Abstract

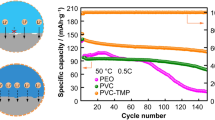

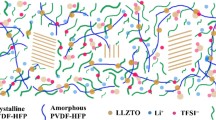

Solid electrolyte interphases generated using electrolyte additives are key for anode-electrolyte interactions and for enhancing the lithium-ion battery lifespan. Classical solid electrolyte interphase additives, such as vinylene carbonate and fluoroethylene carbonate, have limited potential for simultaneously achieving a long lifespan and fast chargeability in high-energy-density lithium-ion batteries (LIBs). Here we report a next-generation synthetic additive approach that allows to form a highly stable electrode-electrolyte interface architecture from fluorinated and silylated electrolyte additives; it endures the lithiation-induced volume expansion of Si-embedded anodes and provides ion channels for facile Li-ion transport while protecting the Ni-rich LiNi0.8Co0.1Mn0.1O2 cathodes. The retrosynthetically designed solid electrolyte interphase-forming additives, 5-methyl-4-((trifluoromethoxy)methyl)-1,3-dioxol-2-one and 5-methyl-4-((trimethylsilyloxy)methyl)-1,3-dioxol-2-one, provide spatial flexibility to the vinylene carbonate-derived solid electrolyte interphase via polymeric propagation with the vinyl group of vinylene carbonate. The interface architecture from the synthesized vinylene carbonate-type additive enables high-energy-density LIBs with 81.5% capacity retention after 400 cycles at 1 C and fast charging capability (1.9% capacity fading after 100 cycles at 3 C).

Similar content being viewed by others

Introduction

Lithium-ion batteries (LIBs) have been unrivaled energy sources for portable devices, such as laptops and smartphones, over the last three decades. The materials technology and the manufacturing processes for LIBs have advanced considerably, which have vastly improved their capacities and rendered them capable of powering electric vehicles (EVs)1,2,3,4,5. Securing high-energy-density LIBs with a long lifespan and fast charging performance is vital for realizing their ubiquitous use as superior power sources for electric vehicles. Among the materials developed for EV-adoptable high-energy-density LIBs, Si, and Ni-rich layered oxides have been prime choices for electrode material construction, owing to their high-energy storage capabilities6,7,8,9,10. However, Si-based anodes and Ni-rich cathodes suffer from structural instabilities induced by anisotropic volume changes and interface deterioration. Unlike graphite, the lithiation of Si provokes the generation of Li–Si alloys, which cause a colossal volume expansion (>300%) and fatal mechanical fractures of the Si particles10,11. Therefore, the solid electrolyte interphases (SEIs) at Si anodes degrade severely. This degradation induces the exposure of the Si surface, which leads to the continuous electrolyte decomposition-induced thickening of the SEI and eventual electrolyte depletion, thus rendering the battery unusable12.

Electrolyte additives have been extensively employed for extending the cycle life of LIBs while preventing electrolyte decomposition at the electrodes13,14,15,16,17. So far, reductive compounds possessing fluorine-donating moiety or vinyl group18,19,Full size image

To elucidate the roles of the SEI in the morphological stability of the Si nanolayer of the Si–C anode, nanoindentation by atomic force microscopy was performed47,48,49 (Supplementary Fig. 39). The slope of the force curves from Si–C anodes cycled with VC showed a continued increase during cycling (Supplementary Fig. 40a, b). The Young’s modulus of the Si–C anode50 (Supplementary Fig. 39b), was 1.15 MPa before cycling and increased to 6.0 MPa after 20 cycles with VC (Fig. 5g). On contrary, the Young’s modulus of the Si-C anode cycled with VC + DMVC-OCF3 + DMVC-OTMS was significantly lower than that for the anode cycled with VC alone. A lower Young’s modulus indicates higher elasticity51; thus, the Si–C anode cycled with VC + DMVC-OCF3 + DMVC-OTMS retains a more elastic SEI than the Si–C anode cycled with VC, which experienced penetration by the electrolyte decomposition byproducts. This elastic SEI is beneficial for enduring the volumetric stress; thereby, mechanical fracturing and the electrical isolation of Si are effectively mitigated.

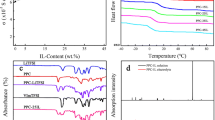

The chemical structure of the VC + DMVC-OCF3 + DMVC-OTMS-derived SEI was revealed via X-ray photoelectron spectroscopy (XPS) measurements. The peak intensity attributed to C–O, C=O, and C–C species for the VC + DMVC-OCF3 + DMVC-OTMS-derived SEI was similar to the VC-derived SEI because of the similarity of their frameworks (C 1s XPS in Fig. 6a). The CF2 peak, which might be formed by the reduction of the OCF3 anion, appeared at 292 eV in the case of VC + DMVC-OCF3 + DMVC-OTMS (Supplementary Table 4). A noticeable feature of the Si-C anode with VC + DMVC-OCF3 + DMVC-OTMS is that the peak intensity associated with the C=O and metal-O decreased drastically (O 1 s XPS in Fig. 6a and Supplementary Table 5). This result implies that DMVC-OCF3 and DMVC-OTMS modify the structure of the VC-derived SEI. Notably, the LiF peak intensity substantially increased at the SEI on the Si–C anodes precycled in VC + DMVC-OCF3 + DMVC-OTMS (Supplementary Table 6). This is attributable to the decomposition of OCF3− generated by the reduction of DMVC-OCF3. The metal-O peak at 529.5 eV increased noticeably (Supplementary Table 7), likely because a thinner CEI is formed on the cathode surface with VC + DMVC-OCF3 + DMVC-OTMS. The peaks corresponding to LiF and the P-F moiety in the CEI were of remarkably lower intensity in VC + DMVC-OCF3 + DMVC-OTMS than those in VC (Fig. 6b and Supplementary Table 8). The XPS analysis of the cathodes after precycling clearly indicates that the LiPF6 decomposition and the LiF formation at the cathode are suppressed by VC + DMVC-OCF3 + DMVC-OTMS (Fig. 6b and Supplementary Table 9).

The Si–C anode cycled with the VC had severely cracked particles, indicating the loss of their electrical connection (Fig. 7a, b). The exposure of the active surface of the Si–C anode particles leads to continuous electrolyte decomposition, causing thickening of the SEI to block Li-ion transfer and electron movement between the Si-C anode particles. The feature on the Si–C anode with VC + DMVC-OCF3 + DMVC-OTMS was strikingly different. The morphology of the Si–C anode particles was intact without any clear signs of mechanical fracture (Fig. 7c). This finding reveals that VC + DMVC-OCF3 + DMVC-OTMS forms a multifunctional SEI that accommodates the strain raised by repeated lithiation and delithiation of the Si–C anode, and effectually protects the Si–C anode against HF attack and transition metal deposition. The Si–C anode with VC showed an enormous volume expansion of approximately 176% after 400 cycles (Fig. 7d–f). Importantly, VC + DMVC-OCF3 + DMVC-OTMS effectively alleviated the increase in the thickness of Si–C anodes compared to that with VC alone (Fig. 7f). The EDS map** images in TEM of Si–C anodes after 400 cycles demonstrated the severe volume expansion of Si with VC (Fig. 7h and Supplementary Fig. 42e). The C and O EDS map** images of Si–C anodes precycled with VC showed that the electrolyte decomposition byproducts permeate into the Si nanolayer (Supplementary Fig. 41c, d). In contrast, the Si nanolayer of Si–C anodes with VC + DMVC-OCF3 + DMVC-OTMS stably maintained its original layered structure without irreparable damage (Fig. 7g, i and Supplementary Fig. 42f). Additionally, the SEI fabricated using VC + DMVC-OCF3 + DMVC-OTMS was thinner than the VC-derived SEI (Supplementary Fig. 41a, e).

a–f Surface morphologies of a pristine Si–C anode (a) and Si–C anodes obtained from NCM811/Si–C full cells cycled during 400 cycles at 25 °C with VC (b) or VC + DMVC-OCF3 + DMVC-OTMS (c), cross-sectional views of the pristine Si–C anode (d) and Si–C anodes from NCM811/Si–C full cells cycled during 400 cycles at 25 °C with VC (e) or VC + DMVC-OCF3 + DMVC-OTMS (f). g–i EDS map** in TEM of the pristine Si–C anode (g) and Si–C anodes after 400 cycles with VC (h) or VC + DMVC-OCF3 + DMVC-OTMS (i).

Corrosive HF causes the undesired elution of transition metal cations from the cathode and the irreversible deposition of leached transition metal cations on the anode surface52,53. Moreover, HF severely damages the CEI and SEI structures that must be maintained throughout the charge–discharge cycles to protect the anodes and cathodes54. To elucidate the vital role of DMVC-OTMS in HF scavenging, 1 wt% water was introduced to the additive-free and DMVC-OTMS-containing electrolytes, and the solutions were kept in storage for 1 day at 25 °C. The 19F NMR spectra of the additive-free electrolyte with 1% water shows peaks near −193.9 and −85.1 ppm that could be assigned to HF and PO2F2−, respectively (Supplementary Fig. 43a). Additionally, PO3F2−, which was formed by the subsequent conversion of PO2F2−, was detected in the 31P NMR spectrum (Supplementary Fig. 43c). As expected, the DMVC-OTMS-containing electrolyte with 1% water did not show the characteristic resonance of HF at −193.9 ppm (Supplementary Fig. 43b) and those for PO2F2− and PO3F2− (Supplementary Fig. 43d). This result provides strong evidence that DMVC-OTMS effectively scavenges HF and prevents the sequential hydrolysis of LiPF6 to HPO2F2 and H2PO3F (Supplementary Fig. 43e).

The impact of additives on the extent of transition metal deposition on the cycled Si–C anodes was examined using inductively coupled plasma–optical emission spectroscopy (Supplementary Table 10). After 400 cycles, the Si–C anode cycled with VC + DMVC-OCF3 + DMVC-OTMS showed a further reduction in the amount of Ni deposited on the surface (37.7 ppm), which was lower than the 55.2 ppm of Ni deposited on the Si–C anode cycled with VC + DMVC-OCF3, thus revealing the suppression of the transition metal dissolution effect of DMVC-OTMS via HF scavenging.

In conclusion, we demonstrated that the creation of a stable and spatially deformable SEI on a high-capacity Si–C anode could tolerate the inevitable volume changes induced by the lithiation of Si and could enable a long lifespan and fast chargeability of high-energy-density lithium-ion batteries. DMVC-OCF3 prepared by silver-mediated O-trifluoromethylation of DMVC-OH initiated the facile construction of the flexible and robust SEI on the Si–C anode while producing LiF as a mechanical enhancer of the SEI. Notably, HF, which severely damages the CEI and SEI layers, was effectively scavenged by the OTMS group in DMVC-OTMS; thereby, the structural integrity of the CEI and SEI layers was preserved. This work presents a breakthrough in the development of electrolyte additives for high-energy-density Li-ion batteries. We expect that our systematic approach for rational molecular design and DFT-aided mechanism development offers a promising way to discover next-generation additives.