Abstract

Environmental contamination by hexavalent chromium (Cr(VI)) and antibiotic drug residues pose significant challenges to public health and ecosystems. This study investigates the application of CoTiO3/BiVO4@MIL-Fe(53) (CT/BV@Fe-MOF) for the reduction of Cr(VI) and degradation of tetracycline (TCL) under visible light. After grafting an iron-based metal–organic framework MIL-Fe(53) on a modified CoTiO3/BiVO4 composite, the photogenerated electrons could easily be transferred from CoTiO3 to BiVO4/Fe-MOF species via interfacial charge transfer. UV–vis diffuse reflectance spectroscopy showed that charge carriers were formed in response to visible light absorption. The effect of different operating parameters, including catalyst load, pH, initial Cr(VI), and TCL concentration, was systematically evaluated during the photocatalytic process. The CT/BV@Fe-MOF composite exhibited 98.7% reduction efficiency in Cr(VI) (50 ppm) and 97.5% degradation efficiency towards TCL (30 ppm) within 90 min, resulting in a greater efficiency than the pristine CoTiO3, BiVO4, and Fe-MOF materials. The CT/BV@Fe-MOF composite displayed excellent stability over six cycles, highlighting its potential for practical applications. In addition, the plausible degradation pathway of TCL was evaluated using LC-ESI/MS analysis, while the TEST program was utilized to investigate the toxicity of the products generated during the degradation process.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Water sources are increasingly contaminated with organic and inorganic pollutants. About 1.1 billion people are in risk contracting waterborne diseases due to poor water access [1]. Chromium (Cr(VI)) and tetracycline (TCL) are two common inorganic and organic pollutants that can contaminate water sources and posing a significant environmental and health risks [2, 16, 17]. Notably, these non-destructive methods result only in the transformation of drug molecules into solids or sludge, which, in turn, produce secondary pollutants that needs to be treated and purified. Also, some of these techniques may not be specific to the target pollutant, leading to remove other beneficial ions or molecules from the water [18]. Given these limitations, a growing need exists to develop and implement more efficient, cost-effective, and environmentally friendly advanced technologies for removing Cr(VI) and TCL pollutants from water resources [Full size image

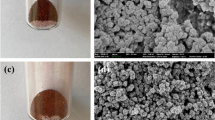

HR-TEM images were obtained for tri-composite CT/BV@Fe-MOF nanohybrids and the images revealed that the CoTiO3 and BiVO4 are uniformly attached to the surface of MIL-53 (Fe), consistent with the FE-SEM results. The HR-TEM image (Fig. 1e-f) show lattice fringes at d-spacings of 0.25 nm, 0.29 nm, and 0.32 nm, correlating to crystal planes (110), (004), and (111) of CoTiO3, BiVO4, and MIL-53 (Fe). These evidences confirm the formation of heterojunctions by enhancing the ability to transport charge and increasing the efficiency of photocatalysis. In addition, the high-annular angle dark field (HAADF) STEM imaging along with the elemental map** substantiate that in the CT/BV@Fe-MOF composite sample all the components (Co, Ti, Bi, V, Fe, O, and C) which are intact during heterojunction formation to promote the enhanced catalytic activity during photodegradation process (Fig. 1g-o).

The BET-specific surface area and BJH analysis of all the synthesized materials showed a type-IV isotherm pattern with a clear H3 hysteresis loop, designating a mesoporous structure (Fig. 2a, b). Based on the results, the pristine MIL-53 (Fe) exhibits a high surface area value of 209.73 m2g−1, a total pore volume of 0.184 cm3g−1, and an average pore diameter of 3.04 nm. On the other hand, the bare BiVO4 has the least surface area of 10.64 m2g−1 with a pore volume of 0.0106 cm3g−1 and an average pore diameter of 3.49 nm. Additionally, the BET surface area of CoTiO3 was measured to be 45.73 m2g−1 with pore volumes and diameters of 0.117 cm3g−1 and 3.40 nm, respectively. However, after forming the heterostructure, the composite material CT/BV@Fe-MOF exhibits an impressive surface area of around 105.62 m2g−1 (pore volumes of 0.094 cm3g−1 and pore diameters of 3.05 nm), which is significantly greater than the pure BiVO4 and CoTiO3. As a result of this increased surface area, more reaction sites and adsorption points could be provided on the nanocomposite surface, which facilitates the photocatalytic reduction and degradation of both inorganic and organic pollutants [42, 56].The detailed information on the surface area, pore volume, and pore size of all samples can be found in Table 1.

The XPS analysis was carried out to determine the oxidation state and elemental composition of the prepared nanocomposites. The results indicating the presence of Co 2p, Ti 2p, Bi 4f, V 2p, Fe 2p, C 1 s, and O1s elements in the CT/BV@Fe-MOF, confirming the photocatalyst's purity (Fig. S3a). A deconvoluted XPS peak for the Co 2p exhibits distinct binding energy at 780.5 and 796.3 eV, which suggests + 2 oxidation state of Co (Fig. S3b). Likewise, the deconvoluted Ti 2p spectrum (Fig. S3c) reveals two significant peaks at binding energies of 457.8 and 463.7, corresponding to Ti 2p3/2 and Ti 2p1/2 of Ti4+, respectively. Meanwhile, high-resolution Bi spectra (Fig. S3d) show two prominent peaks at 158.6 and 163.9 eV, corresponding to Bi 4f7/2 and Bi 4f5/2 of Bi, indicating that Bi3+ is presented in BiVO4. Similarly, the deconvoluted V5+ also displayed two distinct peaks at 516.2 and 523.8 eV, corresponding to V 2p3/2 and V 2p1/2 orbital states (Fig. S3e). The Fe 2p spectrum corresponding to MIL-53 (Fe) shows peaks at 724.3 and 710.4 eV associated with Fe 2p1/2 and Fe 2p3/2, respectively, with a difference of 13.9 eV, suggesting the presence of Fe3+ in Fe-oxo clusters. Furthermore, satellite peaks corresponding to the same were observed at 715.3 eV and 719.4 eV (Fig. S3f). The deconvoluted C 1 s spectrum corresponding to MIL-53 (Fe) exhibits three significant peaks at 288.1, 285.0, and 284.0 eV, which are corresponds to the C = O in the carboxylic group of terephthalates, the C-O between the benzene ring and Fe-oxo cluster, and the C = C in the benzene ring, respectively (Fig. S3g). Furthermore, the O 1 s characteristic peaks were deconvoluted into two peaks at 529.3 and 530.7 eV, corresponding to Co–O-Ti and Bi-O-V lattice oxygen. In addition, the peak induced by the oxygen atom in the carboxylic group corresponding to MIL-53 (Fe) appeared at a binding energy of 533.4 eV (Fig. S3h). Thus, these results suggested that all the elements are uniformly distributed in the as prepared CT/BV@Fe-MOF nanocomposite.

3.2 Photocatalytic Cr(VI) reduction

To verify the photocatalytic reduction performance of CT/BV@Fe-MOF nanocomposite, an aqueous Cr(VI) solution was used as a test solution. Photocatalytic reduction efficiency was calculated using the following Eq. (1).

where C0 represents the initial concentration of a Cr(VI) pollutant, and Ct represents the final concentration of a Cr(VI) pollutant after t-min of photocatalysis. As a result of 90 min of visible light illumination, it has been observed that the heterojunction composite obtained have a remarkable reduction efficiency when compared to other pristine materials, resulting in reduction percentages of 5.8%, 33.5%, 47.1%, 55.3%, 60.1% and 99.2% for BiVO4, CoTiO3, MIL-53 (Fe), CoTiO3/Fe-MOF, BiVO4/Fe-MOF and CT/BV@Fe-MOF, respectively (Fig. 3a). Due to the rapid recombination of photogenerated electrons and holes, bare materials have limited photocatalytic activity, while the CT/BV@Fe-MOF heterojunction with a nanorod structure improves the efficient transfer of photogenerated electrons and holes, which is a critical parameter for improved Cr(VI) reduction.

It is estimated that the original Cr(VI) solution has a pH of approximately 5.2 and is predominantly present in the form of HCrO4− and Cr2O72−. An investigation on the effect of pH during photocatalytic reduction of Cr(VI) was conducted at different pH levels (2.0–11.0) using 0.1 N HCl and 0.1 N NaOH. As a result (Fig. 3b), the nanocomposite of CT/BV@Fe-MOF exhibits a remarkable adsorption and reduction efficiency at pH 3.0 (97.5%) since the cationic charge of photocatalyst can electrostatically interact with negatively charged HCrO4− and Cr2O72− species. Consequently, Cr(VI) ions at this specific pH can efficiently bind to the photocatalyst and be reduced to Cr(III). In addition, the decline in photocatalysis rate at pH 2 is caused by the large quantity of H + ions generated in the reaction mixture in acidic media. These ions not only deposit on the surface of the photocatalyst but also partially block the pores in the material, thereby preventing Cr(VI) molecules from easy access to active sites. In contrast, above pH 3.0, the surface of the catalyst becomes negatively charged, resulting in a repulsive force between the material and Cr2O72− species. Additionally, the precipitation of Cr(OH)3 with an increase in pH will block the active sites of CT/BV@Fe-MOF, decreasing reduction efficiency.

To further determine how the concentration of photocatalyst affects the reduction of Cr(VI) during photocatalysis, various concentrations of CT/BV@Fe-MOF (25 mg to 150 mg) were used (Fig. 3c). The results indicated that the reduction efficacy increases as catalyst concentration increases from 25 to 75 mg, and thereafter the pattern decreases. This is attributed to the light scattering, and some saturation occurred as the solution opacity increased.

Figure 3d shows the effect of metal ion concentration on the photocatalytic reduction of Cr(VI). At first, optimal conditions (75 mg of catalyst, pH-3.0) were established to equilibrate Cr(VI) species with concentrations ranging from 10–70 ppm. Then, the reduction efficiency of Cr(VI) pollutants was evaluated over varying periods. Due to the availability of more active sites on the surface of the photocatalyst, a lower Cr(VI) concentration (10–30 ppm) resulted in a faster reduction rate. Conversely, when Cr(VI) concentrations increased above 50 ppm, the reduction efficiency of Cr(VI) decreased rapidly because a high amount of Cr(VI) species adsorb on the photocatalyst surface, which ultimately reduced the penetration of photons and consequently decreased the photo-generated radicals. As a result, the 50 ppm Cr(VI) concentration was determined to be optimal for further reduction studies.

Recyclability studies were performed for Cr(VI) reduction studies to further assess the stability of the composite. After centrifugation, the CT/BV@Fe-MOF catalyst can be separated from the Cr(VI) suspension and thoroughly cleaned with deionized water. The recycle study revealed that the reduction efficiency was decreased by 7.5% after six recycles (Fig. 3e). To further support the stability of the catalyst, after recovery of the photocatalyst from the multiple cycles of reusability experiments, the water samples are subjected to ICP-MS analysis to authenticate the precipitation of photocatalyst material on experimental conditions. The analysis reveals that no significant amount of Bi, Co or Fe ions were found, which confirms that no dissolution or precipitation of composite were noticed in the system. This suggested that the prepared composite appears to have a sound reduction efficiency even after six cycles of repeated application, supporting its practical utility in real-time applications.

To further understand the main reactive oxygen species involved during the photocatalytic reduction of Cr(IV), various radical quenchers, such as isopropyl alcohol (IPA), triethanolamine (TEOA), and p-benzoquinone (BQ) have been used. The results revealed that the relative changes in the Cr(VI) reduction efficiency are 34.89%, 84.91%, and 59.91% for the IPA, TEOA, and BQ scavengers, respectively (Fig. 3f). It is noticed that in the presence of TEOA, the photocatalytic system containing Cr(VI) showed a slight decrease in the efficiency profile. However, IPA and BQ relatively inhibit the Cr(VI) reduction efficiency, denoting the involvement of h+ and ∙O2− as the main reactive species during reduction process.

3.3 TCL degradation kinetics, DFT, and pathway

The degradation kinetics of TCL by the as-prepared catalysts were carried out in a laboratory-made photoreactor equipped with a 300 W Xe lamp as a visible light source. Firstly, the factors that influences the degradation of TCL have been investigated, and various pH ranges were studied, ranging from 3.0 to 11.0. The results indicated that high degradation efficiency has been identified in acidic conditions that turn into faster kinetics (Fig. 4a). The higher degradation efficiency at pH 5 can be attributed to the strong attraction forces between the negatively charged TCL molecule and positively charged composite surface. In addition, at lower pH values, the positively charged composite can provide more active sites for TCL adsorption and generate more reactive oxygen species for further degradation. The lower efficiency at higher pH values can be due to the repulsive force between the negatively charged TCL molecule and the composite. This leads to lower degradation efficiencies than the acidic values [57, 58].

The influence of catalyst loading on TCL degradation has been further investigated, and the results indicated a significant increase from 51.6% to 97. 5% when the catalyst loads are at 25 mg and 50 mg, respectively (Fig. 4b). Interestingly, further increase in catalyst loading tremendously reduced the degradation of TCL in which at 75 mg of catalyst the efficiency was about 73.1%, while at 100 mg it further reduced to 61.4%. This can be attributed to the fact that at the optimum catalyst loading (50 mg), the composite has higher active sites for TCL adsorption and provides higher ROS generation [4f). In comparison, with the addition of TEOA as h+ trap** agent, and NaN3 as 1O2 trap** agent, the TCL degradation efficiencies were around 84% and 80.8%, respectively. Thus, these results strongly suggested that OH• − and O2• − are the dominant ROS for efficient TCL degradation by the as-prepared CT/BV@Fe-MOF composite [62, 63].

The geometric properties of TCL have been optimized through DFT calculations conducted in the gaseous phase using the B3LYP/6-31G (d,p) method (Fig. 5a). It is evident from the results that the TCL molecule exhibits three-dimensional geometric orientations. HOMOs and LUMOs have been used to evaluate the locations of TCL that are affected by the electrophilic and nucleophilic species, respectively. As shown in Fig. 5b, the HOMO & LUMO orbitals are systematically arranged, revealing a bandgap energy of 4.19 eV. The HOMO orbital of TCL is primarily associated with the amine, hydroxyl, and amide groups. In contrast, the LUMO orbital is associated with the aromatic groups, indicating that these areas of TCL are vulnerable to ROS attack.

Additionally, Fig. 5c illustrates the TCL molecular electrostatic potential map (ESP) diagram. According to the electron density analysis, sites with a higher charge density are more vulnerable to ROS attacks. ESP diagram further shows a negatively charged region that is susceptible to electron deprivation, indicating that TCL atoms within this region are vulnerable to attack by negatively charged O2– molecules.

To further understand the detailed degradation pathway of TCL by the as-prepared CT/BV@Fe-MOF composite, the LC/ESI–MS analysis was carried out at positive ion mode, and the corresponding path is shown in Fig. 5d. From the results, it is evident that there are two possible degradation pathways. In pathway-I, firstly, the TCL molecule can be attacked by the O2• − and lose the methyl group to generate DP-1 (m/z = 414.14), followed by further attack of OH• − or O2• − for deamination to generate DP-2 (m/z = 401.15). The intermediate structure can be further attacked by O2• − to lose the N-methyl group to cause DP-3 (m/z = 373.12), followed by the loss of hydroxyl groups to generate DP-4 (m/z = 357.16), which further undergoes ring opening process by the attack of OH• − or O2• − to generate harmless smaller molecules, CO2 and H2O (Fig. 5d). In the pathway-II, the TCL could be attacked by the OH• − and undergoes hydroxylation to generate DP-9 (m/z = 460.15), followed by further attack with OH• − to generate DP-10 (m/z = 428.86) and DP-11 (m/z = 396.17). The O2• − could further attack the intermediate products for deamination to cause DP-12 (m/z = 353.11), followed by ring opening reactions to generate smaller degradation products, which can finally convert into CO2 and H2O. To monitor the extent of TCL molecules mineralization, samples are subjected to TOC analysis. A TOC plot reveals that the total organic content of the drug samples decreases exponentially with increasing irradiation time. As a result of irradiating the CT/BV @Fe-MOF photocatalyst under optimal conditions, the residual TOC is observed to be 2.0 ppm within 1.5 h of photocatalytic irradiation (Fig. S4). As a result of this decrease, it can be concluded that the prepared nanocomposite is capable of effectively degrading the organic group in tetracycline and mineralizing it into CO2 and H2O.

3.4 Toxicity assessment

Toxicity assessment analysis is essential to understand the efficacy of the degradation process in detoxifying the TCL molecule during the degradation process by the as-prepared CT/BV@Fe-MOF composite. The toxicity analysis of TCL and its degradation products was assessed by the Toxicity Estimation Software Tool (TEST) [64, 65]. From the results, it showed that the TCL LC50 for fathead minnows suggesting it very toxic, and majority of the degradation products showed less toxicity compared to pure TCL (Fig. 6a). In the similar manner the LC50 of daphnia magna for TCL was found to be around 5.6 mg/L and with increase in degradation process the generated products showed decreased toxicity towards daphnia magna (Fig. 6b). Furthermore, the bioaccumulation factor for most of the developed degradation products has been reduced significantly compare to TCL, while DP-6 and DP-7 showed highest bioaccumulation with values BCF = 10.8 and BCF = 11.3, respectively (Fig. 6c). The degradation products DP-7, DP-11, DP-12, DP-13, and DP-14 showed negative mutagenicity while all other degradation products showed positive (Fig. 6d). Moreover, the developmental toxicity results revealed that except DP-2, DP-10, DP-11, and DP-12 all other degradation products showed lower developmental toxicity than pure TCL molecule (Fig. 6e). In general, it is worth to mention that although the toxicity of the TCL molecule has been significantly reduced during degradation process by the CT/BV@Fe-MOF composite, majority of the degradation products still hold their toxic nature.

3.5 Photocatalysis mechanism

To determine the band edge potentials of the valence and conduction bands of CoTiO3, BiVO4, and MIL-53 (Fe), Mulliken electronegativity empirical Eqs. (2) and (3) were applied.

Here, EVB and ECB represent the band edge potentials of the valence and conduction bands, respectively, while χ is the electronegativity of the semiconductors, CoTiO3 (5.76), BiVO4 (6.04), and MIL-53 (Fe) (5.55 eV). The Ee represents the energy of free electrons on the hydrogen scale (Ee = 4.5 eV), and Eg is the band gap energy determined by UV–Vis-DRS analysis for BiVO4, CoTiO3, and MIL-53(Fe), which are 2.65, 2.50, and 2.30 eV, respectively. Accordingly, the ECB values for CoTiO3, BiVO4, and MIL-53 (Fe) were observed to be 0.01, 0.22, and -0.1 eV, respectively. Following this, the obtained EVB values are calculated as 2.51, 2.87, and 2.2 eV, respectively. All of these values are in consistent with the existing literature.

The results mentioned above demonstrated the formation of a unique heterojunction between CoTiO3, BiVO4, and MIL-53 (Fe) semiconductors, illustrating a traditional heterojunction-type photocatalytic mechanism (Fig. 7). In the presence of visible light irradiation, both MIL-53 (Fe) and CoTiO3 have the potential to be excited since their band gaps lie within the visible light range. The photoexcited electrons from the conduction band (CB) of MIL-53 (Fe) can easily migrate to the conduction band (CB) of CoTiO3, which further transfers to the conduction band (CB) of BiVO4. In addition, the photogenerated holes move from the valence band (VB) of BiVO4 to the valence band (VB) of CoTiO3. Thus, an efficient separation of the photogenerated charge carriers could be possible to generate a more significant number of ROS such as OH• − and O2• −. In the meantime, the separated e- could efficiently react with the O2 to produce O2•—on its surface, followed by the generation of h+ at the VB of CoTiO3 that could efficiently be further utilized for photochemical reactions to create OH• -. As a result, electron/hole recombination is reduced to a greater extent, and reactive oxygen species are formed, encouraging the photocatalytic degradation of Tetracycline and reduction Cr(VI). As summarized in Table 2, the proposed photocatalyst has exhibited superior performance compared to other reported materials in the literature for Cr(VI) reduction and TCL mineralization, respectively.