir-free candidates that emerge from the active learning workflow, Pt3Ru-M (M: Fe, Co, or Ni) alloys were successfully synthesized and experimentally verified to be more active toward ammonia oxidation than Pt, Pt3Ir, and Pt3Ru. More importantly, feature attribution analyses using the machine-learned representation of site motifs provide fundamental insights into chemical bonding at metal surfaces and shed light on design strategies for high-performance catalytic systems beyond the d-band center metric of binding sites.

Similar content being viewed by others

Introduction

Ammonia (NH3), an essential molecule of the planetary nitrogen cycle, has been widely used in modern industries ranging from medicine, food, and agriculture to the manufacturing of household chemicals. Particularly promising is its application for energy generation and storage technologies because of its easy liquefaction and high volumetric energy density, appealing characteristics for co** with the variability of renewable energy sources, e.g., wind, solar, and hydro1. In this aspect, design of materials for efficiently catalyzing the ammonia oxidation reaction (AOR) at the anode of direct ammonia fuel cells (DAFCs) holds the key to enable the transition away from fossil feedstocks to a sustainable energy economy. Platinum (Pt) is known as the best elemental metal catalyst for NH3 oxidation to benign dinitrogen (N2) in alkaline media, albeit suffering from large overpotentials (~0.5 V)2,Full size image

To gain insights into the local structure of the alloy nanoparticles, we conducted high-angle annular dark-field-scanning transmission electron microscopy (HAADF-STEM) and EDS measurements. The STEM images showed the cubic nanoparticle with a particle diameter of 10.0 ± 0.2 nm (Fig. 3b), and the enlarged image (in red circle, Fig. 3c) displays the atomic structure of the surface region of Pt3Ru1/2Co1/2 with the lattice fringes of 0.212 ± 0.01 nm at the lateral direction and 0.312 ± 0.02 nm at the angular direction, corresponding to (111) and (220) planes of Pt3Ru1/2Co1/2 alloys, respectively. These lattice fringes are slightly smaller than that of the standard pure Pt (JCPDS: 04-0802), with the corresponding lattice fringes of 0.221 nm and 0.360 nm, respectively. Figure 3d shows the overlay of elemental map** images, where the atom columns of Pt, Ru and Co are also clearly resolved in Supplementary Figs. 14, 15. Energy-dispersive X-ray spectroscopy line scanning further demonstrates the uniform distribution of Pt, Ru, and Co atoms in nanostructures (EDS, Supplementary Fig. 16).

The X-ray diffraction (XRD) patterns in Fig. 3e show broad diffraction peaks at ca. 23.8°, assigning to the (002) facet of carbon from the reduced graphene oxide37. The diffraction peaks of the pure Pt catalyst can be identified at ca. 39.8, 46.2, 67.5, 81.3 and 85.7°, corresponding to the (111), (200), (220), (311) and (222) facets of face centered cubic crystalline Pt (JCPDS: 04-0802). Compared to the pure Pt catalyst, these diffraction peaks in Pt3Ir and Pt3Ru1/2Co1/2 catalysts show slightly positive shift because Pt atoms were partially replaced by smaller Ir or Ru/Co atoms, leading to a lattice compression of the nanoparticles13,14. These results further confirm the formation of Pt3Ir and Pt3Ru1/2Co1/2 alloy nanoparticles. X-ray photoelectron spectroscopy (XPS) was conducted to identify the near surface elemental compound and chemical state. High-resolution XPS of Pt 4 f in rGO-supported Pt3Ir and Pt3Ru1/2Co1/2 (Fig. 3f) shows that the binding energy of Pt 4 f shifts to a higher value relative to rGO-supported Pt, which can be attributed to the strong electronic interaction within the Pt3Ir and Pt3Ru1/2Co1/238.

Catalytic performance of the Pt, Pt3Ir, Pt3Ru and Pt3Ru1/2Co1/2 nanocubes were tested via cyclic voltammetry (CV) in an Ar-saturated 1.0 M KOH + 0.1 M NH3 aqueous electrolyte (Pt3Ru was included as a reference system). Figure 4a shows that Pt3Ir has the lowest onset potential of 0.35 V vs. RHE, while Pt3Ru and Pt3Ru1/2Co1/2 have onset potentials of 0.46 and 0.42 V, all of which are lower than pure Pt of 0.48 V. Nevertheless, Pt3Ru1/2Co1/2 has the highest peak mass current activity of 174.0 A g–1Pt, higher than those of pure Pt (78.6 A g–1Pt), Pt3Ir (33.1 A g–1Pt) and Pt3Ru (80.2 A g–1Pt) catalysts. Further CO strip** measurements in CO-saturated 0.1 M HClO4 aqueous solution were conducted to estimate the electrochemical activate area (ECSA) of those Pt-based catalysts (see Supplementary Fig. 17). The ECSA values for Pt, Pt3Ir, Pt3Ru and Pt3Ru1/2Co1/2 were estimated to be 27.8, 37.7, 19.6 and 23.7 m2 g–1, respectively, which were summarized in Supplementary Fig. 18. Accordingly, the AOR specific activities for those Pt-based catalysts were plotted in Fig. 4c, showing a similar activity trend as the mass activity. The temperature dependent AOR activity of the rGO-supported Pt3Ru1/2Co1/2 catalyst was further measured, as shown in Fig. 4d. With increasing temperature from 25 to 80 °C, the AOR current significantly increased, resulting in lowered onset potentials and six-fold enhancement of the peak current density. In addition, the synthesized rGO-supported Pt3Ru1/2Ni1/2 and Pt3Ru1/2Fe1/2 nanocubes (Supplementary Fig. 19, 20) also show more active AOR performance than Pt, Pt3Ir, and Pt3Ru (Supplementary Fig. 21). For example, the highest peak current densities for Pt3Ru1/2Ni1/2 and Pt3Ru1/2Fe1/2 are 123.0 and 181.4 A g–1Pt, respectively. These activity trends correspond well with the prediction trend from the screening shown in Fig. 2g, further validating the design approach. It is important to note that the adsorption energies of both *N bridge and hollow species on Pt3Ru1/2Ni1/2, Pt3Ru1/2Fe1/2 and Pt3Ru1/2Co1/2 are within 0.1 eV, which is similar to the uncertainty of the microkinetic models introduced by linear adsorption-energy scaling relations. The short-term AOR stability of the Pt, Pt3Ir, Pt3Ru and Pt3Ru1/2Co1/2 nanocubes was studied via chronoamperometry (CA) at 0.55 V vs. RHE in an Ar-saturated 1.0 M KOH + 0.1 M NH3 aqueous electrolyte. As shown in Fig. 4b, a rapid decline in current density is noticed during the CA running. The initial rapid decline is derived from the removal of non-faradaic double-layer currents, while the subsequent decay is due to the deactivation of surface sites37,39,40. This is likely attributed to the formation of poisoning species such as *NO that blocks the active sites40,41. Compared to pure Pt, Ir alloying results in an enhanced AOR activity (Fig. 4a), while Ru does not improve the activity and shows a faster activity loss during the CA running (Fig. 4b). Encouragingly, the introduction of Co tends to stabilize surface sites in Pt3Ru1/2Co1/2, and showed ~4 times higher remained current than Pt3Ru, further indicating the critical role of both Ru and Co atoms in the ternary alloy system. Specifically, the Pt3Ru1/2Co1/2 retained the highest current density (6.7 A g–1Pt) after 1,800 s of CA running when compared with Pt3Ir (5.6 A g–1Pt), Pt3Ru (1.7 A g–1Pt) and Pt (4.2 A g–1Pt). Furthermore, their electrochemical surface area changes before and after 1800 s of CA testing was studied and shown in Supplementary Fig. 22, which further confirmed the superiority of the ternary Pt3Ru1/2Co1/2 toward AOR electrocatalysis. Most importantly, those catalysts are Ir-free, which is an important step toward potentially large-scale commercial applications of direct ammonia fuel cells.

a Electrocatalytic performance testing of the Pt, Pt3Ir, Pt3Ru and Pt3Ru1/2Co1/2 nanocubes via cyclic voltammetry (CV) with a rotating speed of 900 rpm in Ar-saturated 1.0 M KOH + 0.1 M NH3 under ambient conditions. b The NH3 electrooxidation short-term stability of the Pt, Pt3Ir, Pt3Ru and Pt3Ru1/2Co1/2 nanocubes at 0.55 V vs. RHE using the same testing conditions. c Specific activity comparisons for the Pt, Pt3Ir, Pt3Ru and Pt3Ru1/2Co1/2 nanocubes. d Cyclic voltammetry curves for the Pt3Ru1/2Co1/2 in Ar-saturated 1.0 M KOH + 0.1 M NH3 electrolytes operating at temperatures of 25, 40, 60 and 80 °C with a scanning rate of 5 mV s–1 and rotating speed of 900 rpm.

Advancing theory of chemisorption with interpretable deep learning

To gain physical insights into the superior AOR activity of Pt3Ru–M (M: Fe, Co, or Ni) electrocatalysts, we have inspected the causal relationships between the machine-learned features of a site motif and reactivity descriptors using post hoc interpretation techniques. This type of fundamental interrogation of deep learning models is enabled by the interpretable nature of the TinNet framework that embeds a physically transparent, data-derived map** from neural state variables to output targets. We used the Shapley Additive exPlanations (SHAP)42,43,44 that are built upon cooperative game theory for a local interpretation of reactivity origin of metal sites, by computing the SHAP value of each machine-learned feature, i.e., feature contribution to a prediction relative to a baseline or reference (see Methods). As shown in Fig. 5a, a local interpretation of Pt3Ru relative to Pt and Pt3Ru1/2Co1/2 to Pt3Ru, taking *Nh as an example, suggests that the adsorbate resonance energies of the frontier N2p orbitals are the most important factors in governing site reactivity instead of the commonly employed d-band center metric. Even though the d-band center of the Ru atom 2 and 3 in the Pt-Ru ensemble relative to pure Pt shifts up by +1.07 and +1.12 eV, respectively, it only leads to a –0.55 eV energy stabilization. In contrast, the adsorbate resonance energy of the *N 2pz (2px and 2py) orbital shifts up by +0.96 (+0.56 and +0.62) eV at Pt3Ru relative to that at Pt, which contributes –0.47 (–0.30 and –0.29) eV stabilization to Nh adsorption. Interestingly, the 3rd metal Co at the atom site 3 (most stable position) weakens Nh adsorption by slightly shifting down the resonance energies of the N2p orbitals, giving near-optimal reactivity descriptors. Local interpretable model-agnostic explanations (LIME) analysis was also performed, showing consistent interpretation where the variations in binding strengths can be largely explained due to the changes in the adsorbate resonance energies of frontier orbitals (Supplementary Fig. 23). Nevertheless, the factors that govern the surface reactivity, i.e., adsorption energies, are system dependent. In the case of Pt, Pt3Ru, and Pt3Ru1/2Co1/2, the variation of Nh adsorption energies can be explained by the resonance energies of adsorbate frontier orbitals. However, there also exist many systems in which the electronic structure of an active site, e.g., d-band center, dominates. This can be illustrated by SHAP analysis of Pt-terminated Pt3Ru1/2Ir1/2 and Pt3Ag surfaces relative to pure Pt, as shown in Supplementary Fig. 24. The effect of adsorbate resonance energies on chemical bonding can be illustrated through a graphic solution to the Newns–Anderson model in Fig. 5b. The upper intersect of an adsorbate line with the Hilbert-transformed chemisorption function represents the adsorbate-metal antibonding state. In accordance with the DFT-calculated density of states projected onto the N 2pz orbital, an upshift (downshift) in the adsorbate resonance energy results in higher (lower) lying antibonding states pinning across the Fermi level, thus influencing the occupancy of those states and adsorption energies. Consequently, the Co plays an important role in tailoring the adsorbate resonance energies of frontier orbitals, pushing the site motif toward the top of the activity volcano. A global SHAP analysis for Nb adsorption models in Fig. 5c further consolidates a pivotal role of adsorbate resonance energies in chemical bonding across a diverse range of ternary Pt alloy surfaces.

a Local interpretation of Nh adsorption on Pt3Ru(100) relative to Pt(100) and Pt3Ru1/2Co1/2(100) to Pt3Ru(100). b A graphical illustration of the Newns-Anderson model for an adsorbate resonance state interacting with metal d-states. DFT-calculated DOS projected onto the 2pz orbital of *Nh on Pt3Ru1/2Co1/2, Pt3Ru, and Pt are shown with adsorbate-metal antibonding states highlighted for comparison. c Global SHAP analysis of TinNet models of Nb adsorption showing a strong correlation of the machine-learned adsorbate resonance energy with the adsorption-energy contribution, i.e., the SHAP value.