Abstract

Electrochemical CO2 reduction (ECR) is highly attractive to curb global warming. The knowledge on the evolution of catalysts and identification of active sites during the reaction is important, but still limited. Here, we report an efficient catalyst (Ag-D) with suitable defect concentration operando formed during ECR within several minutes. Utilizing the powerful fast operando X-ray absorption spectroscopy, the evolving electronic and crystal structures are unraveled under ECR condition. The catalyst exhibits a ~100% faradaic efficiency and negligible performance degradation over a 120-hour test at a moderate overpotential of 0.7 V in an H-cell reactor and a current density of ~180 mA cm−2 at −1.0 V vs. reversible hydrogen electrode in a flow-cell reactor. Density functional theory calculations indicate that the adsorption of intermediate COOH could be enhanced and the free energy of the reaction pathways could be optimized by an appropriate defect concentration, rationalizing the experimental observation.

Similar content being viewed by others

Introduction

The extensive consumption of coal, oil and other fossil fuels has resulted in the emission of enormous amounts of carbon dioxide (CO2) into the surrounding atmosphere, which is the culprit of the global greenhouse effect1,2,3,4. Therefore, the management of CO2 concentrations in the atmosphere has become an important topic5. The use of clean carbon-neutral fuel systems, CO2 sequestration, and CO2 transformation into high value−added products are several strategies for inhibiting continuous increases in or even reducing the CO2 concentration in the atmosphere6. Among these techniques, electrochemical CO2 reduction (ECR) driven by clean and renewable electricity sources (e.g. solar energy) is particularly promising7,8, and can synthesize a wide variety of chemicals, such as formic acid, carbon monoxide (CO), alcohol and methane, along with the elimination of CO29,10,11,12,13. Among the synthesized chemicals, CO is regarded as having the most potential to achieve positive gross margins in terms of techno-economic assessments6,14,15. However, due to the small difference in standard reaction potentials for different products, it is a substantial challenge to achieve high selectivity towards one specific chemical, which requires the adoption of highly selective and efficient electrocatalysts16.

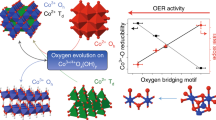

Among various electrocatalysts for ECR to CO investigated over past decades, metal-based materials11, especially metallic Ag17,18, may be the most promising candidate for industrial development in view of their remarkable performance and economic viability compared to noble Au-based materials19. It has been found that the performance (selectivity, activity and stability) of Ag-based catalysts is strongly related to their morphologies, shapes, particle sizes, crystal facets, electronic structures and so on17. Unmodified polycrystalline Ag metal, such as traditional Ag foil, shows an unsatisfactory CO faradaic efficiency (FE) of only 70–80%. Various design strategies for novel Ag catalysts17, such as shape controlling20, alloying21 and the construction of nanostructures22,23, have therefore been proposed to optimize the performance of ECR to CO. In particular, defect engineering has been identified as a significant method to enhance reactivity3,24. For instance, it has been proposed that plasma oxidation pretreatment of Ag foil could introduce an enhanced content of low-coordinated active sites, leading to an improved FE and a remarkably reduced overpotential (η) for ECR to CO25. Electrochemical reduction of metal oxides, such as Au oxides and Cu oxides, could also introduce vacancies or other defects to result in better performance26,27; this approach is highly attractive because of its simplicity compared to plasma treatment. However, how electrochemical reduction facilitates defect generation is still unclear.

Advanced operando X-ray, optical and electron-based characterizations may provide useful information about defect generation under real reaction conditions28,29,30,17. Although the DFT calculations demonstrated the strengthened binding of intermediate COOH by defect sites, which accounts for the enhanced FE for ECR to CO, the mechanism for the dramatically inhibited HER is still ambiguous. Examining the possible reaction pathways of HER and ECR to CO may provide some useful clues. As shown in Fig. 5c, it is believed that HER in acidic electrolytes begins from a Volmer reaction, where an electron transfer is coupled with a proton adsorption on an empty active site of the electrode. After the formation of an absorbed hydrogen atom, two different reaction processes, the Tafel reaction or Heyrovsky reaction, may occur to yield the final H2 product77. In contrast, the reaction pathways for ECR are quite complex due to the multi-electron and multi-proton transfer steps. For ECR to CO, the COOH is generally regarded as a key intermediate74,78, which is also reported in our present work. According to Kortlever et al., the formation of *COOH may have two different mechanisms78, as shown in Fig. 5d. In the two-step mechanism (purple arrows), the electron and proton transfer processes occur in two separate steps, while in another mechanism (light green arrows), the proton transfer is coupled with the electron transfer (PCET). Regardless of the initial step, the formed *COOH will subsequently react with another electron and proton to yield H2O and *CO. Then *CO desorbs from the electrode to release CO and leaves an empty active site39. As shown in Fig. 5a, on the defect Ag surface, the COOH and CO stably bind at the vacancy edge sites where two Ag atoms are occupied, which likely blocks the adsorption of protons to Ag, leading to the poor selectivity of the HER.

Discussion

In summary, the nanostructured Ag-D catalyst exhibits outstanding performance for ECR to CO, both in an H-cell reactor and a flow-cell reactor. Fast operando XAS measurements and ex situ SEM and TEM images revealed that massive defects are efficiently created at the initial stage of ECR. Carbon dioxide in the electrolyte is proved to undertake a role in the protection of these defect sites since their formation. We proposed the concept of the RCd based on the coordination numbers to quantify the defects, which may give insights to the future work on the quantitative discussion of the defects, especially for the metal and metallic oxides. DFT calculations demonstrated that the adsorption of intermediate COOH is strengthened on Ag atoms surrounding the defect sites, benefiting the activation of CO2. Therefore, combining the experimental and theoretical results, the origin of the high performance of Ag-D catalyst was attributed to the abundant defect sites. Our work not only highlights the importance of operando characterization techniques with high time resolution, but also provides new insights into Ag-based catalysts for ECR.

Methods

Sample preparation

The Ag2O nanoparticles were synthesized by a precipitation reaction. In detail, 0.02 mol AgNO3 was first dissolved in a volume of 200 mL deionized water. Then, a volume of 100 mL sodium hydroxide solution (0.2 M) was dropped in the AgNO3 solution under stirring to enable a homogenous mixture. The final product of Ag2O was collected after filtration and drying at ~60 °C. Ag-D was prepared by operando electrochemical reduction of Ag2O, which endowed massive defects in Ag-D. Polycrystalline Ag foil (0.127-mm thick, 99.9%, annealed) was purchased from Alfa Aesar. Ag powder was purchased from Aladdin.

Characterization

XRD was conducted on a Rigaku Smartlab with filtered Cu Kα radiation (λ = 1.5418 Å) to determine phase constitutions and crystal structures. XPS was carried out on a PHI5000 VersaProbe spectrometer using an Al-Kα X-ray source to analyse element states of the electrocatalysts. SEM images were obtained from a scanning electron micro-analyzer (HITACHIS4800). TEM images (JEOL JEM 2100, 200 kV) were collected to uncover catalysts’ morphology and structure.

Electrode preparation

The electrode ink for Ag-D was prepared as follows. Pristine Ag2O powder (10 mg) and Super P Li (10 mg) were suspended in a mixture containing 5 wt% Nafion solution (100 μL) and ethanol (1 mL) via ultrasound. Then, 30 μL of the above homogeneous ink was spread on a prepolished L-type GCE with a diameter of 8 mm. The loading of Ag2O in this electrode was ~0.543 mg cm−2. Polycrystalline Ag foil served as the working electrode for comparison after thorough ultrasonic cleaning in acetone and ethanol.

For the fabrication of the cathodic GDE, the same ink was dropped onto the gas diffusion layers (29BC, SGL) with an Ag2O loading of ~2 mg cm−2. To avoid the possible ‘flooding’ of GDE, another commercial PTFE film (~0.22 μm pore size) was fitted on top of the GDE.

ECR performance measurements and product analysis

Electrochemical tests were conducted on a workstation (CHI 760E) at 25 °C. A gas-tight H-cell reactor segregated with a Nafion-117 membrane was used for the electrolysis experiments. In the cathodic chamber (100 mL), an L-type GCE and Ag/AgCl served as the working and reference electrode, respectively. A Pt foil in the anodic chamber (100 mL) served as a counter electrode. Each chamber contained 50 mL KHCO3 (99.99%, Macklin) electrolyte (0.1 M, pH = 6.8). Carbon dioxide was continuously purged (30 mL min−1, 99.999%, Shangyuan) during the ECR process. All potentials were recalculated into RHE by ERHE = EAg/AgCl + 0.1989 + 0.0591 × pH according to Nernst equation unless otherwise stated54,65, and iR compensation was also taken into consideration.

For the measurements in the flow cell, the as-prepared cathodic GDE (geometric active area of 1 cm2) was separated from the anode with a commercial anion exchange membrane (PK130, Fumatech). A Pt plate acted as the anode. Since 1 M KOH electrolyte was used, the Hg/HgO electrode was mounted in the catholyte stream at a fixed location, serving as the reference electrode. All measured potentials vs. Hg/HgO were recalculated into RHE through ERHE = EHg/HgO + 0.098 + 0.0591 × pH according to the Nernst equation unless otherwise stated. The catholyte (~30 mL) was circulated by a peristaltic pump (BT100-2J, Longer).

Gaseous products were analyzed by a gas chromatograph (GC, HOPE 9860) with a thermal conductivity detector (TCD) and flame ionization detectors (FID). Nuclear magnetic resonance spectroscopy (1H NMR, Bruker ACF-400) was used to analyze the liquid-phase products.

The cathodic energy efficiency (EE) was calculated as follows79,80:

where E0, FE and E represented standard potential, faradaic efficiency and applied potential, respectively.

Fast operando XAS measurements

For the conventional XAS, it usually takes 15–30 min to obtain a single spectrum, and its quality may be unsatisfactory due to some accidental disturbances. Therefore, employing conventional XAS to study the chemical information of the catalyst may give confusing results, since the real state of the catalyst may change quickly with time. Moreover, the tracking of the changing process has been pursued and received growing attention in order to gain a comprehensive understanding on the reconstruction of catalysts28. Obviously, advanced characterization techniques with high time resolutions are essential for obtaining the desired information. The fast XAS technique introduced here can provide not only a clear evolution information on the catalyst, but also a reliable data quality, both of which are crucial for the further analysis on the structure of catalysts. Fast operando XAS was collected at the 44 A beam line of TPS. The 44 A beam line equipped with a quick-scanning monochromator (Q-Mono) can provide 120 sheets of spectra per minute. By averaging these spectra, a good quality of the final spectra can be ensured. A PMMA reactor was prepared for fast operando experiments, as shown in Supplementary Fig. 5. Catalysts were hand-brushed onto carbon-fibre paper serving as a working electrode. Carbon dioxide was constantly bubbled into the electrolyte (0.1 M KHCO3). A potential of −1.5 V vs. Ag/AgCl was applied to the working electrode to study the evolution of catalysts. All spectra were obtained in transmission mode and analyzed using Athena and Artemis81. The k range for Fourier transforms (FT) was from 2.5 to 12.2 Å-1. Fitting of the EXAFS spectra χ(k)k2 for Ag–O and Ag–Ag bond was conducted in R space in the range from Rmin = 1.2 Å to Rmax = 3.5 Å. When fitting the single peak for Ag–Ag bond, the Rmin was set to 2.16 Å. For Ag-D after 6, 8 and 10 min, the high shells were fitted, respectively. The Rmax was accordingly set to 6.0 Å. Phase corrections were taken into consideration during the fitting process.

DFT calculations

To obtain a deeper insight into the effects of Ag defects on electrocatalytic reactions, DFT calculations were performed. In the current study, we built three vacancy models with point defects as representatives of defect structures to investigate their influence on ECR. The Ag (111) crystal surface is selected on the basis of the experimental observation and theoretical consideration. The Ag-D catalyst exhibited the strongest peak for (111) facet in XRD pattern, which was also frequently observed in HRTEM images. DFT calculations based on the selected Ag (111) plane was also reported in literatures for the mechanism studies20,25,82. Thus, it is reasonable to choose the representative Ag (111) facet to perform the DFT calculations in the present work. A three layer p(3 × 3) (111) slab with 20 Å of vacuum avoiding imaging interactions in the z-axis was constructed to represent the Ag pristine model. Meanwhile, the Ag (111)-vacancy system was built by removing one Ag atom from the optimized pristine Ag (111) system, and then further geometry optimization was performed to relax the system. Since the CN and DW factors reflect the coordination environment and structural disorder of the catalysts, accordingly, in the DFT studies, the influence of defects on the Ag (111) surface structures was also taken into consideration by optimizing lattice parameters and atomic positions of the slab. As shown in Supplementary Table 4, the existence of the vacancy does not change the cell shape of the slab, but leads to slight variation of the cell volume. This indicates that the vacancy gives rise to structural changes to some extent. For the clarity, the vacancy concentration is defined as \({\mathrm{C}}_{\mathrm{v}} = \frac{{{\mathrm{N}}_{\mathrm{v}}}}{{{\mathrm{N}}_{{\mathrm{total}}}}}\), where Nv is the number of vacancy, and Ntotal is the number of atoms of the first atomic layer in Ag (111)-pristine slabs. In this case, Cv = 1/27 ≈ 4%, and the model is referred to as Ag (111)-4% vacancy. The p(2 × 2) (111) slab models were constructed to simulate higher vacancy concentrations. By removing one and two Ag atoms, we obtained the models with Cv of ca. 8% and 17%, respectively (Supplementary Fig. 19). From Supplementary Table 4, we can see that when Cv is ca. 17%, the vacancies lead to slight variation of the cell shape compared with lower vacancy concentration carrying models, which indicates larger structural fluctuations with respect to the pristine structure. Note that, the Cv is not exactly equivalent to the RCd. The aim to introduce the Cv into DFT calculations is for the quantitative discussion on the effects of defect structures. For all models, the bottom layer was immobilized at the optimized lattice constant (2.03 Å), agreeing with the value of 2.04 Å obtained in experiments83. Initial adsorption configurations of COOH and CO intermediates at four sites (top site, bridge site, fcc hollow site and hcp hollow site, Supplementary note 1 and Supplementary Fig. 21) were constructed to study the adsorption properties.

The Vienna Ab-initio Simulation Package (VASP) was used to conduct periodic DFT calculations84. Electron-core interactions were described by the projector augmented wavefunction (PAW) method85. The Perdew-Burke-Ernzerhof (PBE) functional in a plane wave pseudopotential implementation within the generalized gradient approximation (GGA) was applied for describing the electron exchange-correlation86. Grimme’s semi-empirical correction for the dispersion potential (DFT-D3) was applied to include the long-range dispersion effect87. Plane wave cut-off energies of 700 eV and 450 eV were chosen for the bulk primitive crystal cell and slab models, respectively. The Monkhorst–Pack technique was used to automatically generate the gamma centred 3 × 3 × 1 k-points grid in the Brillouin zone88. The width of 0.1 eV was employed for Gaussian smearing. The electronic self-consistent iteration convergence criterion was 1.0 × 10−6 eV. The convergence criteria for the force was 0.01 eV/Å for each free atom.

Data availability

All relevant data are available from the corresponding authors on reasonable request.

References

Dinh, C. T. et al. CO2 electroreduction to ethylene via hydroxide-mediated copper catalysis at an abrupt interface. Science 360, 783–787 (2018).

Singh, M. R., Goodpaster, J. D., Weber, A. Z., Head-Gordon, M. & Bell, A. T. Mechanistic insights into electrochemical reduction of CO2 over Ag using density functional theory and transport models. Proc. Natl Acad. Sci. USA 114, E8812 (2017).

Wang, Y., Han, P., Lv, X., Zhang, L. & Zheng, G. Defect and interface engineering for aqueous electrocatalytic CO2 reduction. Joule 2, 2551–2582 (2018).

Clark, E. L. et al. Standards and protocols for data acquisition and reporting for studies of the electrochemical reduction of carbon dioxide. ACS Catal. 8, 6560–6570 (2018).

AlOtaibi, B., Fan, S., Wang, D., Ye, J. & Mi, Z. Wafer-level artificial photosynthesis for CO2 reduction into CH4 and CO using GaN nanowires. ACS Catal. 5, 5342–5348 (2015).

Prajapati, A. & Singh, M. R. Assessment of artificial photosynthetic systems for integrated carbon capture and conversion. ACS Sustain. Chem. Eng. 7, 5993–6003 (2019).

Singh, M. R., Clark, E. L. & Bell, A. T. Thermodynamic and achievable efficiencies for solar-driven electrochemical reduction of carbon dioxide to transportation fuels. Proc. Natl Acad. Sci. USA 112, E6111 (2015).

Hahn, C. et al. Engineering Cu surfaces for the electrocatalytic conversion of CO2: controlling selectivity toward oxygenates and hydrocarbons. Proc. Natl Acad. Sci. USA 114, 5918 (2017).

Singh, M. R., Kwon, Y., Lum, Y., Ager, J. W. & Bell, A. T. Hydrolysis of electrolyte cations enhances the electrochemical reduction of CO2 over Ag and Cu. J. Am. Chem. Soc. 138, 13006–13012 (2016).

Singh, M. R., Clark, E. L. & Bell, A. T. Effects of electrolyte, catalyst, and membrane composition and operating conditions on the performance of solar-driven electrochemical reduction of carbon dioxide. Phys. Chem. Chem. Phys. 17, 18924–18936 (2015).

Zhu, D. D., Liu, J. L. & Qiao, S. Z. Recent advances in inorganic heterogeneous electrocatalysts for reduction of carbon dioxide. Adv. Mater. 28, 3423–3452 (2016).

Yang, H. B. et al. Atomically dispersed Ni(I) as the active site for electrochemical CO2 reduction. Nat. Energy 3, 140–147 (2018).

Ringe, S. et al. Double layer charging driven carbon dioxide adsorption limits the rate of electrochemical carbon dioxide reduction on gold. Nat. Commun. 11, 33 (2020).

Nitopi, S. et al. Progress and perspectives of electrochemical CO2 reduction on copper in aqueous electrolyte. Chem. Rev. 119, 7610–7672 (2019).

Gabardo, C. M. et al. Combined high alkalinity and pressurization enable efficient CO2 electroreduction to CO. Energy Environ. Sci. 11, 2531–2539 (2018).

Gao, D., Arán-Ais, R. M., Jeon, H. S. & Roldan Cuenya, B. Rational catalyst and electrolyte design for CO2 electroreduction towards multicarbon products. Nat. Catal. 2, 198–210 (2019).

Sun, D., Xu, X., Qin, Y., Jiang, S. P. & Shao, Z. Rational design of Ag-based catalysts for the electrochemical CO2 reduction to CO: a review. ChemSusChem 13, 39–58 (2020).

Deng, W. et al. Achieving convenient CO2 electroreduction and photovoltage in tandem using potential-insensitive disordered Ag nanoparticles. Chem. Sci. 9, 6599–6604 (2018).

Kuhl, K. P. et al. Electrocatalytic conversion of carbon dioxide to methane and methanol on transition metal surfaces. J. Am. Chem. Soc. 136, 14107–14113 (2014).

Liu, S. et al. Shape-dependent electrocatalytic reduction of CO2 to CO on triangular silver nanoplates. J. Am. Chem. Soc. 139, 2160–2163 (2017).

Li, Y. C. et al. Binding site diversity promotes CO2 electroreduction to ethanol. J. Am. Chem. Soc. 141, 8584–8591 (2019).

Luan, C. et al. High-performance carbon dioxide electrocatalytic reduction by easily fabricated large-scale silver nanowire arrays. ACS Appl. Mater. Interfaces 10, 17950–17956 (2018).

Lu, Q. et al. A selective and efficient electrocatalyst for carbon dioxide reduction. Nat. Commun. 5, 3242 (2014).

Jia, Y. et al. Identification of active sites for acidic oxygen reduction on carbon catalysts with and without nitrogen do**. Nat. Catal. 2, 688–695 (2019).

Mistry, H. et al. Enhanced carbon dioxide electroreduction to carbon monoxide over defect-rich plasma-activated silver catalysts. Angew. Chem. Int. Ed. 56, 11394–11398 (2017).

Chen, Y., Li, W. C. & Kanan, W. M. Aqueous CO2 reduction at very low overpotential on oxide-derived Au nanoparticles. J. Am. Chem. Soc. 134, 19969–19972 (2012).

Li, C. W., Ciston, J. & Kanan, M. W. Electroreduction of carbon monoxide to liquid fuel on oxide-derived nanocrystalline copper. Nature 508, 504–507 (2014).

Handoko, A. D., Wei, F., Jenndy, Yeo, B. S. & Seh, Z. W. Understanding heterogeneous electrocatalytic carbon dioxide reduction through operando techniques. Nat. Catal. 1, 922–934 (2018).

Firet, N. J. et al. Operando EXAFS study reveals presence of oxygen in oxide-derived silver catalysts for electrochemical CO2 reduction. J. Mater. Chem. A 7, 2597–2607 (2019).

Zhu, Y., Wang, J., Chu, H., Chu, Y.-C. & Chen, H. M. In situ/operando studies for designing next-generation electrocatalysts. ACS Energy Lett. 5, 1281–1291 (2020).

**ao, Z. et al. Operando identification of the dynamic behavior of oxygen vacancy-rich Co3O4 for oxygen evolution reaction. J. Am. Chem. Soc. 142, 12087–12095 (2020).

Lee, J. H. et al. Tuning the activity and selectivity of electroreduction of CO2 to synthesis gas using bimetallic catalysts. Nat. Commun. 10, 3724 (2019).

Sun, H. et al. Ternary phase diagram-facilitated rapid screening of double perovskites as electrocatalysts for the oxygen evolution reaction. Chem. Mater. 31, 5919–5926 (2019).

Bergmann, A. & Roldan Cuenya, B. Operando insights into nanoparticle transformations during catalysis. ACS Catal. 9, 10020–10043 (2019).

Chen, G. et al. An amorphous nickel–iron-based electrocatalyst with unusual local structures for ultrafast oxygen evolution reaction. Adv. Mater. 31, 1900883 (2019).

Zhou, J. et al. Voltage- and time-dependent valence state transition in cobalt oxide catalysts during the oxygen evolution reaction. Nat. Commun. 11, 1984 (2020).

Sun, H. et al. Bulk and surface properties regulation of single/double perovskites to realize enhanced oxygen evolution reactivity. ChemSusChem 13, 3045–3052 (2020).

Tsai, F.-T. et al. The HER/OER mechanistic study of an FeCoNi-based electrocatalyst for alkaline water splitting. J. Mater. Chem. A 8, 9939–9950 (2020).

Ma, M., Trześniewski, B. J., **e, J. & Smith, W. A. Selective and efficient reduction of carbon dioxide to carbon monoxide on oxide-derived nanostructured silver electrocatalysts. Angew. Chem. Int. Ed. 55, 9748–9752 (2016).

Fabbri, E. et al. Dynamic surface self-reconstruction is the key of highly active perovskite nano-electrocatalysts for water splitting. Nat. Mater. 16, 925–931 (2017).

Lin, S.-C. et al. Operando time-resolved X-ray absorption spectroscopy reveals the chemical nature enabling highly selective CO2 reduction. Nat. Commun. 11, 3525 (2020).

Peterson, A. A. & Nørskov, J. K. Activity descriptors for CO2 electroreduction to methane on transition-metal catalysts. J. Phys. Chem. Lett. 3, 251–258 (2012).

Zhong, M. et al. Accelerated discovery of CO2 electrocatalysts using active machine learning. Nature 581, 178–183 (2020).

Weekes, D. M., Salvatore, D. A., Reyes, A., Huang, A. & Berlinguette, C. P. Electrolytic CO2 reduction in a flow cell. Acc. Chem. Res. 51, 910–918 (2018).

Tjeng, L. H. et al. Electronic structure of Ag2O. Phys. Rev. B 41, 3190–3199 (1990).

Feng, X., Jiang, K., Fan, S. & Kanan, M. W. A direct grain-boundary-activity correlation for CO electroreduction on Cu nanoparticles. ACS Cent. Sci. 2, 169–174 (2016).

Sun, H. et al. Boosting the oxygen evolution reaction activity of a perovskite through introducing multi-element synergy and building an ordered structure. J. Mater. Chem. A 7, 9924–9932 (2019).

Liu, H. et al. Insight into the role of metal–oxygen bond and O 2p hole in high-voltage cathode LiNixMn2–xO4. J. Phys. Chem. C. 121, 16079–16087 (2017).

Chen, P.-T. et al. Size-selective reactivity of subnanometer Ag4 and Ag16 clusters on a TiO2 surface. J. Phys. Chem. C. 121, 6614–6625 (2017).

Masai, H. et al. X-ray absorption near-edge structure of Ag cations in phosphate glasses for radiophotoluminescence applications. J. Ceram. Soc. JAPAN 127, 924–930 (2019).

Buckley, J. J., Gai, P. L., Lee, A. F., Olivi, L. & Wilson, K. Silver carbonate nanoparticles stabilised over alumina nanoneedles exhibiting potent antibacterial properties. Chem. Commun. 4013–4015 (2008). https://pubs.rsc.org/--/content/articlelanding/2008/cc/b809086f/unauth#!divAbstract.

Sarode, P. R. et al. Study of local environment of Ag in Ag/CeO2 catalyst by EXAFS. Mater. Res. Bull. 37, 1679–1690 (2002).

Sanson, A. et al. Negative thermal expansion and local dynamics in Cu2O and Ag2O. Phys. Rev. B 73, 214305 (2006).

Li, H. et al. Colloidal silver diphosphide (AgP2) nanocrystals as low overpotential catalysts for CO2 reduction to tunable syngas. Nat. Commun. 10, 5724 (2019).

Zhang, W. et al. Atypical oxygen-bearing copper boosts ethylene selectivity toward electrocatalytic CO2 reduction. J. Am. Chem. Soc. 142, 11417–11427 (2020).

Calle-Vallejo, F. et al. Why conclusions from platinum model surfaces do not necessarily lead to enhanced nanoparticle catalysts for the oxygen reduction reaction. Chem. Sci. 8, 2283–2289 (2017).

Ikemoto, H. & Miyanaga, T. Extended X-ray absorption fine structure study of local structure and atomic correlations of tellurium nanoparticles. Phys. Rev. Lett. 99, 165503 (2007).

Vila, F. D., Rehr, J. J., Rossner, H. H. & Krappe, H. J. Theoretical x-ray absorption Debye-Waller factors. Phys. Rev. B 76, 014301 (2007).

Kenji, K. et al. XAFS analysis of crystal GeCu2Te3 phase change material. Z. Phys. Chem. 230, 433–443 (2016).

**e, C. et al. Defect chemistry in heterogeneous catalysis: recognition, understanding, and utilization. ACS Catal. 10, 11082–11098 (2020).

Lee, Y. et al. Raman analysis of mode softening in nanoparticle CeO2−δ and Au-CeO2−δ during CO oxidation. J. Am. Chem. Soc. 133, 12952–12955 (2011).

Banhart, F., Kotakoski, J. & Krasheninnikov, A. V. Structural defects in graphene. ACS Nano 5, 26–41 (2011).

Guan, D. et al. Utilizing ion leaching effects for achieving high oxygen-evolving performance on hybrid nanocomposite with self-optimized behaviors. Nat. Commun. 11, 3376 (2020).

Yan, D. et al. Defect chemistry of nonprecious-metal electrocatalysts for oxygen reactions. Adv. Mater. 29, 1606459 (2017).

Luo, W., Zhang, J., Li, M. & Züttel, A. Boosting CO production in electrocatalytic CO2 reduction on highly porous Zn catalysts. ACS Catal. 9, 3783–3791 (2019).

Dunwell, M., Luc, W., Yan, Y., Jiao, F. & Xu, B. Understanding surface-mediated electrochemical reactions: CO2 reduction and beyond. ACS Catal. 8, 8121–8129 (2018).

Gavrilov, A. N. et al. On the influence of the metal loading on the structure of carbon-supported PtRu catalysts and their electrocatalytic activities in CO and methanol electrooxidation. Phys. Chem. Chem. Phys. 9, 5476–5489 (2007).

Wang, S., Jiang, S. P., White, T. J., Guo, J. & Wang, X. Electrocatalytic activity and interconnectivity of Pt nanoparticles on multiwalled carbon nanotubes for fuel cells. J. Phys. Chem. C. 113, 18935–18945 (2009).

Wang, Y. et al. Layered double hydroxide nanosheets with multiple vacancies obtained by dry exfoliation as highly efficient oxygen evolution electrocatalysts. Angew. Chem. Int. Ed. 56, 5867–5871 (2017).

Wang, H. et al. Enhanced CO selectivity and stability for electrocatalytic reduction of CO2 on electrodeposited nanostructured porous Ag electrode. J. CO2 Util. 15, 41–49 (2016).

Liu, K., Smith, W. A. & Burdyny, T. Introductory guide to assembling and operating gas diffusion electrodes for electrochemical CO2 reduction. ACS Energy Lett. 4, 639–643 (2019).

McElhiney, G., Papp, H. & Pritchard, J. The adsorption of Xe and CO on Ag(111). Surf. Sci. 54, 617–634 (1976).

Chen, B. W. J., Kirvassilis, D., Bai, Y. & Mavrikakis, M. Atomic and molecular adsorption on Ag(111). J. Phys. Chem. C. 123, 7551–7566 (2019).

Firet, N. J. & Smith, W. A. Probing the reaction mechanism of CO2 electroreduction over Ag films via operando infrared spectroscopy. ACS Catal. 7, 606–612 (2017).

Ju, W. et al. Understanding activity and selectivity of metal-nitrogen-doped carbon catalysts for electrochemical reduction of CO2. Nat. Commun. 8, 944 (2017).

Gao, D. et al. Enhancing CO2 electroreduction with the metal–oxide interface. J. Am. Chem. Soc. 139, 5652–5655 (2017).

Guan, D. et al. Screening highly active perovskites for hydrogen-evolving reaction via unifying ionic electronegativity descriptor. Nat. Commun. 10, 3755 (2019).

Kortlever, R., Shen, J., Schouten, K. J. P., Calle-Vallejo, F. & Koper, M. T. M. Catalysts and reaction pathways for the electrochemical reduction of carbon dioxide. J. Phys. Chem. Lett. 6, 4073–4082 (2015).

Liu, S., Sun, C., **ao, J. & Luo, J.-L. Unraveling structure sensitivity in CO2 electroreduction to near-unity CO on silver nanocubes. ACS Catal. 10, 3158–3163 (2020).

Wang, Y. et al. Catalyst synthesis under CO2 electroreduction favours faceting and promotes renewable fuels electrosynthesis. Nat. Catal. 3, 98–106 (2020).

Ravel, B. & Newville, M. ATHENA, ARTEMIS, HEPHAESTUS: data analysis for X-ray absorption spectroscopy using IFEFFIT. J. Synchrotron Radiat. 12, 537–541 (2005).

Feng, L. et al. Structural identification of silicene on the Ag(111) surface by atomic force microscopy. Phys. Rev. B 98, 195311 (2018).

Suh, I.-K., Ohta, H. & Waseda, Y. High-temperature thermal expansion of six metallic elements measured by dilatation method and X-ray diffraction. J. Mater. Sci. 23, 757–760 (1988).

Kresse, G. & Furthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54, 11169–11186 (1996).

Kresse, G. & Joubert, D. From ultrasoft pseudopotentials to the projector augmented-wave method. Phys. Rev. B 59, 1758–1775 (1999).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865–3868 (1996).

Grimme, S., Ehrlich, S. & Goerigk, L. Effect of the dam** function in dispersion corrected density functional theory. J. Comput. Chem. 32, 1456–1465 (2011).

Monkhorst, H. J. & Pack, J. D. Special points for Brillouin-zone integrations. Phys. Rev. B 13, 5188–5192 (1976).

Acknowledgements

We thank the financial support from the Jiangsu Nature Science Foundation for Distinguished Young Scholars under the contract number of BK20170043, and the Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD). We are grateful to the High Performance Computing Center of Nan**g Tech University for supporting the computational resources. We acknowledge the support from the Max Planck-POSTECH-Hsinchu Center for Complex Phase Materials.

Author information

Contributions

X.W. and W.Z. conceived and designed the project. Y.G. conducted the DFT calculations. X.W., Z.S. and F.X. performed the structural characterizations and electrochemical measurements. X.W., D.G., Z.H., Y.H., C.P. and J.C. performed XAS characterization and analyzed the results. J.D. provided assistance in figures. F.Y. gave help in TEM analysis. Z.H., W.Z. and Z.S. supervised the project. X.W. and Y.G. drafted the manuscript and all other authors contributed to the final version of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Peer review information Nature Communications thanks Alessandro Longo, Meenesh Singh and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wu, X., Guo, Y., Sun, Z. et al. Fast operando spectroscopy tracking in situ generation of rich defects in silver nanocrystals for highly selective electrochemical CO2 reduction. Nat Commun 12, 660 (2021). https://doi.org/10.1038/s41467-021-20960-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-021-20960-8

- Springer Nature Limited

This article is cited by

-

Electrosynthesis of amino acids from NO and α-keto acids using two decoupled flow reactors

Nature Catalysis (2023)

-

Atomically precise alkynyl-protected Ag20Cu12 nanocluster: Structure analysis and electrocatalytic performance toward nitrate reduction for NH3 synthesis

Nano Research (2023)

-

Applying machine-learning screening of single transition metal atoms anchored on N-doped γ-graphyne for carbon monoxide electroreduction toward C1 products

Nano Research (2023)

-

Coupling of nanocrystal hexagonal array and two-dimensional metastable substrate boosts H2-production

Nature Communications (2022)

-

Homoleptic alkynyl-protected Ag32 nanocluster with atomic precision: Probing the ligand effect toward CO2 electroreduction and 4-nitrophenol reduction

Nano Research (2022)