Abstract

Soil is a vital resource to humans and soil health is a concern of modern societies. One of the problems is the existence of heavy metals (HMs) pollution, which can affect food, water sources and biodiversity. This experimental work studies the effect of multiwall carbon nanotubes (MWCNTs) and surfactants characteristics on HMs immobilization in a contaminated soil. The testing program comprises the characterization of the MWCNTs and surfactants, followed by two distinct adsorption tests: suspension tests designed to supply preliminary information regarding the adsorption capacity of soil particles towards the different HMs, and percolation tests to evaluate the HMs immobilization in conditions mimicking a real in-situ scenario. The different HMs exhibit different affinities order to the soil studied: Pb > Cu > Ni > Zn. Results indicated that the inherent soil particles can immobilize significant quantities of HMs (especially Pb and Cu) due to their fine size and the existence of a substantial amount of organic matter content in the soil matrix. Molecular weight and charge density of the surfactant are characteristics with an impact on the MWCNTs dispersion and also on the adsorption capacity of the different HMs, namely in the case of Ni2+ and even in the case of Zn2+ possessing lower electronegativity and higher mobility. The findings of the study allow concluding that MWCNTs possess the potential to reduce the mobility of heavy metals in soil, even when employed at very low concentration (0.01% w/w), which is an important feature considering their cost.

Article Highlights

-

Effect of MWCNTS on the decrease of the mobility of heavy metals in a contaminated soil.

-

Influence of surfactant characteristics on the dispersion of the MWCNTs.

-

MWCNTs dispersion quality is correlated with the capacity of soil to retain heavy metals.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

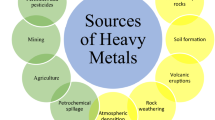

Soil is a vital resource for human life, and thus, soil health is getting more and more attention, namely, at the European level. One of the major problems regarding soil health is related to the existence of heavy metals (HMs) in contaminated soils, which can have a strong impact on food, water sources and biodiversity. Sources of heavy metals pollution can be of natural or anthropogenic origin [1,2,3]. Amongst the human activities leading to soil contamination by heavy metals, pesticides and fertilizers usage, mining practices, and, in general, emissions from several industries are among the most significant sources [1, 2]. Although not so important, forest fires which can originate powders rich in heavy metals, contributing to soil contamination by heavy metals [3]. Also very important is the fact that heavy metals do not naturally degrade, and thus, besides affecting the quality of the soil, they can leachate, and due to that, affect the quality of vegetables, livestock, and eventually affect human health [4, 5].

HMs mobility in soils depends a lot on the soil characteristics: organic matter content, grain size distribution, and soil pH [5,6,7,8,9,10]. Generally, HMs are more soluble and thus present higher mobility in acidic environments, while alkaline soils tend to accumulate HMs [6]. Also, soils with fine particles, those rich in silt and clay, have got a higher capacity to retain HMs, while coarser soils, that allow an easier water flow, are less prone to retain HMs [7]. In general, organic matter in the soil promotes the retention of heavy metals due to the interactions established between the different components of the organic matter and the HMs [5, 8].

Conventional soil remediation techniques, ex-situ or in-situ methodologies [2, 5, 6, 14]. The most common method used to remediate HMs-contaminated soils is based on excavation and transfer to a landfill, which involves high costs. The limited landfills availability [15], and the possibility of the continued hazardous exposure to the environment when using this traditional remediation technique, have been leading to the development of new, more cost-effective methods, less detrimental to the environment, like, for instance, the solidification/stabilization (S/S) of contaminated soils [16].

S/S entails blending additives with the soil, aiming at reducing the migration of HMs and, in this way, the risk of contaminating neighbouring areas. Binders such as Portland cement and lime are among the most commonly used additives in S/S of soils, with effective results [2, 5, 52]. The poly(diallyldimethylammonium) chloride (polyDADMAC MMW), produced by Sigma Aldrich, is a polymer of large dimensions with a hydrodynamic diameter of 848.6 nm, a medium average molecular weight of 240.0 kDa, and with a positive zeta potential of + 69.5 mV. This cationic surfactant was selected based on its charge, opposite to the MWCNTs, with the objective to ensure a good dispersion of the MWCNTs.

2.4 Experimental Procedures

2.4.1 MWCNTs complementary characterization

With the aim to investigate the MWCNTs crystallinity and the presence of metal oxides/ionic impurities on MWCTs surface a complementary characterization was performed by Atomic Absorption Spectroscopy and X-Ray Diffraction. It should be highlighted that, to date, there is no well-established method to characterise the metal oxides/ionic impurities of CNTs, neither is the true effect of such impurities on the performance of CNTs well known [49, 50, 53].

In order to evaluate the presence of ionic contaminants on the surface of the carbon nanotubes, the MWCNTs were analysed by Atomic Absorption Spectroscopy (Per-kin Helmer 3300, Perkin Helmer, Waltham, MA, USA), after going through a digestion procedure. First, the MWCNTs (390.43 mg) were calcinated at 600 ºC for 2 h. The ashes were then treated with HCl (6N) in three stages. 5 ml of HCl were first added to the sample which was heated afterward to evaporate all the acid. This procedure was repeated twice. Finally, another 5 ml of HCl were added to the digested sample which was then heated at 100 ºC during 5 min. The final sample was vacuum filtered using a 0.22 μm filter, to remove any insoluble material, and the filtrate was collected to be analysed by Flame Atomic Absorption Spectroscopy, to identify the presence of different metals.

Another technique that may help to identify the presence of metal oxides/ionic impurities on the surface of the MWCNTs is the X-Ray Diffraction (XRD). Indeed, the XRD technique allows to characterize the structural features of MWCNTs such as their structure, morphology, interlayer distances, as well as their crystallinity and the presence of impurities [54, 55]. The MWCNTs characterization was carried out in an X-ray diffractometer, Rigaku Smarlab, of the Materials Testing and Wear Laboratory of the Institute Pedro Nunes. The equipment allows to perform analyses in conventional incidence θ-2θ (where the detector is solidary with the rotation of the sample). The accelerating voltage was 40 kV and the current intensity was 50 mA, according to a Bragg–Brentano geometry. The anticathode used was copper with wavelengths of 1.54056 and 1.54439 Å. The range of angles scanned was from 2 to 100°, with a step size of 0.02°, the acquisition time corresponding to 2°/min. For the characterisation of the MWCNTs, two specimens were obtained from the same MWCNTs sample. The specimens were placed on the XRD support in a random manner and without any order. Interpretation of results was facilitated by the use of the equipment's own software, complemented by the authors’ analysis.

2.4.2 MWCNTs dispersion

Due to the natural tendency to the formation of CNTs aggregates causing the loss of part of their advantages [34], it is of utmost importance to ensure a good dispersion of the nanoparticles. For such, the MWCNTs were previously dispersed by applying ultrasonic energy (20 kHz, 500 W, amplitude 75%, for a duration of 15 min, via a sonicator probe Sonics Vibracell 501) on an aqueous suspension enriched with surfactants. The surfactants selected were previously dissolved in the aqueous medium at the concentrations of 0.03% (w/w), 0.015%:0.015% (w/w) or 0.020%:0.010% (w/w) for the surfactants applied individually or in mixtures, respectively, as presented in Table 4. The surfactant concentration was defined in previous optimization studies [56,57,58] where it was proved that a concentration of 0.03% (w/w) is efficient for the dispersion of the MWCNTs when applied at a concentration of 0.01% (w/w).

The efficiency/quality of the MWCNTs dispersion was assessed through the measurement of the size distribution of the aqueous MWCNTs suspension, prepared in the conditions mentioned above. The Z average diameter (Dz) of the optimized MWCNTs suspension was measured by Dynamic Light Scattering (Nanosizer ZN from Malvern Instruments, UK), as presented in Table 4. For all MWCNTs suspensions studied the quality report was good, indicating the inexistence of large aggregates. Also, the replicate measurements present a low variability (Table 4). In general, a MWCNTs suspension is better dispersed the lower the Dz value and, looking at the average diameters (Dz) obtained with the different surfactants, always below 307.7 nm, it is possible to conclude that it was always possible to obtain a good dispersion of the MWCNTs even if some differences can be noticed.

The cationic surfactant (polyDADMAC) leads to a less effective dispersion, and higher Dz, in spite of its relatively high MW and positive charge. This may be related to an adsorption process on the MWCNTs surface based on the patching mechanism, creating, in this way, positive patches in the CNTs surface, which can result in electrostatic interaction between the additivated CNTs leading to some aggregation of the CNTs. The anionic surfactant of high MW (SDBS) results in the best dispersion of the MWCNTs. The non-ionic surfactants (Pluronic F-127 and TX100) lead also to a reasonable dispersion of the MWCNTs despite their low molecular weight and hydrodynamic diameter, even if, as expected, TX 100 did not allow a dispersion as good as with Pluronic F-127. So, apparently, the steric dispersion mechanism, which must be associated with the surfactants SDBS, Pluronic F-127, and TX 100, favours a better dispersion of the CNTs.

Some mixtures of surfactants were also considered aiming at improving the immobilization of the HMs, which are positively charged. The idea was to favour a trap** strategy combining an anionic surfactant (SDBS) with the nonionic ones (Pluronic F-127 and TX-100). Mixtures of the cationic polyDADMAC MMW with SDBS were also considered. Regarding dispersion of the MWCNTs, the presence of polyDADMAC MMW seems to hinder, again, the dispersion of the nanotubes, which is less problematic for the lower polyDADMAC MMW concentration.

2.4.3 Adsorption tests

The objective of the suspension adsorption tests was to provide preliminary information about the adsorption ability of the MWCNTs for the different HMs tested in this work and to evaluate if the presence of MWCNTs could contribute to enhancing the adsorption capacity of the dual system (soil + MWCNTs). Figure 1 supplies a scheme of the laboratory procedure adopted in the suspension adsorption tests.

Two different types of tests were performed:

-

1.

Adsorption tests with soil alone contaminated with the HMs (reference test) to evaluate the adsorption capacity of the soil particles on its own;

-

2.

Adsorption tests using soil contaminated with HMs which was combined with MWCNTs (at a concentration of 0.01% (w/w) referred to the dry mass of soil), pre-treated with ultrasounds, and through the addition of a surfactant. The objective is to evaluate the benefits of using the dual system (soil + MWCNTs) on the adsorption capability of the soil.

2.4.4 Percolation tests

Percolation experiments were conducted to evaluate the efficacy of MWCNTs in immobilizing the HMs under study within a simulated real on-site scenario. Two sets of tests were performed: one using solely the soil (referred to as reference tests), and the other involving soil amended with MWCNTs. The objective was to assess the capacity of MWCNTs to immobilize HMs within a setup resembling an actual on-site scenario. The experimental protocol involved the utilization of small soil samples (37.6 cm3), either with or without MWCNTs, through which water was percolated as illustrated in Fig. 2. The procedure comprised three phases:

-

1.

Contamination and Preparation (Phase 1): initially, four equal portions of soil (5 kg each) were obtained from the ground. These portions were subsequently air-dried and mixed with solutions containing lead, copper, nickel, or zinc. Care was taken to ensure that all samples maintained their original water content at 80.9% w/w. Each contaminated soil portion was allowed to rest for a period of 7 days to ensure a uniform distribution of the HMs throughout the sample.

-

2.

Addition of MWCNTs (Phase 2): In this phase, a representative small sample was gathered from each of the four soil portions contaminated with distinct HMs. These samples were mixed with suspensions of MWCNTs, applied at a concentration of 0.01% (w/w) referred to the dry mass of soil.

-

3.

Percolation Tests (Phase 3): The soil samples, now contaminated with various HMs and either amended with MWCNTs or not, were placed into PVC tubes measuring 35 mm in height and 37 mm in diameter. A paper filter was positioned at the top of each tube, with two perforated PVC discs (one at the top and one at the bottom) to prevent particles loss during percolation tests. Water was applied under a hydraulic head of 5 m to facilitate percolation. The leachate was collected in a beaker, and the percolation test was considered concluded when the volume of leachate equalled that of the sample. The collected leachate was subsequently filtered, and the concentration of HMs was determined using Atomic Absorption Spectrometry, following the same analytical strategy as employed in the suspension adsorption tests. The gas used was a mixture of acetylene and air, at a temperature of 2300 ºC. Different lamps had to be used to measure the concentration of the different HMs (Pb: Perkin Elmer Intensitron Lamp, wave length 261.4 nm; Cu: Cathodeon Hollow Cathode Lamp, wave length 324.8 nm; Ni: Perkin Elmer Intensitron Lamp, wave length232.0 nm; Zn: Cathodeon Hollow Cathode Lamp, wave length 213.9 nm).

2.4.5 Leaching tests

To assess the possibility of release of MWCNTs to the groundwater when applied on-site, leaching tests were also conducted. These tests were performed for contaminated soil with and without MWCNTs (concentration of 0.01% (w/w)). The sample preparation method followed that of the percolation tests. The leaching tests were conducted according to the standard NEN 7345 [59]: (i) contaminated soil samples were enfolded in a 5 μm mesh nylon tissue and put under ultrapure water at least 2 cm below water surface; (ii) the test was conducted at a constant temperature of 22 °C, after each leachate collection interval (at 1, 3, 7, and 14 days), the ultrapure water was renewed; (iii) pH was measured for each leachate sample and the presence of carbon nanotubes was checked by acquiring optical microscopy and SEM images of the leachate samples after drying. The equipment used was an optical microscope, Olympus BH2, with an image acquisition camera (magnification 125x) and, in the SEM measurements, a JEOL JSM-5310 model.

3 Results and discussion

3.1 Complementary characterization of the MWCNTs

The metal oxides/ionic impurities evaluated by Atomic Absorption Spectroscopy are summarized in Table 5. As it may be seen the content of metal impurities ranged from ca. 2 ppm for nickel to more than 8000 ppm for aluminium. Indeed, aluminium is by far the dominant metal impurity as it is the basis of the catalyst support during CNTs manufacturing [46]. Sodium and calcium are also common metal impurities in MWCNTs [60].

X-Ray Diffraction (XRD) tests allow to characterize some important features of MWCNTs, namely their crystallinity and the presence of impurities [54, 55]. As can be seen from Fig. 3, the diffractogram of the MWCNTs used in the present study is characterized by a well-defined peak (002), around a 2θ ≈ 25° called the Bragg’s peak, from which the distance between the MWCNTs tubular layers can be estimated as 3.46 Å, a value in agreement with literature [4).

So, from the suspension tests performed it is possible to conclude that the strategy of additivating the soil with well dispersed MWCNTs can be an effective choice for the remediation of soils contaminated with heavy metals, especially if high mobility metals are involved. This positive adsorption performance, after the addition of the MWCNTs, is directly related to their negative charge, small size and high surface area, as well as with their low crystallinity, which indicates they exhibit a greater potential ability to interact with the neighbouring particles, in agreement with literature [51, 52].

Additionally, competitive adsorption tests were also conducted using all four metals, simultaneously, to contaminate the soil. These tests were also suspension adsorption tests, that is the contaminated soil, additivated with the MWCNTs, was suspended in water and adsorption was monitored over time. The surfactant used to disperse the MWCNTs was the SDBS since it was the one that led to a better dispersion of the MWCNTs (see Table 4), and also the one that led to a better yield of adsorption, when the soil was contaminated, individually, with each metal. Figure 5 presents the results of the competitive adsorption tests. In this plot, the results of the adsorption tests when the soil was contaminated with a single HM are also presented, for clarity of the discussion.

Looking at these results, we can conclude that the Pb2+ adsorption is not affected by the competition with the other metals. Its much higher electronegativity favours its preferential adsorption in both the soil and the MWCNTs. The HM for which adsorption was most affected by the competition with the other metals was Ni2+, which is understandable considering its much lower electronegativity compared to Pb2+. Thus, its higher mobility hinders further its adsorption, when Ni2+ is competing with the other metals for the adsorption sites. Despite the similar electronegativity of Cu2+ and Ni2+, the last one possesses a lower ionic radius, which can explain why Ni2+ adsorption was more affected by the competition with the other metals than in the case of Cu2+. The adsorption of Zn2+ was also hindered by the competition with the other HMs, even if the difference when comparing with the individual adsorption is not so high in this case, since individual adsorption was already quite low for Zn2+ (19.4% yield in the case of individual adsorption and 13.6% in the competitive adsorption). Zn2+ is in fact the most difficult metal to retain which may require further developments of the strategy proposed, for instance increasing the MWCNTs concentration. The HMs adsorption affinity order identified in the competitive tests was Pb > Cu > Ni ≈ Zn, which is in agreement with the literature [62].

3.3 Percolation tests

Regarding the percolation tests which mimic better what happens in a real site, tests were conducted for soil contaminated, individually, with each HM and using SDBS as the main surfactant (applied individually or mixed with polyDADMAC MMW) to disperse the MWCNTs, since they represent opposite tendencies regarding the dispersion of the nanotubes (Table 4) and also in the adsorption tests using suspended soil (Fig. 4). The objective is to try to assess better the influence of the quality of the dispersion of the MWCNTs on their performance in HMs retention.

Looking at the results of these tests (Fig. 6) it is even more evident the high adsorption capacity of the soil tested, even for the metals with higher mobility (Ni2+ and Zn2+) for which it presents an adsorption yield of 69% and 59%, respectively, due to its composition, especially the high organic matter content and fine particle size, as already discussed.

Still, in the case of Ni2+ and Zn2+, the adsorption capacity of the soil increases when well dispersed MWCNTs are combined with the soil, more evident in the case of Zn2+, for which adsorption increases from 59 to 76%. This positive adsorption effect, resulting from the addition of MWCNTs, can be related to their negative charge, small size and high surface area, when presented in a well dispersed state, as well as to their low crystallinity, indicating they exhibit a greater potential ability to interact with the neighbouring particles [51, 52], which is more evident the lower the electronegativity of the heavy metals. The results also show the importance of the choice of surfactant used to disperse the MWCNTs, being clear that the SDBS:polyDADMAC MMW surfactant, leading to a poor dispersion of the MWCNTs, has a negative or negligible effect in terms of adsorption of the heavy metals nickel and zinc, respectively. So, based on these preliminary results, the addition of MWCNTs, in very small amount (0.01% w/w), seems to be a promising strategy to reduce the mobility of lower electronegativity HMs from the soil. However, further tests of this type, percolation tests, are clearly still required, namely varying the concentration of the MWCNTs and especially the concentration of SDBS, to better understand if the additional trap** effect of the anionic surfactant can increase the adsorption efficiency, even without increasing the MWCNTs concentration, having in mind their higher cost. It may also be interesting to test other surfactants in the percolation tests, for instance, the nonionic Pluronic F-127, which also leads to a good dispersion of the MWCNTs, and despite not possessing a trap** effect, as happens with SDBS, can leave more free adsorption sites for the HMs adsorption on the MWCNTs surface, due to its lower molecular weight. Another strategy to be studied aiming at improving the adsorption efficiency of the system soil + MWCNTs is the removal of metal/ionic impurities from the MWCNTs. However, this MWCNTs ‘purification’ should be done carefully as: (i) depending on the purification method, the MWCNTs structure may be affected [50]; (ii) the true effect of such impurities on MWCNTs adsorption is not well known, with some authors indicating that their removal is beneficial [38, 39, 49], but other authors indicating the opposite [46, 50]; (iii) it involves energy consumption and higher costs, which should be minimized to prevent this technique from becoming less competitive.

3.4 Leaching tests

Leaching tests and acquisition of Optical microscopy and SEM images of the leachate were carried out to verify that MWCNTs are not being liberated from the soil matrix to the environment. For each leachate sample, gathered at 1, 3, 7, and 14 days, Optical microscopy images and SEM images of the dry powder samples were acquired (examples presented in Fig. 7). In both types of images, the presence of MWCNTs particles (9.5 nm in diameter, 1500 nm long) was never detected. The images of the samples from leachates originating from soil alone, without MWCNTs, were similar to the ones acquired for leachates resulting from soil additivated with MWCNTs. In the case of the optical microscope images the polyhedron particles observed in both situations can be associated with silt and/or sand particles present in the soil. Therefore, it can be concluded from the tests conducted that the presence of MWCNTs was never detected in the leachates, and thus there is no evidence of release of the MWCNTs to the aqueous medium.

Optical microscopy images of the powder originating from a leachate sample collected at 7 days: a contaminated soil without MWCNTs and b contaminated soil additivated with MWCNTs; SEM images of the powder originating from a leachate sample collected at 3 days: c contaminated soil without MWCNTs and d contaminated soil additivated with MWCNTs

4 Conclusions

This study evaluated the effectiveness of MWCNTs to immobilize the heavy metals lead (Pb2+), copper (Cu2+), nickel (Ni2+), and zinc (Zn2+) in soil. The selection of the heavy metals tested took into account the most common contaminants in Portuguese soils.

An important parameter that can affect the performance of the MWCNTs is the degree of dispersion of the carbon nanotubes. The addition of surfactants improves the MWCNTs dispersion, which affects afterward the yield of adsorption of the different HMs. Molecular weight and charge density of the surfactant are characteristics with an impact on the MWCNTs dispersion and thus on the adsorption capacity of the MWCNTs, which were analysed in detail in this study.

The results presented in this work lead to the conclusion that the different HMs exhibit different affinities to the soil studied, possessing a high organic matter content; the affinity order was Pb > Cu > Ni > Zn. The addition of MWCNTs in a concentration of 0.01% (w/w), proved to be efficient for the immobilization of the heavy metals studied, which may be related not only to the MWCNTs negative charge, small size and high surface area, but also to the low crystallinity of the MWCNTs. In future studies it is important to study further the possible influence of MWCNTs metals oxides/ionic impurities, resulting from the production process, on their performance as HMs adsorbents and, eventually, evaluate possible purification strategies. Additionally, the results obtained confirm that the nanoparticles were not released into the water when the soil additivated with MWCNTs was exposed to water for up to a maximum of 14 days.

From the results obtained, it can be said that MWCNTs, if adequately dispersed, can be a viable alternative to the traditional method involving the addition of Portland cement to immobilize contaminants in soils.

Data availability

Some or all data, models, or code generated or used during the study are available from the corresponding author upon reasonable request.

References

Alloway BJ. Sources of heavy metals and metalloids in soils. In: Heavy metals in soils: trace metals and metalloids in soils and their bioavailability. New York: Springer; 2013. p. 11–50.

Liu J, Zha F, Xu L, Yang C, Chu C, Tan X. Effect of chloride attack on strength and leaching properties of solidified/stabilized heavy metal contaminated soils. Eng Geol. 2018;246:28–35.

Odigie KO, Flegal AR. Trace metal inventories and lead isotopic composition chronicle a forest fire’s remobilization of industrial contaminants deposited in the Angeles National Forest. PLoS ONE. 2014;9:52–61.

Li Z, Huang B, Huang J, Chen G, Xong W, Nie X, Ma W, Zeng G. Influence of different phosphates on adsorption and leaching of Cu and Zn in red soil. Trans Nonferrous Metals Soc China. 2016;26:536–43.

Mulligan CN, Yong RN, Gibbs BF. Remediation technologies for metal-contaminated soils and groundwater: an evaluation. Eng Geol. 2001;60:193–207.

Wuana RA, Okieimen FE, Heavy Metals in Contaminated Soils: A Review of Sources, Chemistry, Risks and Best Available Strategies for Remediation. ISRN Ecology, 2011;402647. https://doi.org/10.5402/2011/402647

Yao Q, Wang X, Jian H, Chen H, Yu Z. Characterization of the particle size fraction associated with heavy metals in suspended sediments of the Yellow River. Int J Environ Res Public Health. 2015;12:6725–44.

Stevenson FJ, Humus Chemistry: Genesis, Composition, Reactions. 2nd Edition, published by Wiley. 1997;512.

Gomes P, Fontes M. Selectivity sequence and competitive adsorption of heavy metals by Brazilian soils. Soil Sci Soc Am J. 2001;65:1115–21.

Houben D, Pircar J, Sonnet P. Heavy metal immobilization by cost-effective amendments in a contaminated soil: effects on metal leaching and phytoavailability. J Geochem Explor. 2012;123:87–94.

Peng W, Li X, **ao S, Fan W. Review of remediation technologies for sediments contaminated by heavy metals. J Soils Sediments. 2018;18(4):1701–19.

Vaddoriya K. Immobilization of heavy metals using solidification / stabilization treatment : a review. Int J Adv Res Innov Ideas Educ. 2016;2:49–53.

Du YJ, Liu SY, Liu ZB, Chen L, Zhang F, ** F. An Overview of Stabilization/Solidification Technique for Heavy Metals Contaminated Soils. 2010. In: Chen Y, Zhan L, Tang X. (eds) Advances in Environmental Geotechnics. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-04460-1_93

Sharma S, Tiwari S, Hasan A, Saxena V, Pandey LM. Recent advances in conventional and contemporary methods for remediation of heavy metal-contaminated soils. 3 Biotech. 2018;8(4):216. https://doi.org/10.1007/s13205-018-1237-8.

Scanferla P, Ferrari G, Pellay R, Ghirardini AV, Zanetto G, Libralato G. An innovative stabilization/solidification treatment for contaminated soil remediation: demonstration project results. J Soils Sediments. 2009;9(3):229–36.

Liu Y, Tang Y, Zhong G, Zeng H. A comparison study on heavy metal/metalloid stabilization in Maozhou River sediment by five types of amendments. J Soils Sediments. 2019;19(12):3922–33.

Wang F-H, Zhao B, Zhang F, Gao J, Hao H-T, Zhang S. A novel heavy metal chelating agent sixthio guanidine acid for in situ remediation of soils contaminated with multielements: its synthesis, solidification, biodegradability, and leachability. J Soils Sediments. 2016;16(2):371–81.

Dermatas D, Meng X. Utilization of fly ash for stabilization/solidification of heavy metal contaminated soils. Eng Geol. 2003;70:377–94.

Wang L, Cho D-W, Tsang DCW, Cao X, Hou D, Shen Z, Alessi DS, Ok YS, Poon CS. Green remediation of As and Pb contaminated soil using cement-free clay-based stabilization/solidification. Environ Int. 2019;126:336–45.

Li W, Ni P, Yi Y. Comparison of reactive magnesia, quick lime, and ordinary Portland cement for stabilization/solidification of heavy metal-contaminated soils. Sci Total Environ. 2019;671:741–53.

Goyal MK, Chauhan A . Environmental Pollution Remediation through Solidification / Fixation of Heavy Metal Ions in Portland Cement. Journal of Environmental and Analytical Toxicology, 2015;5:6. https://doi.org/10.4172/2161-0525.1000323

Kumpiene J, Lagerkvist A, Maurice C. Stabilization of As, Cr, Cu, Pb and Zn in soil using amendments—a review. Waste Manage. 2008;28(1):215–25.

Mueller NC, Nowack B. Nanoparticles for remediation: solving big problems with little particles. Elements. 2010;6:395–400.

Dai Y, Liang Y, Xu X, Zhao L, Cao X. An integrated approach for simultaneous immobilization of lead in both contaminated soil and groundwater: laboratory test and numerical modeling. J Hazard Mater. 2018;342:107–13.

Ihsanullah AA, Al-Amer AM, Laoui T, Al-Marri MJ, Nasser MS, Khraisheh M, Atieh MA. Heavy metal removal from aqueous solution by advanced carbon nanotubes: critical review of adsorption applications. Sep Purif Technol. 2016;157:141–61.

Evanoff K, Khan J, Balandin AA, Magasinski A, Ready WJ, Fuller TF, Yushin G. Towards ultrathick battery electrodes: aligned carbon nanotube-enabled architecture. Adv Materials (Deerfield Beach, Florida). 2012;24:533–7.

Dey P, Das N. Carbon nanotubes: it’s role in modern health care. Int J Pharm Pharm Sci. 2013;5:9–13.

Thakur VK, Thakur MK. The use of carbon nanotubes in the treatment of water and wastewater. In Chemical functionalization of carbon nanomaterials: chemistry and applications, C. Press, Editor. 2015. p. 705–719.

Zhao X, Jia Q, Song N, Zhou W, Li Y. Adsorption of Pb(II) from an aqueous solution by titanium dioxide/carbon nanotube nanocomposites: kinetics, thermodynamics, and isotherms. J Chem Eng Data. 2010;55:4428–33.

Li YH, Luan ZK, **ao X, Zhou XW, Xu CL, Wu DH, Wei BQ. Removal of Cu2+ ions from aqueous solutions by carbon nanotubes. Adsorpt Sci Technol. 2003;21:475–85.

Gadhave A, Waghmare J. Removal of heavy metal ions from wastewater by carbon nanotubes (CNTs). Int J Chem Sci Appl. 2014;5:56–67.

Matos MPSR, Correia AAS, Rasteiro MG. Application of carbon nanotubes to immobilize heavy metals in contaminated soils. J Nanopart Res. 2017;19:126.

Correia AAS, Matos MPSR, Gomes AR, Rasteiro MG. Immobilization of heavy metals in contaminated soils—performance assessment in conditions similar to a real scenario. Appl Sci. 2020;10(22):7950.

Datsyuk V, Landois P, Fitremann J, Peigney A, Galibert AM, Soula B, Flahaut E. Double-walled carbon nanotube dispersion via surfactant substitution. J Mater Chem. 2009;19:2729.

Rossell MD. Impact of sonication pretreatment on carbon nanotubes: a transmission electron microscopy study. Carbon. 2013;61:404–11.

Rastogi R, Kaushal R, Tripathi SK, Sharma AL, Kaur I, Bharadwaj LM. Comparative study of carbon nanotube dispersion using surfactants. J Colloid Interface Sci. 2008;328:421–8.

Figueiredo DTR, Correia AAS, Hunkeler D, Rasteiro MGBV. Surfactants for dispersion of carbon nanotubes applied in soil stabilization. Colloids Surf, A. 2015;480:405–12.

Berrada N, Desforges A, Bellouard C, Flahaut E, Gleize J, Ghanbaja J, Vigolo B. Protecting carbon nanotubes from oxidation for selective carbon impurity elimination. J Phys Chem C. 2019;123(23):14725–33.

Guo Z, Zhong S, Cao M, Zhong Z, **ao Q, Huang J, Chen J. High-temperature-annealed multi-walled carbon nanotubes as high-performance conductive agents for LiNi0.5Co0.2Mn0.3O2 lithium-ion batteries. Metals. 2023;13(1):36.

Flygare M, Svensson K. Quantifying crystallinity in carbon nanotubes and its influence on mechanical behaviour. Mater Today Commun. 2019;18:39–45.

Correia AAS. Applicability of deep mixing technique to the soft soil of Baixo Mondego. PhD Thesis, Univ. of Coimbra, Coimbra, Portugal. 2011.

ASTM-D2487, ASTM D2487, Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System). 1998, ASTM International.

Inácio M, Pereira V, Pinto M. The soil geochemical atlas of Portugal: overview and applications. J Geochem Explor. 2008;98:22–33.

Costa C, Jesus-Rydin C. Site investigation on heavy metals contaminated ground in Estarreja—Portugal. Eng Geol. 2001;60:39–47.

Environment, M.o.t., Soil, Groundwater and Sediment Standards for the Use Under, Part XV.1 of the Environmental Protection Act. Ontario. 2011.

Kiciński W, Dyjak S. Transition metal impurities in carbon-based materials: pitfalls, artifacts and deleterious effects. Carbon. 2020;168:748–845.

Lee D-K, Jeon S, Jeong J, Yu IJ, Song KS, Kang A, Yun WS, Kim JS, Cho W-S. Potential role of soluble metal impurities in the acute lung inflammogenicity of multi-walled carbon nanotubes. Nanomaterials. 2020;10(2):379.

Darne C, Desforges A, Berrada N, Fontana C, Guichard Y, Gaté L, Bégin D, Le Normand F, Valsaque F, Ghanbaja J, Gleize J, Vigolo B. A non-damaging purification method: decoupling the toxicity of multi-walled carbon nanotubes and their associated metal impurities. Environ Sci Nano. 2019;6(6):1852–65.

Santangelo S, Piperopoulos E, Fazio E, Faggio G, Ansari S, Lanza M, Neri F, Messina G, Milone C. A safer and flexible method for the oxygen functionalization of carbon nanotubes by nitric acid vapors. Appl Surf Sci. 2014;303:446–55.

Pumera M. Voltammetry of carbon nanotubes and graphenes: excitement, disappointment, and reality. Chem Rec. 2012;12(1):201–13.

Kobashi K, Ata S, Yamada T, Futaba DN, Okazaki T, Hata K. Classification of commercialized carbon nanotubes into three general categories as a guide for applications. ACS Appl Nano Mater. 2019;2(7):4043–7.

Correia AAS, Figueiredo D, Rasteiro MG. An experimental design methodology to evaluate the key parameters on dispersion of carbon nanotubes applied in soil stabilization. Appl Sci. 2023;13(8):4880.

Koyama S, Kim YA, Hayashi T, Takeuchi K, Fujii C, Kuroiwa N, Koyama H, Tsukahara T, Endo M. In vivo immunological toxicity in mice of carbon nanotubes with impurities. Carbon. 2009;47(5):1365–72.

Das R, Hamid BAS, Ali ME, Ramakrishna S, Yongzhi W. Carbon nanotubes characterization by X-ray powder diffraction—a review. Curr Nanosci. 2015. https://doi.org/10.2174/1573413710666140818210043.

Cao A, Xu C, Liang J, Wu DZ, Wei B. X-ray diffraction characterization on the alignment degree of carbon nanotubes. Chem Phys Lett. 2001;344(1):13–7.

Matos M. Soil decontamination using nanomaterials, Msc Thesis, University of Coimbra, Coimbra, Portugal. 2016:80.

Oliveira ARL. Heavy metal ions removal from aqueous solutions by multiwalled carbon nanotubes. Msc Thesis, University of Coimbra, Coimbra, Portugal; 2016.

Gomes AR. Remediation of heavy metal in contaminated soil using nanoparticles, Msc Thesis, University of Coimbra, Coimbra, Portugal. 2017.

NEN 7345: Leaching characteristics of moulded or monolithic Building and waste materials - determination of leaching of inorganic components with the diffusion test, Netherlands Normalisation Institute. 2004.

Jun LY, Mubarak NM, Yon LS, Bing CH, Khalid M, Abdullah EC. Comparative study of acid functionalization of carbon nanotube via ultrasonic and reflux mechanism. J Environ Chem Eng. 2018;6(5):5889–96.

Khoerunnisa F, Futamura R, Mukai S, Konishi T, Fujikawa T, Kaneko K. X-ray absorption anomaly of well-characterized multiwall carbon nanotubes. Carbon. 2019;145:209–17.

Wang Z, Xu W, Jie F, Zhao Z, Zhou K, Liu H. The selective adsorption performance and mechanism of multiwall magnetic carbon nanotubes for heavy metals in wastewater. Sci Rep. 2021;11(1):16878.

Acknowledgements

This work was financially supported by the Portuguese Foundation for Science and Technology, FCT, through the Strategic Research Centre Project UIDB00102/2020. The authors express their gratitude to the MSc students Martim Matos, Ana Rita Oliveira and Ana Rita Gomes for their support in carrying out the experimental part.

Funding

The authors have no relevant financial or non-financial interests to disclose.

Author information

Authors and Affiliations

Contributions

Conceptualization, A.A.S.C. and M.G.R.; methodology, A.A.S.C. and M.G.R.; investigation, A.A.S.C. and M.G.R.; resources, A.A.S.C. and M.G.R.; writing original draft preparation, A.A.S.C. and M.G.R.; writing, review and editing, A.A.S.C. and M.G.R.; project administration, M.G.R.; funding acquisition, A.A.S.C. and M.G.R. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors have no competing interests to declare that are relevant to the content of this article. All authors certify that they have no affiliations with or involvement in any organization or entity with any financial interest or non-financial interest in the subject matter or materials discussed in this manuscript. The authors have no financial or proprietary interests in any material discussed in this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Correia, A.A.S., Rasteiro, M.G. Effect of multiwall carbon nanotubes and surfactants characteristics on immobilization of heavy metals in contaminated soils. Discov Appl Sci 6, 205 (2024). https://doi.org/10.1007/s42452-024-05827-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-024-05827-z